Saponification Kinetics

advertisement

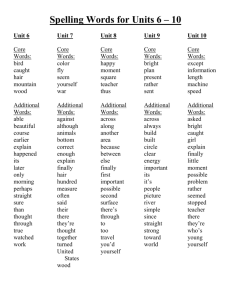

CHEMICAL ENGINEERING LABORATORY CHEG 4137W/4139W Reaction Kinetics Saponification of Isopropyl Acetate with Sodium Hydroxide Objective: The purpose of this experiment is to examine and determine the reaction kinetics of a simple homogenous liquid-phase system and to model this reaction in a continuously stirred-tank reactor (CSTR). Simple batch (flask) reactions will be run initially to determine initial rate data from concentration versus time profiles before using the continuous reactor. Major Topics Covered: Chemical reaction kinetics, reaction order, Arrhenius-style rate law. Theory: The reaction: Isopropyl Acetate + Sodium Hydroxide → Sodium Acetate + Isopropyl Alcohol is an example of a saponification reaction (the reverse reaction would be esterification). This reaction may be either reversible or irreversible. For the irreversible case, the rate equation for a batch reactor may be written: rA = -d[A]/dt = k[A][B] where k is the rate constant and [A] and [B] are the concentrations of the reactants in the appropriate units. If strictly equimolar concentrations of reactants are used, the rate equation can be simplified to a general nth-order reaction. rA = kn [A]n where n ≅ 2. With good experimental data, this model allows the determination of the reaction order for an irreversible reaction. The effect of temperature on the rate constant can be compared with that predicted by the Arrhenius expression: k = Ae(-E/RT), where A is the frequency factor, E is the activation energy of the reaction, R is the gas constant, and T is the absolute temperature. Rate data at various temperatures can be used to determine the frequency factor and activation energy of the reaction. Once basic rate data is obtained, it can be used to size or design reactors, or determine the maximum conversion for a reactor of a given size. Design equations for different types of reactors are provided in the references. Safety Precautions: 1. This lab uses both acids and bases. Use caution when handling these reagents, as well as when sampling from flasks or the reactor. Appropriate personal protective equipment should be used at all times. 2. Always make sure that the pump reservoirs are filled prior to turning on the pumps. 3. The ester solution should be mixed in a well-ventilated area. Available Variables: Batch Experiment: Temperature. CSTR Experiment: Temperature, reactor residence time. Procedure: See Kinetics Operational Checklist Analysis: Your analysis must include: 1. A graphical determination of the reaction order as determined by the batch reaction experiment. 2. Determination of the activation energy and frequency factor for the reaction, and a comparison with appropriate literature values. 3. A predictive model for CSTR results based on the batch results and intended CSTR operating conditions. 4. A comparison of CSTR experimental results with the predictive model, and a discussion surrounding the agreement/disagreement between theory and experiment. Report: Describe the design of your experiments and the results obtained, including an error analysis. Provide thoughtful and quantitative discussion of results, explain trends using physical principles and relate your experimental observations to predicted results (e.g. discrepancies between predicted CSTR results and experimental data). Express any discrepancies between observed and predicted results in terms of quantified experimental uncertainties or limitations of the correlations or computational software used. Pro Tips: 1. Because of variations in density of the solutions, generate your calibration curves using the actual reagents, not pure water. The setup allows you to continuously recycle the reagents during the calibration phase. 2. For ease of taking data, it is recommended to start at lower temperatures and work incrementally upward. 3. Flush both pumps with pure water at the end of the experiment; this will prolong the life of the pump internals. 4. Carefully monitor the level in the reactor, and adjust the inlet or outlet flow rates to keep the level steady. Only take data when the system is at steady state. References: 1. Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice-Hall, Inc., Englewood Cliffs, NJ, 2nd Ed., 1992. 2. C. H. Bamford and C. F. H. Tipper, eds., Comprehensive Chemical Kinetics, vol. 10, 3. "Ester Formation and Hydrolysis," Elsevier, New York, NY, 1972. International Critical Tables, 7,129 (1930). APPENDIX A On Curved Kinetic Data and the Straight Scoop on Straight Lines Why straight lines? Many experimental results are analyzed in a fashion that produces a straight-line plot. For example, the Arrhenius theory appears as k = Ae − E / RT (1) ln k = ln A − E / RT (2) and yet is plotted as to get, obviously, a straight line. Why is this? Can one simply analyze Eq. 1? The historical reason for the straight lines is simple: it was virtually impossible for the experimentalist to do anything else until about the 1960’s when digital computers became available. Even a straight-line least squares (LS) analysis was tedious. Thus engineers and scientists sought straight lines as the final result in their analyses, and these analyses became a part of the literature. You still find them in textbooks and probably always will. “Everyone” understands that an Arrhenius plot is ln k vs. 1/T, and not k vs. T. However, you can analyze Eq. 1 directly and forget about taking logs. The key is nonlinear least squares (NLLS), available on most spread sheets, numerical packages and plotting programs (e.g., Polymath, Excel). What’s good about straight lines? Aside from tradition, straight lines allow the eye to see slight deviations from the expected behavior, because the eye is very sensitive to straight vs. curved. What’s bad about straight lines? In the case of the Arrhenius plot, probably nothing. However, it is important to realize that one is making several assumptions in any least-squares analysis; some are: 1. Every data point is independent; that is, there is no more connection between any two points than any other two points. 2. There is no error in the independent variable (x axis). 3. The errors in the data are normally distributed and have equal variances. It’s the latter that can cause trouble with transforms (e.g., ln k) vs. the real data (k), but the transform can also improve the agreement with item 3. In the case of the Arrhenius plot, it often helps, because the errors in rate data tend to be relative rather than absolute. If you have enough data, you can tell from the plot; the "scatter" should be about the same everywhere. The big problem with the urge to get straight lines as the bottom line of an analysis is one of hidden parameters, so BEWARE OF HIDDEN PARAMETERS! Watch the following: x= C A0 − C A C A0 (3) Eq. 3 looks like a perfectly correct conversion of concentration CA to conversion x using the initial concentration CA0. After all, we know that the latter is, say, 0.05 mole/L. Or do we? In fact, in the same sense as we have error in each CA , we do not really know what CA0 is; it’s a hidden parameter and is not a constant like π. If the CA0 assumed is off only slightly, high errors in x will result, especially at low x. So what is one to do? The solution is simple and accessible to all. Cast the theory you are testing in terms of actual observations and unknown parameters. For example, second-order kinetics for the disappearance of species A is classically analyzed using the equation: 1 1 − = kt C A C A0 (4) assuming stoichiometric, irreversible reaction with rate constant k. No problem here--it comes straight from integration of the mass-action theory. But wait! Are there any hidden parameters in our observations of the concentration of A, i.e., CA? Good question. With direct titration of product resulting from CA , don’t we get CA free from worry? Unfortunately, there are hidden parameters, and a careful look at the mass balance with no assumptions about the concentration of anything gives the nonlinear equation Vt = V∞ − 1 Nkt 1 + V∞ − V0 Vs (5) where Vt (the observation) is the titer in mL at time t, V∞ is the titer at t = ∞ ( a parameter), V0 is the titer needed at t = 0 (another parameter, and not an observation or a constant), N is the normality of the titration solution, and Vs is the volume of the sample. Of course, k is the rate constant that we want to find. Unfortunately, the rate constant is tied up with N and Vs.; there is little we can do about separating them and they therefore must be accurately known. If N and Vs are in error, the errors will appear in k and we will never know it. But note that all the worry about the zero-time titer is gone. That’s the trick: expose the hidden parameters, and let the data tell you what their values are. The penalty is more parameters and no nice straight lines (usually). An example is shown in Figure 1. This is real data from a previous year. The points labeled “conventional analysis” are plotted according to a measured zero-time titer of 0.5 mL and assumed to be free of error. The points labeled NLLS are simply the observations straight from the burette at times other than zero. The line is Eq. 5. Note that the changes are accurately described, whereas the conventional analysis is not straight, mainly because of the too-high zero-time titer. The rate constant from the NLLS is about the same as the steep slope drawn on the conventional analysis. However, unlike the practice of using just the first few data from the conventional analysis to get the slope, the NLLS uses all the points and therefore has far greater precision. The truly dedicated will note that there are other possibilities, including reversible reaction and lack of stoichiometry, to explain curved data on the conventional plot. It may be possible with very accurate and plentiful data to distinguish these, but probably not with any great confidence. The underlying message is that all experimental observations will have error. If you treat an observation as a constant, then you are asking for systematic error in the end result. 1/(CA, mol/L) and 10.( Vt , mL) 90 ? 80 ? 70 Conventional analysis 60 50 40 NLLS on Vt (t) 30 20 10 0 0 500 1000 1500 2000 2500 3000 Time, s Figure 1. Saponification of isopropyl acetate using 0.05 M NaOH. There are exceptions to the rule that all named variable are either variables or parameters. An example is the Arrhenius expression given in the Kinetics handout: ln k = ln k0 – E(1/T − 1/T0)/R (6) In this version, T0 is an arbitrary temperature and k0 is the rate constant at T0. As the original Arrhenius equation (Equation 1) contains only two parameters, A and E, one of the extra symbols introduced in Equation 6 is arbitrary and can be set at any value. It can thus be regarded as a constant.