Impact of Target Costing on Competitive Advantage in the

advertisement

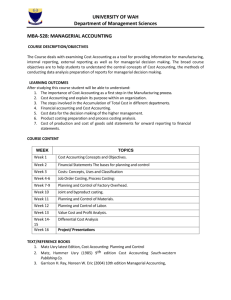

International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4, No.3, July 2014, pp. 97–108 E-ISSN: 2225-8329, P-ISSN: 2308-0337 © 2014 HRMARS www.hrmars.com Impact of Target Costing on Competitive Advantage in the Manufacturing Industry: A Study of Selected Manufacturing Firms in Nigeria Adeniyi Segun IDOWU Department of Accountancy, Nnamdi Azikiwe University, Awka, Nigeria E-mail: princeadeidowu@gmail.com Abstract Key words The research work examined target costing and competitive advantage in the manufacturing industry. The main objective of this study is to ascertain the impact of target costing on competitive advantage in Nigeria manufacturing firms. The specific objectives are: to determine how target costing enhance cost advantage in manufacturing firms, to ascertain how target costing enhance product quality advantage in manufacturing firms, and to ascertain the challenges faced by manufacturing firms in adopting target costing. Chief Accountants, Marketing Directors and Production Engineers were used to determine the impact of target costing on competitive advantage in Nigeria manufacturing firms. Survey design was adopted for this study. Copies of questionnaires were administered to 134 sample respondents. Analysis of variance (ANOVA) was used to analyze data collected statistically at 5% or 0.05 level of significance to find out the impact of target costing on competitive advantage in manufacturing firms using difference in proportion, and in testing the hypotheses; Regression analysis was used, with the aid of statistical package for social sciences (SPSS)20.0 soft ware. The test showed that target costing enhance cost advantage and quality advantage in competitive manufacturing industry, despite some teething problems encountered by firms in adopting the technique. The researcher recommends that internally, coordination and involvement of financial and accounting professionals is needed to implement target costing and a close monitoring of marketing and quality control throughout the entire process in order to be a success. Moreover, senior management team should support and pay more attention to application of target costing to achieve the substantial reductions in production costs to strengthen competitiveness. Target costing, manufacturing industry, competitiveness, quality control, analysis DOI: 10.6007/IJARAFMS/v4-i3/1025 1. URL: http://dx.doi.org/10.6007/IJARAFMS/v4-i3/1025 Introduction Globalization, technological advancements, increasingly shorter product life cycle, new competitors breaking into market, the growing and changing customer needs have greatly complicated today’s business world. Businesses have started to change their manufacturing systems by means of using modern manufacturing technologies. Congruously, present costing methods that are insufficient to provide efficient cost information in these conditions of competition, has been called into question. Cost information and cost management have become an essential fact for businesses that want to be more successful in the risen heat of the competition of today’s economic climate. Today, new methods that consist of advanced and elaborate technical studies and approach to cost reduction factors individually, started to find their way into operations. One of these methods emerged in this process is Target Costing technique. Target costing is a contemporary management accounting tool developed principally by Japanese manufacturers (Kato, 1993; Tani et al., 1994). The practice endeavours to design new products to meet a cost, which is calculated by subtracting the desired profit margin from a market-based price for the product (Cooper and Slagmulder, 1999; Guilding et al., 2000; Dekker and Smidt, 2003). Target costing attempts to reduce a product’s life-cycle costs before production begins in order to achieve desired profitability (Kato, International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS 1993). Target costing assists in making the new product competitive in terms of cost, quality and functionality (Cooper and Chew, 1996). According to the CIMA Official Terminology (CIMA, 2005) a target cost is ''a product cost estimate derived by subtracting a desired profit margin from a competitive market price.'' Sakurai (1989) defines target costing as a ''cost management tool for reducing the overall cost of a product over its entire life cycle with the help of the production, engineering, R&D, marketing, and accounting departments''. Regarding the globalization of markets and the issue of joining world trade market, the companies would be inevitably led into competitive environment and would be forced to use the target costing in order to survive in such environment. The increase in standards of rivals' products, economics globalization, high competition in prices and lower life cycle of products suggest that market seeks those products that are supplied with lower prices in addition to previous performance whilst they cannot reduce their profitability. Research shows that target costing is being used worldwide (for example, Adler et al., 2000; Carr and Ng, 1995; Dekker and Smidt, 2003; Dyer, 1996; Guilding et al., 2000; Joshi, 2001; Nicolini et al., 2000; Shank and Fisher, 1999; Wijeweardena and De Zoysa, 1999). However there is still little research outside of Japan, and scant research in Nigeria context. In a competitive environment, the ever increasing cost is regarded as one of the principal parameters for customers. In reply to cost improvement, many Manufacturers have embarked on accepting and utilizing the management accounting tools and techniques among them is the target based costing (Muia, 2012). The goals of becoming and remaining internationally competitive in terms of price and quality are of utmost importance for the survival of the Nigerian manufacturing industry. The dilemma for manufacturers is to match the lower prices of the global competition and still offer the highest quality products that customers demand. Some manufacturing firms find it difficult to practice target costing in this competitive market. However, some manufacturing firms practicing target costing can hardly justify their competitive advantage in manufacturing industry. 1.1. Statement of problem The rapid developments in the modern production environment, such as increased local and international competition, the speed of technological progress, the diversity of customer needs, and the short product life cycle, showed inadequate traditional and management accounting methods to cope with these developments, therefore, they imposed new dimensions to the concepts of cost, the content of the measurement accuracy, and cost comparisons methods. Those factors have led to the emergence of target cost method as one of the tools of cost management. The dilemma for manufacturers is to match the lower prices of the global competition and still offer the highest quality products that customers demand. Some manufacturing firms find it difficult to practice target costing in this competitive market. However, some manufacturing firms practicing target costing can hardly justify their competitive advantage in manufacturing industry. Based on the foregoing, therefore, the study was designed to determine the impact of target costing on competitive advantage in Nigeria manufacturing firms. 1.2. Objective of the study The general objective of the study is to ascertain the impact of target costing on competitive advantage in Nigeria manufacturing firms. The specific objectives for the study are: i. To determine how target costing enhance cost advantage in manufacturing firms. ii. To ascertain how target costing enhance product quality advantage in manufacturing firms. iii. To ascertain the challenges faced by manufacturing firms in adopting target costing. 1.3. Research questions The study will seek to answer the following questions: i. To what extent does target costing enhance cost advantage in manufacturing firms? 98 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS ii. To what extent does target costing enhance product quality advantage in manufacturing firms? iii. What are the challenges faced by Nigeria manufacturing firms in the adoption of target costing? 1.4. Research hypotheses This research work is guided by the following hypotheses: Ho 1: Target costing does not enhance cost advantage in manufacturing firms. Ho 2: Target costing does not enhance product quality advantage in manufacturing firms. Ho3: Nigeria manufacturing firms do not face any serious challenges in the adoption of target costing. 1.5. The significance of the study The outcome of the study will help to educate manufacturers in Nigeria on the need for efficient use of target costing technique for strategic pricing approach to enhance effective cost management and to match the lower price of the global competition and still offer the highest quality products customers demand. It will help Managers’ to have comprehensive and integrated information on all aspects of performance and costs associated with it to be able to run it in a way that will make them to compete favorably in this global competition. 1.6. Scope of the study The study was designed to determine the impact of target costing on competitive advantage in Nigeria manufacturing firms. Seven companies were selected from Food and beverage manufacturing industry quoted in Nigeria Stock Exchange and has their head office in Lagos State. The companies are: Guinness Nigeria Plc., Nigeria Breweries (NB) Plc., Cadbury plc., Nestle Nigeria Plc., Honeywell Nigeria Plc., Flour mill Nigeria Plc., and Dangote flour plc. We choose food and beverage companies for this study due to great pressure on the industry to lower costs and improve the quality and efficiency of operations in the industry. However, some companies within food and beverage industry are practicing target costing system. 2. Literature review In the accounting literature, target costing has been introduced as a strategic management accounting system for the management of product costs (Ewert and Ernst, 1999). It is a costing technique to manage a firm’s future profits by explicitly including target costs in the product development process (Cooper and Slagmulder, 1999). Target costing is a contemporary management accounting tool developed principally by Japanese manufacturers (Kato, 1993; Tani et al., 1994). The practice endeavours to design new products to meet a cost, which is calculated by subtracting the desired profit margin from a market-based price for the product (Cooper and Slagmulder, 1999; Guilding et al., 2000; Dekker and Smidt, 2003). Target costing attempts to reduce a product’s life-cycle costs before production begins in order to achieve desired profitability (Kato, 1993). The target costing team assists in making the new product competitive in terms of cost, quality and functionality. Cooper and Chew (1996), states that by influencing products and processes, target costing are concerned with shaping the foundations of the organization and can be regarded as the most proactive of all the uses of costing. According to the CIMA Official Terminology (CIMA, 2005) a target cost is ''a product cost estimate derived by subtracting a desired profit margin from a competitive market price.'' Sakurai defines target costing as a ''cost management tool for reducing the overall cost of a product over its entire life cycle with the help of the production, engineering, R&D, marketing, and accounting departments'' (Sakurai, 1989). Management utilizes this pricing technique to meet both the demands of its customers as well as company profit goals. The target costing technique was first developed in the Japanese automobile industry in order to help the decision of making and selling new products, as well as analyzing product costs and marginal returns. According to Cooper and Kaplan (1998) the target costing essence can be divided in three main parts: (a) allow the market to establish the product sale price (b) subtract the determined product margin required by the company and (c) resulting in the target costing. Sale Price – Required Return = Target Costing 99 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS Ansari et al (1997) state that since target costing is market driven, the views of customers are of utmost importance and should therefore be taken into account throughout the entire process. Understanding the needs of customers and what competitors are currently doing or might do to meet those needs is essential. Quality, cost and time requirements of customers are thus incorporated in product and process decisions and guide cost analysis. Engineering development activities are driven by a focus on customers and are shaped by the demands of the market. Target costing has been widely adopted in Japan since it was first introduced at Toyota in the middle of the 1960s (McMann and Nanni, 1995). Tani et al. (1994) find 60.6 per cent of Japanese manufacturing firms listed on the Tokyo Stock Exchange have adopted the practice, while Kato (1993) claims over 80 per cent of major assembly companies in Japan employ target costing. Articles on how the Japanese use target costing began to appear in English in the business and accounting literature less than twenty years ago (for example, Hiromoto, 1988 and Sakurai, 1989). A number of case studies have been undertaken in leading Japanese manufacturers, such as Matsushita Electric, Toyota, Sony, Olympus, Komatsu, Mitsubishi, Nissan and Daihatsu, and published in English (Fisher, 1995; Cooper, 1996a, Kato et al., 1995). There has been some research on the adoption of target costing outside of Japan. Guilding et al.’s (2000) survey of the adoption of various management accounting techniques in New Zealand, the United States, and Britain finds moderate use and perception of target costing useful. Similarly, Adler et al.’s (2000) survey of the adoption of advanced management accounting techniques by New Zealand manufacturers finds that less than seven percent use target costing. Dekker and Smidt (2003) conducted a detailed examination of target costing in Dutch firms revealing an adoption rate of 59.4 per cent for listed manufacturing companies. Chenhall and Langfield-Smith (1998) find 38 per cent of Australia’s largest manufacturers use target costing, while Joshi (2001) establishes that 35 per cent of sample of Indian manufacturers have adopted the practice. Target costing has a number of implementation challenges. Banham (2000) quotes the Senior Manager of Finance at Boeing and agrees implementation barriers include: lack of understanding in corporate America (in fact the term is not well known and much of the Japanese literature on "drifting cost" has not been translated); cultural barriers against cross-functional cooperation; organizational barriers to team oriented work (difficult to achieve in a functional structure); and a perceived irrelevance about the effects. Still other barriers may include the organizations information systems and its lack of total system integration. To share cost reductions, supply chain partners must be able to share initial cost and production data. Liu (2003) opines that the company's competitive advantage means the company advantage from the perspective of market of the product that will bring more competitive position for it. While Stevenson (2007) stresses on that it is practically aims at meeting customer’s needs and desires in order to possess the company's products. Jones (2008) said a company has a sustainable competitive advantage when it can be able to maintain the rate of profit higher than the rate of profitability of the industry for several years through its ability to produce its products at lower costs than its competitors. However, Abdel-El-Dayem (2001), opines that target costing is considered as the technical support of the organization’s activities in addition to its assistance in access what is the best by providing senior management with the necessary information to manage costs, because they represent a comprehensive system of planning profit, and works to reduce production costs. 3. Methodology of research A cross sectional survey design was used to address the problem of this study. The use of the survey design allowed the issues to be addressed in their organizational setting rather than in a contrived laboratory setting. It allows the collection of large amount of data from a sizeable population in a highly economical way. The participants are the Chief Accountants and Marketing Managers and Production Engineers of; Guinness Nigeria Plc., Nigeria Breweries (NB) Plc., Seven Up bottling Company plc., International Breweries Plc., Cadbury Nigeria plc., Nestle Nigeria Plc., Honeywell Nigeria Plc., Dangote Sugar Refinery Plc., Flour mill Nigeria Plc., and Dangote flour mill plc was selected to represent the population size to be covered. The choice of these participants was due to; applying target costing or having a similar process, have extensive market analyses and marketing information systems. They follow balanced competition strategies. They have comprehensive cost estimation systems and can be considered as applying cost planning successfully. Correspondingly, most of these companies have the understanding of product life cycle costing. 100 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS Table 1. The sample size of 190 selected from the population was tabulated below: S/N 01 02 03 04 05 06 07 08 09 10 Respondents (management Staff) Guinness Nigeria Plc. Nigeria Breweries (NB) Plc. International Breweries Plc. Seven Up bottling Company plc. Cadbury Nigeria plc. Nestle Nigeria Plc. Dangote Sugar refinery Plc. Honeywell Nigeria Plc. Flour mill Nigeria Plc. Dangote flour plc. Total Total 25 24 22 21 19 22 13 12 17 15 190 Source: field survey 2014 4. Method of data analysis The data collected from the questionnaire administered and hypotheses formulated have been statistically tested with the aid of SPSS 20.0 software. The statistical model chosen for the analysis of data is multiple regression analysis and analysis of variance [ANOVA]. The model in its functional form was specified as follows: Tacost= f (C1, Qj, Ak) Three sets of hypotheses were advanced for confirmation in this study. The first null hypothesis is; target costing does not enhance cost advantage in manufacturing firms. Test items were developed to obtain cost advantage behaviour score. The model to be used to confirm this proposition is presented below: Tacost i = B0 + B1 C 1 + ei Bi > 0; R2t > 0. (1) The Bi is a measure of the impact of target costing on cost advantage. The second null hypothesis is; Target costing does not enhance product quality advantage in manufacturing firms. The model to be used to confirm this proposition is presented below: Tacost j = B0 + B1Qj + ej Bi > 0; R2Q > 0 (2) Bi measures the impact of target costing on quality advantage. The third hypothesis is; Nigeria manufacturing firms do not face any serious challenges in the adoption of target costing. The model to be used to confirm this proposition is presented below: Tacost k = B0 + B1Ak + ek Bi > 0; R2A > 0 (3) B1 measure serious challenges facing the adoption of target costing by manufacturing firms. Where: Tacost = Target costing; C1 = Cost advantage; Qj = Quality advantage; Ak = Challenges for adoption of target costing; e = Error term; B0 …….. B3 = Coefficient. 101 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS 5. Presentation and analysis of data In carrying out this study, questionnaire was used for collection of primary sources of data and secondary sources were also collected, which were analyzed. The two major methods used in analyzing the data collected were: Analysis of variance and Regression analysis. The researcher administered one hundred and ninety copies of questionnaires randomly to Chief Accountants, Production Engineers and Marketing Managers out of which one hundred and thirty -four copies were successfully retrieved representing 71% of the number of questionnaire administered. The test concerning the parameter was carried out using Analysis of Variance, and to test secondary data, correlation coefficient was used. Table 2. Administration of questionnaire Details Copies administered Copies returned Wrongly filed/unreturned copies Number of copies 190 134 56 Percentage (%) 100 % 71 % 29 % Source: field survey 2014 6. Analysis of Response Table 3. To what extent does target costing enhance cost advantage in manufacturing firms? 1. 2. 3. 4. 5. 6. X Statement The process of reducing cost of the product is one of the main priorities in the company objectives. SA 64 A 53 D 11 SD 06 T 134 3.31 Remark A The management of the company determines the costs gap by comparing the cost of the initial design and target cost of the product. There is a mutual relationship between the company and suppliers in the field of the quality and the cost of the product components. The management of the company tries to reduce waste and loss to the least extent in marketing and administrative costs. The management of the company tries to reduce waste and loss to the least extent in storage costs. The senior management evaluates the cost performance for sections, quarterly and annually. 60 57 10 07 134 3.27 A 63 53 09 09 134 3.27 A 66 52 10 06 134 3.23 A 62 55 12 5 134 3.30 A 67 52 11 4 134 3.36 A Source: field survey, 2014 This tablet shows the opinion of different respondents as well as their mean score on how target costing enhance cost advantage in competitive environment. The process of reducing cost of the product is one of the main priorities in the company objectives. This is supported by a mean score of 3.31. Also, the management of the company determines the costs gap (differences /deviations) by comparing the cost of the initial design and target cost of the product. Support to this response is backed by a mean score of 3.27 which is accepted. There is a cooperative relationship between the company and suppliers in the field of the quality and the cost of the product components. This response is supported by mean score of 3.27 which is accepted. The management of the company tries to reduce waste and loss to the least extent in marketing and administrative costs. This response is baked by the mean score of 3.23 which is accepted. The management of 102 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS the company tries to reduce waste and loss to the least extent in storage costs. This is supported with a mean score of 3.30 which is accepted. Moreover, the senior management evaluates the cost performance for sections, quarterly and annually. This is supported with a mean score of 3.36 which is accepted. It could be observed that target costing enhance cost advantage in manufacturing firms. This is clearly shown in the grand mean score of 3.29. Table 4. To what extent does target costing enhance product quality advantage in manufacturing firms? 7. 8. 9. 10. 11. 12. Statement The management of the company supports reducing the percentage of the defective and damaged products, compared with similar companies. The management of the company does its best to produce products that have specifications which are identical to the standard specifications. The management of the company supports the improvement in the quality of product design. The management of the company supports the application of the requirements for ISO certification. Management Circulate quality standards manual to all the employees in the company. The management of the company enhances awareness about the quality in the company X SA 76 A 32 D 17 SD 9 T 134 3.31 Remark A 82 35 13 4 134 3.46 A 71 45 11 7 134 3.34 A 76 24 18 16 134 3.19 A 69 36 22 7 134 3.25 A 79 42 9 4 134 3.46 A Source: field survey, 2014 This table shows the opinion of different respondents towards the effect of target costing on product quality advantage in manufacturing firms. The management of the company supports reducing the percentage of the defective and damaged products, compared with similar companies. This is supported by a mean score of 3.31 which is accepted. Also, the management of the company does its best to produce products that have specifications which are identical to the standard specifications. This is supported by a mean score of 3.46 which is accepted. The management of the company supports the improvement in the quality of product design. This is supported by a mean score of 3.34 which is accepted. The management of the company supports the application of the requirements for ISO certification. This is supported by a mean score of 3.19 which is accepted. Management Circulate quality standards manual to all the employees in the company. This is supported by a mean score of 3.25 which is accepted. Therefore, the management of the company enhances awareness about the quality in the company. This has a mean score of 3.46 which is acceptable. The idea is accepted with grand mean score of 3.34 that target costing enhance product quality advantage in manufacturing firms. Table 5. What are the challenges faced by Nigeria manufacturing firms in the adoption of target costing? 13. 14. 15. Statement While target costing has a straight forward logic, the implications in practice are more difficult, particularly when the culture has previously embraced a cost-plus approach to pricing. Lack of understanding of costs throughout the supply chain and not having tightly linked, communicating supply chain partners. Many managers regard target costing as just another buzz word or accounting term with little relevance to manufacturing or marketing. X SA 83 A 34 D 07 SD 10 T 134 3.42 Remark A 63 46 18 07 134 3.23 A 72 44 11 07 134 3.35 A 103 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS 16. 17. 18. Statement The design process must be broken down into its lowest level components. This requires the involvement of manufacturing, design engineering, product engineering and marketing. There is a cultural barrier as “people tend to build fences around their responsibilities because that is what they believe they are measured on”. There is an organizational barrier as “employees are organized according to functions in most companies.” X SA 61 A 53 D 04 SD 16 T 134 3.19 Remark A 79 36 07 12 134 3.36 A 76 42 10 6 134 3.49 A Source: field survey, 2014 This table shows the opinion of different respondents towards the challenges faced by Nigeria manufacturing firms in the adoption of target costing. While target costing has a straight forward Logic, the implications in practice are more difficult, particularly when the culture has previously embraced a cost-plus approach to pricing. This is supported by a mean score of 3.42 which is accepted. Also, Lack of understanding of costs throughout the supply chain and not having tightly linked, communicating supply chain partners. This is supported by a mean score of 3.23 which is accepted. Many managers regard target costing as just another buzz word or accounting term with little relevance to manufacturing or marketing, their mean score is 3.25, signifying acceptance. The design process must be broken down into its lowest level components. This requires the involvement of manufacturing, design engineering, product engineering and marketing. This is supported by a mean score of 3.19 which is acceptable. There is a cultural barrier as “people tend to build fences around their responsibilities because that is what they believe they are measured on.” This is supported by a mean score of 3.36 which is accepted. In addition, there is an organizational barrier as “employees are organized according to functions in most companies”. Their mean score is 3.49 which signify acceptance. This entails that Nigeria manufacturing firms do face serious challenges in the adoption of target costing based on the respondents’ opinion with the grand mean score of 3.34. 7. Testing of Hypotheses The decisions reached on hypotheses are based on the result obtained from regression calculation and the tabulated value of the regression distribution. We reject Ho if F – calculated is greater than F – tabulated at 5% level of significance, otherwise we accept. Hypothesis One Ho: Target costing does not enhance cost advantage in manufacturing firms. Hi: Target costing enhances cost advantage in manufacturing firms. In testing of hypothesis one, question 1, 2,3,4,5, and 6 was drawn to seek response on relationship between cost advantage and target costing. Table 6a. Regression coefficient for target costing on cost advantage R B Constant 113.671 Cost advantage 19.541 2 R = .92, F(1, 4) =47.496, P =.002 Beta .96 T = test T= 3.47, p = 0.26 T= 6.89, p =.002 Table 6b. Analysis of variance table Model Regression Residual 104 Sum of square 69811.93 5879.41 Df 1 4 Mean square 69811.93 1469.85 F 47.496 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS Target costing explain 92 per cent of variation experience in cost advantage, and this result is significant F ( 1, 4) = 47.496, P < 0.05. Target costing makes a positive impact on cost advantage and this is significant, t (6. 89), p <.005. Decision Based on the analysis above, the null hypothesis (H0) is therefore rejected while the alternative hypothesis (H1) is accepted; which state that target costing enhances cost advantage in manufacturing firms. Hypothesis Two Ho: Target costing does not enhance product quality advantage in manufacturing firms. Hi: Target costing enhances product quality advantage in manufacturing firms. In testing of hypothesis two, question 7,8,9,10,11, and 12 was drawn to seek response on relationship between product quality advantage and target costing. Table 7a. Regression coefficient for target costing on quality advantage R B Constant 135.996 Cost advantage 118.369 R2 = .95, F(1, 4) =36.90, P =.004 Beta .95 T = test T= 4.80, p = .009 T= 6.08, p =.004 Table 7b. Analysis of variance table Model Regression Residual Sum of square 63943.86 6931.48 Df 1 4 Mean square 63943.86 1732.87 F 36.90 Target costing explain 95 per cent of variation experience in quality advantage, and this result is significant F (1, 4) = 36.90, P < 0.05. Target costing makes a positive impact on cost advantage and this is significant, t (6. 09), p <.005. Decision Based on the analysis above, the null hypothesis (H0) is therefore rejected while the alternative hypothesis (H1) is accepted; which state that target costing enhances quality advantage in manufacturing firms. Hypothesis Three Ho: Nigeria manufacturing firms do not face any serious challenges in the adoption of target costing. Hi: Nigeria manufacturing firms do encountered serious challenges in the adoption of target costing. In testing of hypothesis three, question 13, 14,15,16,17, and 18 was drawn to seek response on serious challenges in the adoption of target costing. Table 8a. Regression coefficient on serious challenges for adopting target costing R B Constant 119.362 Cost advantage 20.695 2 R = .92, F(1, 4) =21.996, P =.009 Beta .92 T = test T= 3.10, p = .036 T= 4.68, p =.009 Table 8b. Analysis of variance table Model Regression Residual Sum of square 50275.15 9184.35 Df 1 4 Mean square 50275.15 2296.10 F 21.996 105 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS Problems of adopting target costing was explained by 92 per cent of variation experience in manufacturing firms, this result is not significant F (1, 4) = 21.996, P > 0.05. Target costing makes a positive impact on cost advantage and this is significant, t (4.68), p <.005. Decision Based on the analysis above, the alternative hypothesis (H1) is therefore rejected while the null hypothesis (H0) is accepted; which state that Nigeria manufacturing firms do not face any serious challenges in the adoption of target costing. 8. Summary of findings, conclusion and recommendation Based on analyzed data, the findings in this study include the followings: 1. The study found the process of reducing cost of the product as one of the main priorities in the company objectives. However, the management of the company determines the cost gap by comparing the cost of the initial design and target cost of the product. 2. It was also discovered that target costing enhance quality advantage in manufacturing firms. The management of the company produces products that have specifications which are identical to the standard specifications. The management of the company supports the application of the requirement of ISO certification. 3. The study found that while target costing has a straight forward logic, the applications in practice are more difficult, particularly when the culture has previously embraced a cost – plus approach to pricing. 4. We discovered that target costing enhances competitive advantage in Nigeria manufacturing firms. Based on the theoretical presentation of findings, the following conclusions were drawn: Target costing encourage all participating functions of the firm to examine designs which enable to manage costs before they are incurred rather than afterward due to the fact that majority of production costs occur at the design stage. Therefore, the study found the relationship between the target costing and cost advantage to be positive and concludes that target costing should be employed in competitive environment to be able to have cost advantage over other competitors in the market, Target costing enables manufacturing firms to ascertain a more realistic prices as well as well as strengthen competition among firms to offer quality products at lower cost. We discovered that target costing technique enhances quality advantage in competitive environment. The study discovered that there are some challenges encountered in the process of adopting target costing in manufacturing firms. Most of the challenges can be well managed by the management of the company. However, target costing assist managers to have comprehensive and integrated information on all aspect of performance and cost associated with it to be able to run it in a way that will make them to compete favorably in the global competition. Based on the conclusion that target costing enhances cost advantage and quality advantage in competitive environment despite some teething problems. The study makes the following recommendations for the effectiveness of target costing and indirectly reduces or eliminates challenges facing the manufacturing firms in adopting target cost method in Nigeria. 1. Carefully choosing the right supply chain partner makes the difference in whether the target cost is reached or not. A bad choice can be disastrous and conversely a good partner can be a tremendous asset. 2. If the company has difficulty meeting a target cost, the firm may review the target cost to determine if the cost can be raised or if margins can be reduced. However, the manufacturing process can be review for possible modification or relaxation of product functionality requirement. 3. Internally, coordination and involvement of financial and accounting professionals is needed to implement target costing and a close monitoring of marketing and quality control throughout the entire process in order to be a success. 4. The necessity of supporting and paying attention of senior management to apply target cost method to achieve the substantial reductions in production costs to strengthen competitiveness. 106 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS References 1. Abdel-Dayem, and Safaa’ Mohammed. (2001). Toward a proposed framework for the management target costing in the modern manufacturing environment. The scientific journal of the economy of Commerce, Ain Shams University, third edition, p: 470. 2. Adler, R., Everett, A.M. and Waldron, M. (2000), “Advanced management accounting techniques in manufacturing: utilization, benefits, and barriers to implementation”, Accounting Forum, Vol. 2, pp. 131-50. 3. Ansari, Shahid L.and Jan E. Bell (1997). Target Costing: The Next Frontier in Strategic Cost Management, A CAM-I/CMS Model for Profit Planning and Cost Management, IRWIN Professional Publishing, USA. 4. Ansari, S., Bell, J., and Swenson, Dan. (2006). A Template for Implementing Target Costing. Cost Management, 20(5), 21-27. 5. Banham, R. (2000). Cost optimization: Off target? CFO, 127-130. 6. Bayou, M. and Reinstein, A. (1998), “Three routes for target costing”, Managerial Finance, Vol. 24 No. 1, pp. 28-45. 7. Chenhall, Robert. H. and Kim Langfield-Smith (1998). Adoption and benefits of management accounting practices: an Australian study, Management Accounting Research, Vol. 9, pp.1-19. 8. Carr, C. and Ng, J. (1995), “Target cost control: Nissan and its U.K. supplier partnerships”, Management Accounting Research, Vol. 6, pp. 347-65. 9. CIMA publishing,( 2005). CIMA Official Terminology. 10.CIMA. 2005. Target costing in the NHS. [Online]. Available: http://www.cimaglobal.com/cps/rde/ xbcr/SID-0AE7C4D1 11.65518BE4/live/tech_dispap_target_costing_in_the_NHS_2005.pdf [Date accessed: 2nd June, 2014] 12.Cooper, R. (1996), “Costing techniques to support corporate strategy: evidence from Japan”, Management Accounting Research, Vol. 7, pp. 219-46. 13.Cooper, R. (1995), “Lean enterprises and the confrontation strategy”, The Academy of Management Executive, Vol. 10 No. 3, pp. 28-39. 14.Cooper, R., and Chew, W. B. (1996). Control tomorrow's costs through today's designs. Harvard Business Review, 88-97. 15.Cooper, R., and Slagmuder. (2002). Target costing from New Product Development: Product level Target costing. Journal of Cost Management. 16.Cooper, R. and Slagmulder, R. (1997). Target costing and value engineering. Portland, Oregon: Productivity Press and Montvale, NJ: The IMA Foundation for Applied Research, Inc. 17.Cooper, R. and Slagmulder, R. (1999). Develop profitable new products with target costing. Sloan Management Review, 40(4), 23-33 18.Collier, P.M. and Agyei-Ampomah, S. (2007). Management Accounting Risk and Control Strategy. Oxford: Elsevier. 19.Dekker, H. and Smidt, P. (2003). A survey of the adoption and use of target costing in Dutch firms. International Journal of Production Economics, 84(3), 293-299. 20.Dyer, J. (1996), “How Chrysler created an American Keiretsu”, Harvard Business Review, Vol. 74 No. 4, pp. 42-56. 21.Ellram, L. M. (2000). Purchasing and supply management's participation in the target costing process. Journal of Supply Chain Management, 36(2), 39-45. 22.Ewert, R., and Emst, C. (1999). Target costing, co-ordination and strategic cost management. European Accounting Review, 8(1), 23-49. http://dx.doi.org/10.1080/096381899336131 23.Evans and Collier. (2007). Operation Management an Integrated Goods and Services Approach. USA: Thomson South Western. 24.Fisher, J. (1995). Implementing target costing. Implementing target costing. Journal of Cost Management, 9(2), 50-59. 25.Gagne, M. L., and Discenza, R. (1995). Target Costing. Journal of Business & Industrial Marketing. 10 (1), 16-25. 26.Guilding, C., Cravens, K. and Tayles, M. (2000), “An international comparison of strategic management accounting practices”, Management Accounting Research, Vol. 11, pp. 113-35. 107 International Journal of Academic Research in Accounting, Finance and Management Sciences Vol. 4 (3), pp. 97–108, © 2014 HRMARS 27.Hill Charles W. L., and Jones, Gareth R. (2008). Strategic Management: an Integrated Approach. (8th ed.). Houghton Mifflin Company, USA. 28.Hibbets, A. R,, Albright, T, and Funk, W. (2003), The competitive environment and strategy of target costing implementers: evidence from the field. Journal of Managerial Issues, 15(1), 65-81. 29.Joshi, P. (2001), “The international diffusion of new management accounting practices: the case of India”, Journal of International Accounting, Auditing and Taxation, Vol. 10, pp. 85-109. 30.Kato, Y. (1993). Target costing support systems: Lessons from leading Japanese companies. Management Accounting Research, 33-47. http://dx.doi.org/10.1006/mare.1993.1002 31.Kato, Y., Bõer, G., and Chow, C.W. (1995). Target costing: an integrative management process. Cost Management, 9(1), 39-51. 32.Kato, Y. (1993), “Target costing support systems: lessons from leading Japanese companies”, Management Accounting Research, Vol. 4, pp. 33-47. 33.Laseter, T, M. (1998). Supply chain management: The ins and outs of target costing. Purchasing, 124(3), 22-25. 34.Liu, Tsai-Lung. (2003). Organization Learning and Social Network Market Orientation: The Role of Resource-Based View Strategy Gaining in Dynamic, Capabilities Advantage. [Online] Available: http://www.hicbusiness.org/biz2003proceedings/Tsai-Lung%20Liu.pdf 35.McMann, P. and Nanni, A. (1995), “A review of the literature on Japanese management accounting”, Management Accounting Research, Vol. 6, pp. 313-46. 36.Nicolini, D., Tomkins, C., Holti, R., Oldman, A. and Smalley, M. (2000), “Can target costing and whole life costing be applied in the construction industry?”, Evidence from two case studies, British Journal of Management, Vol. 11, pp. 303-24. 37.Nicolini, D,, Tomkins, C, Holti, R., Oldman, A. and Smalley, M, (2000), Can target costing and whole life costing be applied in the constmction industry? Evidence from two case studies, British Journal of Management, 11, 303-324. 38.Pitts, R., and David, L. (1999). Strategic Management Building and Sustaining Competitive Advantage. USA: West Publishing Company. 39.Pierce, B, (2002), Target cost management: Comprehensive benchmarking for a competitive market. Accountancy Ireland, 34(2), 30-33. 40.Shank, J, K, and Fisher, J. (1999) Case study: Target costing as a strategic tool. Sloan Management Review, 41(1), 73-82. 41.Stevenson, William. J. (2007). Production/Operations Management. (8th ed.). Von Hoffmann Press. 42.Swenson, D,, Ansari, S., Bell, J., and Kim, I. (2003). Best practices in target costing. Management Accounting Quarterly, 4(2), 12-17. 43.Tanaka, T. (1994). Target costing at Toyota. Journal of Cost Management, 4-11. 44.Zsidisin, G, A, Ellram, L, M,, and Ogden, J. A, (2003). The relationship between purchasing and supply management's perceived value and participation in strategic supplier cost management activities. Journal of Business Logistics, 24(2), 129-154. 45.Tani, T. (1995), “Interactive control in target cost management”, Management Accounting Research, Vol. 6, pp. 399-414. 46.Tani, T., Okano, H., Shimizu, N., Iwabuchi, Y., Fukuda, J., and Cooray, S., (1994). Target Costing Management in Japanese Companies: Current state of Art. Management Accounting Research. 5, 67- 81. 47.Wijeweardena, H. and De Zoysa, A. (1999), “A comparative analysis of management accounting practices in Australia and Japan: an empirical investigation”, The International Journal of Accounting, Vol. 34, pp. 49-70. 48.Sakurai, M., (1989). Target costing and How to Use It, Journal of Cost Management for the Manufacturing Industry. pp 39-50. 108