Rehabilitation of Temporary Composite Dams — Case Study

advertisement

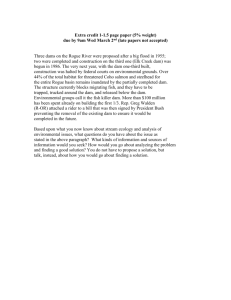

Changing Times — The Challenges and Risks of Managing Aging Infrastructure Under a New Financial Reality 33rd Annual USSD Conference Phoenix, Arizona, February 11-15, 2013 Co-Hosted by Bureau of Reclamation and Salt River Project On the Cover The original Theodore Roosevelt Dam was completed in 1911, the first major structure built by the Bureau of Reclamation on the Salt River Project. The dam, located about 75 miles northeast of Phoenix, had an original height of 280 feet, and was highest masonry dam in the world. In 1996, a project to expand and renovate the dam was completed. This project raised the dam by 77 feet for a total height of 357 feet and resulting in a 20 percent increase in reservoir capacity. The expansion of the dam was accomplished using a concrete overlay. The cost of the expansion totaled $430 million and included the realignment of a highway over a new bridge, improvements to the power plant and a tunneled lake tap. U.S. Society on Dams Vision To be the nation's leading organization of professionals dedicated to advancing the role of dams for the benefit of society. Mission — USSD is dedicated to: • Advancing the knowledge of dam engineering, construction, planning, operation, performance, rehabilitation, decommissioning, maintenance, security and safety; • Fostering dam technology for socially, environmentally and financially sustainable water resources systems; • Providing public awareness of the role of dams in the management of the nation's water resources; • Enhancing practices to meet current and future challenges on dams; and • Representing the United States as an active member of the International Commission on Large Dams (ICOLD). The information contained in this publication regarding commercial projects or firms may not be used for advertising or promotional purposes and may not be construed as an endorsement of any product or from by the United States Society on Dams. USSD accepts no responsibility for the statements made or the opinions expressed in this publication. Copyright © 2013 U.S. Society on Dams Printed in the United States of America Library of Congress Control Number: 2013930528 ISBN 978-1-884575-58-7 U.S. Society on Dams 1616 Seventeenth Street, #483 Denver, CO 80202 Telephone: 303-628-5430 Fax: 303-628-5431 E-mail: stephens@ussdams.org Internet: www.ussdams.org REHABILITATION OF TEMPORARY COMPOSITE DAMS — CASE STUDY: MARED SOIL-SHEET PILE DAM Saber Alidadi1 Masoud Hakami2 ABSTRACT Flow rate of Karun river, which is the longest and largest river in Iran, decreased from 600 m3/s to 100 m3/s in average, due to the drought in early 2008. This reduction caused water from Persian Gulf to advance farup-river and reach araw water supply basin and increase water electrical conductivity (EC) to 5,000 μmoh/cm. A temporary dam constructed from soil-sheet pile was installed to prevent salty water progress to the water supply location. Heavy rain fall and flooding with a flow rate of 1000 m3/s destroyed one-third of the dam in November 2008 and therefore, the lives of nearly 300,000 people were in danger due to water shortcoming. In this paper a new and innovative method for repairing the aforementioned dam is presented considering constraints such as type of dam destruction, limited time and cost, and other operating limitations. In this method, the damaged section of the dam was restored by composite geo-box piles. The piles were installed in two rows against the water to create a corridor and then the corridor was filled with soil geo-boxes. Based on the seepage and overturning analysis, and considering implementation conditions, the geometry of proposed method was selected. After successful implementation of the plan, the dam was restored and consequently the EC of the water was reduced to 1,800 μmoh/cm and raw water quality improved significantly in less than 2 months with minimum cost. It was finally realized that the soil erosion inside the cells was reduced; the bed was stabilized and its integrity over the dynamic loads was sustained. Therefore, it can be said that there is a significant uniformity between the fixed part and the existing structure of the dam. It can be concluded that this method of rehabilitation is an innovative and fast method to fix the damaged dams with minimum cost. INTRODUCTION Drought and advance of seawater has caused the confluence of saline water with Karoon River in the Mared region, near the town of Abadan and has even disturbed the ordinary life of Local residents. According to studies conducted by Mahab Qods and Seoko Consulting Engineering Companies, construction of a permanent dam at the current site of Mared could solve the problem of salty water interference. Since the plan was never executed, the decision was made to construct a temporary dam with the priority of meeting local drinking and agricultural water demands and controlling floods. Considering the geotechnical characteristics of the region and various parameters by Mahab Qods Consultant Engineers, a soil-sheet pile dam was constructed based on cost 1 MSc. Geotechnical Engineering, Khuzestan Water & Power Authority, Department of Dam and Powerplant Development, Ahwaz, Iran. Phone:00989166141235, email:alidadis@yahoo.com 2 Khuzestan Water & Power Authority, Department of Dam and Powerplant Development, Ahwaz, Iran. Phone:00989166177933, email:hakami@kwpa.ir Rehabilitation of Temporary Composite Dams 1125 analysis, executive conditions and design parameters. The Mared earth-fill sheet pile dam was constructed by a combination of AU sheet piles and circular cells made of sheet piles as supports and an embankment around the sheet piles (Fig. 1). Many different cell dams have been constructed around the world. A number of such dams have been also established in Abadan, in southwestern Iran. In an earth-fill sheet pile dam, sheet piles are integrated to each other to create a large cell. However, due to it being a temporary structure, circular cells made of sheet piles are used as supports along with an inner core made of a row of sheets to connect the cells. A year after Mared Soil Sheet Pile Dam was constructed, a flood of 1,000 m3/s flow (a 200 years of return period) occurred in the Mared region in late September 2008. Since a flood of such volume would not be considered in the dam design parameters, 90m long segments of the sheet pile dam were destroyed (Fig. 3) where they interlock and were buried in the river bed. By breaking of the dam, saline seawater advanced into river, leading to insufficient water supplies available to local residents of the region. Water EC also reached 5,000 μmoh/cm. After this structure was completely destroyed, the sheet piles in the river bed were turned up due to extreme horizontal force of the water. Only a few sheet piles near main dam cells (no.1 and 2) remained undamaged due to their direct attachment to cells structure. Figure 1. Plan and Section of Mared Soil-Sheetpile Dam 1126 Karun River, the longest and largest river in Iran, has flows of 500 m3/s with a 300m×10 m rectangular section in the Mared region. A pumping station with 100 m3/s flow has been constructed upstream to supply drinking water (Fig. 2). Figure 2. Plan Location of Project The advance of sea tides with saline water continues to 20 km, then it enters the pumping station reservoir. The temporary dam prevents water from advancing into the section. About 90 m of the distance between cells 1 and 2 of sheet pile core was destroyed up to 95%, so that after water overtopped the dam, upstream and downstream embankments were washed away and the sheet pile core could operated as a free spillway for as long as 7 hours (Figures 3 & 4). The water height on the sheet piles reached to 1/6 m leading to sheet pile damage. The destruction continued rapidly in the section. By studying the conditions of river at this point one would notice that a permanent concrete spillway needs to be constructed in this area to maintain river water level to its maximum capacity, and after water rise, water would overflow permanently from the dam crest. Also, it would prevent tidal water from proceeding to the section to stop saline water advance into river. However, the construction of such dam with the intended specifications would require significant funding and sufficient time for water diversion and supplying raw water to meet local demands during construction phase. This led to the decision to restore the temporary dam. Rehabilitation of Temporary Composite Dams 1127 Figure 3. Mared Composite Dam after Failure Figure 4. The Failed Section 10 days after Flood MATERIALS AND METHODS Some of the main reasons of failure in Mared dam are as follows: neglecting a flood of the volume above in designing of the dam section, insufficient depth of sheet piles in soil and high leakage from bottom of the sheet piles that ended in instability and sheet pile failure during a flood event. The only resisting force to keep the core sheet constantly against water force was the sheet piles interlocking and their bending resistance at the sections, which was not sufficient because of soil erosion at the bottom of sheet piles and their loose connection to bed soil. After a careful visit to the destroyed sheet piles by professional divers, it was found that due to high integrity between existing sheets in the dam body, all the sheet piles had withstood the conditions in the past; however, they were twisted in each other’s locks and because of high flow forces of the river and weakness of the bed soil, they were buried in the riverbed. Although because of sheet piles pounding with more lengths, lower depth of the river in the section, and different geotechnical characteristics of riverbed, the seepage flow was still negligible and did not damage these sections. Considering the destructed river section, two plans were proposed. According to the first plan, the dam would be reconstructed by restoring sheet piles buried in the riverbed. Second, a new system would be designed which could operate continuously with the existing structure having a high safety factor against the loads. After studying 1128 circumstances and doing necessary computations, it became clear that a direct force of 120 tons would be required to raise and restore 30 m of the total length of existing sheet piles. However, since water diversion was not feasible in the region due to extensive farmlands along river banks, the reconstruction works would be performed along the continuous flow of the river. The position of farmlands along river and using barges to mobilize work on water flow did not allow force to be applied directly or by pulley to the destroyed sheet piles. Using vehicles like a bulldozer and by the help of a crane, piles were pulled by pulley to the left bank (adjacent to 1 cell). Due to the water force, soil and sheet pile weights, locks and sheet piles complexity in their section, the sheet piles could not fit into their actual sections more than a few inches. Since according to geotechnical data, characteristics of erosion in bed section were favorable as such that during high flows an erosion of 10m was expected in bed, measures needed to be taken to not only narrow the section to block it, but also bed erosion would be taken into account. Strong tidal water occurred at the project site as the tidal difference was almost 1.2 m. Considering the project duration of 2 months, the second plan was chosen as: 1. The system could withstand flood water force without using embankment, so that if overtopping should occur because of the reasons above and the embankment be destroyed, the dam core could resist. 2. In addition to having an effective safety factor against drive forces, the system should be able to resist excessive seepage from the dam body riverbed erosion in this section. Actually, this system should help to reinforce the riverbed in the intended section. 3. The proposed system should maintain stability between two cells to act together against driving forces. The sheet piles adjacent to the second cell remained in their desired shape because of being close to the support. Of course, due to insufficient depth and weak sections against strong tidal forces, the sheet piles began to move with respect to their initial location, although they were connected to the buried sheet piles in riverbed soil. Also, the soil inside the 2nd cell was being removed due to the reciprocating movements of sheet piles and high seepage flow from the connections of sheet piles to cells. According to the calculations and also considering the prevailing situation at site, the restoration of dam would be achieved by applying different practices including expanding geo-tube on the river bed, remaking sheet piles with a stronger section and even constructing an additional cell. Nonetheless, since metal sheet piles with suitable depth are not available in Iran and also to integrate dam sections, a decision was made to design a new, combined method for the dam restoration. Considering the prevailing conditions, cost, time restriction and practical difficulties it was found that the use of a geo-box pile composite structure was the best method. A computer model was developed by Plaxis code, and considering water dynamic and static forces, seepage analysis results, structure settlement and diversion control in structure design, the piles arrangements, section and length were obtained. However, the application of the method was executed stepwise considering complexities of damages and changing river flow regime. Rehabilitation of Temporary Composite Dams 1129 Methods Application Because of soil erosion inside the 2nd cell, the restoration of driving sheet piles ending to the 2nd cell, moving in flabellate form in the tidal direction was the first priority. This was performed by pounding 24 m fender piles first, in rising tide and then in ebb tide, on both sides of the sheet pile such that the sheet piles movement was reduced to a few centimeters. After the restoration of 20 sheet piles in 14 m length was completed, the river section became narrower and the flow rate increased through the still-breached section. Also, due to the decrease of seepage flow from connection points of sheet piles to the cell, and water stillness in that section, soil fracture was reduced inside the 2nd cell. Because of suitable depth, free pounding in severe tidal conditions and resistance against lateral and vertical loads, the use of piles in the section with 24 m of length (Fig. 4) seemed to be suitable . Figure 4. Plan of Combination Pile-Geobox The 50 cm distance between piles would be used for easy pounding and using geo-boxes as fillers. It is of note that the load resistance mechanism by pounded piles is such that due to geotechnical characteristics of the region and an average 14m infiltration depth, the piles resisted frictionally against vertical loads including their own weight and the upper embankment. Also they resisted by bending resistance against lateral loads. The piles also stabilized the river bed. The 2 m distance between two piles, was used for a safety factor against diversion. Additionally, the volume of filling materials should be cost effective. The geo-boxes of 2 m x2 m x 0.5 m size were filled, loaded and settled with the region soil. Steel pile pounding was faced with difficulties caused by tidal conditions, The piles could not be placed vertically by using a dynamic impact hammer, so a structure was used to perform balanced, orderly pounding of piles. Pounding two opposite rows of piles began with the first cell making a 30 m length corridor. Then the geo-boxes were filled and settled, and then earth filling was performed simply in a 20 m distance. At this stage, in order to block the second cell, the section length was reduced from 90 m to 45 m and the flow rate became 2 m/s. Also, the flow rate was too much to allow settling geo-boxes, since it carried them out of the corridor. It 1130 was decided to close the corridor by pounding some piles against the flow direction. In fact, the remaining 45 m was divided into 3 corridors, each of 15 m to stop flow by settling and earth-filling geo-boxes. It is notable that settling geo-boxes was performed by crane installed on the barge. The destroyed portions were blocked in less than 30 days. Since the seepage from dam body and bottom was negligible, provided that no piping phenomenon would occur, the possibility of water passage through dam section was provided due to the use of proper structure, and no soil erosion because of pile pounding occurred. Now that the problem of salty drinking water of the residents is solved, it is possible to either construct canals on the left and right banks to prevent flow overtopping during flood events or install a spillway on the crest so it can take out the water during ebb time and in high tide and the water is prevented from reaching the top. In fact, the pounded piles in the dam core could act as a foundation pile for this metal spillway. CONCLUSION 1. When conditions do not allow water diversion and timing is seriously restricted, pile pounding and filling them by soil fillers can be used to establish temporary earth dams. 2. The application of this method with due regard to the materials used leads to integrity between the new and old structures, and the restored dam section works effectively against driving forces. 3. In the case of constructing a permanent dam and removing the temporary structure, the main dam structure, including piles and geoboxes can be taken out completely from the river to prevent any probable environmental damages. 4. Water quality was significantly improved and water EC decreased from 3,500 to 500moh/cm; also, the problem of saline water entering the drinking water at the pumping station reservoir was resolved. 5. By the use of piles, the structure can resist against vertical loads, and one can construct a metal spillway on a section of the dam body. ACKNOWLEDGEMENTS Mr. Kamran Ajdari, Mechanics Engineer, Khuzestan Water & Power Authority Mr. Ali Abuhamidi, Mechanics Engineer ,Khuzestan Water & Power Authority Mr. Amin Jasayeri, Civil Engineer ,Khuzestan Water & Power Authority Rehabilitation of Temporary Composite Dams 1131 REFERENCES 1. Ashraf A Ahmed Design of hydraulic structures considering different sheetpile configurations and flow through canal banks Original Research Article,Computers and Geotechnics, Volume 38, Issue 4, June 2011, Pages 559-565 2. Emilios M. Comodromos, Mello C. Papadopoulou, Ioannis K. Rentzeperis, Pile foundation analysis and design using experimental data and 3-D numerical analysis Original Research Article, Computers and Geotechnics, Volume 36, Issue 5, June 2009, Pages 819-836 3. Professor Kamran M. Nemati, University of Washington Department of Construction Management Cm 420 Temporary Structures, Winter Quarter 2007 4. U.S. Army Corps of Engineers, Design of Sheet Pile Walls ,EM 1110-2-2504, 31 March 1994 5. U.S. Army Corps of Engineers, Design of Sheet Pile Cellular Structures Coffedams And Retaining Structures, 29 September 1989 6. USBR, (1987), Design of Small Dams, U. S. Bureau of Reclamation, Department of Interior, Col., USA 7. Sherard, J. L. et al., (1963), Earth and Rockfill Dams, John Wiley and Sons Inc., New York 8. Sarma S. K., Seismic Stability of Earth Dams and Embankment, Geotechnique, Vol. 25, NO 4, 1975, 743-761. 9. Stability of Earth-Rockfill Dams: Influence of Geometry on the Three-Dimensional Effect .Computers and Geotechnics, Volume 32, Issue 5. 10. Fundamentals of Geotechnical Engineering by Braja M. Das (Nov 29, 2007) 1132