Due to the large

advertisement

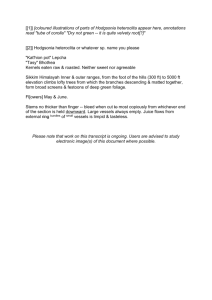

Smooth water transportation by means of highly effective drag reduction system Due to the large length of some flat-bottomed boats, there is a large contact surface between the bottom of such vessels and the water. This causes a lot of drag during movement of the vessel Photo of the cavity. View from the bottom. Picture was taken with a longer exposure time and in the water. A team of TU Delft scientists developed a solution to shows a time averaged wave profile. reduce this drag substantially. complicated to be applied and used. Unique is the fact that the cavities Moreover prior state of art is limited to can be formed when a vessel moves Flat-bottomed vessels are primarily specific ship types and not suitable to in forward as well as in backward built for river and canal transport of be used at all conditions. direction. As installing this system does heavy goods or persons. As some not require major modifications of a vessels are not self-propelled, they Efficient design vessel, this invention is more costneed to be towed or pushed by The TU Delft invention solves existing effective to apply than prior state of towboats. These towboats can easily technological problems by means of art. tow or push up to six such vessels. As a simple and efficient design of the As the system can be applied to a result of the large contact surface air cavities system. This air cavity existing and newly built vessels, of those vessels there is a lot of drag system is a separate system that this invention is very interesting during transportation. can be installed to the bottom of for shipbuilding companies as well existing vessels. The air cavity system repairing companies and shipyards. Drawbacks prior state of art creates a number of cavities by Fuel savings in the order of 10 till 20% The TU Delft invention is based on injecting compressed air. Depending are realistic. the principle of ship drag reduction on the velocity of the vessel and the by air lubrication. Isolating a part of water depth a number of cavities in Advantages a hull from water by air reduces the longitudinal direction can be selected •h igh efficiency at different velocities wetted area, and thus the drag of a to minimize the wetted area of the and water depths vessel. Many types of air lubrication bottom. In order to guarantee the • fuel savings 10 - 20% have been suggested in the past, but stability of a vessel with respect to roll •m ore cost-effective solution than in spite of many investigations and motion it’s possible to select a number prior state of art inventions, air lubrication has not of cavities in the traversal direction. •e asy to manufacture, install and been widely applied in practice on operate cargo vessels. The reason for this is Forward and backward •h ighly functional in both forward and that existing technologies have some Besides controlling the number backward direction major drawbacks. Prior state of art has of cavities it is also possible to • c an be applied to existing and newly a low efficiency in general and is too control the length of the cavities. built vessels • s uitable for inland waterway ships, barges, containerships and cruiseboats Ref. TU Delft OCT-13-079 TU Delft / Valorisation Centre Mekelweg 4 2628 CD Delft T: 015-2786751 www.patent.tudelft.nl Photo shows an instantaneous wave profile of the developing cavity. Picture was taken with a short exposure time.