MSP-FET430 Flash Emulation Tool (FET

advertisement

MSP-FET430 Flash Emulation Tool (FET)

(for Use With Code Composer Essentials for

MSP430 Version 3.1)

User's Guide

Literature Number: SLAU157I

May 2005 – Revised February 2009

2

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Contents

Preface ............................................................................................................................... 7

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

...................................................................................................... 11

Flash Emulation Tool (FET) Overview................................................................................... 12

Kit Contents, MSP-FET430PIF ........................................................................................... 12

Kit Contents, eZ430-F2013 ............................................................................................... 12

Kit Contents, eZ430-T2012 ............................................................................................... 12

Kit Contents, eZ430-F2500 ............................................................................................... 13

Kit Contents, MSP-FET430UIF ........................................................................................... 13

Kit Contents, MSP-FET430Uxx ('U14, 'U28, 'U38, 'U23x0, 'U48, 'U64, 'U80, 'U100, 'U100A, 'U5x100) ....... 13

Kit Contents, MSP-TS430xx ('PM64, 'PZ100A, 'PZ5x100) ........................................................... 14

Software Installation ....................................................................................................... 16

Hardware Installation, MSP-FET430PIF ................................................................................ 16

Hardware Installation, MSP-FET430UIF ................................................................................ 16

Hardware Installation, eZ430-F2013, eZ430-RF2500 ................................................................. 17

Get Started Now!

1.13

Hardware Installation, MSP-FET430Uxx ('U14, 'U28, 'U38, 'U23x0, 'U48, 'U64, 'U80, 'U100, 'U100A,

'U5x100) and MSP-TS430xxx ('PM64, 'PZ100A, 'PZ5x100) ......................................................... 17

1.14

Flashing the LED ........................................................................................................... 17

1.15

Important MSP430 Documents on the CD-ROM and Web ........................................................... 18

2

.................................................................................................... 19

Using Code Composer Essentials (CCE) ............................................................................... 20

2.1.1 Creating a Project From Scratch ................................................................................ 20

2.1.2 Project Settings .................................................................................................... 21

2.1.3 Using an Existing CCE v3 or CCE v2.x Project ............................................................... 21

2.1.4 Stack Management ............................................................................................... 21

2.1.5 How to Generate Binary-Format Files (TI-TXT and INTEL-HEX) ........................................... 21

2.1.6 Overview of Example Programs and Projects ................................................................. 22

Using the Integrated Debugger ........................................................................................... 22

2.2.1 Breakpoint Types .................................................................................................. 22

2.2.2 Using Breakpoints ................................................................................................. 23

2.1

2.2

Development Flow

...................................................... 25

3

Design Considerations for In-Circuit Programming

3.1

Signal Connections for In-System Programming and Debugging, MSP-FET430PIF, MSP-FET430UIF,

MSP-GANG430, MSP-PRGS430 ........................................................................................ 26

3.2

External Power

3.3

A

A.1

A.2

A.3

.............................................................................................................

Bootstrap Loader ...........................................................................................................

28

29

...................................................................................... 31

Hardware .................................................................................................................... 32

Program Development (Assembler, C-Compiler, Linker, IDE) ....................................................... 33

Debugging ................................................................................................................... 34

Frequently Asked Questions

................................................................................................................. 37

B

Hardware

B.1

Schematics and PCBs ..................................................................................................... 38

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Contents

3

www.ti.com

B.2

MSP-FET430UIF Revision History ....................................................................................... 67

.............................................................................. 69

C

IAR 2.x/3.x/4.x to CCE C-Migration

C.1

Interrupt Vector Definition ................................................................................................. 70

C.2

Intrinsic Functions .......................................................................................................... 70

C.3

Data and Function Placement ............................................................................................ 70

C.3.1 Data Placement at an Absolute Location ...................................................................... 70

C.3.2 Data Placement Into Named Segments ........................................................................ 71

C.3.3 Function Placement Into Named Segments ................................................................... 71

C.4

C Calling Conventions ..................................................................................................... 72

C.5

Other Differences........................................................................................................... 72

.........................................................................

Custom Boot Routine .............................................................................................

Predefined Memory Segment Names ..........................................................................

Predefined Macro Names ........................................................................................

C.5.1 Initializing Static and Global Variables

C.5.2

C.5.3

C.5.4

72

73

73

74

................................................................. 75

D

IAR 2.x/3.x/4.x to CCE Assembler Migration

D.1

Sharing C/C++ Header Files With Assembly Source .................................................................. 76

D.2

Segment Control

D.3

Translating A430 Assembler Directives to Asm430 Directives ....................................................... 77

...........................................................................................................

76

D.3.1 Introduction ......................................................................................................... 77

D.3.2 Character Strings .................................................................................................. 77

D.3.3 Section Control Directives ........................................................................................ 78

D.3.4 Constant Initialization Directives

................................................................................

78

D.3.5 Listing Control Directives ......................................................................................... 79

D.3.6 File Reference Directives

........................................................................................

79

D.3.7 Conditional Assembly Directives ................................................................................ 80

D.3.8 Symbol Control Directives ........................................................................................ 80

D.3.9 Macro Directives ................................................................................................... 81

D.3.10 Miscellaneous Directives........................................................................................ 81

D.3.11 Alphabetical Listing and Cross Reference of Asm430 Directives ......................................... 82

D.3.12 Unsupported A430 Directives (IAR) ........................................................................... 83

E

E.1

F

F.1

.................................................................................................. 85

Menus ........................................................................................................................ 86

E.1.1 Debug View: Advanced Run → Free Run ..................................................................... 86

E.1.2 Target → Connect Target ........................................................................................ 86

E.1.3 Target → Make Device Secure .................................................................................. 86

E.1.4 Project → Properties → TI Debug Settings → Target → MSP430 Properties → Clock Control ....... 86

E.1.5 Window → Show View → Breakpoints ......................................................................... 86

E.1.6 Window → Show View →Trace ................................................................................. 86

E.1.7 Project → Properties → TI Debug Properties → Target → MSP430 Properties → Target Voltage ... 87

FET-Specific Menus

....................................................................................... 89

Hardware Installation ...................................................................................................... 90

Hardware Installation Guide

Document Revision History ................................................................................................. 95

Important Notices ............................................................................................................... 96

4

Contents

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

www.ti.com

List of Figures

3-1

3-2

B-1

B-2

B-3

B-4

B-5

B-6

B-7

B-8

B-9

B-10

B-11

B-12

B-13

B-14

B-15

B-16

B-17

B-18

B-19

B-20

B-21

B-22

B-23

B-24

B-25

B-26

B-27

B-28

B-29

F-1

F-2

F-3

F-4

F-5

F-6

Signal Connections for 4-Wire JTAG Communication.................................................................

Signal Connections for 2-Wire JTAG Communication (Spy-Bi-Wire)................................................

MSP-TS430PW14 Target Socket Module, Schematic ................................................................

MSP-TS430PW14 Target Socket Module, PCB .......................................................................

MSP-TS430DW28 Target Socket Module, Schematic ................................................................

MSP-TS430DW28 Target Socket Module, PCB .......................................................................

MSP-TS430PW28 Target Socket Module, Schematic ................................................................

MSP-TS430PW28 Target Socket Module, PCB .......................................................................

MSP-TS430DA38 Target Socket Module, Schematic .................................................................

MSP-TS430DA38 Target Socket Module, PCB ........................................................................

MSP-TS430QFN23x0 Target Socket Module, Schematic ............................................................

MSP-TS430QFN23x0 Target Socket Module, PCB ...................................................................

MSP-TS430DL48 Target Socket Module, Schematic .................................................................

MSP-TS430DL48 Target Socket Module, PCB ........................................................................

MSP-TS430PM64 Target Socket Module, Schematic.................................................................

MSP-TS430PM64 Target Socket Module, PCB ........................................................................

MSP-TS430PN80 Target Socket Module, Schematic .................................................................

MSP-TS430PN80 Target Socket Module, PCB ........................................................................

MSP-TS430PZ100 Target Socket Module, Schematic ................................................................

MSP-TS430PZ100 Target Socket Module, PCB .......................................................................

MSP-TS430PZ100A Target Socket Module, Schematic ..............................................................

MSP-TS430PZ100A Target Socket Module, PCB .....................................................................

MSP-TS430PZ5x100 Target Socket Module, Schematic .............................................................

MSP-TS430PZ5x100 Target Socket Module, PCB ....................................................................

MSP-FET430PIF FET Interface Module, Schematic ..................................................................

MSP-FET430PIF FET Interface Module, PCB .........................................................................

MSP-FET430UIF USB Interface, Schematic (1 of 4) ..................................................................

MSP-FET430UIF USB Interface, Schematic (2 of 4) ..................................................................

MSP-FET430UIF USB Interface, Schematic (3 of 4) ..................................................................

MSP-FET430UIF USB Interface, Schematic (4 of 4) ..................................................................

MSP-FET430UIF USB Interface, PCB ..................................................................................

WinXP Hardware Recognition ............................................................................................

WinXP Hardware Wizard ..................................................................................................

WinXP Driver Location Selection Folder ................................................................................

WinXP Driver Installation ..................................................................................................

Device Manager Using MSP-FET430UIF or eZ430-F2013 ...........................................................

Device Manager Using eZ430-RF2500 .................................................................................

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

List of Figures

27

28

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

90

90

91

92

93

94

5

www.ti.com

List of Tables

1-1

1-2

1-3

2-1

6

Flash Emulation Tool (FET) Features ...................................................................................

System Requirements .....................................................................................................

Code Examples .............................................................................................................

Device Breakpoints and Other Emulation Features ...................................................................

List of Tables

12

16

17

22

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Preface

SLAU157I – May 2005 – Revised February 2009

Read This First

About This Manual

This manual describes the Texas Instruments MSP-FET430 Flash Emulation Tool (FET). The FET is the

program development tool for the MSP430 ultra-low-power microcontroller. Both available interface types,

the parallel port interface and the USB interface, are described.

How to Use This Manual

Read and follow the instructions in the Get Started Now! chapter. This chapter lists the contents of the

FET, provides instructions on installing the software and hardware, and describes how to run the

demonstration programs. After you see how quick and easy it is to use the FET, TI recommends that you

read all of this manual.

This manual describes the setup and operation of the FET but does not fully describe the MSP430 or the

development software systems. For details of these items, see the appropriate TI documents listed in

Section 1.15, Important MSP430 Documents on the CD-ROM and Web.

This manual applies to the following tools (and devices):

• MSP-FET430PIF (debug interface with parallel port connection, for all MSP430 flash-based devices)

• MSP-FET430UIF (debug interface with USB connection, for all MSP430 flash-based devices)

• eZ430-F2013 (USB stick form factor interface with attached MSP430F2013 target, for all

MSP430F20xx devices)

• eZ430-T2012 (three MSP430F2012 based target boards)

• eZ430-RF2500 (USB stick form factor interface with attached MSP430F2274/CC2500 target, for all

MSP430F20xx and MSP430F22xx devices)

IAR Embedded Workbench is a registered trademark of IAR Systems AB.

ThinkPad is a registered trademark of Lenovo.

Microsoft, Windows, Windows Vista are registered trademarks of Microsoft Corporation.

All other trademarks are the property of their respective owners.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Read This First

7

Information About Cautions and Warnings

www.ti.com

The following tools contain the USB debug interface (MSP-FET430UIF) and the respective target socket

module:

• MSP-FET430U14 (for MSP430 devices in 14-pin PW packages)

• MSP-FET430U28 (for MSP430 devices in 20- and 28-in DW or PW packages)

• MSP-FET430U38 (for MSP430 devices in 38-pin DA packages)

• MSP-FET430U23x0 (for MSP430F23x0 devices in 40-pin RHA packages only)

• MSP-FET430U48 (for MSP430 devices in 48-pin DL package)

• MSP-FET430U64 (for MSP430 devices in 64-pin PM package)

• MSP-FET430U80 (for MSP430 devices in 80-pin PN package)

• MSP-FET430U100 (for MSP430 devices in 100-pin PZ package)

• MSP-FET430U100A (for MSP430F471xx devices in 100-pin PZ package - red PCB)

• MSP-FET430U5x100 (for MSP430F5x devices in 100-pin PZ package)

Stand-alone target-socket modules (without debug interface):

• MSP-TS430PM64 (for MSP430 devices in 64-pin PM package)

• MSP-TS430PZ100A (for MSP430F471xx devices in 100-pin PZ package - red PCB)

• MSP-TS430PZ5x100 (for MSP430F5x devices in 100-pin PZ packages)

These tools contain the most up-to-date materials available at the time of packaging. For the latest

materials (data sheets, user's guides, software, application information, etc.), visit the TI MSP430 web site

at www.ti.com/msp430 or contact your local TI sales office.

Information About Cautions and Warnings

This document may contain cautions and warnings.

CAUTION

This is an example of a caution statement.

A caution statement describes a situation that could potentially damage your

software or equipment.

WARNING

This is an example of a warning statement.

A warning statement describes a situation that could potentially

cause harm to you.

The information in a caution or a warning is provided for your protection. Read each caution and warning

carefully.

Related Documentation From Texas Instruments

MSP430xxxx device data sheets

MSP430x1xx Family User's Guide, literature number SLAU049

MSP430x2xx Family User's Guide, literature number SLAU144

MSP430x3xx Family User's Guide, literature number SLAU012

MSP430x4xx Family User's Guide, literature number SLAU056

MSP430x5xx Family User's Guide, literature number SLAU208

8

Read This First

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

www.ti.com

If You Need Assistance

If You Need Assistance

Support for the MSP430 devices and the FET development tools is provided by the Texas Instruments

Product Information Center (PIC). Contact information for the PIC can be found on the TI web site at

www.ti.com/support. A Code Composer Essentials specific Wiki page (FAQ) is available, and the Texas

Instruments E2E Community support forums provide open interaction with peer engineers, TI engineers,

and other experts. Additional device-specific information can be found on the MSP430 web site.

FCC Warning

This equipment is intended for use in a laboratory test environment only. It generates, uses, and can

radiate radio frequency energy and has not been tested for compliance with the limits of computing

devices pursuant to subpart J of part 15 of FCC rules, which are designed to provide reasonable

protection against radio-frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case, the user is required to take whatever

measures may be required to correct this interference at his own expense.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Read This First

9

10

Read This First

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Chapter 1

SLAU157I – May 2005 – Revised February 2009

Get Started Now!

This chapter lists the contents of the FET, provides instruction on installing the software and hardware,

and shows how to run the demonstration programs.

Topic

..................................................................................................

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

Flash Emulation Tool (FET) Overview ..........................................

Kit Contents, MSP-FET430PIF .....................................................

Kit Contents, eZ430-F2013 .........................................................

Kit Contents, eZ430-T2012 .........................................................

Kit Contents, eZ430-F2500 .........................................................

Kit Contents, MSP-FET430UIF ....................................................

Kit Contents, MSP-FET430Uxx ('U14, 'U28, 'U38, 'U23x0, 'U48,

'U64, 'U80, 'U100, 'U100A, 'U5x100)..............................................

Kit Contents, MSP-TS430xx ('PM64, 'PZ100A, 'PZ5x100) ................

Software Installation ..................................................................

Hardware Installation, MSP-FET430PIF ........................................

Hardware Installation, MSP-FET430UIF ........................................

Hardware Installation, eZ430-F2013, eZ430-RF2500 .......................

Hardware Installation, MSP-FET430Uxx ('U14, 'U28, 'U38, 'U23x0,

'U48, 'U64, 'U80, 'U100, 'U100A, 'U5x100) and MSP-TS430xxx

('PM64, 'PZ100A, 'PZ5x100) ........................................................

Flashing the LED ......................................................................

Important MSP430 Documents on the CD-ROM and Web ...............

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Page

12

12

12

12

13

13

13

14

16

16

16

17

17

17

18

Get Started Now!

11

Flash Emulation Tool (FET) Overview

1.1

www.ti.com

Flash Emulation Tool (FET) Overview

TI offers several flash emulation tools to meet different requirements.

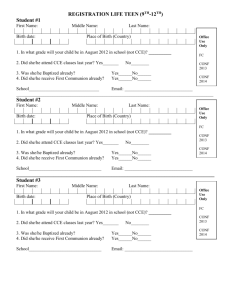

Table 1-1. Flash Emulation Tool (FET) Features

eZ430-F2013

eZ430-RF2500

Supports all MSP430 flash-based devices

(F1xx, F2xx, F4xx, F5xx)

Supports MSP430F20xx devices only

MSP-FET430UIF

MSP-FET430PIF

X

X

X

Supports MSP430F20xx/F21x2/F22xx only

X

Allows fuse blow

X

Adjustable target supply voltage

X

Fixed 2.8-V target supply voltage

Fixed 3.6-V target supply voltage

X

X

X

X

X

4-wire JTAG

2-wire JTAG (1)

X

Application UART

X

X

X

X

Supported by IAR

X

X

X

X

READ ME FIRST document

MSP430 CD-ROM

MSP-FET430PIF interface module

25-conductor cable

14-conductor cable

One QUICK START GUIDE document

One eZ430-F2013 CD-ROM

One eZ430-F2013 development tool including one MSP430F2013 target board

Kit Contents, eZ430-T2012

•

12

One

One

One

One

One

Kit Contents, eZ430-F2013

•

•

•

1.4

The 2-wire JTAG debug interface is also referred to as Spy-Bi-Wire (SBW) interface.

Kit Contents, MSP-FET430PIF

•

•

•

•

•

1.3

X

Supported by CCE

(1)

1.2

X

X

Three MSP430F2012 based target boards

Get Started Now!

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Kit Contents, eZ430-F2500

www.ti.com

1.5

Kit Contents, eZ430-F2500

•

•

•

•

1.6

QUICK START GUIDE document

eZ430-RF2500 CD-ROM

eZ430-RF2500 development tool including one MSP430F2274/CC2500 target board

eZ430-RF2500T target board with battery holder and batteries

Kit Contents, MSP-FET430UIF

•

•

•

•

•

1.7

One

One

One

One

One

One

One

One

One

READ ME FIRST document

MSP430 CD-ROM

MSP-FET430UIF interface module

USB cable

14-conductor cable

Kit Contents, MSP-FET430Uxx ('U14, 'U28, 'U38, 'U23x0, 'U48, 'U64, 'U80, 'U100,

'U100A, 'U5x100)

•

•

•

•

•

One READ ME FIRST document

One MSP430 CD-ROM

One MSP-FETP430UIF USB interface module. This is the unit that has a USB B-connector on one end

of the case and a 2×7-pin male connector on the other end of the case.

One 32.768-kHz crystal

One target socket module

MSP-FET430U14: One MSP-TS430PW14 target socket module. This is the PCB on which is mounted

a 14-pin ZIF socket. It fits all MSP430 devices in 14-pin PW packages. A 2×7-pin male connector is

also present on the PCB.

MSP-FET430U28: One MSP-TS430PW28 target socket module. This is the PCB on which is mounted

a 28-pin ZIF socket. It fits all MSP430 devices in 20- and 28-pin PW packages. A 2×7-pin male

connector is also present on the PCB.

MSP-FET430U38: One MSP-TS430DA38 target socket module. This is the PCB on which is mounted

a 38-pin ZIF socket. It fits all MSP430 devices in 38-pin DA packages. A 2×7-pin male connector is

also present on the PCB.

MSP-FET430U23x0: One MSP-TS430QFN23x0 target socket module (former name

MSP-TS430QFN40). This is the PCB on which is mounted a 40-pin ZIF socket. It fits only

MSP430F2330/F2350/F2370 devices in 40-pin RHA packages. A 2×7-pin male connector is also

present on the PCB.

MSP-FET430U48: One MSP-TS430DL48 target socket module. This is the PCB on which is mounted

a 48-pin ZIF socket. It fits all MSP430 devices in 48-pin DL packages. A 2×7-pin male connector is

also present on the PCB.

MSP-FET430U64: One MSP-TS430PM64 target socket module. This is the PCB on which is mounted

a 64-pin ZIF socket. It fits all MSP430 devices in 64-pin PM packages. A 2×7-pin male connector is

also present on the PCB.

MSP-FET430U80: One MSP-TS430PN80 target socket module. This is the PCB on which is mounted

a 80-pin ZIF socket. It fits all MSP430 devices in 80-pin PN packages. A 2×7-pin male connector is

also present on the PCB.

MSP-FET430U100: One MSP-TS430PZ100 target socket module. This is the PCB on which is

mounted a 100-pin ZIF socket. It fits all MSP430 devices in 100-pin PZ packages. A 2×7-pin male

connector is also present on the PCB.

MSP-FET430U100A: One MSP-TS430PZ100A target socket module (red PCB). This is the PCB on

which is mounted a 100-pin ZIF socket. It fits all MSP430F471xx devices in 100-pin PZ packages. A

2×7-pin male connector is also present on the PCB.

MSP-FET430U5x100: One MSP-TS430PZ5x100 target socket module. This is the PCB on which is

mounted a 100-pin ZIF socket. It fits all MSP430F5x devices in 100-pin PZ packages. A 2×7-pin male

connector is also present on the PCB.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Get Started Now!

13

Kit Contents, MSP-TS430xx ('PM64, 'PZ100A, 'PZ5x100)

•

•

•

•

www.ti.com

One USB cable

One 14-conductor cable

Four or eight PCB headers

MSP-FET430U14: Four PCB 1×7-pin headers (two male and two female)

MSP-FET430U28: Four PCB 1×14-pin headers (two male and two female)

MSP-FET430U38: Four PCB 1×19-pin headers (two male and two female)

MSP-FET430U23x0: Eight PCB 1×10-pin headers (four male and four female)

MSP-FET430U48: Four PCB 2×24-pin headers (two male and two female)

MSP-FET430U64: Eight PCB 1×16-pin headers (four male and four female)

MSP-FET430U80: Eight PCB 1×20-pin headers (four male and four female)

MSP-FET430U100: Eight PCB 1×25-pin headers (four male and four female)

MSP-FET430U100A: Eight PCB 1×25-pin headers (four male and four female)

MSP-FET430U5x100: Eight PCB 1×25-pin headers (four male and four female)

One small box containing two or four MSP430 device samples

MSP-FET430U14: MSP430F2013IPW

MSP-FET430U28: MSP430F2132IPW

MSP-FET430U38: MSP430F2274IDA

MSP-FET430U23x0: MSP430F2370IRHA

MSP-FET430U48: MSP430F4270IDL

MSP-FET430U64: MSP430F417IPM and MSP430F169IPM

MSP-FET430U80: MSP430FG439IPN

MSP-FET430U100: MSP430FG4619IPZ

MSP-FET430U100A: MSP430F47197IPZ

MSP-FET430U5x100: MSP430F5438IPZ

Consult the device data sheets for device specifications. Device errata can be found in the respective

device product folder on the web, provided as a PDF document. Depending on the device, errata also may

be found in the device bug database at www.ti.com/sc/cgi-bin/buglist.cgi.

1.8

Kit Contents, MSP-TS430xx ('PM64, 'PZ100A, 'PZ5x100)

•

•

•

•

•

•

14

One READ ME FIRST document

One MSP430 CD-ROM

One 32.768-kHz crystal

One target socket module

MSP-TS430PM64: One MSP-TS430PM64 target socket module. This is the PCB on which is mounted

a 64-pin ZIF socket. It fits all MSP430 devices in 64-pin PM packages. A 2×7-pin male connector is

also present on the PCB.

MSP-TS430PZ100A: One MSP-TS430PZ100A target socket module (red PCB). This is the PCB on

which is mounted a 100-pin ZIF socket. It fits all MSP430F471xx devices in 100-pin PZ packages. A

2×7-pin male connector is also present on the PCB.

MSP-TS430U5x100: One MSP-TS430PZ5x100 target socket module. This is the PCB on which is

mounted a 100-pin ZIF socket. It fits all MSP430F5x devices in 100-pin PZ packages. A 2×7-pin male

connector is also present on the PCB.

Eight PCB headers

MSP-TS430PM64: Eight PCB 1×16-pin headers (four male and four female)

MSP-TS430PZ100A: Eight PCB 1×25-pin headers (four male and four female)

MSP-TS430PZ5x100: Eight PCB 1×25-pin headers (four male and four female)

One small box containing two MSP430 device samples

MSP-TS430PM64: MSP430F417IPM and MSP430F169IPM

MSP-TS430PZ100A: MSP430F47197IPZ

MSP-TS430PZ5x100: MSP430F5438IPZ

Get Started Now!

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Kit Contents, MSP-TS430xx ('PM64, 'PZ100A, 'PZ5x100)

www.ti.com

Consult the device data sheets for device specifications. Device errata can be found in the respective

device product folder on the web, provided as a PDF document. Depending on the device, errata also

may be found in the device bug database at www.ti.com/sc/cgi-bin/buglist.cgi.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Get Started Now!

15

Software Installation

1.9

www.ti.com

Software Installation

To install Code Composer Essentials v3.1 for MSP430 (CCE), run setup_CCE_3.x.x.x.x_MSP430.exe

from the CD-ROM or download location and follow the instructions shown on the screen. The hardware

drivers for the parallel-port FET (MSP-FET430PIF) and the drivers for the USB JTAG emulator

(MSP-FET430UIF) are installed automatically when installing CCE.

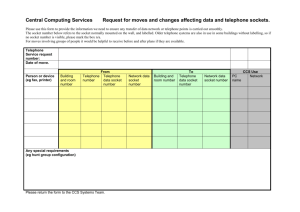

Table 1-2. System Requirements

Recommended System Requirements

Minimum System Requirements

Pentium 4 or similar

Pentium 3 or similar

1 GB

512 MB

Processor

RAM

Free Disk Space

Operating System

500 MB

Microsoft®

Windows®

XP with SP2 (32 bit) or

Windows Vista® (32 bit)

450 MB

Microsoft®

Windows® XP with SP2 (32 bit) or

Windows Vista® (32 bit)

1.10 Hardware Installation, MSP-FET430PIF

Follow these steps to install the hardware for the MSP-FET430PIF tools:

1. Use the 25-conductor cable to connect the FET interface module to the parallel port of the PC. The

necessary driver for accessing the PC parallel port is installed automatically during CCE installation.

Note that a restart is required after the CCE installation for the driver to become active.

2. Use the 14-conductor cable to connect the parallel-port debug interface module to a target board, such

as an MSP-TS430xxx target socket module. Module schematics and PCBs are shown in Appendix B.

1.11 Hardware Installation, MSP-FET430UIF

Follow these steps to install the hardware for the MSP-FET430UIF tool:

1. Use the USB cable to connect the USB-FET interface module to a USB port on the PC. The USB FET

should be recognized, as the USB device driver should have been installed already with the CCE

software. If the install wizard starts, follow the prompts and point the wizard to the driver files located in

C:\Program Files\Texas Instruments\MSP430_USB_DRIVERS_v3\ (this is the default location unless

another installation directory was specified during CCE installation). Detailed driver installation

instructions are found in Appendix F.

2. After connecting to a PC, the USB FET performs a selftest during which the red LED flashes for about

two seconds. If the selftest passes successfully, the green LED lights permanently.

3. Use the 14-conductor cable to connect the USB-FET interface module to a target board, such as an

MSP-TS430xxx target socket module.

4. Ensure that the MSP430 device is securely seated in the socket, and that its pin 1 (indicated with a

circular indentation on the top surface) aligns with the "1" mark on the PCB.

5. Compared to the parallel-port debug interface, the USB FET has additional features including JTAG

security fuse blow and adjustable target VCC (1.8 V to 3.6 V). Supply the module with up to 100 mA.

16

Get Started Now!

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Hardware Installation, eZ430-F2013, eZ430-RF2500

www.ti.com

1.12 Hardware Installation, eZ430-F2013, eZ430-RF2500

Follow these steps to install the hardware for the eZ430-F2013 and eZ430-RF2500 tools:

1. Connect the eZ430-F2013 or eZ430-RF2500 to a USB port of the PC.

2. The USB FET should be recognized by the PC. The USB device driver should have been installed with

Code Composer Essentials. If the install wizard starts, follow the prompts and point the wizard to the

driver files located in C:\Program Files\Texas Instruments\MSP430_USB_DRIVERS_v3\ (this is the

default location unless another installation directory was specified during CCE installation). Detailed

driver installation instructions can be found in Appendix F.

1.13 Hardware Installation, MSP-FET430Uxx ('U14, 'U28, 'U38, 'U23x0, 'U48, 'U64, 'U80,

'U100, 'U100A, 'U5x100) and MSP-TS430xxx ('PM64, 'PZ100A, 'PZ5x100)

Follow these steps to install the hardware for the MSP-FET430Uxx and MSP-TS430xxx tools:

1. Connect the MSP-FET430PIF or MSP-FET430UIF debug interface to the appropriate port of the PC.

Use the 14-conductor cable to connect the FET interface module to the supplied target socket module.

2. Ensure that the MSP430 device is securely seated in the socket and that its pin 1 (indicated with a

circular indentation on the top surface) aligns with the "1" mark on the PCB.

3. Ensure that the two jumpers (LED and VCC) near the 2×7-pin male connector are in place. Illustrations

of the target socket modules and their parts are found in Appendix B.

1.14 Flashing the LED

This section demonstrates on the FET the equivalent of the C-language "Hello world!" introductory

program. CCEv3.1 includes plain C and ASM code files as well as fully preconfigured projects. The

following describes how an application that flashes the LED is developed, downloaded to the FET, and

run.

1. Start Code Composer Essentials Start → All Programs → Texas Instruments → Code Composer

Essentials v3.1 → Code Composer Essentials v3.1.

2. Create a new Project by selecting File → New → Managed Make C/ASM Project (recommended).

3. Enter a project name and click next until the Device Selection Page is shown. Select the Device

Variant used in the project.

4. Add the flashing LED code example to the project by clicking Project → Add Files to Active Project.

Code examples are located in <Installation Root>\examples\msp430. Use Table 1-3 to select the

appropriate source code file:

Table 1-3. Code Examples

MSP430 Devices

Code Example

MSP430x1xx device family

<...>\msp430x1xx\C-Source\msp430x1xx.c

MSP430x2xx device family

<...>\msp430x2xx\C-Source\msp430x2xx.c

MSP430x4xx device family

<...>\msp430x4xx\C-Source\msp430x4xx.c

MSP430x5xx device family

<...>\msp430x5xx\C-Source\msp430x5xx.c

5. If using a USB Flash Emulation Tool such as the MSP-FET430UIF or the eZ430 Development Tool,

they should be already configured by default. The debug interface may be changed via Project →

Properties → TI Debug Settings → Setup.

6. To compile the code and download the application to the target device, go to Run → Debug Active

Project.

7. The application may be started by selecting Run → Run (F8) or clicking the Play button on the toolbar.

See FAQ Debugging #1 if the CCE debugger is unable to communicate with the device.

Congratulations, you have just built and tested an MSP430 application!

Predefined projects, which are located in <Installation Root>\examples\msp430\example projects, can be

imported by selecting File → Import → General → Existing Project.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Get Started Now!

17

Important MSP430 Documents on the CD-ROM and Web

www.ti.com

1.15 Important MSP430 Documents on the CD-ROM and Web

The primary sources of MSP430 information are the device-specific data sheets and user's guides. The

most up-to-date versions of these documents available at the time of production have been provided on

the CD-ROM included with this tool. The MSP430 web site (www.ti.com/msp430) contains the latest

version of these documents.

18

Get Started Now!

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Chapter 2

SLAU157I – May 2005 – Revised February 2009

Development Flow

This chapter discusses how to use Code Composer Essentials (CCE) to develop application software and

how to debug that software.

Topic

2.1

2.2

..................................................................................................

Page

Using Code Composer Essentials (CCE) ...................................... 20

Using the Integrated Debugger ................................................... 22

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Development Flow

19

Using Code Composer Essentials (CCE)

2.1

www.ti.com

Using Code Composer Essentials (CCE)

The following sections are a brief overview of how to use CCE. For a full discussion of software

development flow with CCE in assembly or C, see MSP430 Assembly Language Tools User’s Guide

(SLAU131) and MSP430 Optimizing C/C++ Compiler User’s Guide (SLAU132).

2.1.1 Creating a Project From Scratch

This section presents step-by-step instructions to create an assembly or C project from scratch and to

download and run the application on the MSP430 (see Section 2.1.2, Project Settings). Also, the MSP430

Code Composer Essentials Help presents a more comprehensive overview of the process.

1. Start the CCE (Start → All Programs → Texas Instruments → Code Composer Essentials v3.1 →

Code Composer Essentials v3.1).

2. Create new project (File → New → Project → C → Managed Make C/ASM Project (Recommended)).

Click Next and enter the name for the project. Click Next until reaching the New Project window titled

Device Selection. Select the appropriate device and click Finish. For assembly only projects ensure to

click "Configure as an assembly only project.”

3. Create a new source file (File → New → Source File). Enter file name and remember to add the suffix

.c or .asm. If, instead, the user wants to use an existing source file for his/her project, click Project →

Add Files to Active Project and browse to the file of interest. Single click on the file and click Open or

double-click on the file name to complete the addition of the file into the project folder. Note that adding

a file to the project makes a copy of the file in the project directory. To point to a file in the directory

structure without physically adding it to the project directory, click Project → Link Files to Active Project

instead.

4. Enter the program text into the file.

Note:

Use .h files to simplify code development.

CCE is supplied with files for each device that define the device registers and the bit names.

Using these files is recommended and can greatly simplify the task of developing a program.

To include the .h file corresponding to the target device, add the line #include

<msp430xyyy.h> for C and .cdecls C,LIST,"msp430xyyy" for assembly code, where xyyy

specifies the MSP430 part number.

5. Configure the project options (Project → Properties); e.g., to select debug interface, or accept the

default factory settings.

6. Build the project (Project → Build Active Project).

7. Debug the application (Run → Debug Active Project). This starts the debugger, which gains control of

the target, erases the target memory, programs the target memory with the application, and resets the

target.

See FAQ Debugging #1 if the debugger is unable to communicate with the device.

8. Click Run → Run to start the application.

9. Click Run → Terminate to stop the application and to exit the debugger. To return to the code editor,

click Window → Open Perspective → C/C++ or use the tab on the right top corner of CCE.

10. Click File → Exit to exit CCE.

20

Development Flow

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

www.ti.com

Using Code Composer Essentials (CCE)

2.1.2 Project Settings

The settings required to configure the CCE are numerous and detailed. Most projects can be compiled

and debugged with default factory settings. The project settings are accessed by clicking Project →

Properties for the active project. The following project settings are recommended/required:

• Specify the target device for debug session (Project → Properties → TI Build Settings → Device

Variant). The corresponding Linker Command File is selected automatically.

• To more easily debug a C project, disable optimization (Project → Properties → C/C++ Build → Tool

Settings → MSP430 Compiler → Optimization).

• Specify the search path for the C preprocessor (Project → Properties → C/C++ Build → Tool Settings

→ MSP430 Compiler → General Options).

• Specify the search path for any libraries being used (Project → Properties → C/C++ Build → Tool

Settings → MSP430 Linker → File Search Path).

• Specify the debugger interface. Select Project → Properties → TI Debug Settings → Setup →

Connection → TI MSP430 LPTx for the parallel FET interface or TI MSP430 USBx for the USB

interface.

• Enable the erasure of the Main and Information memories before object code download (Project →

Properties → TI Debug Settings → Target → MSP430 Properties → Download Options → Erase Main

and Information Memory).

• To ensure proper standalone operation, disable Software Breakpoints (Project → Properties → TI

Debug Settings → Target → MSP430 Properties → Use Software Breakpoints). If Software

Breakpoints are enabled, ensure proper termination of each debug session while the target is

connected; otherwise, the target may not be operational standalone.

2.1.3 Using an Existing CCE v3 or CCE v2.x Project

CCE v3.1 supports the conversion of workspaces and projects created in version 2 and 3 to the

version 3.1 format (File → Import → General → Existing Projects into Workspace → Next. Browse to

legacy CCE workspace containing the project to be imported. The Import Wizard lists all projects in the

given workspace. Specific Projects can then be selected and converted.

While the support for assembly projects has not changed, the header files for C code have been modified

slightly to improve compatibility with the IAR Embedded Workbench® IDE (interrupt vector definitions). The

definitions used in CCE 2.x are still given, but have been commented out in all header files. To support

CCE 2.x C code, remove the "//" in front of #define statements, which are located at the end of each .h

file, in the section "Interrupt Vectors".

2.1.4 Stack Management

The reserved stack size can be configured through the project options dialog (Project → Properties →

C/C++ Build → Tool Settings → MSP430 Linker → Runtime Environment → Set C System Stack Size).

Stack size is defined to extend from the last location of RAM for 50 to 80 bytes (i.e., the stack extends

downwards through RAM for 50 to 80 bytes, depending on the RAM size of the selected device).

Note that the stack can overflow due to small size or application errors. See Section 2.2.2.1 for a method

of tracking the stack size.

2.1.5 How to Generate Binary-Format Files (TI-TXT and INTEL-HEX)

The CCE installation includes the hex430.exe conversion tool. It can be configured to generate output

objects in TI-TXT format for use with the MSP-GANG430 and MSP-PRGS430 programmers, as well as

INTEL-HEX format files for TI factory device programming. The tool can be used either standalone in a

command line (located in <Installation Root>\tools\compiler\msp430\bin) or directly within CCE. In the

latter case, a post-build step can be configured to generate the file automatically after every build by

selecting predefined formats such as TI-TXT and INTEL-HEX in the "Apply Predefined Step" menu

(Project → Properties → C/C++ Build → Build Steps → Post-Build Step). The generated file is stored in

the <Workspace>\<Project>\Debug\ directory.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Development Flow

21

Using the Integrated Debugger

www.ti.com

2.1.6 Overview of Example Programs and Projects

Example programs for MSP430 devices are provided in <Installation Root>\examples\msp430. Assembly

and C sources are available in the appropriate subdirectory.

To use the examples, create a new project and add the example source file to the project by clicking

Project → Add Files to Active Project. In addition, example projects corresponding to the code examples

are provided in <Installation Root>\examples\msp430\example projects. The projects can be imported by

File → Import (see Section 1.14 for more information).

2.2

Using the Integrated Debugger

See Appendix E for a description of FET-specific menus within CCE.

2.2.1 Breakpoint Types

The debugger breakpoint mechanism uses a limited number of on-chip debugging resources (specifically,

N breakpoint registers, see Table 2-1). When N or fewer breakpoints are set, the application runs at full

device speed (or "realtime"). When greater than N breakpoints are set and Use Software Breakpoints is

enabled (Project → Properties → TI Debug Settings → Target → MSP430 Properties → Use Software

Breakpoints), an unlimited number of software breakpoints can be set while still meeting realtime

constraints.

Note:

A software breakpoint replaces the instruction at the breakpoint address with a call to

interrupt the code execution. Therefore, there is a small delay when setting a software

breakpoint. In addition, the use of software breakpoints always requires proper termination of

each debug session; otherwise, the application may not be operational standalone.

Both address (code) and data (value) breakpoints are supported. Data breakpoints and range breakpoints

each require two MSP430 hardware breakpoints.

Table 2-1. Device Breakpoints and Other Emulation Features

4-Wire

JTAG

2-Wire

JTAG (1)

Breakpoints

(N)

Range

Breakpoints

Clock

Control

CC430F513x

X

X

2

X

X

CC430F612x

X

X

2

X

X

CC430F613x

X

X

2

X

X

MSP430F11x1

X

2

MSP430F11x2

X

2

MSP430F12x

X

2

MSP430F12x2

X

2

MSP430F13x

X

3

X

MSP430F14x

X

3

X

MSP430F15x

X

8

X

MSP430F16x

X

8

MSP430F161x

X

8

MSP430F20xx

X

MSP430F21x1

X

MSP430F21x2

X

X

MSP430F22x2

X

MSP430F22x4

X

MSP430F23x

X

Device

(1)

22

X

State

Sequencer

Trace

Buffer

X

X

X

X

X

X

X

X

X

X

X

2

X

2

X

2

X

X

2

X

X

2

3

X

X

X

The 2-wire JTAG debug interface is also referred to as Spy-Bi-Wire (SBW) interface. Note that this interface is supported only

by the USB emulators (eZ430-xxxx and MSP-FET430UIF USB JTAG emulator) and the MSP-GANG430 production

programming tool. The MSP-FET430PIF parallel port JTAG emulator does not support communication in 2-wire JTAG mode.

Development Flow

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Using the Integrated Debugger

www.ti.com

Table 2-1. Device Breakpoints and Other Emulation Features (continued)

Device

4-Wire

JTAG

2-Wire

JTAG (1)

Breakpoints

(N)

Range

Breakpoints

Clock

Control

State

Sequencer

Trace

Buffer

X

X

X

X

X

X

MSP430F23x0

X

2

MSP430F24x

X

3

X

X

MSP430F241x

X

8

X

X

MSP430F2410

X

3

X

X

MSP430F261x

X

8

X

X

MSP430F41x

X

2

X

MSP430F41x2

X

2

X

MSP430F42x

X

2

X

MSP430FE42x

X

2

X

MSP430FE42x2

X

2

X

MSP430FW42x

X

2

X

MSP430F42x0

X

2

X

MSP430FG42x0

X

2

X

MSP430F43x

X

8

MSP430FG43x

X

2

X

MSP430F43x1

X

2

X

MSP430F44x

X

8

X

X

X

X

MSP430FG461x

X

8

X

X

X

X

MSP430F47x

X

2

X

MSP430FG47x

X

2

X

MSP430F47x3

X

2

X

MSP430F47x4

X

2

MSP430F471xx

X

8

X

X

X

X

MSP430F54xx

X

8

X

X

X

X

X

X

X

X

X

X

2.2.2 Using Breakpoints

If the debugger is started with greater than N breakpoints set and software breakpoints are disabled, a

message is output that informs the user that not all breakpoints can be enabled. Note that the CCE

permits any number of breakpoints to be set, regardless of the Use Software Breakpoints setting of CCE.

If software breakpoints are disabled, a maximum of N breakpoints can be set within the debugger.

Resetting a program requires a breakpoint, which is set on the address defined in Project → Properties →

TI Debug Settings → Target → Generic → Run To.

The Run To Cursor operation temporarily requires a breakpoint.

Console I/O (CIO) functions, such as printf, require the use of a breakpoint. If these functions are compiled

in, but you do not wish to use a breakpoint, disable CIO functionality by changing the option in Project →

Properties → TI Debug Settings → Target → Generic → Enable CIO function use.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Development Flow

23

Using the Integrated Debugger

2.2.2.1

www.ti.com

Breakpoints in CCE v3.1

CCE supports a number of predefined breakpoint types that can be selected by opening a menu found

next to the Breakpoints icon in the Breakpoint window (Window → Show View → Other...→ Debug →

Breakpoints). In addition to traditional breakpoints, CCE allows setting watchpoints to break on a data

address access instead of an address access. The properties of breakpoints/watchpoints can be changed

in the debugger by right clicking on the breakpoint and selecting Properties.

• Break in program range

Stops code execution when the program attempts to execute code in a specific range.

• Break before program address

Stops code execution when the program attempts to execute code before a specific address.

• Break after program address

Stops code execution when the program attempts to execute code after a specific address.

• Break on DMA transfer

• Break on DMA transfer in range

Breaks when a DMA access within a specified address range occurs.

• Break on stack overflow

It is possible to debug the applications that caused the stack overflow. Set Break on Stack Overflow

(right click in debug window and then select "Break on Stack Overflow" in the context menu). The

program execution stops on the instruction that caused the stack overflow. The size of the stack can

be adjusted in Project → Properties → C/C++ Build → MSP430 Executable Linker → General Options.

• Hardware breakpoint

Forces a hardware breakpoint if software breakpoints are not disabled.

• Watchpoint on data address range

Stops code execution when data access to an address in a specific range occurs.

• Watchpoint with data

Stops code execution if a specific data access to a specific address is made with a specific value.

Restriction 1: Watchpoints are applicable to global variables and non-register local variables. In the

latter case, set a breakpoint (BP) to halt execution in the function where observation of the variable is

desired (set code BP there). Then set the watchpoint and delete (or disable) the code breakpoint in the

function and run/restart the application.

Restriction 2: Watchpoints are applicable to variables 8 bits and 16 bits wide.

Note:

Not all options are available on every MSP430 derivative (see Table 2-1). Therefore, the

number of predefined breakpoint types in the breakpoint menu varies depending on the

selected device.

For more information on advanced debugging with CCE, see the application report Advanced Debugging

Using the Enhanced Emulation Module (EEM) With CCE Version 3 (SLAA393).

24

Development Flow

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Chapter 3

SLAU157I – May 2005 – Revised February 2009

Design Considerations for In-Circuit Programming

This chapter presents signal requirements for in-circuit programming of the MSP430.

Topic

3.1

3.2

3.3

..................................................................................................

Page

Signal Connections for In-System Programming and Debugging,

MSP-FET430PIF, MSP-FET430UIF, MSP-GANG430, MSP-PRGS430.. 26

External Power ......................................................................... 28

Bootstrap Loader ...................................................................... 29

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Design Considerations for In-Circuit Programming

25

Signal Connections for In-System Programming and Debugging, MSP-FET430PIF, MSP-FET430UIF, MSP-GANG430,

MSP-PRGS430

www.ti.com

3.1

Signal Connections for In-System Programming and Debugging, MSP-FET430PIF,

MSP-FET430UIF, MSP-GANG430, MSP-PRGS430

With the proper connections, the debugger and an FET hardware JTAG interface (such as the

MSP-FET430PIF and MSP-FET430UIF) can be used to program and debug code on the target board. In

addition, the connections also support the MSP-GANG430 or MSP-PRGS430 production programmers,

thus providing an easy way to program prototype boards, if desired.

Figure 3-1 shows the connections between the 14-pin FET interface module connector and the target

device required to support in-system programming and debugging for 4-wire JTAG communication.

Figure 3-2 shows the connections for 2-wire JTAG mode (Spy-Bi-Wire). While 4-wire JTAG mode is

supported on all MSP430 devices, 2-wire JTAG mode is available on selected devices only. See Table 2-1

for information on which interface method can be used on which device.

The connections for the FET interface module and the MSP-GANG430 or MSP-PRGS430 are identical.

Both the FET interface module and MSP-GANG430 can supply VCC to the target board (via pin 2). In

addition, the FET interface module and MSP-GANG430 have a VCC-sense feature that, if used, requires

an alternate connection (pin 4 instead of pin 2). The VCC-sense feature senses the local VCC present on

the target board (i.e., a battery or other local power supply) and adjusts the output signals accordingly. If

the target board is to be powered by a local VCC, then the connection to pin 4 on the JTAG should be

made, and not the connection to pin 2. This utilizes the VCC-sense feature and prevents any contention

that might occur if the local on-board VCC were connected to the VCC supplied from the FET interface

module or the MSP-GANG430. If the VCC-sense feature is not necessary (i.e., the target board is to be

powered from the FET interface module or the GANG430) the VCC connection is made to pin 2 on the

JTAG header and no connection is made to pin 4. Figure 3-1 and Figure 3-2 show a jumper block that

supports both scenarios of supplying VCC to the target board. If this flexibility is not required, the desired

VCC connections may be hard-wired eliminating the jumper block. Pins 2 and 4 must not be connected

simultaneously.

Note that in 4-wire JTAG communication mode (see Figure 3-1), the connection of the target RST signal

to the JTAG connector is optional when using devices that support only 4-wire JTAG communication

mode. However, when using devices that support 2-wire JTAG communication mode in 4-wire JTAG

mode, the RST connection must be made. The MSP430 development tools and device programmers

perform a target reset by issuing a JTAG command to gain control over the device. However, if this is

unsuccessful, the RST signal of the JTAG connector may be used by the development tool or device

programmer as an additional way to assert a device reset.

26

Design Considerations for In-Circuit Programming

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Signal Connections for In-System Programming and Debugging, MSP-FET430PIF, MSP-FET430UIF,

MSP-GANG430, MSP-PRGS430

www.ti.com

VCC

J1 (see Note A)

VCC/AVCC/DVCC

J2 (see Note A)

R1

47 kW

(see Note B)

JTAG

VCC TOOL

VCC TARGET

TEST

C2

10 µF

C3

0.1 µF

MSP430Fxxx

RST/NMI

2

1

4

3

6

5

8

7

10

9

12

11

14

13

TDO/TDI

TDO/TDI

TDI

TDI/TCLK

TMS

TCK

TMS

TCK

GND

RST (see Note D)

TEST (see Note C)

C1

10 nF/2.2 nF

(see Notes B and E)

VSS/AVSS/DVSS

A

Make either connection J1 in case a local target power supply is used or connection J2 to power target from the

debug/programming adapter.

B

The RST/NMI pin R1/C1 configuration is device family dependent. See the respective MSP430 family user's guide for

the recommended configuration.

C

The TEST pin is available only on MSP430 family members with multiplexed JTAG pins. See the device-specific data

sheet to determine if this pin is available.

D

The connection to the JTAG connector RST pin is optional when using 4-wire JTAG communication mode

capable-only devices and not required for device programming or debugging. However, this connection is required

when using 2-wire JTAG communication mode capable devices in 4-wire JTAG mode.

E

When using 2-wire JTAG communication capable devices in 4-wire JTAG mode, the upper limit for C1 should not

exceed 2.2 nF. This applies to both TI FET interface modules (LPT/USB FET).

Figure 3-1. Signal Connections for 4-Wire JTAG Communication

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Design Considerations for In-Circuit Programming

27

External Power

www.ti.com

VCC

J1 (see Note A)

VCC/AVCC/DVCC

J2 (see Note A)

R1

47 kW

(see Note B)

C2

10 µF

C3

0.1 µF

MSP430Fxxx

JTAG

VCC TOOL

VCC TARGET

TEST

2

1

4

3

6

5

8

7

10

9

12

11

14

13

TDO/TDI

RST/NMI/SBWTDIO

TCK

GND

R2

330 W

(see Note C)

TEST/SBWTCK

C1

2.2 nF

(see Note B)

VSS/AVSS/DVSS

A

Make either connection J1 in case a local target power supply is used or connection J2 to power target from the

debug/programming adapter.

B

The device RST/NMI/SBWTDIO pin is used in 2-wire mode for bidirectional communication with the device during

JTAG access and that any capacitance attached to this signal may affect the ability to establish a connection with the

device. The upper limit for C1 is 2.2 nF when using current TI FET interface modules (USB FET).

C

R2 is used to protect the JTAG debug interface TCK signal against the JTAG security fuse blow voltage that is

supplied by the TEST pin during the fuse blow process. If fuse blow functionality is not needed, R2 is not required

(becomes 0 Ω), and the connection TEST must not be made.

Figure 3-2. Signal Connections for 2-Wire JTAG Communication (Spy-Bi-Wire)

3.2

External Power

The PC parallel port can source a limited amount of current. Because of the ultra-low-power requirement

of the MSP430, a standalone FET does not exceed the available current. However, if additional circuitry is

added to the tool, this current limit could be exceeded. In this case, external power can be supplied to the

tool via connections provided on the target socket modules. See the schematics and pictorials of the

target socket modules in Appendix B to locate the external power connectors.

The MSP-FET430UIF can supply targets with up to 100 mA through pin 2 of the 14-pin connector. VCC for

the target can be selected between 1.8 V and 5 V in steps of 0.1 V. Alternatively, the target can be

supplied externally. In this case, the external voltage should be connected to pin 4 of the 14-pin connector.

The MSP-FET430UIF then adjusts the level of the JTAG signals to external VCC automatically. Only pin 2

(MSP-FET430UIF supplies target) or pin 4 (target is externally supplied) must be connected; not both at

the same time.

When a target socket module is powered from an external supply, the external supply powers the device

on the target socket module and any user circuitry connected to the target socket module, and the FET

interface module continues to be powered from the PC via the parallel port. If the externally supplied

voltage differs from that of the FET interface module, the target socket module must be modified so that

the externally supplied voltage is routed to the FET interface module (so that it may adjust its output

voltage levels accordingly). See the target socket module schematics in Appendix B.

28

Design Considerations for In-Circuit Programming

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Bootstrap Loader

www.ti.com

3.3

Bootstrap Loader

The JTAG pins provide access to the flash memory of the MSP430Fxxx devices. On some devices, these

pins are shared with the device port pins, and this sharing of pins can complicate a design (or sharing may

not be possible). As an alternative to using the JTAG pins, most MSP430Fxxx devices contain a program

(a "bootstrap loader") that permits the flash memory to be erased and programmed using a reduced set of

signals. The MSP430 Memory Programming User's Guide (SLAU265) describes this interface. TI does not

produce a BSL tool. However, customers can easily develop their own BSL tools using the information in

the application reports, or BSL tools can be purchased from third parties. See the MSP430 web site for

the application reports and a list of MSP430 third-party tool developers.

TI suggests that MSP430Fxxx customers design their circuits with the BSL in mind (i.e., TI suggests

providing access to these signals via, for example, a header).

See FAQ Hardware #12 for a second alternative to sharing the JTAG and port pins.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Design Considerations for In-Circuit Programming

29

30

Design Considerations for In-Circuit Programming

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Appendix A

SLAU157I – May 2005 – Revised February 2009

Frequently Asked Questions

This appendix presents solutions to frequently asked questions regarding hardware, program

development, and debugging tools.

Topic

A.1

A.2

A.3

..................................................................................................

Page

Hardware ................................................................................. 32

Program Development (Assembler, C-Compiler, Linker, IDE) ......... 33

Debugging ............................................................................... 34

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Frequently Asked Questions

31

Hardware

A.1

www.ti.com

Hardware

1. The state of the device (CPU registers, RAM memory, etc.) is undefined following a reset.

Exceptions to the above statement are that the PC is loaded with the word at 0xFFFE (i.e., the reset

vector), the status register is cleared, and the peripheral registers (SFRs) are initialized as documented

in the device family user's guides. The CCE debugger resets the device after programming it.

2. MSP430F22xx Target Socket Module (MSP-TS430DA38) – Important Information

Due to the large capacitive coupling introduced by the device socket between the adjacent signals

XIN/P2.6 (socket pin 6) and RST/SBWTDIO (socket pin 7), in-system debugging can disturb the

LFXT1 low-frequency crystal oscillator operation (ACLK). This behavior applies only to the Spy-Bi-Wire

(2-wire) JTAG configuration and only to the period while a debug session is active.

Workarounds:

• Use the 4-wire JTAG mode debug configuration instead of the Spy-Bi-Wire (2-wire) JTAG

configuration. This can be achieved by placing jumpers JP4 through JP9 accordingly.

• Use the debugger option "Run Free" that can be selected from the Advanced Run dropdown menu

(at top of Debug View). This prevents the debugger from accessing the MSP430 while the

application is running. Note that, in this mode, a manual halt is required to see if a breakpoint was

hit. See the IDE documentation for more information on this feature.

• Use an external clock source to drive XIN directly.

3. The 14-conductor cable connecting the FET interface module and the target socket module must not

exceed 8 inches (20 centimeters) in length.

4. The signal assignment on the 14-conductor cable is identical for the parallel port interface and the

USB FET.

5. To utilize the on-chip ADC voltage references, C6 (10 µF, 6.3 V, low leakage) must be installed on

the target socket module.

6. To utilize the charge pump on the devices with LCD+ Module, C4 (10 µF, low leakage) must be

installed on the target socket module.

7. Crystals/resonators Q1 and Q2 (if applicable) are not provided on the target socket module. For

MSP430 devices that contain user-selectable loading capacitors, the effective capacitance is the

selected capacitance plus 3 pF (pad capacitance) divided by two.

8. Crystals/resonators have no effect upon the operation of the tool and the CCE debugger (as any

required clocking/timing is derived from the internal DCO/FLL).

9. On 20-pin and 28-pin devices with multiplexed port/JTAG pins (P1.4 to P1.7), "Run Free" (in

Advanced Run menu at top of Debug View) must be selected to use these pins in their port

capacity.

10. As an alternative to sharing the JTAG and port pins (on 20 and 28 pin devices), consider using

an MSP430 device that is a "superset" of the smaller device. A very powerful feature of the

MSP430 is that the family members are code and architecturally compatible, so code developed on

one device (e.g., one without shared JTAG and port pins) port effortlessly to another (assuming an

equivalent set of peripherals).

11. Information memory may not be blank (erased to 0xFF) when the device is delivered from TI.

Customers should erase the Information Memory before its first usage. Main Memory of packaged

devices is blank when the device is delivered from TI.

12. The device current increases by approximately 10 µA when a device in low-power mode is

stopped (using Halt) and then the low-power mode is restored (using Run). This behavior appears

to happen on all devices except the MSP430F12x.

32

Frequently Asked Questions

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Program Development (Assembler, C-Compiler, Linker, IDE)

www.ti.com

13. The following ZIF sockets are used in the FET tools and target socket modules:

• 14-pin device (PW package): Enplas OTS-14-065-01

• 28-pin device (DW package): Wells-CTI 652 D028

• 28-pin device (PW package): Enplas OTS-28-0.65-01

• 38-pin device (DA package): Yamaichi IC189-0382-037

• 40-pin device (RHA package): Enplas QFN-40B-0.5-01

• 48-pin device (DL package): Yamaichi IC51-0482-1163

• 64-pin device (PM package): Yamaichi IC51-0644-807

• 80-pin device (PN package): Yamaichi IC201-0804-014

• 100-pin device (PZ package): Yamaichi IC201-1004-008

Enplas: www.enplas.com

Wells-CTI: www.wellscti.com

Yamaichi: www.yamaichi.us

A.2

Program Development (Assembler, C-Compiler, Linker, IDE)

Note:

Consider the CCE Release Notes

For the case of unexpected behavior, see the CCE Release Notes document for known bugs

and limitations of the current CCE version. This information can be accessed through the

menu item Start → All Programs → Texas Instruments → Code Composer Essentials v3.1

→ Release Notes.

1. A common MSP430 "mistake" is to fail to disable the watchdog mechanism; the watchdog is

enabled by default, and it resets the device if not disabled or properly managed by the application.

2. Within the C libraries, GIE (Global Interrupt Enable) is disabled before (and restored after) the

hardware multiplier is used.

3. It is possible to mix assembly and C programs within CCE. See the "Interfacing C/C++ With

Assembly Language" chapter of the MSP430 Optimizing C/C++ Compiler User's Guide (literature

number SLAU132).

4. Constant definitions (#define) used within the .h files are effectively reserved and include, for

example, C, Z, N, and V. Do not create program variables with these names.

5. Compiler optimization can remove unused variables and/or statements that have no effect and

can affect debugging. To prevent this, these variables can be declared volatile; e.g.,

volatile int i;.

SLAU157I – May 2005 – Revised February 2009

Submit Documentation Feedback

Frequently Asked Questions

33

Debugging

A.3

www.ti.com

Debugging

The debugger is part of CCE and can be used as a standalone application. This section is applicable

when using the debugger both standalone and from the CCE IDE.

Note:

Consider the CCE release notes

In case of unexpected behavior, see the CCE Release Notes document for known bugs and

limitations of the current CCE version. To access this information, click Start → All Programs

→ Texas Instruments → Code Composer Essentials v3.1 → Release Notes.

1. The debugger reports that it cannot communicate with the device. Possible solutions to this

problem include:

• Ensure that the correct port has been selected in the TI Debug Settings (Project → Properties →

TI Debug Settings → Setup → Connection).

• Ensure that the jumper settings are configured correctly on the target hardware.