3M Metalworking Systems

Power Tools, Accessories and Abrasives

™

Advanced

Metalworking

Solutions

New

New

New

Abrasives & Accessories

Abrasives & Accessories

Wheels & Accessories

Disc Sanders

Die Grinders

Cut-Off Wheel Tools

Guts.

Grit.

Get it All.

3M Metalworking Systems

™

With the addition of the new line of powerful, lightweight 3M™ Metalworking Tools, the advanced

finishing solutions you expect from 3M have come full circle.

The guts to go the distance.

The grit to get the job done.

Whether cutting, grinding, blending or finishing, 3M now offers a

Experience the power of a complete finishing system by

line of quality pneumatic metalworking tools designed to optimize

combining the 3M™ Abrasives and Accessories you’ve

tool and abrasive performance on these applications and more.

always trusted with the new line of 3M™ Tools specifically

Advanced technology and design increase operator comfort by

designed to help get the job done more efficiently.

directing exhaust away from the operator. And most tools feature

the 3M-patented Greptile™ material, so a secure grip can be held

with less effort or slippage.

Revolutionary patented material

offers an incredibly precise grip

with minimal effort.

3M™ Greptile™ Gripping Material utilizes an impressive

microreplication technology pioneered by 3M.

Greptile™ Gripping Material has a two-fold effect. First,

it improves grip. Second, it allows a more effortless grip,

which over time, reduces fatigue. Whether in wet or dry

conditions, Greptile™ Gripping Material provides a grip you

can rely on. (Greptile™ available on all models, excluding

the 2" 3M™ Disc Sander 20230.)

2

At-a-Glance

3M Disc Sanders

™

Model

Number

Tool Dia.

Inch

(mm)

PSI

Max

RPM

Motor

HP (W)

Weight

Pound

(kg)

Length

Inch

(mm)

Height

Inch

(mm)

20230

2" (50)

20231

20232

Airflow

Rate

SCFM (LPM)

90

20,000

.3 (223)

1.08 (.49)

6 (152.4)

2.5 (63.5)

2" (50)

90

20,000

.5 (372)

1.28 (.58)

6.75 (171.5)

3" (76)

90

15,000

1 (744)

1.97 (.89)

8.25 (209.6)

Exhaust

Direction

Air Inlet

Thread

UPC Code

17 (481)

Rear Exhaust

1/4" NPT

051141-20230-3

2.75 (69.9)

23 (651)

Rear Directional

1/4" NPT

051141-20231-0

3.25 (82.6)

35 (991)

Rear Directional

1/4" NPT

051141-20232-7

3M Die Grinders

™

Max

RPM

Motor

HP (W)

Weight

Pound

(kg)

Length

Inch

(mm)

SCFM (LPM)

90

20,000

1 (744)

1.69 (.77)

7.75 (196.9)

20238

90

18,000

1 (744)

1.69 (.77)

20239

90

12,000

1 (744)

20240

90

8,000

1 (744)

Model

Number

PSI

20237

Airflow

Rate

Exhaust

Direction

Air Inlet

Thread

Collet Size

UPC Code

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20237-2

7.75 (196.9)

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20238-9

2.06 (.93)

10 (254)

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20239-6

2.06 (.93)

10 (254)

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20240-2

3M Cut-Off Wheel Tools

™

Model

Number

Tool Dia.

Inch

(mm)

PSI

Max

RPM

Motor

HP (W)

Weight

Pound

(kg)

Length

Inch

(mm)

Height

Inch

(mm)

20233

3" (76)

20234

Airflow

Rate

SCFM (LPM)

90

25,000

1 (744)

2.09 (.95)

7.75 (196.9)

3 (76.2)

4" (100)

90

20,000

1 (744)

2.25 (1.02)

7.75 (196.9)

20235

5" (125)

90

12,000

1 (744)

3.47 (1.57)

20236

6" (152)

90

10,000

1 (744)

3.69 (1.67)

Exhaust

Direction

Air Inlet

Thread

UPC Code

35 (991)

Rear Directional

1/4" NPT

051141-20233-4

3.25 (82.6)

35 (991)

Rear Directional

3/8" NPT

051141-20234-1

8.75 (222.3)

5.25 (133.4)

35 (991)

Rear Directional

3/8" NPT

051141-20235-8

8.75 (222.3)

5.25 (133.4)

35 (991)

Rear Directional

3/8" NPT

051141-20236-5

3

Application Shot:

New cut-off wheel

tool with 3M

Roloc Disc metal

preparation.

™

3M Disc Sanders

™

™

3M got the right angle “right” with the new line of

Disc Sanders for metalworking. By adjusting the

head angle from 90º to 97º, a more comfortable

wrist position improves operating ergonomics.

And the easier-handling, lightweight, compact

design generates less vibration, while improving

operator control. 3M™ Greptile™ gripping

technology* provides a secure grip with less effort

and is easy to maneuver. And the adjustable

directional exhaust feature works the way you

want it to.

1 HP 3" Disc Sander Model

4

20232

5

2

1

9

6

8

7

3

97º head

Designed to be different

1• High-output air motor

2• Directional exhaust (360 degree*)

3• 3M™ Greptile™ Grip*

4• Safety lever throttle to avoid accidental starting

5• Needle and ball bearing supported

.55 H

HPP 2"

2" D

Dis

issc Saand

n err Mod

odel

el

el

.3 HP 2" D

Dis

issc Sa

Sand

n err Mod

nd

odel

el

20231

202

311

20230

202

300

8• Direct mount for use with 3M™ Roloc™ Backup Pads without using a collet

9• Shorter distance to the workpiece generates less vibration and allows

for better control

output spindle

6• Robust spiral bevel gearing

7• 97 degree head (vs. 90 degree) allows

for more comfortable wrist position

Model

Number

Tool Dia.

Inch

(mm)

PSI

Max

RPM

Motor

HP (W)

Weight

Pound

(kg)

Length

Inch

(mm)

Height

Inch

(mm)

20230

2" (50)

20231

20232

Airflow

Rate

SCFM (LPM)

90

20,000

.3 (223)

1.08 (.49)

6 (152.4)

2.5 (63.5)

2" (50)

90

20,000

.5 (372)

1.28 (.58)

6.75 (171.5)

3" (76)

90

15,000

1 (744)

1.97 (.89)

8.25 (209.6)

Exhaust

Direction

Air Inlet

Thread

UPC Code

17 (481)

Rear Exhaust

1/4" NPT

051141-20230-3

2.75 (69.9)

23 (651)

Rear Directional

1/4" NPT

051141-20231-0

3.25 (82.6)

35 (991)

Rear Directional

1/4" NPT

051141-20232-7

*Except on 2" 3M ™ Disc Sander 20230.

4

Disc Sanders

™

3M Quick Attach Systems for

Deburring, Grinding, Blending, Finishing

shing and Cleaning

For quick-change convenience and a selection of discs and

accessories that can be fine-tuned for any application, you can’t

beat the new system of 3M™ Pneumatic Disc Sanders, 3M™ Roloc™

Discs and Backup Pads.

From high performance 3M™ Roloc™ Coated Abrasives and

Scotch-Brite™ Roloc™ Discs to everyday general-purpose aluminum

oxide and a full range of accessories in variable hardness, you’ll

have what you want to suit your application. And 3M tools give

you the horsepower you need, so you can start experiencing the

benefits of an optimized metalworking system.

3M Roloc Discs

™

™

3M™ Roloc™ Discs provide a fast, efficient

method for grinding, blending, leveling and

finishing on all types of metal. They lock

securely in place with just a half twist ...

another half twist and they’re off. Each disc

is color coded by grade. (Excluding

3M™ Roloc™ TSM or 988R products.)

5

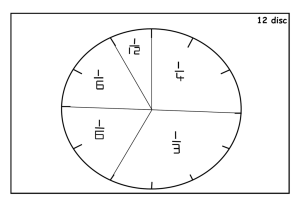

3M Roloc Disc Selection Guide

™

TR

777F

TSM

963G

TR

977F

TR

TR

501C

TSM

785C

TR

983C

TR

TR

Scotch-Brite Roloc

Light Grinding and

Blending Disc

™

™

Roloc TP

Scotch-Brite Roloc SL

Surface Conditioning Disc

Roloc TR

Scotch-Brite Roloc SE

Surface Conditioning Disc

Roloc TR

Scotch-Brite Roloc PD

Surface Conditioning Disc

Roloc TR

Roloc TR

™

™

™

™

™

™

™

™

™

™

™

Roloc TSM

24-120

24-80,

P100-P120

24-80

Super Duty-ACRS

Heavy Duty-ACRS

ACRS, AMED,

AVFN, SSFN

ACRS, AMED,

HD-ACRS,

SD-ACRS

™

Roloc TSM

™

(plastic button)

™

36-P180

24-120

24-P400

24-120

Available

Grades

36-P600

TSM

Scotch-Brite Roloc

Surface Conditioning Disc

(Brass/Bronze)

Nonferrous

Nickel Alloy

Titanium

Cast Iron

Carbon Steel

Aluminum

Cleaning

Finishing

TR

461F

Roloc TSM

™

(plastic button)

™

ACRS, AMED

Roloc TSM

™

(plastic button)

ACRS, AMED

50, 80, 120,

AXCRS-SVFN

Scotch-Brite Roloc

Bristle Disc

Roloc TR (plastic button)

Scotch-Brite Roloc

EXL Unitized Wheels

Roloc TR (plastic button)

Scotch-Brite Roloc

Clean and Strip XT Disc

Roloc TR (plastic button)

SXCS

Scotch-Brite Roloc

Coating Removal Disc

Roloc TR (plastic button)

SXCS

™

™

™

™

6

METAL TYPE

Stainless Steel

TSM

Deburring

TR

361F

Blending

Attachment System

Light Grinding

Abrasive Disc

APPLICATIONS

Grinding

™

™

™

™

™

™

™

™

™

3M Roloc Coated Abrasive Disc Button

Color-Grade Chart

™

™

24 - Black

80 - Yellow

36 - Brown

100 - Blue

50 - Green

120 - White

180 - Brown

60 - Orange

150 - Black

240 - Green

Disc Sanders, Abrasives & Accessories

Optimal mineral selections for each application

3M Roloc Discs with

Cubitron Abrasive Grain

™

™

™

The best choice for long life and fast stock removal.

For grinding under higher pressures, or where fast cut rates and

Looking for a great, versatile

product to use on stainless

steel and carbon steel?

A little bit high performance, a little

bit general purpose, and a convenient

option to have when your applications

fall somewhere in between.

long life are critical, select a coated abrasive disc that contains

3M Roloc Fibre Disc 501C

™

3M™ Cubitron™ Abrasive Grain.

For Stainless Steel Applications

3M Roloc Disc 977F

™

™

™

• Aluminum zirconia provides a good option for

both stainless and mild steel applications

• Improved life and cut compared to most aluminum oxide products

• Features cloth backing for durability

and a grinding aid for cooler running

• Maximum Cubitron™ Grain content

33M Roloc Disc 777F

™

™

For General Purpose and Maintenance Applications

When you need a disc to get everyday jobs done

right and deliver good value, select an

aluminum oxide disc.

• Features cloth backing for durability

and a grinding aid for cooler running

3M Roloc Disc 361F

33M Roloc Fibre Disc 785C

• Aluminum oxide on a tough,

™

™

• A fibre-backed disc with a grinding aid for

™

™

heavy-duty backing

cooler running

For Mild Steel Applications

A

3M Roloc Cloth Disc 963G

™

™

A sharp mineral, silicon carbide can give stainless

steel a brighter finish, and is great for grinding glass,

titanium and nonferrous metals.

• Features cloth backing for durability

• Maximum Cubitron™ Grain content

3M Roloc Fibre Disc

98

983C/988C

™

™

3M Roloc Disc 461F

™

™

• Silicon carbide on a YF-weight, durable cloth backing

• Use to grind, blend and deburr

• Designed for high-pressure

weld leveling and deburring

• Cloth backing for durability

• Maximum Cubitron™ Grain content

7

Scotch-Brite Roloc Discs

™

™

For grinding and blending in a single step,

try the NEW Scotch-Brite Roloc

Light Grinding and Blending Discs

™

™

Is it a coated abrasive disc or a nonwoven? It acts like both.

This new light grinding and blending disc removes a grade 36

or finer scratch, offers extremely long life, but also leaves a

very paintable finish – saving both time and money.

Scotch-Brite Roloc

Light Grinding and Blending Discs

™

™

Compare Best Options for Quality Scotch-Brite Discs

™

• 3M™ Cubitron™ Abrasive Grain

• Great for light grinding, deburring and blending

LGB

New

CUT RATE

• Resists edge wear

• Works great for weld burn-throughs

SE SL

• Grades:

PD

Heavy Duty – Maroon

SC

SC

Super Duty – Blue

DURABILITY

Scotch-Brite Roloc

Surface Conditioning Discs –

™

™

The Industry Standard for blending and finishing

Scotch-Brite Roloc

Surface Conditioning Discs

™

™

• Scotch-Brite™ surface conditioning,

nonwoven web provides a burr-free

• Removes grind marks, rust and coatings

Scotch-Brite Roloc SL

Surface Conditioning Discs

™

™

™

™

• Lofty, open, nonwoven abrasive disc

• Resistant to loading on soft metals

Scotch-Brite Roloc SE

Surface Conditioning Discs

™

™

• A nonwoven abrasive product used

for heavy duty deburring, finishing

• Can last up to twice as long as other

and surface preparation

• Delivers outstanding value and

productivity improvements

8

Scotch-Brite Roloc PD

Surface Conditioning Discs

• Cuts fast without sacrificing finish

surface conditioning discs

SE and SL

LGB

Deburr

Deburr

Deburr

Grind

Grind

Grind

Clean

Clean

Clean

Refine

Refine

Refine

Finish

Finish

Finish

Better

Best

Good

and oily surfaces

decorative finish

PD and SC

• More durable than the standard surface

conditioning product and delivers higher

cut rate and longer life

Disc Sanders, Abrasives & Accessories

Scotch-Brite Roloc

Wheels have the

edge in deburring

™

™

Scotch-Brite Roloc EXL

Unitized Wheels

™

™

The

quick, consistent deburring and finishing

Difference

on a wide variety of metals

For 50 years, 3M has set the standard in nonwoven

• A nonwoven abrasive product that provides

• Delivers consistent finish throughout the

products, providing maximum performance, proven

value, greater selection – and continuous innovation

life of the product

to make even the most challenging finishing, blending

Scotch-Brite Roloc Discs are great

for cleaning and coating removal

and grinding tasks easier.

Scotch-Brite Roloc Bristle Discs

than Scotch-Brite™ products.

™

™

™

™

• The bristles are filled with Cubitron™

Today, no 3M technology better embodies these qualities

Only Scotch-Brite products:

™

Abrasive Grain used predominantly for

cleaning and coating removal applications

• Contains no wire filaments; eliminating

the hazards of loose wires

• Available in a wide range of grades

to meet various finish requirements

• Improve surfaces without significantly changing

workpiece shape or dimension

• Are equally well-suited for cleaning, blending,

deburring, finishing and polishing

• Help prevent undercutting or gouging, through

their controlled abrasive action

Scotch-Brite Roloc

Clean and Strip XT Discs

™

™

• The purple XT disc is an extra-coarse,

open-web disc for stripping, weld cleaning,

and rust and paint removal on all surfaces

• Higher durability and cut rate compared

• Provide consistent, uniform finishes because fresh

abrasive is continuously exposed to the work surface

• Run cool and resist loading with their open-web

construction, reducing the risk of part

discoloration and warping, while also

extending the life of the products

to coating removal disc

Scotch-Brite

Coating Removal Discs

™

• Silicon carbide – extra coarse

• Made for right-angle tools from aggressive

clean and strip web

• Nonloading design is ideal for removing

rust and coatings

9

Accessories

Choose the 3M™ Roloc™ Disc Pad for your specific application.

Tech Tip Recommended Disc Pad Starting Points by Application

Abrasive Type

Grinding

Blending & Deburring

Finishing

Polishing

Extra Hard

Hard

Medium

Medium

Hard

Hard

Medium

Medium

Unitized Wheels

Hard

Medium

Bristle Discs

Hard

Medium

Coated Abrasives

Nonwoven Abrasives

3M Roloc TR Disc Pads

™

™

• Rubber backup pads are available in different diameters

and degrees of hardness for various grinding applications

• Pads are internally threaded to receive any standard

1/4" – 20 thread shaft

Diameter

Cleaning

Hard

Hard

Max RPM

Hardness

UPC

(051144-)

Qty / Case

1/4" – 20 internal thread

1"

30,000

Medium

45101-2

Soft

45098-5

1 1/2"

30,000

Medium

45099-2

Hard

45100-5

Soft

45094-7

Medium

45095-4

Hard

45096-1

Extra Hard

45097-8

15,000

Soft

45090-9

18,000

Medium

45092-3

2"

3"

25,000

20,000

Hard

45091-6

Extra Hard

45093-0

5

Optional

1/4" Collet

1/4" x 1/4"-20

Threaded Shaft

#45102

3M™ Roloc™

Disc Pad

Direct mount to

disc pad shown here.

10

3M™ Roloc™

Disc Pad

3M™ Roloc™

Disc or Wheel

3M™ Roloc™

Disc or Wheel

1/4" Collet Mount

“Tall”

= For Hard To Reach Applications

= Allows More Accessory

& Abrasives Options

Direct Mount

“Short”*

= Low Profile

= Less Vibration

= Better Control

*Direct mount to disc pad.

Disc Sanders, Abrasives & Accessories

3M Roloc TS or TSM Disc Pads

™

™

Diameter

Max RPM

1 1/2"

30,000

2"

25,000

• For use with 3M™ Roloc™ TSM Discs

3M™ Roloc™ TS

3M™ Roloc™ TSM

3M Roloc TP Disc Pads

™

™

• For use with

3M™

Roloc™

Hardness

UPC

(051144-)

Medium

77729-7

Hard

77728-0

Medium

14211-8

Hard

14212-5

18,000

Medium

14215-6

20,000

Hard

14216-3

Diameter

Max RPM

Hardness

UPC

(051144-)

2"

25,000

3"

TP Discs

3"

Medium

14197-5

Hard

14198-2

18,000

Medium

14201-9

20,000

Hard

14202-6

Qty / Case

5

Qty / Case

5

3M Roloc + Holder

™

1/4" Threaded Shaft

™

• Plastic holder for use with

3M™ Roloc™ Unitized Wheels

• Needed with all 3M™ Roloc™ Disc Pads

Size

UPC (051144-)

Min / Case

L x Shaft Diameter

Max RPM

UPC (048011-)

Qty / Case

1/4" x 1/4" x 20 Thread

45102-9

10 / 50

1" x 1/4"

25,000

15408-4

5

11

Application Shot:

New cut-off wheel

tool with 3M

Roloc Disc metal

preparation.

™

3M Die Grinders

™

™

The 3M line of pneumatic die grinders is designed to

efficiently handle all your cylindrical polishing, buffing,

shaping and deburring needs. Grinders are packed with the

power to perform a variety of functions. Built-in comfort

innovations include 3M™ Greptile™ Gripping Material to help

reduce vibration for a more secure grip. And the adjustable

directional exhaust feature allows airflow to be directed

away in any direction preferred. Plus, 3M offers four

different RPM models for a wide variety of applications.

8,000 and 12,000 RPM

Die Grinder Models

20239, 20240

4

7

6

2

1

5

3

18,000

18,000

18,0

00 and

and 20,000

220,

0,00

0000 RPM

RPM

Diee Grinder

D

Di

G indder Models

Gr

M deels

Mo

20237, 20238

20238

Designed to be different

1• High-output air motor

2• Directional exhaust (360 degree)

3• 3M™ Greptile™ Grip

4• Safety lever throttle to avoid accidental starting

5• Double ball bearings on output spindle

6• Double-taper collet assembly

7• Offset gear box for increased torque

12

Max

RPM

Motor

HP (W)

Weight

Pound

(kg)

Length

Inch

(mm)

SCFM (LPM)

90

20,000

1 (744)

1.69 (.77)

7.75 (196.9)

20238

90

18,000

1 (744)

1.69 (.77)

20239

90

12,000

1 (744)

20240

90

8,000

1 (744)

Model

Number

PSI

20237

Airflow

Rate

Exhaust

Direction

Air Inlet

Thread

Collet Size

UPC Code

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20237-2

7.75 (196.9)

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20238-9

2.06 (.93)

10 (254)

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20239-6

2.06 (.93)

10 (254)

35 (991)

Rear Directional

1/4" NPT

1/4"

051141-20240-2

Die Grinders

3M Abrasives for Specialty Applications

™

The following chart will help you select the right abrasive for the job. Detailed information

about the abrasives shown in this chart are displayed on the following pages.

™

Scotch-Brite Flap Brushes – Cut & Polish

Clean & Finish

P80, P120, P180

AVFN, ACRS, AMED

36-80, P100-P150

A160-A6

Titanium

Available

Grades

Cast Iron

Nonferrous

Scotch-Brite Stars

Carbon Steel

Aluminum

Stainless Steel

Polishing

Cleaning

™

Finishing

Scotch-Brite Combi-S Wheels

METAL TYPE

Deburring

Blending

Specialty Abrasive

Light Grinding

APPLICATIONS

™

Scotch-Brite Clean & Strip

™

Scotch-Brite EXL Unitized Wheels

™

747D Flap Wheels

237AA Trizact Flap Wheels

™

241E / 244D / 244E Flap Wheels

AMED

ACRS, SFIN

SXCS

SMED, SVFN

AXCS-AFIN

241E – 50-320

244E/D – 60-120

241D Cartridge Rolls

P24-P400

237AA Cartridge Rolls

A160-A6

747D Cartridge Rolls

50-80, P100-P150

963G Cartridge Rolls

241D Square Pads

P24-P400

747D Square Pads

50-80, P100-P150

24-120

241D Cross Pads

P24-P400

747D Cross Pads

50-80, P100-P150

A160-A6

P24-P400

50-80, P100-P150

237AA Bands

241D Bands

747D Bands

963G Bands

Scotch-Brite Radial Bristle Discs

Scotch-Brite Cross Buffs

™

™

24-120

36-Polish

HS, AVFN

13

3M Flap Wheels

™

Flap wheels offer the benefit of a long-lasting supply of fresh

abrasives and load resistance for extended work without abrasive

changeovers and downtime. They also can work flat and contoured

areas equally well.

The 3M line offers mounted and unmounted products containing

3M™ Cubitron™ Abrasive Grain for more aggressive cut and durability,

as well as quality aluminum oxide products. And for final finishing,

nothing beats the consistency of 3M™ Trizact™ Abrasives.

For final finish & polishing

3M Trizact Flap Wheels 237AA

™

™

• Trizact™ Abrasives deliver extreme consistency in finishes

3M Flap Wheels 747D

™

• 3M™ Cubitron™ Abrasive Grain

blend on a resin-bonded X-weightt

• Aluminum oxide product constructed on an X-weight, durable

cloth backing

• Resin-bonded for heat resistance

• Features grinding aid for cooler grinding

cloth backing

• Includes a grinding aid for cooler

running on stainless steel

3M Flap Wheels 241E/244E

T83 – 1/4" Straight

™

• Aluminum oxide – XE-weight cloth

T84 – 1/4" x 20 Threaded

• General-purpose flap wheel delivers consistent

finish and uniform cut

3M™ Wheel Adaptor No. 81A

3M Wheel Adaptor No. 81A

™

For use with Type 81 and Type 84 PG Wheels. This adaptor has a

1/4" diameter shank and a 1/4" – 20 thread female acceptor end.

Size

Part Number

UPC (051144-)

Qty / Inner

Qty / Case

1/4"

45081

45081-7

1

1

Tech Tips

• To optimize wheel life, use light pressure, making sure only the tips of the flap wheel contact the metal surface.

• Use with a grinding paste to create a finer finish and extend wheel life.

• Be sure to lubricate your grinder daily for maximum performance.

14

Die Grinders, Abrasives & Accessories

3M Specialty Abrasives

Aluminum oxide for general purposes

3M Bands and Cartridge Rolls

3M Bands 241D

and Cartridge Rolls

™

™

™

The 3M line offers products containing 3M™ Cubitron™ Abrasive

• Aluminum oxide – X-weight cloth

Grain for more aggressive cut and durability, as well as quality

• General purpose evenrun bands

aluminum oxide products. For final finishing and extreme

consistency, select 3M™ Trizact™ Abrasive Bands and Cartridge

Rolls. Bands are excellent for producing a straight-line finish.

Cartridge rolls excel at getting to hard to reach places. They expose

Tech Tips

• Use bands to grind with the grain to restore or matchh a finish.

• Cartridge rolls are ideal for deburring internal edges of

stamped parts.

new layers of abrasives as they wear, for longer life and continued

sharp cutting. 3M™ Cartridge Rolls are available in regular and

full-taper design.

3M Bands and Cartridge Rolls 963G

™

• For aggressive cut

• Works on a variety of metals; ideal for carbon steel applications

• Cubitron™ Abrasive Grain abrasive product constructed on

a YN-weight

• Polyester cloth backing

For the finishing touch

3M Trizact Bands

and Cartridge Rolls 237AA

™

™

• Trizact™ Abrasives deliver extreme

consistency in finishes

• Aluminum oxide product constructed

on an X-weight, durable cloth backing

• Resin-bonded for heat resistance

• Resin-bonded for heat resistance

• Can be run wet or dry

• Features grinding aid for cooler grinding

3M Bands and

Cartridge Rolls 747D

™

• 3M™ Cubitron™ Abrasive Grain – X-weight cloth

• Resin-bonded cloth for heat resistance

• Features grinding aid for cooler running

15

Accessories for

3M Cartridge Rolls

Accessories

for 3M Bands

3M Mandrels

Rubber Slotted

Expander Wheels

™

™

™

• Screw-type mandrels for

securing cartridge rolls to tool

• Slotted wheels for use with bands

• Match pilot diameter with

center hole of cartridge rolls

Shank

Diameter

Pilot

Length

Pilot Diagram x Pilot Length x Shank

UPC (051144-)

1/8" x 1" x 1/4"

3/16" x 1" x 1/4"

45119-7

3/16" x 1 1/2" x 1/4"

45118-0

45117-3

Pilot

Diameter

Qty / Case

25

Max RPMS: 24,000 for 1/2" and smaller cartridge roll diameter

16,000 for 5/8" - 3/4" cartridge roll diameter

Diameter x W x Shaft

Max RPM

UPC (051144-)

1" x 1" x 1/4"

1 1/2" x 1" x 1/4"

18,000

77717-4

14,000

77718-1

2" x 1" x 1/4"

12,000

77720-4

Qty / Case

1

Rubber Cushion

Polishing Wheels

• Use with bands when

creating fine finishes

• Part numbers apply to complete

wheel, not cushions

16

Diameter x W x Shaft

Max RPM

UPC (051144-)

1/4" x 1/2" x 1/8"

1/2" x 1/2" x 1/4"

23,000

45159-3

30,000

45156-2

1/2" x 1" x 1/4"

1/2" x 1 1/2" x 1/4"

15,000

3/4" x 1" x 1/4"

Qty / Case

45153-1

45152-4

17,000

45145-6

3/4" x 1 1/2" x 1/4"

10,000

45144-9

1" x 1" x 1/4"

1" x 1 1/2" x 1/4"

18,000

45139-5

10,000

45138-8

1 1/2" x 1" x 1/4"

1 1/2" x 1 1/2" x 1/4"

14,000

45132-6

10,000

45131-9

1 1/2" x 2" x 1/4"

2" x 1" x 1/4"

8,000

45130-2

11,000

45129-6

10

5

Die Grinders, Abrasives & Accessories

3M Cross and Square Pads

™

Cross pads are used for close-tolerance polishing of small radii

and channels, deburring the ends and insides of tubing, and other

special applications. Square pads are ideal for fast grinding/

blending of channels, fillets, corners or spotting on flat surfaces.

As the square pads rotate, the corners exert a fast, biting action

and gradually wear down, exposing fresh abrasives.

The 3M line offers products containing 3M™ Cubitron™ Abrasive

Grain for more aggressive cut and durability (like the 747D),

as well as quality aluminum oxide products (like the 241D).

RPM Ratings for Cross and Square Pads

3M Cross and Square Pads 747D

™

• Made with Cubitron™ Abrasive Grain

Square Pad Size

Eyelet

Max RPM

2" x 2"

2 1/2" x 2 1/2"

1/4" – 20

1/4" – 20

12,000

10,000

3" x 3"

1/4" – 20

9,000

Cross Pad Size

Eyelet

Max RPM

Less than 2"

8 – 32

24,000

2"

8 – 32

18,000

2"

1/4" – 20

1/4" – 20

20,000

1/4" – 20

1/4" – 20

15,000

1/4" – 20

1/4" – 20

10,000

• Includes grinding aid for cool running on stainless steel,

titanium and other heat-sensitive metals

• X-weight, durable cloth backing

• Grades: 36-P150

3"

1

3 /2"

4" and 4 1/2"

3M Cross and Square Pads 241D

™

• Made with aluminum oxide mineral

• Constructed on an X-weight, durable cloth backing

5"

• Grades: P24-P400

6"

18,000

12,000

9,000

3M Cross and Square Pad Mandrels

™

Used for holding Square Pads

and Cross Pads with 1/4" – 20 and

8 – 32 internal threaded inserts.

UPC (051144-)

Description

14308-5

1/4" – 20 External Thread

14307-8

8 – 32 External Thread

Qty / Case

1

17

Scotch-Brite

Specialty Products

™

Scotch-Brite Flap Brush

CPFB-S and CPFB-R

™

• Heavy-duty brush

• Excellent for removing handling marks

and surface imperfections

• Available on 1/4" shaft (CPFB-S) or

3M™ Roloc™ + attachment system (CPFB-R)

Scotch-Brite Flap Brush

CFFB-S and CFFB-R

™

• Ideal for decorative finishes and light

deburring applications

• Available on 1/4" shaft (CFFB-S) or

3M™ Roloc™ + attachment system (CFFB-R)

Scotch-Brite Combi Wheel,

Combi-S

™

• Made of alternating flaps of coated

Scotch-Brite

EXL Unitized Deburring Wheels

™

abrasive and Scotch-Brite™ web

• Provides aggressive cut and fine finishes

• Excellent for deburring and polishing a wide range

of metals, plastics and composites

Scotch-Brite Clean and

Strip Discs CSD2-S

™

• Cool running allows more pressure to be applied

• Cleaner than buffs and compounds

• Aggressive web is excellent for

cleaning welds, rust, paint

No. 936

and coatings

No. 990

Mandrels

• Designed for use with Scotch-Brite™ Unitized Wheels

Length x Shank Dia. x

Flange Dia.

Max RPM

UPC (048011-)

Qty / Case

2 1/16" x 1/4" x 3/4"

22,200

04018-9

5

Length x Shank Dia.

Max RPM

UPC (048011-)

Qty / Case

15012-3

5

Mandrel No. 936

Mandrel No. 990 – with 3" wheel

1 3/4" x 1/4"

18

18,200

FEATURED PRODUCT

New

Scotch-Brite Cross Buffs

™

Scotch-Brite™ Cross Buffs are used for deburring, cleaning, finishing,

edgework and polishing of internal diameters on parts requiring a

high-luster finish. Durable design is ideal for use with hand and power

Scotch-Brite Stars

™

tools on valves, fittings, tubing, dies and more.

• Perfect for polishing internal diameters of pipe and tubing

• Conformable Scotch-Brite™ construction assures complete

cleaning and polishing of all surfaces

Cleaning

• Easy to use and quick change as a

surface oxidation remover

Mandrel No. 944

• Ideal for surface preparation prior to coating

Scotch-Brite™

• Use in conjunction with

Stars for cleaning and

• Recommended for removing surface

coatings for part inspections

polishing internal diameters of pipe and tubing

Shank x Thread

Max RPM

UPC (048011-)

Qty / Case

1/4" x 1/4" – 20 EXT

25,100

13928-9

10

• Good at removing corrosion on dies

Polishing

• Withstands heavy edge work to produce

For final finishes

Scotch-Brite Radial Bristle Discs, 3"

™

• Create a uniform finish even around protrusions, detail

grooves, patterns, and other hard-to-reach areas

• Works fast and offers long life compared to traditional

abrasive products

• Available grade equivalents: 80-1 micron

smooth polishing on parts, such as round

and square tubing and valve spools

• Provides a buff mold and die polish

• Shaped for polishing and honing inside

diameters of lifter bores, valve bodies

and brake cylinders

• Flexible design allows the buffs to

conform to the part, yet maintain

critical tolerances

Mandrels

UPC (048011-)

3M Mandrel

For making a brush

15012-8

No. 990

1/8" – 1/2" wide

™

Available Sizes: 1", 1 1/2" and 2"

Use with 3M™ Cross and Square Pad Mandrel Part No. 14307.

19

Die Grinders, Abrasives & Accessories

Mini Mandrel No. 935

• Use with desired Scotch-Brite™

strips to clean and polish inner

diameters and other tight areas

• Has 1/4" shank to fit desired tool

Length x Shank Dia.

Max RPM

UPC (048011-)

Qty / Case

2-7/8" x 1/4"

14,000

04020-2

5

L x Slot Width x Slot Length x Shaft

haft Dia.

UPC (051144-)

Qty / Case

3" x 1/16" x 3/4" x 1/4"

45121

45121-00

10

3M Forked Spindle

ndle

™

Scotch-Brite Cut & Polish Rolls

™

• A unique and aggressive material for cleaning and finishing

• Sturdy, long-lasting web material is great for heavy industrial

cleaning and light deburring applications

3M Portable Utility Roll 314D

™

• Portable for ease of use at jobsite

• Protective plastic pack resists dirt, oil, water and

serves as a convenient dispenser

• Aluminum oxide abrasive product sheets constructed

on X- or J-weight, durable cloth backing

20

New

3M Cut-Off Wheel Tools

™

Designed to easily handle cutting through everything

from standard rebar to oversized bolts, you can count

on the performance and dependability of the new line

of 3M™ Cut-Off Wheel Tools. Their compact design and

built-in safety features make these the tools of choice

for any job. 3M™ Greptile™ Gripping Technology reduces

vibration and provides a secure grip that can be held with

less effort. And the adjustable directional exhaust

feature works the way you want it to.

5" and 6" Cut-Off Wheel Tool Models

4

20235, 20236

7

2

1

6

3

5

8

8

3" and 4"

Cut-Off Wheel

Tool Models

20233, 20234

Designed to be different

1• High-output air motor

6• Robust spiral bevel gearing

2• Directional exhaust (360 degrees)

7• 4-place indexable head

3• 3M™ Greptile™ Grip

8• 360 degree rotatable safety guard

4• Safety lever throttle to avoid accidental starting

5• Over-sized ball bearings on output spindle

Model

Number

Tool Dia.

Inch

(mm)

PSI

Max

RPM

Motor

HP (W)

Weight

Pound

(kg)

Length

Inch

(mm)

Height

Inch

(mm)

20233

3" (76)

20234

Airflow

Rate

SCFM (LPM)

90

25,000

1 (744)

2.09 (.95)

7.75 (196.9)

3 (76.2)

4" (100)

90

20,000

1 (744)

2.25 (1.02)

7.75 (196.9)

20235

5" (125)

90

12,000

1 (744)

3.47 (1.57)

20236

6" (152)

90

10,000

1 (744)

3.69 (1.67)

Exhaust

Direction

Air Inlet

Thread

UPC Code

35 (991)

Rear Directional

1/4" NPT

051141-20233-4

3.25 (82.6)

35 (991)

Rear Directional

3/8" NPT

051141-20234-1

8.75 (222.3)

5.25 (133.4)

35 (991)

Rear Directional

3/8" NPT

051141-20235-8

8.75 (222.3)

5.25 (133.4)

35 (991)

Rear Directional

3/8" NPT

051141-20236-5

21

Systems for Cutting

You want the right system for cutting tube, pipe and sheet metal,

or for removing gates, risers and more. Fast, smooth and cool

cuts can make the job easier and safer.

3M offers tools and wheels with the power to perform. For fast

cuts, cooler running and longer wheel life, select a wheel containing

3M™ Cubitron™ Abrasive Grain. Cubitron™ Grain, combined with

3M’s 1-horsepower tools, can quickly cut through carbon steel,

stainless steel and other materials.

For reliable performance in general purpose applications,

use 3M™ General Purpose Cut-Off Wheels.

3M Cubitron Abrasive Grain

™

™

This innovative abrasive grain is one

of the hardest, longest-lasting

minerals available. Perfect for

moderate to heavy stock removal,

it’s engineered to cut fast and handle

intense heat and stress applications.

It’s ideal for use with stainless steel.

Compared to others, our product design can help:

• Eliminate process steps

• Improve cut-rate consistency

• Produce finer finishes

3M Cut-Off Wheels

Best Life

Sizes

with 3M™ Cubitron™ Abrasive Grain

•

2", 3", 4",

4 1/2", 5", 6"

™

with Aluminum oxide (General Purpose)

4", 6"

Tech Tips

• For greatest cutting efficiency, run the tool at the Max RPM of the

abrasive wheel being used. NOTE: Tool RPM and abrasive RPM mayy

not be the same. Never exceed the Max RPM of the abrasive wheel

being run.

• Never run cut-off wheels on tools without guards.

22

• Reduce cost per part

• Extend disc life

Technical Recommendations

for 3M Air-Powered Tools

™

• Use a clean, dry, lubricated air supply that will give a measured

air pressure at the tool of 6.2 bar (90 psig) when the tool is

running with the lever fully depressed.

• Use an approved 10 mm (3/8") or 13 mm (1/2") x 8 m (25')

maximum length air line.

• Connect the tool to the air supply as shown in Figure 1.

• It is strongly recommended that an air filter, regulator and

lubricator (FRL) be used as shown in Figure 1, to supply clean,

lubricated air at the correct pressure to the tool. If such

equipment is not used, the tool should be manually lubricated.

To manually lubricate the tool:

• Disconnect the air line and put 2 to 3 drops of suitable

pneumatic motor lubricating oil, such as 3M™ Air Tool

Lubricant 20451, into the hose end (inlet) of the tool.

• Reconnect tool to the air supply and run tool for a

few seconds to allow air to circulate the oil.

• Lubricate daily if the tool is used frequently or if

the tool starts to slow or lose power.

• Tools can be run at lower pressures, but should never

be run higher than 6.2 bar (90 psig). If run at a lower

pressure the performance of the tool is reduced.

Recommended Air Line Diameter:

10 mm

13 mm

Minimum: 3/8"

Minimum: 1/2”

Recommended Maximum Hose Length:

8 meters

25'

Air Pressure

Maximum Working Pressure: 6.2 bar 90 psig

3M Air Tool Lubricant

™

Used to keep pneumatic air tools running efficiently. Use 2-3 drops

ops

at the end of each day, or as needed, to maintain tool performance.

ce.

Part #

20451

Size

4 fl. oz. / 188 ml

UPC

051141-20451-2

23

For more information visit our website

http://www.3M.com/Metalworking

For warranty and

repair service, call

1-800-362-3550.

Product Use: All statements, technical information and recommendations contained in this document are based upon tests or experience that 3M believes

are reliable. However, many factors beyond 3M’s control can affect the use and performance of a 3M product in a particular application, including the

conditions under which the 3M product is used and the time and environmental conditions in which the product is expected to perform. Since these factors

are uniquely within the user’s knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit for a particular

purpose and suitable for the user’s method of application.

Warranty and Limited Remedy: 3M warrants this tool against defects in workmanship and materials under normal operating conditions for one (1) year

from the date of purchase. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, CUSTOM

OR USAGE OF TRADE. User is responsible for determining whether the 3M tool is fit for a particular purpose and suitable for user’s application. User

must operate the tool in accordance with all applicable operating instructions, safety precautions, and other procedures stated in the operating manual

to be entitled to warranty coverage. 3M shall have no obligation to repair or replace any tool or part that fails due to normal wear, inadequate or improper

maintenance, inadequate cleaning, non-lubrication, improper operating environment, improper utilities, operator error or misuse, alteration or modification,

mishandling, lack of reasonable care, or due to any accidental cause. If a tool or any part thereof is defective within this warranty period, your exclusive

remedy and 3M’s sole obligation will be, at 3M’s option, to repair or replace the tool or refund the purchase price.

Limitation of Liability: Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising from the 3M product, whether

direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.

3M, Cubitron, Green Corps, Greptile,

Roloc, Scotch-Brite and Trizact are

trademarks of 3M.

Abrasive Systems Division

3M Center

Building 223-6N-01

St. Paul, MN 55144-1000

www.3M.com/Abrasives

Please recycle. Printed in U.S.A.

Blgr. 8070123

© 3M 2008. All rights reserved.

61-5002-8217-5