GUIDENCE FOR LIVERY DOC A/W

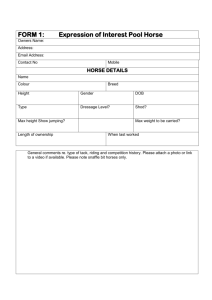

advertisement