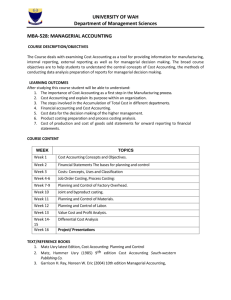

Target Costing for Effective Cost Management: Product Cost

advertisement