MSC.ADAMS interface

advertisement

MSC.ADAMS interface®

Version 4.2 – summer 2004

Copyright © IMAGINE S.A. 1995-2004

AMESim® is the registered trademark of IMAGINE S.A.

AMESet® is the registered trademark of IMAGINE S.A.

ADAMS, EASY5, MSC, MSC., MSC.ADAMS, MSC.EASY5, and all product names in

the MSC.ADAMS Product Line are trademarks or registered trademarks of

MSC.Software Corporation and/or its subsidiaries.

MATLAB and SIMULINK are registered trademarks of the Math Works, Inc.

Netscape and Netscape Navigator are registered trademarks of Netscape

Communications Corporation in the United States and other countries. Netscape’s logos

and Netscape product and service names are also trademarks of Netscape

Communications Corporation, which may be registered in other countries.

PostScript is a trademark of Adobe Systems Inc.

UNIX is a registered trademark in the United States and other countries exclusively

licensed by X / Open Company Ltd.

Windows, Windows NT, Windows 2000 and Windows XP are registered trademarks of

the Microsoft Corporation.

X windows is a trademark of the Massachusetts Institute of Technology.

All other product names are trademarks or registered trademarks of their respective

companies.

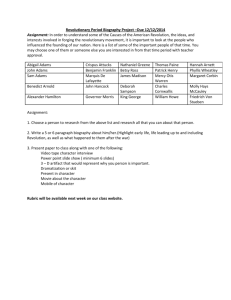

TABLE OF CONTENTS

Using AMESim MSC.ADAMS Interface................................................................2

1

Introduction..................................................................................................................2

2

Preliminaries ................................................................................................................4

3

4

2.1.

License requirements ........................................................................................4

2.2.

Compiler requirements .....................................................................................4

2.3.

Versions of MSC.ADAMS supported ..............................................................4

2.4.

Platforms supported ..........................................................................................5

2.5.

Setting up the environment ...............................................................................5

Importing MSC.ADAMS into AMESim .....................................................................7

3.1.

Antenna example ..............................................................................................9

3.2.

Preparing a MSC.ADAMS model for export to AMESim .............................10

3.3.

Importing the model in AMESim ...................................................................13

3.4.

Analyzing results in both software .................................................................18

Importing AMESim into MSC.ADAMS ...................................................................19

4.1.

Preparing an AMESim model for export to MSC.ADAMS ...........................19

4.2.

Importing the model in MSC.ADAMS...........................................................20

5

Co-simulation or Full Export? ...................................................................................24

6

Advanced use of the interface....................................................................................27

7

6.1.

How to setup interface with template-based MSC.ADAMS products............27

6.2.

Using more than one interface ........................................................................28

Advanced configuration of the interface....................................................................28

7.1.

2004

Configuration file............................................................................................28

Table of Contents

1//39

Using AMESim MSC.ADAMS Interface

1

Introduction

The AMESim MSC.ADAMS interface enables you to link an AMESim model with an

MSC.ADAMS multibody model of a mechanical structure. By coupling motion

simulation and system simulation, this interface improves the accuracy of your full system

simulation.

This interface is useful when hydraulic or pneumatic fluid power systems or other

AMESim systems interact with complex mechanical structures.

The interface is designed so that you can continue to use many of the AMESim facilities

while the model is running in MSC.ADAMS. In particular, you can change the parameters

of the AMESim model within AMESim in the normal way and monitor the results by

creating plots just as if you were producing a regular run.

Normally you will have AMESim and MSC.ADAMS running simultaneously so that you

can use the full facilities of both packages. Process illustration follows:

Construct the AMESim model with

import/export icon from/to MSC.ADAMS

Modify AMESim submodel parameters

Complete the MSC.ADAMS model and link

with AMESim part

Run the simulation

Examine AMESim submodel

results in AMESim

Examine MSC.ADAMS

system results in

MSC.ADAMS

When the process is finished, the user can change the AMESim model parameters within

AMESim, as well as the MSC.ADAMS parameters within MSC.ADAMS.

2004

Using AMESim MSC ADAMS Interface

2//39

Organization of this manual

This manual describes both the two-way full export interface (using MSC.ADAMS or

AMESim integrator exclusively for the full system) and the two-way co-simulation

interface (where both solvers are used, one of them being called by the other).

The main part of the manual deals with the standard interface and section 5 looks at the

differences between export and co-simulation.

The structure of this manual is the following:

• Section 1: Introduction, is the current section.

• Section 2: Preliminaries, describes how you must set your working environment so

that you can use the interface.

• Section 3: Importing MSC.ADAMS into AMESim, describes with a simple

example how to create an AMESim model and configure it to run in cooperation

with MSC.ADAMS.

• Section 4: Importing AMESim into MSC.ADAMS, describes how MSC.ADAMS

imports the AMESim model.

• Section 5: Co-simulation or Full Export? This describes the differences between

co-simulation interface and the export facility.

• Section 6: Tips on using the interface, gives some advice on efficient use of the

interface.

• Section 7: Advanced use of the interface and Section 8: Advanced configuration of

the interface, are useful for customized use of the interface (advanced users).

Sometimes a section of text is only valid for a UNIX or Linux environment, for such text,

the following presentation is used:

Using UNIX:

Description for Unix/Linux based environments.

Similarly, sometimes a section of text is only valid for a Windows environment, for such

text, the following presentation is used:

Using Windows:

Description for Windows based environments.

We assume that either the reader of this manual is already familiar with using AMESim

and MSC.ADAMS or an AMESim user and an MSC.ADAMS user will collaborate in

performing the task.

For new AMESim users we recommend that they at least do the tutorial examples in the

AMESim manual before attempting a combined simulation. Similarly, a new

MSC.ADAMS user should become familiar with using MSC.ADAMS before attempting a

combined simulation.

2004

Using AMESim MSC ADAMS Interface

3//39

2

Preliminaries

2.1.

License requirements

When the user is running coupled simulation from AMESim environment, an Adams

interface license is required in AMESim in combination with a classical AMESim

runtime license. In the MSC.ADAMS side the module Adams/Controls (A/Controls) is

needed.

When running simulation from MSC.ADAMS the user only needs Adams interface and

AMESim runtime licenses, A/Controls is unused.

2.2.

Compiler requirements

Using Unix:

You will need an ANSI C compiler.

Using Windows:

You must have Microsoft Visual C++.

If using the interface from MSC.ADAMS environment, a FORTRAN compiler is also

highly recommended1 in order to compile the AMESim system as an MSC.ADAMS

subroutine.

MSC.ADAMS 2003 software specifications are:

Intel and Intel-compatible PCs with Windows OS

Compaq Visual Fortran 6.6B

Intel and Intel-compatible PCs with Linux OS

Intel Fortran 7, GNU g77

Hewlett-Packard

f90 2.4.13

SGI

7.3.1.2m

IBM

XL Fortran 7.1

Sun Microsystems

6 update 1

2.3.

Versions of MSC.ADAMS supported

This manual applies to MSC.ADAMS 2003. The interface was developed using this

version and when using a mode that requires A/Controls (i.e. importing into AMESim)

we suggest that you use that version with following patches:

A/View 2003 Service Pack 1 APN-130-240

A/Solver 2003 Service Pack APN-130-252

A/Controls 2003 Service Pack APN-130-256

1

In section 7 you will see how to compile the AMESim system without a Fortran compiler.

2004

Using AMESim MSC ADAMS Interface

4//39

2.4.

Platforms supported

Windows, Sun, SGI and IBM.

2.5.

Setting up the environment

In order to use the AMESim MSC.ADAMS interface it is necessary to set an

environment variable that points to the MSC.ADAMS installation directory. If this is not

set, AMESim will not be able to find the files necessary to compile the system.

To find out if this environment variable is set, type the following line in a terminal

window:

Using Unix:

echo $AME_ADAMS_HOME

This should result in something like:

/opt/Adams2003

being printed on screen. If nothing is printed, or the message “AME_ADAMS_HOME:

Undefined variable” is displayed, you must set this variable. To do this you need to know

where MSC.ADAMS is installed. If your working environment is set up properly to run

MSC.ADAMS, type either:

which adams03 (if you are using C shell) or,

whence adams03 (for Korn shell - ksh or Bourne shell - sh) or,

type adams03 (for some versions of Bourne shells).

This will tell you the location of the command to start MSC.ADAMS e.g.

/opt/bin/adams03

Then type:

ls –l /opt/bin/adams03

This finds the link to MSC.ADAMS directory, it may give something like:

/opt/bin/adams03 à /opt/Adams2003/mdi*

Remove the last part from this pathname to get the value to set for

AME_ADAMS_HOME, in this case /opt/Adams2003. If you are using Unix C shell,

you can then set the environment variable as follows:

setenv AME_ADAMS_HOME /opt/Adams2003

This statement can also be added to your .cshrc file so that the environment variable is set

every time you login.

For Bourne or Korn shells the corresponding would be:

AME_ADAMS_HOME=/opt/Adams2003; export AME_ADAMS_HOME

Add these statements to your .profile file so that the environment variable is set every time

you login or add it to a script that launches AMESim.

2004

Using AMESim MSC ADAMS Interface

5//39

Using Windows:

echo %AME_ADAMS_HOME%

This should result in something like:

C:\ADAMS2003

being printed on screen. If the environment variable is not set, %AME_ADAMS_HOME% is

printed and you need to set the environment variable to point to the MSC.ADAMS

installation directory. This can be done from the Windows Control Panel.

If you want to use this interface from MSC.ADAMS side, you will need a Fortran

compiler as stated in section 2.2.

Using Windows:

In this case the file dfvars.bat must be copied in $AME. This file sets up the

environment to use Fortran libraries.

For Compaq Visual Fortran this file can be found here:

C:\Program Files\Microsoft Visual Studio\DF98\BIN

Copy this file in the AMESim installation directory.

Using Unix:

You need access to a Fortran compiler. To be certain that the compiler is installed, type

one of the following command in a terminal window.

For IBM type: xlf, for SGI type f77 and for Sun type f77.

If the command issues an error message, please contact your system administrator.

Finally in AMESim the $AME/libadams directory must be in the current path list.

2004

Using AMESim MSC ADAMS Interface

6//39

3

Importing MSC.ADAMS into AMESim

The recommended way of working is to first create independent sub-system models in

AMESim and MSC.ADAMS that have a very simple model of the other domain subsystem.

Thus if the end result of a simulation study is to investigate how an hydraulic actuator

system will work in a mechanical system it is often best to first model the hydraulic

system separately with a simplified model of the mechanical system using the mechanical

submodels available in AMESim. This would probably be a prescribed velocity and

displacement.

In parallel a separate model of the mechanical system would be built in MSC.ADAMS

with a simplified hydraulic system. This would probably be a prescribed force instead of

an actuator. The two sub-system models should then be verified thoroughly. As much

independent tuning of the sub-systems as possible should be done at this stage. When the

two separate models work properly, they can be integrated.

A good general rule is that the ports where the hydraulic and multi-body sub-systems are

connected will correspond to hydraulic linear actuator rods or the shafts of hydraulic

pumps, motors or rotary actuators.

It is not too difficult to think of exceptions but the overwhelming majority of applications

will satisfy this rule.

You will look at one simple system that uses this way of interfacing. The tutorial case is

the MSC.ADAMS tutorial example of the antenna. It is strongly recommended that you

reproduce this system.

There are four potential problems when using the interface:

•

units,

•

sign conventions,

•

implicit variables (when using AMESim from MSC.ADAMS) and,

•

numerical problems.

With reasonable care these can be avoided.

The problem of different units in MSC.ADAMS and AMESim often leads to the need for

the interfacing variables to be adjusted with some unit conversion factor.

What we mean by a sign convention is the significance of the sign of forces,

displacements and velocities in both AMESim and MSC.ADAMS. It is almost always

necessary to reverse the sign of displacements and velocities when they are imported into

AMESim if hydraulic jacks or hydraulic pumps, motors or rotary actuators are used.

Since the sign convention depends on the interfacing components and variables it is

necessary to use caution regarding the sign. This is another good reason for creating two

separate sub-system models. The single software simulation results will give good insight

into the system behavior and make any sign errors in the combined simulation apparent.

As explained in the AMESim manual, AMESim can solve two kinds of systems of

differential equations: ordinary differential equations (ODEs) and differential algebraic

equations (DAEs). The latter uses implicit variables. The interface between AMESim

and the General State Equation in MSC.ADAMS supports only ODEs. It is therefore

impossible to use any submodel in AMESim that uses implicit variables when exporting

the model into MSC.ADAMS. It may also be necessary to modify the AMESim model to

eliminate any implicit variables that may be created to resolve algebraic loops.

2004

Using AMESim MSC ADAMS Interface

7//39

When working from MSC.ADAMS, numerical problems arise due to the fact that the

interface uses the MSC.ADAMS integrator, which is tuned to work well with the

equations governing multi-body systems. The numerical characteristics of a fluid power

system are different. Another source of numerical problems is that an AMESim model

when run with the AMESim integrators can employ some special tricks to deal with

discontinuities. This is not possible when using the MSC.ADAMS integrator. In fact, the

documentation of the MSC.ADAMS GSE facility, states that the imported system of

ODEs must be continuous. It is therefore recommended to avoid hard discontinuities

completely in the AMESim model. By a hard discontinuity we mean that there are jump

changes in the values of state variables. Fortunately very few AMESim submodels

employ hard discontinuities. Avoid the following hydraulic actuator icons that have an

integral mass as the corresponding submodels employ hard discontinuities.

It is not impossible to use these submodels but if you do, make sure that the jack never

hits its end-stops. However, submodels associated with alternative icons employ elastic

end-stops, which do not have hard discontinuities. Hence it is preferable to use these.

USE THESE ICONS

NOT THESE

Similarly if you use the mechanical icon

, use MAS21 not MAS005.

Looking at the input and output requirements of these preferred submodels and at the

requirements of hydraulic pumps and motors, a second general rule becomes apparent.

The MSC.ADAMS model normally calculates position and velocity, (or angle and angular

velocity) and passes them to the AMESim model, which calculates the corresponding

force (or torque).

Again it is possible to think of exceptions but this rule is very useful.

In the same way when working from AMESim, numerical problems can arise when

importing a large MSC.ADAMS system. AMESim integrator is not designed to solve

such problems, and simulation times may rise significantly.

In these cases the co-simulation interface can be a solution if no workaround is found to

make the full import facility efficient.

2004

Using AMESim MSC ADAMS Interface

8//39

3.1.

Antenna example

As an example, you will use the MSC.ADAMS tutorial of the antenna controlled within

AMESim.

The final sketch in AMESim will look like:

Figure 1: Antenna sketch in AMESim

The example comes from A/Controls tutorials; you should copy the A/View command file

antenna.cmd from {ADAMS_DIR}/controls/examples/antenna into a working directory.

Then, open the file within A/view environment. Select the Edit 4 Deactivate entry. In

the window Database Navigator select azimuth_motion_csd.

Figure 2: Deactivate a motion in A/View

2004

Using AMESim MSC ADAMS Interface

9//39

3.2.

Preparing a MSC.ADAMS model for export to AMESim

In this case, AMESim is the master software, you will launch simulation from AMESim

and this one controls MSC.ADAMS simulation. There are two ways for exporting

MSC.ADAMS to AMESim:

•

Discrete export, or co-simulation mode, AMESim tells MSC.ADAMS to

supply its outputs at fixed intervals, MSC.ADAMS solves its system,

•

Continuous mode, AMESim get the complete system from MSC.ADAMS

and tries to integrate all equations, MSC.ADAMS acts then as a function

evaluator.

These modes require that you have a valid license for A/Controls.

The MSC.ADAMS side of the procedure is unchanged which ever mode you want to use.

It is only in AMESim that you make your choice.

Step 1: Create/Check exchanged variables.

In this step, you will check the definition of some state variables2. You will use them as

exchanged variables between the both software, for example for a hydraulic actuator

modeled in AMESim and acting on an MSC.ADAMS mechanical structure, these

variables should be something like a force, a position and a velocity. Indeed AMESim

needs position and velocity and computes a force.

Outputs from MSC.ADAMS, often velocity and position, are defined with

MSC.ADAMS intrinsic functions; AZ( ) for an angle measurement, WZ( ) for a rotational

velocity, DM( ) for a displacement magnitude.

2

Be careful the meaning of states variables is not the same in AMESim and in MSC.ADAMS. For the latter

these are simple variables defined by an algebraic equation whereas in AMESim these are the variables

integrated by the solver.

2004

Using AMESim MSC ADAMS Interface

10//39

Figure 3: Creating outputs in ADAMS

Be careful with units (accessible from Settings/Units… menu in A/View). It should be

compatible with what AMESim expects, if you do not want to change it in

MSC.ADAMS, do not forget to place a gain (conversion factor) in AMESim sketch

before inputting the signals into AMESim submodels.

Inputs to MSC.ADAMS, mainly forces/torques, are used in standard elements like single

component force/torque or general force (6 components). At creation, these variables are

set to zero value because the other software (AMESim) will compute their values.

In our example, the unique input variable is referenced in a torque single component using

the function VARVAL.

The element azimuth_actuator can be accessed from the Tools4Database Navigator…

menu in A/View. The control_torque state variable is accessible from Build4System

Elements4State Variables4Modify… menu.

Figure 4: Creating input variable in ADAMS

Once you have created input and outputs variables, in the next section you will learn how

to define the interface in MSC.ADAMS.

Step 2: Create the Interface.

Using the variables you have just created in the step before, use the existing Plant Input

and Plant Output.

Plant Input: {control_torque}, where the torque is used in a single component torque as

VARVAL(control_torque)

and,

2004

Using AMESim MSC ADAMS Interface

11//39

Plant Output: {rotor_velocity, azimuth_position}, where these variables are computed with

MSC.ADAMS functions.

Look at the screenshot below, you can access these windows by using the Database

Navigator… from Tools menu and by selecting the existing plants

Figure 5: Creating Interface component in MSC.ADAMS

The MSC.ADAMS model is now ready for export; in the next section, you will see how to

generate the files necessary to AMESim.

Step 3: Export the system.

You will export the coupled system; if A/Controls plugin is loaded (refer to

MSC.ADAMS documentation to do so), you have access to the Controls menu. There you

can do a Plant Export:

Figure 6: Exporting the coupled system from ADAMS

In this dialog box, you have to fill in:

2004

•

the name (File prefix) that MSC.ADAMS will use to store results files,

•

plant input and plant output created in step two,

•

Control package, choose EASY5_and_MATRIXx,

•

the Type of export, choose between linear and non_linear,

•

if you want MSC.ADAMS to compute an initial static analysis before

running the coupled system choose yes, otherwise choose no,

•

if needed a user defined library name.

Using AMESim MSC ADAMS Interface

12//39

This manipulation creates three files in your working directory, adams2amesim.inf ...adm

and …cmd. You will only focus on the adams2amesim.inf file, but here is a brief

description of the three files:

•

The inf file contains generic information for coupling with other software: the

path of MSC.ADAMS, names of files that MSC.ADAMS will write to, some

information needed by the solver, identities of exchanged variables, and

number of states3.

•

The adm file contains the MSC.ADAMS system readable by the

ADAMS/Solver, that one will be inputted to the solver when running the

simulation.

•

The cmd file also contains all the relevant system information but suitable for

ADAMS/View.

The MSC.ADAMS part of the process is now finished, in the next part you will focus on

AMESim.

3.3.

Importing the model in AMESim

In AMESim construct the simple sketch that will control the antenna model. Necessary

information is given on the sketch.

Save this system in the directory where you have exported MSC.ADAMS files (inf adm

and cmd).

Step 1: Import file generated by MSC.ADAMS.

Once you have created the main part of AMESim system, use the Interface menu to

import MSC.ADAMS model:

Figure 7: Importing MSC.ADAMS model in AMESim

3

The inf file also contains information that is not directly accessible under MSC.ADAMS: interactive or batch

simulation, discrete or continuous interface, step time for discrete mode, solver commands, initial conditions

analysis. These are defined by default in MSC.ADAMS settings (easily accessible under UNIX), most of them

will be accessible under AMESim but if you are an experienced user you can always edit this file.

2004

Using AMESim MSC ADAMS Interface

13//39

This opens a dialog box window in which you select the inf file generated during

MSC.ADAMS export.

Then the inf file is analyzed and you get following tabbed window:

Figure 8: MSC.ADAMS model import window in AMESim

The tabs are used as follows:

•

In the Common tab, number and names of inputs and outputs are

automatically set up following the content of MSC.ADAMS file. Check the

names of variables and give a title to the icon.

•

In the MSC.ADAMS tab, several settings are available:

o

Output prefix name: it is the name of output files of MSC.ADAMS,

o

User executable: eventually add there your user defined library path

needed by MSC.ADAMS model, it usually contains some

subroutines,

o

Simulation mode: Continuous stands for complete import of

MSC.ADAMS system into AMESim and Discrete for co-simulation

mode,

o

Animation mode: specify here if you want to launch A/View while

you run a simulation; namely the Interactive mode that is much

slower than the Batch one, in the last one you can always look the

animation of your model at the end of simulation,

o

MSC.ADAMS output step size: give here the period at which

MSC.ADAMS writes its results,

o

Initialization mode: an MSC.ADAMS option to say that you will do

an initial condition analysis if needed, this option is disabled,

o

Static analysis: same as previous but for an equilibrium analysis

before dynamic run,

o

Initialization commands: it contains ADAMS/Solver commands that

are in the inf file and should work only in Batch mode (Interactive

mode requires A/View commands) this field is not customizable, if

needed modify the inf file directly.

Upon completion of the sketch, you switch to Submodel mode and then Parameter mode.

AMESim compiles the system and you can now focus on parameters available for the

interface submodel.

2004

Using AMESim MSC ADAMS Interface

14//39

Step 2: Parameterization of the interface block.

Depending on the mode you selected in previous step, you have two possibilities. For the

discrete mode you get following parameters:

Figure 9: AMESim parameters for discrete MSC.ADAMS block

You have access to the communication interval; indeed, it is useful to test several values

for this parameter. We will return to this parameter in a later section concerning problems

of co-simulation.

If the block were a continuous one, you would get the following parameters:

Figure 10: AMESim parameters for continuous MSC.ADAMS block

2004

Using AMESim MSC ADAMS Interface

15//39

In this case, since AMESim imports the complete MSC.ADAMS system, it integrates all

states variables coming from MSC.ADAMS4. All these states become AMESim states

variables. Contrarily to other classical submodels you do not have access to initial values

of these states since MSC.ADAMS will compute these ones.

Step 3: Running a simulation.

Change to Simulation mode. Set normally the parameters of the simulation bearing in

mind that if you are using a discrete block and have a sample time step you should use at

most this value for the AMESim communication step.

When you run the simulation depending on the platform you are using, you will notice

that A/Solver is running:

Using Windows:

MSC.ADAMS opens a Command DOS Prompt and you see messages coming from

A/Solver. All the messages are saved in a text file (msg)

Figure 11: MSC.ADAMS command window

4

Actually, MSC.ADAMS converts its algebraic/differential system into a purely differential one and sends the

derivatives of its states to AMESim whenever we ask for it. The conversion methodology introduces

supplementary states and as a result, the states have no physical meaning.

2004

Using AMESim MSC ADAMS Interface

16//39

Using UNIX:

The output messages from A/Solver appear on the AMESim message window.

When running a co-simulation in discrete mode in AMESim the simulation gives an error

message concerning the standard output in Warning/Error tab. On Sun station:

dofio: [-1] end of file

logical unit 6, named ‘stdout’

lately: writing sequential formatted external IO

On Silicon Graphics station:

sfe: Resource temporarily unavailable

apparent state: unit 6 named

last format:

unit 6 is a (null) formatted external file

*** Execution terminated (11) ***

On IBM station:

1525-013: The sequential or stream WRITE statement

cannot be completed because an errno value of 11

(Resource temporarily unavailable) was received while

writing the file (standard output). The program will

stop

This is because MSC.ADAMS sends many messages to the standard output while

AMESim does some treatments on it and it seems that there is no way to avoid all these

messages. The workaround is to launch the simulation from a terminal window, e.g. if

your model is called model.ame in /home/usr/ametest do the following:

cd /home/usr/ametest

./model_

This will execute the model, output messages will appear in the terminal window.

2004

Using AMESim MSC ADAMS Interface

17//39

3.4.

Analyzing results in both software

Upon completion of the simulation, you can analyze the results in both packages. In

AMESim, you can get the variables values exchanged with MSC.ADAMS by clicking the

MSC.ADAMS block. You get the following results:

Figure 12: Results from the co-simulation in AMESim

In MSC.ADAMS, you have to load the results files into the model. To do so, in the File

menu, choose Import and select ADAMS/Solver Analysis (req, gra, res), select one on the

three files created during the simulation and do not forget to fill in the model name so as

to associate results with the model you are working with. You can then look at the

animation or plot any variable as usual within the A/Postprocessor:

Figure 13: MSC.ADAMS results for the co-simulation

2004

Using AMESim MSC ADAMS Interface

18//39

4

Importing AMESim into MSC.ADAMS

In this section you will focus on the other interface method i.e. importing the AMESim

model into MSC.ADAMS. We designed the facility for multiple reasons:

An MSC.ADAMS user needs to integrate a validated AMESim component into its

mechanical system; he can still work with MSC.ADAMS facilities while taking advantage

of AMESim ability to design multi-disciplinary control systems.

•

AMESim may sometimes encounter difficulties in solving a complex

MSC.ADAMS mechanical structure; in this case, we suggest that user tries

the other way for coupling the systems, especially if the AMESim system is

simple.

•

This methodology requires no supplementary license for A/controls product.

In this case, you will use AMESim subsystem in MSC.ADAMS as a general state

equation (GSE) block. MSC.ADAMS executable will communicate with AMESim using

a library. Actually, AMESim will not generate an executable as usual but rather a

dynamic link library (dll) on Windows platforms or a library (so) on UNIX platforms.

One advantage of this methodology is that you do not need to have AMESim installed on

the MSC.ADAMS machine; you will just need an AMESim runtime license.

4.1.

Preparing an AMESim model for export to MSC.ADAMS

In this section, you will see how to export an AMESim system into MSC.ADAMS.

In Sketch mode, construct your AMESim system with non-connected ports corresponding

to MSC.ADAMS inputs and outputs. Then, in the Interface menu, select Create export

icon…, refer to the screen capture below:

Figure 14: Creating export icon in AMESim

It opens a dialog box window named Interface Icon Creation, you select there a Type of

interface it should be Adams or AdamsCosim depending if you want to run discrete

coupling or continuous export.

2004

Using AMESim MSC ADAMS Interface

19//39

Set the number of input variables to MSC.ADAMS and output variables from

MSC.ADAMS and give them a name.

In the antenna case it should be one input and two outputs and the created icon looks like

this:

Figure 15: AMESim subsystem containing MSC.ADAMS block

It is also possible to change the interface status without having to re-do the export, just go

in the Interface menu and select Display interface status. There you can switch from

Adams to AdamsCosim.

Switch then to Submodel mode and Parameters mode, after the compilation of the system

AMESim creates the library. Switch to Simulation mode to generate all necessary files.

You are now ready to work under MSC.ADAMS and import the AMESim system; it is

the subject of next section.

4.2.

Importing the model in MSC.ADAMS

Step 1: Create the arrays for inputs outputs and states.

In A/View go into the Build4Controls Toolkit menu.

First, choose U input array. There you create inputs to AMESim subsystem, so it will be

a 2-dimensionnal array containing MSC.ADAMS variables for velocity and position.

Then, choose X states array. Depending on discrete or continuous export, you

respectively specify 1 (a dummy state variable) or AMESim number of states for the size

of the array (this number is accessible in Simulation mode when you press State Count

button

).

Finally, choose Y output array. It represents the outputs from AMESim so in our case it

will be a 1-dimension array for the control torque.

The figure presents a summary of these operations:

2004

Using AMESim MSC ADAMS Interface

20//39

Figure 16: MSC.ADAMS arrays for import of AMESim subsystems.

Step 2: Association of array output value to the model.

The control torque computed by AMESim needs to be associated to the MSC.ADAMS

model. You do it in the single component torque using ARYVAL MSC.ADAMS function.

This one permits you to get an array value.

Note that, as a first argument to this function you use the array of outputs and the second

argument is the position of wanted value; 1 in our case.

Figure 16: Associate AMESim output to the ADAMS model

2004

Using AMESim MSC ADAMS Interface

21//39

Step 3: Creating the GSE and linking with AMESim library.

In the Build4System Elements4General State Equation menu, choose New… this

opens the following dialog box window:

Figure 17: Creating a GSE in ADAMS; discrete or continuous

Fill in the window according to the previous figure. The States line corresponds to the

coupling method you have chosen previously under AMESim, choose discrete for a cosimulation and continuous for an export. User Function Parameters needs always three

parameters and corresponds respectively to the ID of U Array, Y Array and X Array.

AMESim will need them to be able to get correct values from MSC.ADAMS during

simulation. Once completed, you have to indicate to A/Solver to use the AMESim library.

Go in the Settings4Solver4Solver executable… menu, in the dialog box window for

Solver Library supply the AMESim library path as the below figure shows it:

Figure 18: A/Solver settings when using AMESim library

Step 4: Running a simulation.

Since A/Solver will use an external library only scripted simulation are available.

Follows an example of a simple script:

file/model=Adams

simulate/dynamics, end=0.250000, dtout=0.001

stop

Run the simulation within MSC.ADAMS, in the same time, the AMESim library writes a

result file.

2004

Using AMESim MSC ADAMS Interface

22//39

Figure 20: AMESim as a GSE in MSC.ADAMS

The AMESim model is executed in the background. The communication with

MSC.ADAMS takes place at the library level (dll on Windows and so on Unix platforms).

In the aside figure you can notice that AMESim outputs some messages during the

simulation.

Step 5: Checking the results.

If you have AMESim installed on the same machine, you can look at the results within

AMESim. Otherwise, you can focus on MSC.ADAMS results only.

Check the plots Figure 12: Results from the co-simulation in AMESim at page 18 and

Figure 13: MSC.ADAMS results for the co-simulation page 18.

2004

Using AMESim MSC ADAMS Interface

23//39

5

Co-simulation or Full Export?

When a full export is feasible it is always better than a co-simulation. Indeed having all

the system integrated by one solver makes the analysis of the system easier. For example

using the linear analysis facility in AMESim is more accurate if AMESim knows all

states of the system.

During a full export to MSC.ADAMS, AMESim is used as a function evaluator by

MSC.ADAMS. All derivatives and outputs are passed to MSC.ADAMS whenever it asks

for them. The AMESim solver is not used and values in MSC.ADAMS may be

discontinuous and may make the solver fail.

In the opposite case, during export to AMESim, MSC.ADAMS is used as a function

evaluator. MCS.ADAMS passes derivatives and outputs whenever AMESim needs it.

The precision of MSC.ADAMS values is essential for the success of AMESim integrator.

That is why it is necessary to set a special MSC.ADAMS parameter. In the inf file you

will have to add a command:

NUMBER OF COMMANDS

1

CPAPAR/ALA=1e-10, ALR=1e-10

If necessary you can raise these values to 1e-8.

This controls the coordinate partitioning algorithm for the ABAM (Adams-Bashforth and

Adams-Moulton) integrator. Coordinate partitioning is the action done in order to remove

the constraints of MSC.ADAMS system; from a set of DAEs it gets a set of ODEs that

AMESim can integrate.

A co-simulation can be easier to set-up, especially if the models are complex. During a

co-simulation both solvers exchange information at fixed interval. When MSC.ADAMS

receives a signal, this will stay constant during the whole sample interval, until a new

value is received. The same thing happens in AMESim. You will have to set this

communication interval with care since different values can lead to different results.

We want to use as large an interval as possible to get a quick run and as small as possible

for accurate values! Sampled environments are a difficult subject and there are books

written on the stability of them. How do we set up efficiently a communication interval

for discrete mode?

Keeping in mind that introducing a communication interval is more or less equivalent to

introducing a delay in the system, the following study can be done.

We consider a linear actuator modeled within AMESim and coupled with an

MSC.ADAMS model. In the figure you will notice that some variables are exchanged.

The torque is here always zero.

2004

Using AMESim MSC ADAMS Interface

24//39

Figure 21: AMESim sketch of a linear actuator coupled with MSC.ADAMS

An equivalent system is given above. A simple calculation will give the global inertia

which must be the one of the MSC.ADAMS structure on which AMESim force acts. You

can also include some friction if there is any in the MSC.ADAMS model.

In order to test the validity of a chosen communication interval we want to construct a

similar system in AMESim only.

Figure 22: AMESim sketch with a delay loop.

The sample period of the discrete delay blocks are set to the communication interval we

are testing.

Construct also in the same sketch the same system without the discrete blocks.

2004

Using AMESim MSC ADAMS Interface

25//39

With this sketch you can compare results of both systems, with and without discrete

blocks depending on the delay=communication interval you have chosen.

Figure 19: AMESim sketch without discrete blocks.

Run simulations with different delays (communication interval) and check that results on

both systems are equivalent. Choose the highest communication interval that preserves the

quality of the results.

With this methodology you are able to establish an optimal communication interval.

6

Tips on using the interface

6.1.

How to stop a simulation

Using Windows:

If you use AMESim to run the simulation and stop it for any reason, MSC.ADAMS

continues to run in the command window.

To stop the MSC.ADAMS simulation, click on this command window and type:

Ctrl C

2004

Using AMESim MSC ADAMS Interface

26//39

6.2.

How to execute MSC.ADAMS commands before a cosimulation?

You can edit the inf file and change the following lines:

NUMBER OF COMMANDS

0

Add any A/Solver command at this location, all these commands are executed in

MSC.ADAMS before launching the co-simulation, it can look like:

NUMBER OF COMMANDS

2

SIMULATE/STATICS

SIMULATE/INITIAL_CONDITIONS

7

Advanced use of the interface

7.1.

How

to setup interface

MSC.ADAMS products

with

template-based

Your MSC.ADAMS model may use functionalities of an MSC.ADAMS template-based

product. These products are:

•

ADAMS/Aircraft, ADAMS/Car, ADAMS/Car

ADAMS/Engine and ADAMS/Rail.

Ride,

ADAMS/Driveline,

If your model effectively uses one of these libraries, the import into AMESim requires an

additional step: editing the .inf file.

You always need A/Controls to setup the export in Adams (cf. Figure 6: Exporting the

coupled system from ADAMS, page 9). Once you have selected OK in the Plant export

dialog box, this will create the inf file. Then submit the analysis in a normal way, but

make sure that you choose files_only.

When you set Mode of Simulation to files_only, your template-based product only outputs

the analysis files, .adm and .acf, but it does not perform an analysis. In A/Car, you can use

this option to prepare files for use with A/Controls.

If you have loaded A/Controls (Tools4Plugins4Controls4Load), and your model has

a plant input and a plant output, A/Car will prepare a special _controls.acf file. It supports

a single plant input and output. If you have more than one plant input and output, A/Car

prompts you to select which one you want to see.

The next step to run a co-simulation is to edit the inf file, and make the following changes:

NUMBER OF COMMANDS

1

FILE/COMMAND= _controls.acf

Then MSC.ADAMS will execute the commands that are in the _controls.acf file before

running the co-simulation with AMESim.

2004

Using AMESim MSC ADAMS Interface

27//39

7.2.

Using more than one interface

If your AMESim model and your MSC.ADAMS models are coupled at different

locations, unify all exchanges variables and use only one Plant Input and one Plant Output

in MSC.ADAMS and one interface block in AMESim.

8

Advanced configuration of the interface

This section is useful only for advanced users; it permits you to customize the interface.

8.1.

Configuration file

This section applies only when exporting AMESim system to MSC.ADAMS.

It should be possible to do the tutorial example without any further changes to the

configuration of the interface.

The configuration files for the AMESim export to MSC.ADAMS supplied with a

standard AMESim installation assumes that all functions are written in C and that no

extra libraries with user written functions are needed. If you write your submodels in

Fortran or you use non-standard libraries in your model, some changes to the standard

distribution files are needed. Refer to the standard AMESim manual for these changes.

In a similar way it is possible to customize the AMESim MSC.ADAMS interface. The

files that involved are adams.conf and amesim_adams_gsec.make. They are stored in the

$AME/lib directory. For global customization, they should be edited there. If you do this,

the new configuration becomes the default for all users of the interface. Your system

administrator should normally do this.

It is also possible to alter the configuration locally so that the changes apply only to you

working in a particular directory. To do this copy these files (adams.conf and

amesim_adams_gsec.make) to your project directory and make the necessary changes to

these files.

AMESim looks in the current directory before looking in the standard area ($AME/lib),

any changes made to the local files will therefore override the global configuration.

The file adams.conf contains instructions specifying which files are to be used when

creating the AMESim part of the simulation model. This means that if you decide to

make any local configurations this file must be edited, otherwise the global configuration

will be used. Below the standard adams.conf is shown.

#########################################################

# This file specifies the AMESim export facility to

#

# ADAMS. The entries are as follows:

#

#

#

# 1. the template to use for an explicit system.

#

# 2. the template to use for an implicit system.

#

# 3. the makefile to use.

#

# 4. the button title.

#

# 5. the script file to launch the companion software. #

#########################################################

$AME/lib/adams_cont.etemp

2004

Using AMESim MSC ADAMS Interface

28//39

NULL

$AME/lib/amesim_adams_gsec.make

Adams

NULL

hp:so,ibm:so,lnx:so,sgi:so,sun:so,win32:dll

The lines beginning with # are comments. The line that all local configurations need to

change is the 3rd non-commented line (currently $AME/lib/amesim_adams_gsec.make).

This is the name of a file with instructions on how to create the AMESim simulation

model. If you want AMESim to use a local configuration this line should point to this,

change this line to, for instance, ./adams.make.

In the standard distribution the file $AME/lib/amesim_adams_gsec.make contains the

following lines:

Using Windows:

$(CC) -c -I$(AME)/lib -DAMEADAMS

$(CC) -LD

dformd.lib asutility_imp.lib

Using Unix:

$(CC) -c -I$(AME)/lib -DAMEADAMS

$(AME)/lib/makeadamsso.sh

-L$(AME_ADAMS_HOME)/ADAMS_NOT_DEFINED_FOR_THIS_COMPUTER_TYPE

–lAsUtility

sun:-L$(AME_ADAMS_HOME)/ultra –lAsUtility

sgi:-L$(AME_ADAMS_HOME)/irix32 –lAsUtility

ibm:-L$(AME_ADAMS_HOME)/ibmrs –lAsUtility

The first line is the command for doing some pre-processing of the AMESim generated C

file and to compile it. If your compiler needs any special flags this is where to add them.

For further customization it is possible, under Unix to modify the makeadamsso.sh file or

under Windows to add some specific library. This is for advanced users only.

Using Windows:

The 2nd line specifies the command used for linking the AMESim simulation executable;

this is normally the C compiler.

Using Unix:

The 2nd line specifies the path to the script (makeadams.sh) that will effectively command

the compilation depending on the platform used.

Using Windows:

The 3rd line specifies the required libraries to compile the system. In our case we need the

Fortran library dformd.lib and an MSC.ADAMS library asutility_imp.lib.

You can add here specific libraries if needed, but these ones must be accessible to the

system. To do so, you will have to append your library path to an environment variable

called %lib%. This can be done in a command file (bat), whether when you start

AMESim or in a local copy of the file %AME%/AMEcompile42.bat.

The line should be:

set lib=%lib%;path_to_your_library

Using Unix:

2004

Using AMESim MSC ADAMS Interface

29//39

The 3rd line should never be used. It is only used if the platform is not recognized. The

following lines (4th, 5th and 6th line) are platform dependant.

If your model includes Fortran code amesim_adams_gsec.make probably needs to be

altered by modifying the 4th line (if working with Sun) specifying the additional libraries

needed. An example on such a line is:

sun:-L$(AME_ADAMS_HOME)/ultra –lAsUtility L/opt/SUNWspro/SC3.0.1/lib -lF77 –lsunmath

This is highly system dependent and you probably need to ask your system administrator

for the libraries used on your computer. If many users are using Fortran it is probably a

good idea to let your system administrator change the amesim_adams_gsec.make in the

standard area ($AME/lib/amesim_adams_gsec.make). Another possibility is to use the

Fortran compiler for the link step, that is change the 2nd line to $(F77).

Another reason to modify the 3rd and following lines is if your submodels use user written

utilities or other non-standard files or libraries; this would typically be a change that you

would do locally. For instance, if you would like to include a library called libmyfuncs.a

which is stored in /home/usr/library modify the 4th line:

sun:-L$(AME_ADAMS_HOME)/ultra –lAsUtility L/home/usr/library -lmyfuncs -L/opt/SUNWspro/SC3.0.1/lib lF77 –lsunmath

Note that for a particular simulation, the state of adams.conf when the system is created

and the corresponding amesim_adams_gsec.make are remembered. It will be necessary to

recreate the interface blocks if you wish to change to a different

amesim_adams_gsec.make.

Note that for using AMESim export facility without Fortran compiler you should modify

amesim_adams_gsec.make in the following way.

Using Windows:

$(CC) -c -I$(AME)/lib -DAMEADAMS

$(CC) -LD

ws2_32.lib kernel32.lib asutility_imp.lib

2004

Using AMESim MSC ADAMS Interface

30//39

2004

Using AMESim MSC ADAMS Interface

31//39

Reporting Bugs and using the Hotline Service

AMESim® is a large piece of software containing many hundreds of thousands of lines of

code. With software of this size it is inevitable that it contains some bugs. Naturally we

hope you do not encounter any of these but if you use AMESim® extensively at some

stage, sooner or later, you may find a problem.

Bugs may occur in the pre- and post-processing facilities of AMESim®, AMESet® or in

one of the interfaces with other software. Usually it is quite clear when you have

encountered a bug of this type.

Bugs can also occur when running a simulation of a model. Unfortunately it is not

possible to say that, for any model, it is always possible to run a simulation. The

integrators used in AMESim® are robust but no integrator can claim to be perfectly

reliable. From the view point of an integrator, models vary enormously in their difficulty.

Usually when there is a problem it is because the equations being solved are badly

conditioned. This means that the solution is ill-defined. It is possible to write down sets of

equations that have no solution. It such circumstances it is not surprising that the

integrator is unsuccessful. Other sets of equations have very clearly defined solutions.

Between these extremes there is a whole spectrum of problems. Some of these will be the

marginal problems for the integrator.

If computers were able to do exact arithmetic with real numbers, these marginal problems

would not create any difficulties. Unfortunately computers do real arithmetic to a limited

accuracy and hence there will be times when the integrator will be forced to give up.

Simulation is a skill which has to be learnt slowly. An experienced person will be aware

that certain situations can create difficulties. Thus very small hydraulic volumes and very

small masses subject to large forces can cause problems. The State count facility can be

useful in identifying the cause of a slow simulation. An eigenvalue analysis can also be

useful.

The author remembers spending many hours trying to understand why a simulation failed.

Eventually he discovered that he had mistyped a parameter. A hydraulic motor size had

been entered making the unit about as big as an ocean liner! When this parameter was

corrected, the simulation ran fine.

In follows that you must spend some time investigating why a simulation runs slowly or

fails completely. However, it is possible that you have discovered a bug in an AMESim®

submodel or utility. If this is the case, we would like to know about it. By reporting

problems you can help us make the product better.

On the next page is a form. When you wish to report a bug, please photocopy this form

and fill the copy. Even if you telephone us, having the filled form in front of you means

you have the information we need.

-

To report the bug you have three options:

-

reproduce the information as an email

-

telephone the details

-

fax the form

Use the email address, telephone number or fax number of your local distributor.

HOTLINE REPORT

Creation date:

Created by:

Company:

Contact:

Keywords (at least one):

Problem type:

£ Bug

£ Improvement

£ Other

Summary:

Description:

Involved operating system(s):

£ All

£ Unix (all)

£ PC (all)

£ HP

£ Windows 2000

£ IBM

£ Windows NT

£ SGI

£ Windows XP

£ SUN

£ Linux

£ Other:

£ Other:

Involved software version(s):

£ All

£ AMESim (all)

£ AMERun (all)

£ AMESet (all)

£ AMECustom (all)

£ AMESim 4.0

£ AMERun 4.0

£ AMESet 4.0

£ AMECustom 4.0

£ AMESim 4.0.1 £ AMERun 4.0.1 £ AMESet 4.0.1

£ AMECustom 4.0.1

£ AMESim 4.0.2 £ AMERun 4.0.2 £ AMESet 4.0.2

£ AMECustom 4.0.2

£ AMESim 4.0.3 £ AMERun 4.0.3 £ AMESet 4.0.3

£ AMECustom 4.0.3

£ AMESim 4.1

£ AMECustom 4.1

£ AMERun 4.1

£ AMESet 4.1

£ AMESim 4.1.1 £ AMERun 4.1.1 £ AMESet 4.1.1

£ AMECustom 4.1.1

£ AMESim 4.1.2 £ AMERun 4.1.2 £ AMESet 4.1.2

£ AMECustom 4.1.2

£ AMESim 4.1.3 £ AMERun 4.1.3 £ AMESet 4.1.3

£ AMECustom 4.1.3

£ AMESim 4.2

£ AMECustom 4.2

£ AMERun 4.2

£ AMESet 4.2

Web Site

http://www.amesim.com

FRANCE - ITALY - SPAIN –

PORTUGAL - BENELUX SCANDINAVIA

S.A.

5, rue Brison

42300 ROANNE - FRANCE

Tel. : 04-77-23-60-30

Tel. : (33) 4-77-23-60-37

Fax : (33) 4-77-23-60-31

E.Mail : hotline@amesim.com

UK

U.K.

Park Farm Technology Centre

Kirtlington, Oxfordshire

OX5 3JQ

ENGLAND

Tel: +44 (0) 1869 351 994

Fax: +44 (0) 1869 351 302

E-mail: support.uk@amesim.com

USA - CANADA - MEXICO

Software, Inc.

44191 Plymouth Oak Blvd – Suite 900

PLYMOUTH (MI) 48170 - USA

Tel. : (1) 734-207-5557

Fax : (1) 734-207-0117

Email : support-us@amesim.com

GERMANY – AUSTRIA SWITZERLAND

Software GmbH

Elsenheimerstr. 15

D - 80687 München - DEUTSCHLAND

Tel: +49 89 / 548495-35

Fax: +49 89 / 548495-11

E.Mail : hotline.germany@amesim.com

JAPAN

Japan KK

SATOKURA AKEBONOBASHI Bldg. 2F

SHINJUKU KU, SUMIYOSHI MACHI, 1-19

TOKYO 162-0065 - JAPAN

Tel. : 81 (0) 3 3351 9691

Fax : 81 (0) 3 3351 9692

Email : hotline-japan@amesim.com

CHINA

China

Room. 109

Jinyan Building (Business), N. 3800 Chunshen Road,

Shanghai 201100

CHINA (PRC)

Tél.: +86 21 34 12 34 58

Fax: +86 21 34 12 84 58

E-mail: qing@amesim.com

United Right Technology

Room 716-717

North Office Tower Beijing, New World Center

No.3-B Chong Wen MenWai dajie,

Postal Code: 100062, BEIJING, P.R CHINA

Tel: (86) 10-67082450(52)(53)(54)

Fax: (86) 10-67082449

Email: urt@urtgroup.com

SOUTH KOREA

SHINHO Systems Co., Ltd.

#702

Ssyongyong IT Twin Tower

442-5, Sangdaewon-dong

Jungwon-gu

Seongnam-si

Gyeonggi

South Korea <462-723 >

Tel. : 82-31-608-0434

Fax : 82-31-608-0439

E.Mail : iclee@shinho-systems.co.kr

BRAZIL

KEOHPS

CELTA – Parc Tec ALFA

Rod. SC 401-km 01 – CEP 88030-000

FLORIANOPOLIS – SC BRAZIL

Tel. : (55) 48 239 – 2281

Fax : (55) 48 239 – 2282

Email : info@keohps.com

HUNGARY

Budapest University of

Technology & Economics

Department of Fluid Mechanics

H-1111 BUDAPEST, Bertalan L. U. 4- 6 HUNGARY

Tel. : (36) 1 463 4072 / 463 2464

Fax : (36) 1 463 3464

Email : vad@simba.ara.bme.hu