Separation of Azeotropic Mixtures: Tools for Analysis and

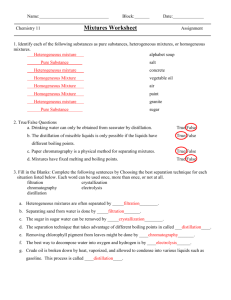

advertisement