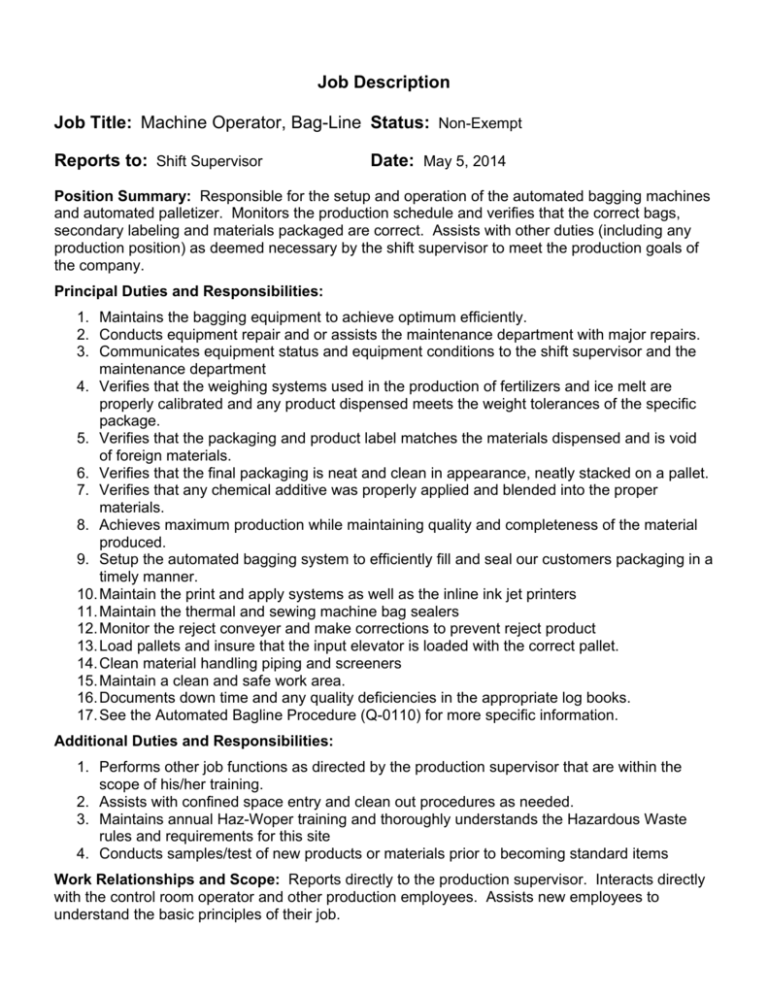

Job Description Job Title: Machine Operator, Bag-Line

advertisement

Job Description Job Title: Machine Operator, Bag-Line Status: Non-Exempt Reports to: Shift Supervisor Date: May 5, 2014 Position Summary: Responsible for the setup and operation of the automated bagging machines and automated palletizer. Monitors the production schedule and verifies that the correct bags, secondary labeling and materials packaged are correct. Assists with other duties (including any production position) as deemed necessary by the shift supervisor to meet the production goals of the company. Principal Duties and Responsibilities: 1. Maintains the bagging equipment to achieve optimum efficiently. 2. Conducts equipment repair and or assists the maintenance department with major repairs. 3. Communicates equipment status and equipment conditions to the shift supervisor and the maintenance department 4. Verifies that the weighing systems used in the production of fertilizers and ice melt are properly calibrated and any product dispensed meets the weight tolerances of the specific package. 5. Verifies that the packaging and product label matches the materials dispensed and is void of foreign materials. 6. Verifies that the final packaging is neat and clean in appearance, neatly stacked on a pallet. 7. Verifies that any chemical additive was properly applied and blended into the proper materials. 8. Achieves maximum production while maintaining quality and completeness of the material produced. 9. Setup the automated bagging system to efficiently fill and seal our customers packaging in a timely manner. 10. Maintain the print and apply systems as well as the inline ink jet printers 11. Maintain the thermal and sewing machine bag sealers 12. Monitor the reject conveyer and make corrections to prevent reject product 13. Load pallets and insure that the input elevator is loaded with the correct pallet. 14. Clean material handling piping and screeners 15. Maintain a clean and safe work area. 16. Documents down time and any quality deficiencies in the appropriate log books. 17. See the Automated Bagline Procedure (Q-0110) for more specific information. Additional Duties and Responsibilities: 1. Performs other job functions as directed by the production supervisor that are within the scope of his/her training. 2. Assists with confined space entry and clean out procedures as needed. 3. Maintains annual Haz-Woper training and thoroughly understands the Hazardous Waste rules and requirements for this site 4. Conducts samples/test of new products or materials prior to becoming standard items Work Relationships and Scope: Reports directly to the production supervisor. Interacts directly with the control room operator and other production employees. Assists new employees to understand the basic principles of their job. Performance Dimensions: Interacts with coworkers in a positive, professional manner Promotes quality in the items packaged with a passion for continuous quality improvement. Follows policies, procedures and guidelines established by the company Promotes teamwork Enhances job growth through continuing education as required or necessary Promotes quality, accuracy, timeliness, reliability and thoroughness of work performed Develops and maintains positive working relationships with other employees Is punctual and reliable Regular and dependable attendance Knowledge, Skills and Abilities: Education/Training: High school diploma, certificate or diploma beyond high school desired Experience: Experience in a manufacturing environment with experience/knowledge of basic mechanical, pneumatic and electrical principles. Skills and Abilities: Posses strong organizational skills Self motivated, work independently without supervision and in a team setting React positively to sudden and frequent changes in priorities Work effectively and non defensively with a variety of personalities Working Conditions: Job Conditions/Work Location: Work is performed primarily in the bag room, and may include working in the screener area or rooftop locations. The average workweek is 42.5 hours. Physical Requirements: The ability to be on your feet the entire day, bending, stooping and lifting up to 50 pounds repeatedly and climb distances up to 98 feet and work from elevated platforms. Capable of wearing a cartridge respirator and becoming respirator certified. Equipment Used: Weight scales, automated bagging system, automated palletizer, various forms of PPE including safety glasses, hearing protection, chemical protective gloves and respirators. Acknowledgment: This job description describes the general nature and level of work performed by an employee assigned to this position. It does not state or imply that these are the only duties and responsibilities assigned to the job. The employee may be required to perform other jobrelated duties as requested by the production supervisor. All requirements are subject to change over time and to possible modifications to reasonably accommodate individuals with a disability I acknowledge that this job description is nether an employment contract nor a legal document. I have received and read and understand the expectations for the successful performance of this job. ____________________________________________ Employee Signature _________________ Date