OPERATING INSTRUCTIONS for the PW4000 SERIES COMMERCIAL TURBOFAN

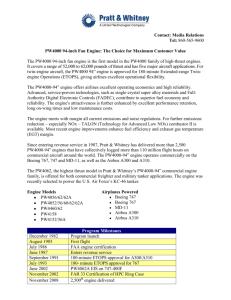

advertisement