Iodine Chemistry (OIC)

advertisement

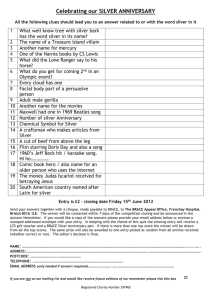

IODINE CHEMISTRY S DICKINSON1, H E SIMS1, E BELVAL-HALTIER2, D JACQUEMAIN 2, C POLETIKO2, F FUNKE3, Y DROSSINOS4, E KRAUSMANN4, B HERRERO5, T ROUTAMO 6 and B J HANDY7 1 AEA Technology plc, Winfrith, Dorchester, Dorset GB-DT2 8DH, UK 2 CEA/IPSN, CE Cadarache, FR-13108 Saint Paul lez Durance, France 3 Siemens AG KWU, Freyeslebenstrasse 1, PO Box 3220, DE-91050 Erlangen, Germany 4 CEC/JRC Institute for Systems, Informatics and Safety, IT-21020 Ispra, Italy 5 Instituto de Technologia Nuclear, Avenida Complutense 22, ES-28040 Madrid, Spain 6 IVO Power Engineering Ltd, Rajatorpantie 8, Vantaa, FI-01019, Finland 7 NNC Ltd, Booths Hall, Chelford Road, Knutsford, GB-WA16 8QZ, Cheshire, UK SUMMARY A shared-cost action on Iodine Chemistry has been completed as part of the CEC 4th Framework programme on Nuclear Fission Safety. Organisations from six EC countries are involved in an integrated programme of experiments and analysis focused on understanding and quantifying the effects of silver on iodine behaviour. This work has provided new experimental data which will be used to validate and improve the existing models and to stimulate code development. In summary, this programme has provided extensive experimental kinetic data on the reaction of aqueous iodine with silver surfaces. Experiments have shown that the volatility of iodine from irradiated iodide solutions is greatly reduced in the presence of excess silver, and that this can be understood in terms of the thermal reactions of I2 with the silver surface. Moreover, the AgI product appears stable to irradiation at the dose rates studied. The experimental data have been used to formulate kinetic models, which have been incorporated into iodine chemistry codes and used in a source term evaluation. These calculations have shown that reaction with silver has significant potential to reduce the formation of volatile iodine under some severe reactor accident conditions. The effect of this reduction on the predicted release of iodine to the environment depends strongly on the sequence being considered. The presence of silver has the greatest potential impact under conditions of low pool pH and high Ag / I ratio. A. INTRODUCTION Iodine is one of the most important fission products which would be released in the event of a severe reactor accident. Plant assessments have shown that it contributes significantly to the source term for a range of accident scenarios. However, the considerable differences between the iodine behaviour observed in Phebus Test FPT0 and that predicted by containment chemistry calculations indicate that the current models do not correctly treat all of the phenomena that could be important in a reactor accident [1,2]. In particular, the presence of a large quantity of silver aerosol appears to influence very strongly the volatility of iodine from solution. It is assumed that iodine released from the fuel in a severe accident would be transported to the containment primarily in the form of iodide. This would dissolve in containment water pools to give involatile I-, which could then be oxidised under irradiation to volatile I2 . Reaction of either I- or I2 with silver to form insoluble AgI would substantially lower the amount of I2 formation, which could have important consequences for active and passive safety measures and for accident management strategies. The shared-cost action F14S-CT95-0005 was a two-year programme which started in January 1996 and was completed on 31 December 1997. The project was focussed on understanding and quantifying the effects of silver on iodine behaviour, and providing new experimental data that will be used to validate and improve the existing models and to stimulate code development. B. WORK PROGRAMME The work programme was divided into three activities: Activity 1, Experimental Studies; Activity 2, Assessment, Analysis and Model Development; and Activity 3, Source Term Evaluation. Activity 1 Experimental Studies This activity comprised three experimental programmes whose objective was to provide new data on the reaction of aqueous iodine with silver under accident-relevant conditions. The two main questions being addressed in this work were: (i) How quickly are I- and I2 removed from solution by reaction with silver surfaces? and (ii) Is the AgI formed in these reactions stable under irradiation? This activity was divided into the four tasks described below. Task 1.0: Definition of the experimental requirements, and in particular the range of conditions and variables to be studied, based on the findings of the literature survey (Task 2.1) and results from the Phebus-FP programme. Task 1.1: Non-irradiated experiments to measure the rate of uptake of aqueous iodine (I2 or I-) onto silver surfaces in the absence of radiation, in order to provide detailed kinetic data to supplement and extend the existing database and to clarify anomalies in previous work. The main focus of this work was initially to investigate the effects of impurities on the reaction rates. As the work progressed the different behaviour of different types of surface became evident and additional tests were performed to clarify these observations. Task 1.2: Experimental studies on the possible effects of irradiation on the silver - iodine reaction. The radiolytic formation of nitric acid in irradiated air-water mixtures could lead to the production of Ag+, which could react directly with I- ions in solution. One of the objectives of this task was therefore to provide experimental data on the rate of HNO3 production at elevated temperature. The other objective was to quantify the effect of silver on the volatility of iodine from irradiated solution, and in particular to assess whether the AgI formed is stable to irradiation. Task 1.3: High-temperature radiolysis experiments. Results from Phebus test FPT0 indicated that silver could be partially present in the sump as a colloidal suspension together with soluble silver. In this task, therefore, the stability of colloidal AgI species is studied under conditions relevant to a severe accident, to quantify the effects of temperature, radiation and Ag+ concentration on the decomposition of silver iodide. Activity 2: Assessment, Analysis and Model Development The overall objective of this activity was to assess both new and existing experimental data on iodine interactions with silver, and to develop a suitable model for incorporation into different iodine chemistry codes. This activity was divided into the following three tasks: Task 2.1: Literature review on the heterogeneous reactions of aqueous I- and I2 with silver surfaces, with particular emphasis on kinetic data, in order to identify remaining uncertainties and gaps where further research is required. Task 2.2: Analysis of new data from the project, together with existing data from previous programmes, with the objective of establishing the reaction mechanism and identifying the ratedetermining process and appropriate rate constants. Task 2.3: Development of a kinetic model describing the reaction of iodine with silver under conditions relevant to a PWR severe accident. This has been implemented in four different iodine chemistry codes (INSPECT, IODE, IMPAIR and ACT-WATCH) in such a way that the models used in the different codes are consistent and functionally equivalent. Activity 3: Source Term Evaluation The experimental work and model developments in the area of iodine chemistry have been assessed in terms of those accident sequences which are important in the overall risk assessment of a nuclear plant. This activity reviewed the implications of the work described above in terms of riskdominant sequences identified in probabilistic safety assessment studies for commercial reactor plants. This involved generic plant calculations to assess the impact of the model developments on reactor source term calculations. C. MAIN ACHIEVEMENTS C.1 Experimental programmes Several programmes of experiments were carried out to provide fundamental data for modelling the iodine – silver reaction, and to study specific effects of irradiation on the reaction. C.1.1I2 - Silver Reaction Kinetics Experiments have been performed to study the kinetics of reaction of I2 in solution with silver surfaces, and in particular to study the effects of representative impurities ( N O −3 , Cl-). The measured first order rate constants are plotted against the silver surface / liquid volume ratio [Ag] in Figure 1. This also shows the best-fit lines for the unstirred and fast-stirred experiments at 25 and 50°C. The gradient of the regression line gives the pseudo-first order rate constant, or deposition velocity, kd, which is defined by − d [I 2 ] = k d [I 2 ][Ag ] dt The figure shows a strong effect of stirring on the reaction rate, implying that the reaction is mass-transfer limited, at least in the unstirred or less rapidly-stirred experiments. The difference between the rate constant at 25 and 50°C is quite small; the higher rate of iodine loss from the solution at the higher temperature is mainly due to evaporation, as shown by the experiments with no silver present. The closed diamonds represent tests with various additives; these do not differ significantly from the other fast-stirred results. A comparison of the Ag - I2 results with earlier data produced by Siemens [3] shows that the measured reaction rate is somewhat higher in the more recent tests. Since the reaction is masstransfer limited, this difference can be attributed to differences between the two experimental facilities. The apparent decrease in the reaction rate with time which was observed in the Siemens tests probably arises from a combination of effects such as particle agglomeration and carry-over, which were avoided in the new work by the use of a silver mesh in place of powder. 0.020 0.018 0.016 0.014 no stirring kd = 1.8E-5 m/s slow medium fast kd = 1.3E-4 m/s 50°C, fast kd = 1.7E-4 m/s various k s -1 0.012 0.010 0.008 0.006 0.004 0.002 0.000 0 50 100 150 200 250 300 350 -1 [Ag] m Figure 1: I2 - Ag Reaction Kinetics C.1.2 I- - Silver Reaction Kinetics An experimental study of the kinetics of the Ag - I- reaction showed that the reaction of I- with silver mesh is considerably slower than that of I2 , with pseudo-first order rate constants of 10-8 to 106 m s-1 being observed at 25°C. The reaction rate was slightly higher at 90°C and showed a fairly weak dependence on pH. The rate was not affected by the presence of 0.01 M concentrations of chloride or nitrate ions at 90°C and pH ~ 5. However, a significant effect of nitrate was observed at low pH. This difference may be due to the oxidation of the silver by the nitric acid; however, oxidation of I- to I2 would also increase the reaction rate. The decrease in I- concentration with time measured in these tests could be fitted equally well by a linear (zero-order rate law) or exponential (first-order rate law) correlation. However, the rate constant was found to be dependent on the initial I- concentration indicating that a zero order rate law is more appropriate. This could be explained by a two stage reaction involving, for example, an initial, rate-limiting, surface oxidation step followed by rapid reaction of iodide with the product. The tests using silver powders showed an initially rapid reaction when the silver was added to the iodide solutions, which was not observed in the tests with silver mesh. This was attributed to different degrees of surface oxidation of the silver powders. Further evidence for the role of surface oxidation is provided by the tests in which silver mesh was immersed in a boric acid solution for 1 or 2 days before adding the iodide; the observed behaviour then resembled the powder tests with an initially rapid removal of I- from the solution. Furthermore, in some high-temperature experiments in which the silver was not fully submerged in the solution, unexpectedly fast reaction rates were observed. This is thought to have been due to enhanced oxidation of the exposed silver in the steam - air above the solution. Earlier work by Siemens [3] has already established the importance of oxygen to the Ag - Ireaction, and the differences between the two sets of tests are probably due to the differing degrees of surface oxidation on the different types of silver used. In the one case where the same type of silver was used in the two programmes, the results were almost identical. C.2 Task 1.2: Radiation Effects C.2.1 Nitric Acid Formation In this task, the work in the literature on radiolytic production of nitric acid has been reviewed and an experimental programme on the effects of temperature and silver surfaces on nitric acid production has been carried out. The temperature and humidity in the containment during a LOCA would be somewhat higher than used in most studies of radiolytic formation of HNO3 and no systematic measurement of the effect of temperature on nitric acid formation in air in contact with liquid water has been reported. The measured nitric acid yields are shown in Figure 2. The solid line shows the yield for a G value of 2.2 molecules HNO3/100 eV. The total amount of nitrate formed in the solution was proportional to the volume of gas in the vial and independent of the liquid volume, confirming that HNO3 is formed mainly by a gas-phase process.. There was no observable effect of increasing temperature from 25°C to 90°C on the yield of HNO3. In tests where silver metal was present, silver was found to be dissolved at a similar concentration to the nitrate. 1.E-04 9.E-05 8.E-05 [NO3-] / mol dm-3 7.E-05 6.E-05 5.E-05 4.E-05 3.E-05 25°C 90°C 2.E-05 Ag1 Ag2 G = 2.2 1.E-05 0.E+00 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 Dose / MRad Figure 2: Nitric Acid Production in Irradiated Air-Water Mixtures C.2.2 Iodine Volatility from Irradiated Solutions In this task, the effect of silver on the radiation chemistry of aqueous CsI has been studied. The experiments showed that the iodine volatility from irradiated solutions was significantly lower in the presence of silver. Simulation of these tests with the INSPECT model showed that the results were consistent with the radiolytically-produced I2 reacting with the silver surface at a mass-transfer controlled rate. The iodine volatility was therefore determined by the competition of this surface reaction with other removal mechanisms. The effect of including the I- reaction was minimal, even at pH 7. When a sample of silver with a surface coating of AgI was placed in a fresh solution of boric acid, irradiated and sparged, less than 3% of the absorbed iodine was released in 64 hours of irradiation (total dose 96 kGy). This is consistent the trace solubility of AgI and indicates that there was no radiolytic decomposition of AgI under these conditions. C.3 Task 1.3: High-Temperature Radiolysis A series of bench-scale experiments was performed in order to study the stability of colloidal AgI species in solution under conditions relevant to a severe reactor accident. Initial tests showed that AgI colloids can be considered as stable species in solution at 80°C in the absence of radiation. Irradiated tests showed that the amount of AgI decomposition increased with temperature, from ~ 0.3% at 60°C to ~ 3% at 110°C. There appears to be no effect of the initial form of the iodine (I- or I2 ) in solution or of the addition of Ag+, as shown in Figure 3. 3 % iodine deposited on the paint I2, no Ag+ I2, 10ppm Ag+ 2.5 I-, no Ag+ I-, 10ppm Ag+ 2 1.5 1 0.5 0 40 50 60 70 80 90 100 110 120 Temperature °C Figure 3: Stability of AgI Colloid under Irradiation C.4 Data Analysis and Model Development The kinetic data obtained in the experiments described above, together with data from Funke [3], have been analysed with the objective of establishing an appropriate model and rate constants for the reactions of I2 and I- with silver surfaces. The experimental results indicate that the reaction of I2 with silver surfaces is limited by the rate of mass transfer of I2 in the liquid phase. Slower rates observed in the earlier tests [3] can be attributed to different mass transfer conditions in the early phase, and to agglomeration and/or colloidal AgI production in the later phase. This reaction can thus be described by d[I 2 ] dt = − k 1 [I 2 ]aq S Ag Vl where 1 1 1 = + k 1 k m k r [ Ag] (7) in which km is the mass transfer coefficient, kr = 2×10-4 m4 mol-1 s-1 and [Ag] is the silver concentration in mol m-3. Since under almost all conditions the reaction with Ag will be very rapid, kr[Ag] >> km, so (7) becomes: S d[I 2 ] = −k m [I 2 ]aq Ag dt Vl (3) The importance of O2 on the reaction of I- with silver was demonstrated by the Siemens tests [3], and differences between the results of the two programmes can be attributed to differing degrees of oxidation of the starting materials. If an oxide layer is initially present on the surface, the uptake of I- is limited by the I- mass transfer in the liquid phase. Once the oxide layer has been consumed, the reaction proceeds much more slowly, probably via a rate-determining oxidation step. This can be expressed simplistically as Ag + O2 → Agox (slow) H+ Agox + I- → AgI + H2O (fast) The rate of I- uptake can thus be described by: [ ] = − d[AgI ] = − k d I− dt dt S Ag 1 Vl [I ] 1 1 1 = + k 1 k m k o [ Ag ox ] − where (8) in which km is the mass transfer coefficient, and ko has a value of about 2×10-3 m4 mol- 1 s-1. The oxide concentration [Agox] is given by d[ Ag ox ] dt = k ox [ Ag] − d[ AgI] dt where kox = ks Sm (9) In the above equations, ks is the rate of oxidation per unit surface area (eg in mol dm-2 s-1), and Sm is the specific surface of the silver (in dm2 mol-1). The value of ks in these tests was (9 ± 4)×10-11 mol dm-2 s-1 at room temperature, with no clear pH dependence. At 90°C ks increased to (2.4 ± 0.7)×10-10 mol dm-2 s-1 at pH 4.6 and (6 ± 1)×10-11 mol dm-2 s-1 at pH 7. This reaction can be neglected at pH > 7 and under conditions where the dissolved O2 concentration is close to zero. This model gives reasonable agreement with the experimental data for a range of I- and Ag concentrations. However it should be noted that the rate of iodine uptake is very sensitive to the initial degree of oxidation of the silver surface, and to the value of kox, both of which are largely unknown under containment conditions. C.5 Source Term Evaluation The objective of this part of the work was to assess the importance of the Ag – I reactions in terms of those accident sequences which are important in the overall risk assessment of a nuclear plant. This involved generic plant calculations to determine the impact of the model developments on the calculated reactor source term for risk-dominant sequences identified in probabilistic safety assessment studies for commercial reactor plants, similar to those described previously by Dutton [4]. Calculations were performed using the INSPECT, IMPAIR and ACT-WATCH codes. Calculations were made for three severe accident sequences: (i) a large break LOCA into the reactor building, (ii) a large break in the residual heat removal system (RHRS) at intermediate shutdown, and (iii) a steam generator tube rupture (SGTR). The input data included design details for the reactor plant and descriptions of the fault progression, thermal-hydraulic and fission product behaviour as predicted by MAAP 3.0B. The main parameters of the work were the Ag particle size, and the inclusion (or not) of the reaction I- with Ag in addition to the I2 reaction. In cases where the I- reaction was important, the degree of oxidation assumed for the silver particles was an important parameter. The results showed that the impact of silver - iodine reaction modelling on the predicted iodine releases to the environment is very sequence-dependent. In the LOCA cases, the predicted releases are low and dominated by aerosol, so although the inclusion of a silver model can strongly influence the chemical behaviour of the iodine, the resulting changes in volatile iodine production do not substantially change the overall release. In contrast, the predicted releases from the auxiliary building and SGTR faults are dominated by gaseous species due to the relatively low pHs and high gas flow rates through the water pools. In these cases there is more sensitivity to the modelling used, both in terms of differences between the models and of the assumptions made in the silver - iodine modelling (particularly the mass transfer rates and particle sizes). However, silver was generally found to have little effect on the iodine release in the SGTR case, largely because of the fairly low Ag / I ratio (~ 1, compared with ~40 in the auxiliary building sequence). D. INTERACTIONS WITH OTHER ACTIVITIES The results of this work will be particularly important for the interpretation of the Phebus-FP tests. The results of the first two tests have shown that the containment iodine chemistry is dominated by the formation of a stable, insoluble compound, which is almost certainly AgI. The new data from this programme has been applied to the modelling of test FPT1, for example via the PHEBEN programme. E. CONCLUSIONS AND BENEFITS The 2-year shared-cost action on Iodine Chemistry began on 1 January 1996 and was completed on 31 December 1997. The main findings are as follows: • The rates of reaction of I2 and I- with silver surfaces have been measured in the absence of irradiation. The I2 reaction is very fast and can be treated as mass-transfer limited. The Ireaction with silver mesh surfaces is much slower and follows pseudo-zero-order kinetics under the conditions of these studies. Test with silver powders showed much higher initial reaction rates and this is attributed to differences in the extent of surface oxidation of the starting materials. The presence of chloride and nitrate impurities has little or no effect on the reaction rates. • The G-value for nitric acid production in air-water mixtures has been measured over the temperature range 25 to 90°C and confirmed to be in the order of 2, with no effect of temperature or steam pressure. These tests have demonstrated that the formation occurs principally by a gas phase process. The G value appears slightly higher when silver is present in contact with the gas phase. • The volatility of iodine from irradiated CsI solutions is greatly reduced when a silver surface is present. Good agreement is obtained between these test results and INSPECT simulations using rate constants derived from the non-irradiated studies. Very little volatile iodine is produced after reaction with the silver surface. There is no evidence for substantial radiolytic decomposition of the AgI under the dose rates used in this work. • Colloidal AgI species in solution are also found to be largely stable under irradiation. The amount of volatile iodine production increases slightly with temperature, but no effect of pH or Ag+ are observed. • Models have been developed to describe the uptake of I2 and I- onto silver surfaces. The effect of this modelling on the calculated source term for three representative accident sequences has been investigated using the INSPECT, IMPAIR and ACT-WATCH codes. This evaluation has shown that the reaction has significant potential to reduce the formation of volatile iodine under some severe reactor accident conditions. The effect of this reduction on the predicted release of iodine to the environment depends strongly on the sequence being considered. The presence of silver has the greatest potential impact under conditions of low pool pH and high Ag / I ratio. The results of the work will be used by all the partners to aid in the validation of severe accident computer codes, and thus reduce the uncertainties associated with determining the consequences of such accidents. Where the utilities and regulatory bodies within the European Union make use of plant safety (PSA) codes in which the treatment of source term behaviour is simplified, a key aspect of the exploitation of this work undertaken within each organisation will be the "benchmarking" of the relevant PSA codes against the more detailed modelling methods developed through this work. References [1] Phebus-FPT0 Preliminary Report, NT IPSN/DRS/SEA/LERES 9/94 (1994). [2] C A Chuaqui, C Hueber, D Jacquemain and C Poletiko, “The role of silver in containment chemistry”, NT IPSN/DRS/SEMAR 95/31 (1995). [3] F Funke et al, 4th CSNI Workshop on the Chemistry of Iodine in Reactor Safety, Würenlingen, June 1996, NEA/CSNI/R(96)6 (1996). [4] Dutton, L.M.C., Grindon, E., Handy, B.J., Sutherland, L., Burns, W.G., Dickinson, S., Sims, H.E., Hueber, C., and Jacqumain, D., 1996. 4th CSNI Workshop on the Chemistry of Iodine in Reactor Safety, Würenlingen, June 1996, NEA/CSNI/R(96)6, 615-634.