Designing grout mixes

Tested, custom-designed grout mixes provide consistent quality

By Bruce A. Suprenant and Jeffrey L. Groom

ant a grout mix with adequate strength, pumpability, and low cost? Then

head to your nearest testing laboratory and ask for a grout mix design. A lab will help you establish

design criteria and make trial

batches to meet those criteria at

the lowest material cost. Then

you can have the grout delivered

ready to use by a ready mix company. Although some contractors

still try volume proportioning in

the field, most specifications

don’t allow this anymore.

W

Design criteria

Unfortunately, most specifiers

and contractors don’t give adequate attention to the design criteria for a grout mix. As with a

concrete mix, the design criteria

for a grout mix are specific for

each job. A grout mix that worked

well on the last job may not be

suitable for the next job.

Don’t go overboard on the design criteria, though. Use two, or

at most, three grout mixes on a

single job. Any more than this requires careful planning and attention to make sure the right mix is

placed in the right location. Consider the following design criteria.

Compressive strength. Most

specifications require grout to

have compressive strength equal

to or exceeding the specified

compressive strength of the masonry, from, but not less than

2000 psi. The compressive

strength is measured in accordance with ASTM C 1019 (Ref. 1).

Durability. The durability of

grout is seldom an issue. The

grout usually is protected from

moisture saturation and thus not

susceptible to freeze-thaw deterioration. If freeze-thaw is a problem,

add an air-entraining admixture.

To minimize rebar corrosion, con-

sider using a corrosion-inhibiting

admixture (calcium nitrite).

Grout space. According to

ASTM C 476 (Ref. 2), grouts are

classified as fine or coarse depending on the maximum aggregate

size. If the maximum aggregate

size is 3⁄8 inch or larger, then the

grout is classified as coarse; less

than 3⁄8 inch is classified as fine.

Grout must flow easily into

confined spaces, so the smaller

the space, the smaller the grout’s

maximum aggregate size must be.

However, coarser grout is more

economical. It shrinks less and

requires a smaller proportion of

cement. Therefore, coarse grout

is preferred wherever conditions

allow it.

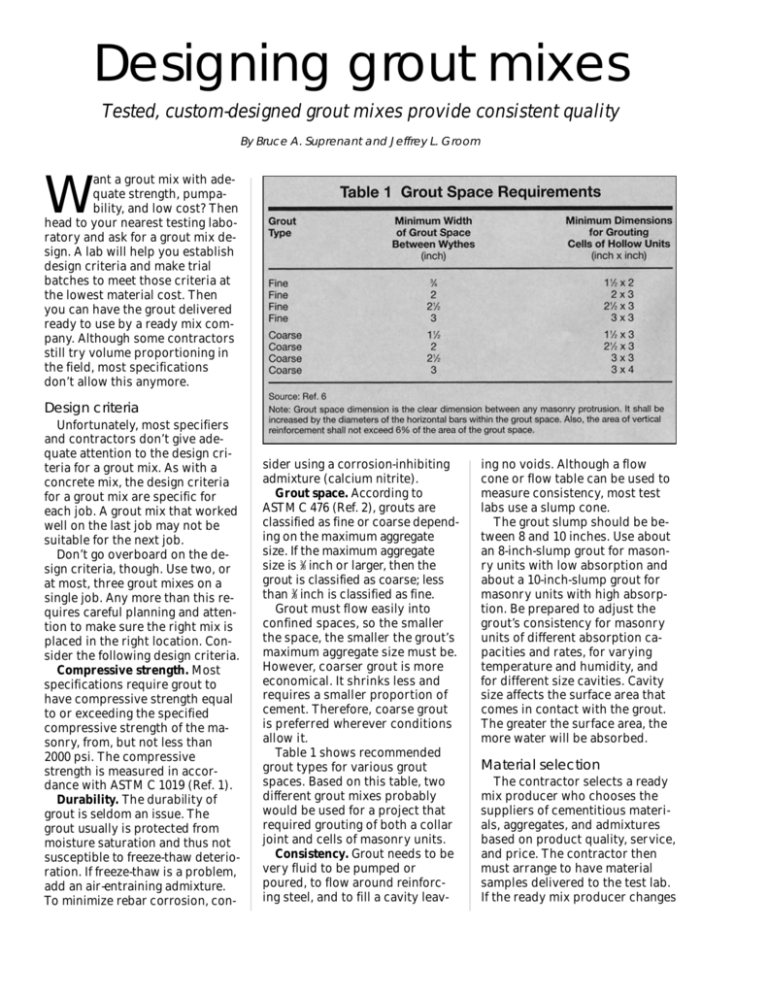

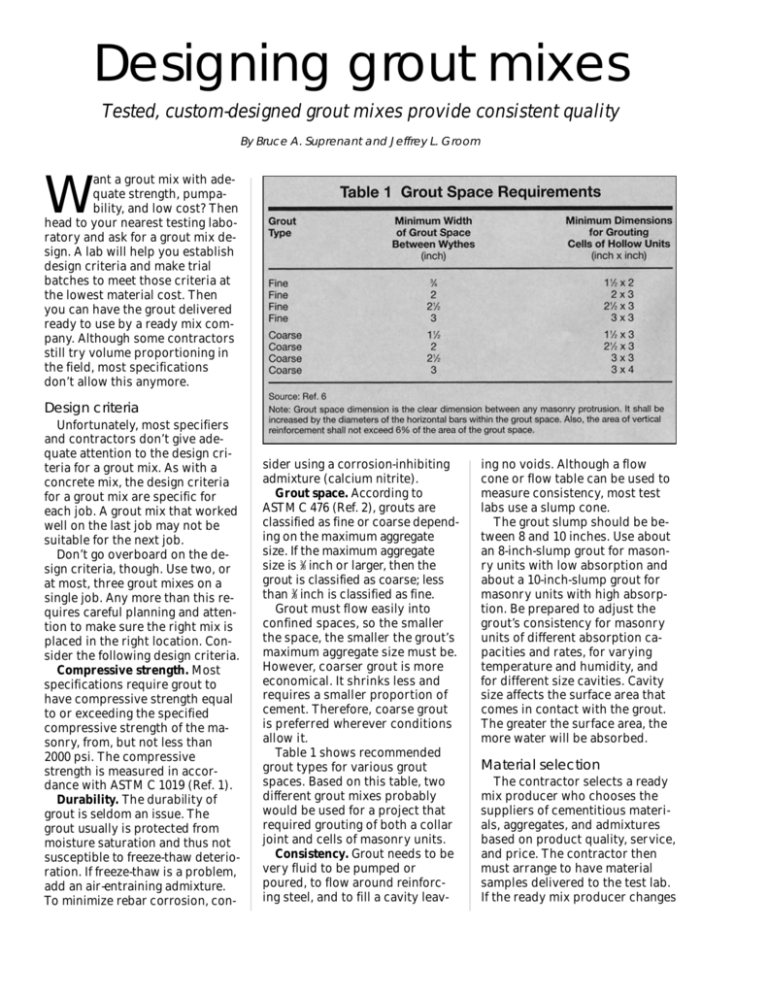

Table 1 shows recommended

grout types for various grout

spaces. Based on this table, two

different grout mixes probably

would be used for a project that

required grouting of both a collar

joint and cells of masonry units.

Consistency. Grout needs to be

very fluid to be pumped or

poured, to flow around reinforcing steel, and to fill a cavity leav-

ing no voids. Although a flow

cone or flow table can be used to

measure consistency, most test

labs use a slump cone.

The grout slump should be between 8 and 10 inches. Use about

an 8-inch-slump grout for masonry units with low absorption and

about a 10-inch-slump grout for

masonry units with high absorption. Be prepared to adjust the

grout’s consistency for masonry

units of different absorption capacities and rates, for varying

temperature and humidity, and

for different size cavities. Cavity

size affects the surface area that

comes in contact with the grout.

The greater the surface area, the

more water will be absorbed.

Material selection

The contractor selects a ready

mix producer who chooses the

suppliers of cementitious materials, aggregates, and admixtures

based on product quality, service,

and price. The contractor then

must arrange to have material

samples delivered to the test lab.

If the ready mix producer changes

material suppliers during the

project, then a mix design should

be made with any new materials.

The test lab, if necessary, can

check each product to make sure

it conforms to ASTM standards.

Cementitious materials. Use

portland cement meeting ASTM C

150 (Ref. 3) or blended cements

meeting ASTM C 595 (Ref. 4). Almost all masonry grouts contain

fly ash as a partial replacement

for portland cement. Fly ash contributes strength, acts as a waterreducer, and costs less than cement. ASTM C 595 permits up to

40% fly ash by weight of the cementitious materials.

Aggregates. Aggregates used in

grout must conform to ASTM C

404 (Ref. 5). This standard defines

gradation for both fine and coarse

aggregate and sets limits on deleterious substances (lightweight

and friable particles), organic impurities, and soundness.

Although ASTM C 404 limits the

maximum aggregate size to 3⁄8 inch,

some engineers allow up to 3⁄4-inch

aggregate for grouting columns,

pilasters, or large voids. The larger aggregate takes up more volume, reduces grout shrinkage,

and requires less cement for

equivalent strength. Some grout

pumps, however, may not pump a

3

4⁄ -inch rock mix.

Admixtures. ASTM C 476

doesn’t allow the use of admixtures in grout unless specified by

the engineer or architect or approved by the contractor. Admixtures, however, can facilitate construction by accelerating grout set

in cold weather and retarding

grout set in hot weather. To maintain the water-cement ratios and

high strength, some engineers

specify a superplasticizer instead

of adding water to increase slump.

Shrinkage-compensating admixtures or grouting aids are the

most common grout admixture.

After placement, grout shrinks

from 5% to 10% as the surrounding masonry units absorb water

from the grout. To minimize this

volume loss, a shrinkage-compensating admixture may be added to

the truck mixer at the jobsite.

These blended admixtures expand the grout, retard its set, and

act as a water-reducer. This combination minimizes grout volume

loss and gives workers more time

to vibrate the grout before it stiffens. Table 2 shows the admixtures typically used for grouting,

their applications, and costs.

Trial batches

After the architect or engineer

sets the design criteria and the

contractor obtains the material

samples, the testing lab suggests

mix proportions that meet the design criteria. Then the lab makes

trial batches to determine the

most economical grout mix. ASTM

C 476 serves only as a rough

guide to mix design. It expresses

proportions in ranges to account

for material differences throughout the United States. The test lab

bases its trial mix proportions on

experience.

Though ASTM C 476 lists grout

proportions by volume (Table 3),

most specifications don’t allow

batching of grout by volume in

the field. Today, test labs and

ready mix companies batch by

weight. Volume proportions can

be changed to equivalent weight

proportions (pounds per cubic

yard) by using the specific gravity

of each ingredient.

Don’t experiment

at the jobsite

A mix design that uses three trial batches costs from $800 to

$1,200. Some contractors try to

avoid a mix design to save $1,000,

but they often pay for it later with

a grout that has low strength and

doesn’t pump. One ready mix supplier tried volume proportioning a

grout mix in accordance with

ASTM C 476 but found that the mix

segregated when pumped. Don’t

try to design a mix at the site; pay

a test laboratory for a mix design.

You’ll sleep a lot better.

Bruce A. Suprenant is a consulting engineer

and adjunct associate professor at the University of Colorado at Boulder. Jeffrey L.

Groom is a senior engineer at CTL/Thompson, a materials engineering and testing laboratory in Denver.

Race St., Philadelphia, PA 19103.

2. ASTM C 476, Standard Specification for

Grout for Masonry, ASTM.

3. ASTM C 150, Standard Specification for

Portland Cement, ASTM.

References

4. ASTM C 595, Standard Specification for

Blended Cements, ASTM.

1. ASTM C 1019, Standard Method of

Sampling and Testing Grout, ASTM, 1916

5. ASTM C 404, Standard Specification for

Aggregates for Masonry Grout, ASTM.

A Mix Design Example

A ready mix company requests

a grout mix for filling block cells.

The design criteria are: minimum

2500-psi compressive strength at

28 days, 8-inch slump, 580 to

700 pounds of cementitious materials, 40% fly ash replacement

of total cementitious materials,

and total entrapped air from

0.5% to 1.0%.

The ready mix company submits these materials for use:

Type I-II portland cement,

Class C fly ash, sand meeting

gradation re q u i rements of Size

No. 1, and coarse aggre g a t e

meeting gradation re q u i rements of Size No. 8.

The test lab mixes and evaluates three trial batches (Table 1).

All three mixes meet the design

criteria. However, the lab recommends a compressive strength

overdesign of 1200 psi. (Although

overdesign is required for concrete mixes, no standards have

been established yet for grout.)

So now the grout must

achieve at least 3700 psi. Tr i a l

Batches 2 and 3 exceed this

s t rength; Trial Batch 1 does

not. To determine the minimum amount of cementitious

materials (the most costly ing redient) needed to achieve

3700 psi, the strengths of the

trial batches are plotted

against their cementitious contents on a graph (Figure 1).

Based on the resulting curv e ,

the lab determines that at least

625 pounds of cementitious

material are needed to re a c h

3700 psi. It thus re c o m m e n d s

the mix described in Table 2.

6. ACI 530.1/ASCE 6, Specifications for

Masonry Structures, American Concrete Institute, P.O. Box 19150, Detroit, Ml 48219.

PUBLICATION #M910218

Copyright 1991

The Aberdeen Group

All rights reserved