PDF document - EE Times Asia

advertisement

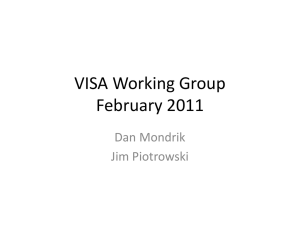

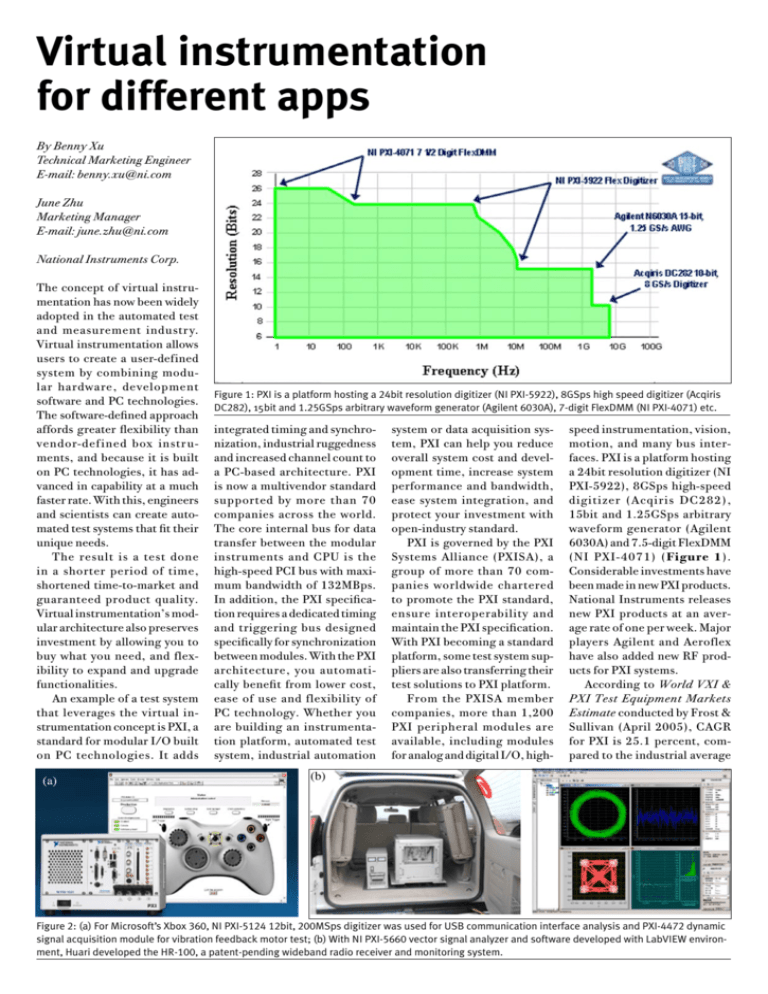

Virtual instrumentation for different apps By Benny Xu Technical Marketing Engineer E-mail: benny.xu@ni.com June Zhu Marketing Manager E-mail: june.zhu@ni.com National Instruments Corp. The concept of virtual instrumentation has now been widely adopted in the automated test and measurement industr y. Virtual instrumentation allows users to create a user-defined system by combining modular hardware, development software and PC technologies. The software-defined approach affords greater flexibility than vendor-def ined box instruments, and because it is built on PC technologies, it has advanced in capability at a much faster rate. With this, engineers and scientists can create automated test systems that fit their unique needs. The result is a test done in a shorter period of time, shortened time-to-market and guaranteed product quality. Virtual instrumentation’s modular architecture also preserves investment by allowing you to buy what you need, and flexibility to expand and upgrade functionalities. An example of a test system that leverages the virtual instrumentation concept is PXI, a standard for modular I/O built on PC technologies. It adds (a) Figure 1: PXI is a platform hosting a 24bit resolution digitizer (NI PXI-5922), 8GSps high speed digitizer (Acqiris DC282), 15bit and 1.25GSps arbitrary waveform generator (Agilent 6030A), 7-digit FlexDMM (NI PXI-4071) etc. integrated timing and synchronization, industrial ruggedness and increased channel count to a PC-based architecture. PXI is now a multivendor standard supported by more than 70 companies across the world. The core internal bus for data transfer between the modular instruments and CPU is the high-speed PCI bus with maximum bandwidth of 132MBps. In addition, the PXI specification requires a dedicated timing and triggering bus designed specifically for synchronization between modules. With the PXI architecture, you automatically benefit from lower cost, ease of use and flexibility of PC technology. Whether you are building an instrumentation platform, automated test system, industrial automation system or data acquisition system, PXI can help you reduce overall system cost and development time, increase system performance and bandwidth, ease system integration, and protect your investment with open-industry standard. PXI is governed by the PXI Systems Alliance (PXISA), a group of more than 70 companies worldwide chartered to promote the PXI standard, ensure interoperability and maintain the PXI specification. With PXI becoming a standard platform, some test system suppliers are also transferring their test solutions to PXI platform. From the PXISA member companies, more than 1,200 PXI peripheral modules are available, including modules for analog and digital I/O, high- speed instrumentation, vision, motion, and many bus interfaces. PXI is a platform hosting a 24bit resolution digitizer (NI PXI-5922), 8GSps high-speed digitizer (Acqiris DC282), 15bit and 1.25GSps arbitrary waveform generator (Agilent 6030A) and 7.5-digit FlexDMM (NI PXI-4071) (Figure 1). Considerable investments have been made in new PXI products. National Instruments releases new PXI products at an average rate of one per week. Major players Agilent and Aeroflex have also added new RF products for PXI systems. According to World VXI & PXI Test Equipment Markets Estimate conducted by Frost & Sullivan (April 2005), CAGR for PXI is 25.1 percent, compared to the industrial average (b) Figure 2: (a) For Microsoft’s Xbox 360, NI PXI-5124 12bit, 200MSps digitizer was used for USB communication interface analysis and PXI-4472 dynamic signal acquisition module for vibration feedback motor test; (b) With NI PXI-5660 vector signal analyzer and software developed with LabVIEW environment, Huari developed the HR-100, a patent-pending wideband radio receiver and monitoring system. 100MHz differential CLK PXI PXI Express SYNC 100 Star trigger PXI peripheral Hybrid peripheral PXIe peripheral PXIe system timing controller PXIe system controller 10MHz CLK Differential star triggers PXI trigger bus (8 TTL triggers) Figure 3: PXI Express provides additional timing and synchronization features to achieve greater measurement accuracy. of 4 percent, making it the fastest growing instrumentation standard since the growth of general-purpose interface bus (GPIB) in the mid-1970s. PXI is now being used in a wide range of industries—from consumer electronics to military, and aerospace to medical device testing. PXI is also a suitable platform to serve an array of applications within each industry. PXI has products fit to different needs for different tasks such as developing benchtop applications in design validation, rack mount applications in manufacturing test, or portable or embedded systems for in-vehicle data logging. Applications In May 2005, Microsoft announced its latest innovation for digital entertainment and gaming, the Xbox 360, along with a new line of Xbox 360 wired and wireless controllers. The Xbox 360 controller-functional test system demanded higherperformance signal capture to qualify the signal integrity of the new controller and ensure high-quality user experience. With the PXI platform and the latest NI modular instruments, the increased functional test requirements for the Xbox 360 controller were fulfilled. NI PXI5124 12bit, 200MSps digitizer was used for USB communication interface analysis and PXI4472 dynamic signal acquisition module for vibration feedback motor test. With the LabVIEW graphical development environment, more than 100 tests were created, Ethernet communication was implemented, and a data storage interface was incorporated into Microsoft SQL Server database (Figure 2a). Another example is Chengdu Huari Telecommunications Co. (Huari Telecom). It required a solution to improve measurement speed for spectral monitoring, directional finding and signal identification. With NI PXI-5660 vector signal analyzer and software developed with LabVIEW environment, Huari developed the HR-100, a patent-pending wideband radio receiver and monitoring system. This system can be used as both a radio receiver and an RF vector signal analyzer to monitor modern wideband digital telecom signals and conventional narrowband analog broadcast signals. Moreover, this system can be configured as a single-channel receiver or a multiple-channel directional finding system. Because the new system uses an open software-defined radio platform, HR-100 can perform standard and custom measurements that previously required several dedicated, standalone instruments. The company can make system updates to meet future needs of wireless standards, which is critical as wireless standards rapidly change (Figure 2b). Technology forecast With the modular architecture of PXI, it can incorporate the most advanced technology to expand the test system’s capability. Because of its high-speed performance and compatibility with PCI, PCIe is a bus suited for test and measurement applications. It provides low latency and higher bus bandwidth—and unlike PCI, LAN, USB and GPIB, it is not shared among devices. A digitizer based on PCIe will have a 1GBps direct path to the CPU module, which is approximately 8x the throughput of 32bit, 33MHz PCI today. To translate this into real measurement terms, a high-resolution 16bit IF digitizer could potentially stream up to 500MHz bandwidth continuously to the CPU without bus limits or sharing bandwidth with adjacent modules. This higher bandwidth will enable many new applications. With PCIe, users can take advantage of a basic communication lane of 250Mbps in each direction with x1 implementation up to 4Gbps and with x16 implementation, an increase of 24x over PCI. In addition, PCIe also improves peer-to-peer communication, enabling instruments within the system to communicate with one another quickly and easily. Lastly, PCIe was designed with compatibility needs in mind. With a layered architecture, it ensures compatibility with future generations and software compatibility with PCI. New apps With its higher performance, modular hardware architecture and compatibility, PCIe has the capability to solve many new test and measurement applications. Some of these used to be served only by expensive and proprietary hardware, including high bandwidth IF instruments for communications systems test, interface to high-speed digital protocols such as LVDS-based proprietary protocols, FireWire and large-channel-count data acquisition systems. Historically, in the case of high-speed video acquisition, users had to settle with the lower bandwidth available and rely on less dependable data to make a decision or use a very expensive, proprietary system to meet bandwidth needs. With the greater bandwidth provided by PCIe, developers can acquire high-speed video with a more accurate and complete representation of the real-time event without the cost of a proprietary system. For instance, using the NI PCIe-1429 image acquisition card enables users to acquire data at a rate of 680MBps compared with using banks of expensive onboard memory that could acquire images only for short periods of time. Integration By taking advantage of PCIe technology in the backplane, PXI Express increases the available PXI bandwidth from 132MBps to 6GBps for a bandwidth improvement of more than 45x, while maintaining software and hardware compatibility with PXI modules. Building on exist- ing timing and synchronization capabilities in PXI, PXI Express provides the additional timing and synchronization features of a 100MHz differential system clock, differential signaling and differential star triggers (Figure 3). By using differential clocking and synchronization, PXI Express systems benefit from increased noise immunity for instrumentation clocks and the ability to transmit at higher-frequency clocks. With the software compatibility of PCIe, the standard software framework provided by PXI will carry into PXI Express. To provide hardware compatibility, the new PXI Express specification defines a new hybrid slot that enables engineers to install modules with either a PXI or PXI Express architecture in a slot. With this technology, engineers and vendors can preserve their existing investments in PXI systems and products through both hardware and software compatibility. As a standard platform for test and measurement applications, PXI takes advantage of commercial technologies to help increase the performance and lower the cost of test systems. Commercial standards have also contributed to PXI’s adoption rate in different applications ranging from test to control. Aggressive new product investments by many vendors in the PXISA are fueling continuous PXI growth and clearing the way for new applications as the functionality continues to expand. The future evolution of PXI based on PCIe technology will expand the platform to serve more applications while maintaining backward-compatibility.