Ford Motor Company's Investment Efficiency Initiative

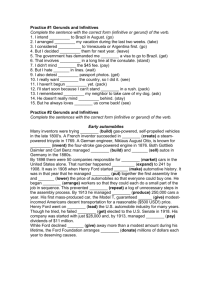

advertisement