Learning G uide

advertisement

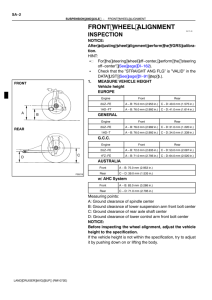

Learning Guide CHASSIS SPECIALIST ALIGNMENT FOR INSTALLERS COURSE NUMBER: W030-01 Chassis Specialist: Alignment for Installers Notice Due to the wide range of vehicles makes and models, the information given during the class will be general in nature and should not be taken as specific to any vehicle/unit. Please consult manufacturer specifications for the correct number/specifications and repair procedures for the vehicle you are testing. This document is meant to be used as a guideline only. For further information, please contact toll-free: 1-855-813-2101 or email info@carstraining.net No part of this book may be reproduced, stored in any retrieval system or transmitted in any form or by any means (including but not limited to electronic, mechanical, photocopying and recording) without prior written permission of CARS Training Network Inc. This applies to all text, illustrations, tables and charts. Copyright © 2014 CARS Training Network Inc Page ii Chassis Specialist: Alignment for Installers Introduction OBJECTIVES Upon successful completion of this segment, the participants should be able to: Identify abnormal tire wear and understand the common underlying causes Perform preliminary vehicle inspections including TSB searches Identify the various types and functions of alignment equipment Understand alignment angles and adjustment procedures (including special tools required) Understand the safety precautions for alignments Perform Two-Wheel Alignments Page 1 Chassis Specialist: Alignment for Installers Alignment for Installers In this module we will run through doing a simple alignment. In many cases toe is the only adjustable angle, but we will describe the common adjustable alignment angles. In the next module we’ll cover four-wheel alignments, more advanced alignment angles and settings as well as problems. Purposes of Alignment: Reduce tire wear Reduced steering effort Maximum fuel mileage Safer vehicle Improved handling Reference Lines: Basis of all alignment angles: Vertical line Vehicle centerline Geometric centerline Thrust line How often should an alignment be done? ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________ Vertical Line Vertical reference point for each wheel and reference for: Camber angle Steering Axis Inclination angle (SAI) Included Angle (IA) Vertical reference line Page 2 Chassis Specialist: Alignment for Installers Vehicle Centerline Longitudinal line splitting vehicle into equal halves Reference for: Geometric Centerline Angle Thrust Line Angle Geometric Centerline: If a line were drawn through the front spindles, the geometric centerline would be between the midpoints of this line and the rear axle. Reference for correcting geometry (angles) of two wheels. Thrust Line: Line bisecting the rear toe angle. Possible problems for solid-axle vehicles include: Axle offset Damage Worn mounts Page 3 Chassis Specialist: Alignment for Installers Wheelbase Difference The distance between the center of the front wheels and the center of the rear wheels. The distance between these two points should be equal on both sides of the vehicle. Set Back The amount by which one front wheel is further back from the front of the vehicle compared to the other front wheel. If the left wheel is further back than the right, setback is negative. If the right wheel is further back than the left, setback is positive. If the alignment machine doesn’t automatically measure these angles, a tape measure can be used to measure the wheelbase. Page 4 Chassis Specialist: Alignment for Installers Basic Angles: Caster Steering Axis Inclination (SAI) Camber Included Angle (IA) Toe in and toe out Toe out on turns Other Angles and Diagnostics Steering Axis Inclination (SAI) Included Angle (IA) Toe-out on turns Set Back Steering Axis Inclination (SAI) The inclination of the top of the steering axis in relation to the vertical, observed from the front of the vehicle This angle is usually between 5 and 15 degrees. Allows the steering wheel to return to the center after having turned Reduces the effect or reaction of the suspension when braking SAI: The angle between the true vertical and the incline of the steering pivots. This image also shows a zero scrub radius. Scrub Radius The point where SAI angle and the tire centerline meet May be either positive or negative Ideally should be as small as possible Not adjustable Positive scrub radius Negative scrub radius Page 5 Chassis Specialist: Alignment for Installers Included Angle Sum of the camber and SAI angles in a front suspension Changing camber changes the included angle Helps diagnose bent suspension parts like spindles and struts. Reading is given as degrees and minutes, or degrees and fractions Specifications may not be available in all service information systems Included Angle Toe-Out on Turns Two different paths for each of the steered wheels (different distances traveled) Tire squeal at low speeds may be a symptom of incorrect turning angle If angle is incorrect, suspect a bent steering arm (more than 1.5 degrees difference side to side) Toe-out on turns Set Back One wheel further back than the other indicates setback Wheelbase difference side to side indicates setback Usually no more than ¼″ difference from side to side May be the cause of incorrect caster (1 degree or more) Setback of the front wheels Page 6 Chassis Specialist: Alignment for Installers Vertical 0° Caster: Vertical angle of a wheel’s steering axis from Negative Positive the side Tilting a steering axis backward is positive caster, forward is negative caster Cross Caster Angle: Caster angles illustrated The difference between side to side caster settings May be set at half a degree difference, but, more than half a degree difference may cause a steering pull toward the side with the most negative (least) caster Caster on the left front wheel is sometimes decreased to compensate for road crown Cross caster reading on an alignment printout What would the reading on the other side be? How is caster adjusted? ________________________________________________________________________________ Page 7 Chassis Specialist: Alignment for Installers Camber: Inward tilt of the wheel (negative camber) and outward tilt of the wheel (positive camber) Can cause tire wear if the angle is incorrect Cross Camber Angle: The difference between the camber angle of the left and right wheels Important for good handling The vehicle will steer towards the side with the highest camber angle Alignment specifications from information sources often only provide this angle Camber tire wear. Watch out for exposed metal pieces! How is camber adjusted? __________________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ Page 8 Chassis Specialist: Alignment for Installers Toe: Measures how much the tire points inward or outward (compared to the vehicle centre line) How is toe adjusted? _____________________ Usually set at or close to zero (parallel) Difference between the leading and trailing edges of two _____________________ tires on the same axle _____________________ Distance comparison between the leading and trailing edges _____________________ of the tires Major cause of tire wear, both front and rear _____________________ _____________________ _____________________ _____________________ _____________________ _____________________ _____________________ ______ Toe Out Toe In Tire wear from incorrect toe, note the “feathered edge” Page 9 Chassis Specialist: Alignment for Installers Preliminary Checks: Customer concerns (verify) Service bulletins Tire pressure/condition/size Sagging suspension/ride height Condition of components Front end inspection Road Test: The under inflated tire on this vehicle will affect the alignment settings. Steering wheel pulls to the left or right Feeling of looseness or wandering Steering wheel vibration or shimmy Steering wheel is not centered when car is moving straight ahead “Bump” or “Memory” steering problems Factors which may be mistaken for alignment problems: Worn suspension components Torque steer Memory steer from seized component Brake pull Tire inflation Power steering problems Module/sensor input Sequence of adjustments (general): 1. Rear camber 2. Rear toe 3. Caster/camber on one front side 4. Caster/camber on the other front side 5. Front toe The cargo in this truck may affect alignment settings Always check service or manufacturer information for exact instructions! Page 10 Chassis Specialist: Alignment for Installers Adjusting the Settings Caster Caster may be adjustable by adding or removing shims, or by moving a cam. (see camber, below) Shims Caster may not be adjustable on all vehicles. Camber/Caster Camber SLA suspensions may use adjuster cams or shims, as used for caster. Strut-type suspensions may be adjustable by repositioning the strut or by using an aftermarket kit—check service information. Toe Front toe is adjusted through the tie rod ends Rear toe adjustment procedures vary Page 11 Chassis Specialist: Alignment for Installers Common Terms and Definitions Two-Wheel Alignment: Front wheels are aligned; if the rear wheels are NOT parallel to the vehicle centerline, the steering wheel may be off-center and the tires may wear unevenly. Four-Wheel Alignment: All four wheels are measured and taken into account, then adjusted as possible. Bump Steer: The tendency to suddenly steer to one side after hitting a bump or pothole. Camber: Inward and outward tilt of a wheel. Caster: Forward and rearward tilt of the steering axis. Cross Camber or Cross Caster: The slight side-to-side difference to compensate for road crown. D-Height: A measurement from the rear suspension components used to determine height Geometric Centerline: Formed by connecting imaginary lines between the midpoint of the front spindles and the midpoint of the rear axle. If the vehicle is properly aligned, the wheels roll in a line parallel with the vehicle’s geometric centerline. Included Angle: The sum of SAI and camber often used to diagnose bent parts. Memory Steer: The steering wheel and wheels wanting to return to a position other than the center after turning. This may cause a pull or drift to one side, usually caused by binding components. Ride Height: A measurement between the ground and a fixed reference point on a vehicle; may be synonymous with “ground clearance.” Road Crown: The slope of the road for proper drainage; excessively crowned roads may cause a vehicle to pull to the right. Set Back: When one of the wheels is further back than the other, the vehicle has setback. Steering Axis Inclination (SAI): The measurement, in degrees, of the steering pivot line when viewed from the front of the vehicle; not usually adjustable and used to diagnose bent components. Thrust Angle: The angle between the thrust line and centerline. Thrustline: A line equally dividing the total rear toe and defining the direction of the rear wheels. Toe: The angle most likely to wear out tires; the difference between front and rear edges of the tires on the same axle. Toe-out on turns: Angles formed by the front wheels when turning; also used to diagnose bent components. Trim Height: Like “Ride height”, but usually referencing “Z-height” or “D-height.” Vertical Reference Line: Perfectly vertical, imaginary line used to reference the angle of a component. Wheelbase: The distance from the center of the front wheels to the center of the rear wheels. Z-Height: A measurement from the front suspension components to determine height. Page 12