Experiment #5: Stress

advertisement

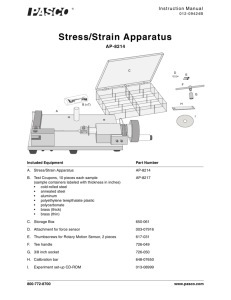

Experiment #5: Stress-Strain Objectives: After completing Experiment 5, student will be knowledgeable with the following areas: Find the relationship between axial (normal) stress and strain for various materials. The StressStrain Apparatus stretches (and in some cases breaks) a test coupon while it measures the amount of stretch and force experienced by the test coupon. Software is used to generate a plot of stress versus strain, which allows: the break point to be ascertained. 1. 2. 3. 4. 5. 6. Young's Modulus The elastic region The plastic region The yield point The break point to be ascertained. Answer questions posted at the end of the lab experiment. Theory: The ratio of the force (F) applied to the cross-sectional area (A) of a material is called the stress: Stress F A units: Newton per square meter or Pascal (Pa) The ratio of the change in length (ΔL) to the original length (Lo) of a material is called the strain: Stress (N/m3) Strain L Lo no units Plastic Region Elastic Region Yield Point Strain 1 Experiment #5: Stress-Strain Background of Equipment: PASCO Stress-Strain Apparatus (AP-8214) The PASCO Stress/Strain Apparatus shows the stress and strain during the entire process of stretching and breaking a material. Since the Stress/Strain Apparatus shows the entire stress versus strain curve, it is possible to measure a wide range of material properties including Young's Modulus, the yield strength, tensile strength, ductility and toughness of the material. In addition, the different curve shapes for different materials can be compared. PASCO PASPORT High Resolution Force Sensor (PS-2189) The study of force is critical to many science explorations. An accurate and rugged sensor will ensure the highest accuracy out of force experiments. The digital design of the High Resolution Force Sensor results in very little drift, ensuring that the tare will hold for hours. PASCO Rotary Motion Sensor (PS-2120) The PASCO Rotary Motion Sensor may be used to study optics, dynamics, centripetal force, motion of a pendulum and many other topics. It measures position, velocity and acceleration (angular and linear) with incredible (0.09 º) resolution and accuracy. Higher maximum spin rate (30 rev/sec) allows students to perform a full range of motion experiments. It also Measures magnitude and direction of motion. 2 Experiment #5: Stress-Strain Materials Needed: PASCO Xplorer GLX Part #PS-2002 (Figure 1) PASCO Stress-Strain Apparatus #AP-8214 (Figure 2) PASCO PASPORT High Resolution Force Sensor #PS-2189 (Figure 3) PASCO Rotary Motion Sensor #PS-2120 (Figure 4) Calipers Computer with PASCO DataStudio software installed. Figure 1. PASCO Xplorer GLX Part #PS-2002 Figure 2. PASCO StressStrain Apparatus Part #AP-8214 Figure 3. PASCO PASPORT High Resolution Force Sensor Part #PS-2189 Figure 4. PASCO Rotary Motion Sensor Part #PS-2120 3 Experiment #5: Stress-Strain SET-UP for PASPORT Sensors Apparatus Setup Figure 5. 1. Attach the Rotary Motion Sensor to the apparatus platform. Remove the rod clamp from the RMS. Place the three-step pulley onto the shaft of the RMS with the largest pulley out. Using the two thumbscrews, fasten the RMS to the apparatus platform from beneath. Seat the belt on the middle step of the three-step pulley and the groove on the crankshaft (Figure 5). 2. Attach the Force Sensor to the apparatus platform. Remove the hook from the Force Sensor and replace it with the force sensor attachment. Place the Force Sensor on the apparatus platform by inserting the post through the support rod mount of the Force Sensor. Insert the long thumbscrew supplied with the Force Sensor through the hole on the Force Sensor marked "Cart" and screw it into the tapped hole in the apparatus platform. Tighten the setscrew in the support rod mount of the Force Sensor (Figure 5). 3. Clamp down the apparatus (optional). Use a large C-clamp to clamp the Apparatus Platform to the edge of the bench or table. One side of the platform has three feet. In order to avoid bending the platform, position the clamp directly over the center foot. 4. Plug the sensors into the interface. Connect the Force Sensor to the interface. Connect the Rotary Motion Sensor to the interface. 5. Prepare DataStudio. Start DataStudio and open the activity file Stress Strain (PP).ds. 4 Experiment #5: Stress-Strain 6. Check RMS orientation. While monitoring data in DataStudio, turn the crank clockwise. Watch the "Displacement" digits display. If displacement decreases, detach and flip the RMS over. Reattach the RMS. Experimental Procedure: Apparatus Calibration During the experiment, as the crank turns, force will be applied to the test coupon, causing it to stretch. However, this force will also cause the apparatus platform and the Force Sensor to bend. The displacement registered by the RMS will be the combination of the coupon stretching and the rest of the apparatus bending. Regardless of how much the coupon stretches, the deformation of the rest of the apparatus is constant for a given force. One can measure this deformation directly by using the calibration bar (which does not stretch significantly) in place of a coupon as force is applied. The goal is to create a plot of Displacement versus Force for the calibration bar, in which the displacement is due only to bending of the apparatus. Later, subtract this plot from a similar plot made with a coupon, in which the displacement results from both bending of the apparatus and stretching of the coupon. The result will be a plot in which the displacement is due only to stretching of the coupon. Figure 6. Calibration bar setup 5 Experiment #5: Stress-Strain Use the following steps to acquire Displacement versus Force data: 1. Mount the Calibration Bar. Remove the nuts and clips from the apparatus platform (Figure 6). Turn the crank to adjust the position of the bolts and slip the bolts through the holes in the calibration bar. Do not replace the nuts when using the calibration bar. Figure 7. Start position 2. Place the lever arm in the starting position. Turn the crank counter-clockwise and pull the lever arm away from the Force Sensor (Figure 7). 3. Plot Position versus Force. Press the Tare button on the Force Sensor. Click the Start button. Wait until the digits of the experiment clock turn yellow. Turn the crank clockwise. Starting just before the lever arm comes into contact with the Force Sensor, turn the crank very slowly. DataStudio will start recording when the force applied to the coupon reaches 2.5 N, or 1% of maximum (as shown in the "% Max Force" digits display). Continue to turn the crank until the force reaches 100% of maximum. At this point, DataStudio will stop recording automatically. In the Data Summary, click and drag the "Displacement(t) vs Coupon Force(t) (mm)" to a Table. Then click on the pencil icon at the top of the table to make an editable copy of this data. Answer “No” when asked “Other displays are viewing this data. Should DataStudio change other displays to show the edited data?” Now a new entry will appear in the Data Summary: “Displacement(t) vs Coupon Force(t) (Editable)(mm)”. Note: Creating an editable copy of the calibration data assures that the calibration data will not be accidentally deleted. DataStudio will not delete editable copies even if “Delete All Runs” is selected. 6 Experiment #5: Stress-Strain DATA COLLECTION - Software Setup Figure 8 1. Prepare the calculation for Calibrated Position. Click the Calculate button at the top of DataStudio. In the Calculator dialog, define the variables for the "Calibrated Displacement(F)" calculation: Drag "Displacement(t) vs Coupon Force(t) (mm)" to "Please define variable 'Displacement'." (Figure 8) Drag "Run #1(Edited)" from the “Displacement(t) vs Coupon Force(t) (Editable)(mm)” to "Please define variable 'Cal'."* (DataStudio will display a warning box stating that a "single run is selected". Click the Yes button in that box.) Click “Accept.” 2. Prepare the calculation for Stress. In the Calculator dialog, select the defined function "Stress(F) = Force/Area". In the Variables section, enter the cross-sectional Area of the coupon in square millimeters. Click “Accept.” 3. Prepare the calculation for Strain. In the Calculator dialog, select the defined function "Strain(F) = Displacement/Length". In the Variables section, enter the Length of the narrow part of the coupon in millimeters. Click “Accept.” 4. Close the Calculator dialog. 7 Experiment #5: Stress-Strain DATA COLLECTION 1. Mount a coupon. Remove the calibration bar and restore the clips and nuts. Place one end of the coupon under one of the clips. Adjust the crank so that the opposite end of the coupon can slip easily under the other clip. Tighten both nuts with the wrench. With no force applied to the coupon, as little twist as possible should be visible in the coupon. The clips should hold the coupon tightly enough that it will not slip when force is applied. However, overtightening the nuts will damage the bolts. Use your best judgment. If in doubt, error on the side of under-tightening (Figure 9). Figure 9 2. Place the lever arm in the starting position. Turn the crank counter-clockwise and pull the lever arm away from the Force Sensor (Figure 7). 3. Collect Data. Press the Tare button on the Force Sensor. Click the Start button. Wait until the digits of the experiment clock turn yellow. Turn the crank clockwise. Starting just before the lever arm comes into contact with the Force sensor, turn the crank very slowly. When finished collecting data, click Stop. (If the maximum force is reached, DataStudio will stop automatically.) If the coupon breaks, it should break in the middle. If the coupon breaks near the end, it was probably twisted slightly when it was mounted, resulting in a point of higher stress where it broke. 4. Rename the data run to identify the coupon. Use the same method used to rename the calibration data. 8 Experiment #5: Stress-Strain DATA ANALYSIS On the Stress versus Strain graph, identify and record the elastic region, the plastic region, the yield point, and the break point (if available). To calculate Young's modulus, select a data region covering the linear, lower left-hand part of the graph. (The very first part of the plot may not be linear. This nonlinearity likely is due to the straightening of bends and twists in the coupon as force is first applied. Do not include this region in the selection.) Apply a linear curve fit to the selected data. The slope of the line is Young's modulus in units of MPa (or MN/m2 or N/mm2). Record Young’s Modulus. Test more coupons. To test another coupon, hide previous runs. From the Data button at the top of the Stress-Strain graph, deselect data runs that need to be hidden. Return to item 2 (page 7) “Prepare the calculation for Stress.” Enter the appropriate values for the calculation of Stress and Strain in the Calculator dialog for the new coupon. Continue with data collection. 9 Experiment #5: Stress-Strain Pre-Laboratory Review Questions (Answers should be turned in at the start of class in correct format) 1. What is stress? 2. How is stress calculated? What are the units? 3. What is strain? 4. What does the elastic region symbolize? 5. What is the yield point of a material? 6. What does the plastic region symbolize? Post Laboratory Review Questions (Answers should be found throughout Laboratory Report in correct format) 1. Define mechanical stress in your own words and include a sketch. Discuss what is physically happening to a coupon when it is experiencing stress. 2. Define mechanical strain in your own words and include a sketch. Discuss what is physically happening to a coupon when it is experiencing strain. 3. Sketch a sample graph of stress v. strain from your data. Identify different regions. Discuss the relationship between stress and strain in these regions. 4. Does the coupon that can withstand the greatest force also experience the greatest stress? Explain. 5. Does the coupon that can withstand the greatest force also experience the greatest strain? Explain. 6. Do the graphs agree with Hooke’s Law? Explain. 7. Compare the brass coupons of different thicknesses with respect to their Young’s Modulus and yield points. Include an explanation at the atomic level. 10 Experiment #5: Stress-Strain 8. If a coupon is stretched beyond its yield limit, but not beyond its break point, will its Young’s Modulus change? Explain. 9. Describe what would happen to the Stress-Strain graph if a coupon were heated. Explain. References: 1. "PASCO : Materials Stress Strain Experiment, PASPORT - EX-9928." PASCO : Home. Web. 09 Dec. 2011. <http://www.pasco.com/prodCatalog/EX/EX-9928_materials-stressstrain-experiment-pasport/>. 2. "PASCO : PASPORT High Resolution Force Sensor - PS-2189." PASCO : Home. Web. 09 Dec. 2011. <http://www.pasco.com/prodCatalog/PS/PS-2189_pasport-high-resolution-forcesensor/index.cfm>. 3. "PASCO : PASPORT Rotary Motion Sensor - PS-2120." PASCO : Home. Web. 09 Dec. 2011. <http://www.pasco.com/prodCatalog/PS/PS-2120_pasport-rotary-motionsensor/index.cfm>. 4. "PASCO : Stress/Strain Apparatus (without Sensors) - AP-8214." PASCO : Home. Web. 09 Dec. 2011. <http://www.pasco.com/prodCatalog/AP/AP-8214_stress-strain-apparatuswithout-sensors/>. 11