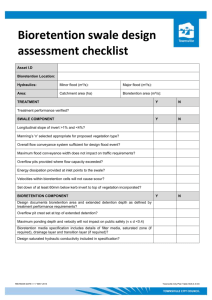

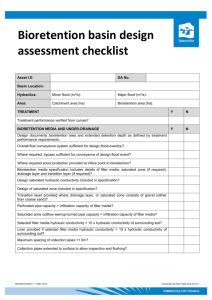

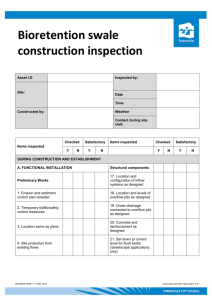

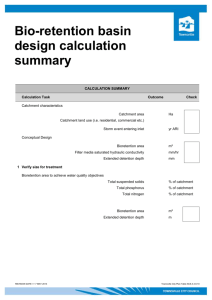

WSUD Design manual – Bioretention Basins

advertisement