Innovations for large shovels

advertisement

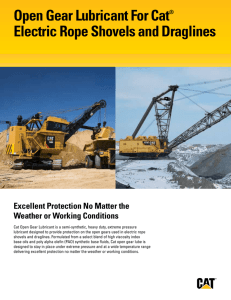

ME Online Exclusive Mining at the lowest cost per ton: Innovations for large shovels by William Gleason, Senior Editor A Cat 7495 electric rope shovel has been in testing at Caterpillar’s proving grounds in Arizona. 2 DECEMBER 2013 W ith its 2011 acquisition of rival equipment company Bucyrus International, Caterpillar added underground mining and large shovels to its line of products and further solidified its standing as the leading mining equipment manufacturer in the world with solutions for every aspect of mining. When Caterpillar spent $8.8 billion to acquire Bucyrus, the global mining business was flourishing, as mining companies around the world worked to keep up with demands for nearly every commodity. Flash forward to 2013, and the global mining landscape looks very different. Lower demand for raw material from China and India and falling commodity prices have Mınıng engıneerıng forced most mining companies to pull back on their production. The reductions from the mining industry have hit equipment makers like Caterpillar and Komatsu hard. In October, Caterpillar reported that its quarterly earnings had fallen 44 percent. The changing conditions have also changed the narrative from Caterpillar and other equipment makers to customers from offering solutions to move the most tons per hour, to now offering solutions for the lowest cost per ton. In September, Caterpillar hosted some of its mining customers and the trade press at its Tinaja Hills Demonstration and Learning Center near Tucson, AZ to talk about its range of products, from its MineStar System designed to help increase efficiency through better equipment management and planning, all the way up to the massive Cat 7495 and 7495HF electric rope shovel lines acquired through the Bucyrus takeover. During the two days of presentations, the recurring theme was more efficient operations with a lower cost per ton and how to achieve this goal. Experts spoke about improving haul roads, cycle times, optimized payloads, improved fuel consumption and mechanical maintenance. One of the ways that Caterpillar plans to help its customers in the near future is with the Cat Power Demand Management System on the Cat 7495 and 7495 HF electric rope shovel. In short, the system generates and stores power during swing deceleration and bucket lowering. The system can then draw on that power when needed. While not yet commercially available, the system that will permit mining companies to power the shovels on just 4 MW of power has been tested and validated as an off-grid solution at Caterpillar’s Tinaja Hills proving grounds. After field trials at an operating mine, it is expected to be commercially available in 2014. The standard practice for large rope shovels uses multiple generators with a total of 8 MW or more capacity to achieve rapid response when peak power is required. Of course, multiple generators increase maintenance and fuel costs. Additionally, generator-powered electric rope shovels require additional systems to dissipate regenerated energy, because they cannot feed electricity back into the power grid. The Cat Power Demand Management System www.miningengineeringmagazine.com ME Online Exclusive stores regenerative energy created during swing deceleration and bucket lowering, and the system uses that power during periods of high demand to reduce the generator load cycle. Ultra capacitors enable the system to store and release energy quickly. The system enables a 4-MW generator to handle a large electric rope shovel, and it reduces fuel consumption by employing regenerative energy. The power demand management system employs two methods of power management: peak shaving and ramp rate limiting. Peak shaving uses stored energy to reduce the peak demand seen by the power supply. The ramp rate limiter is a similar concept, but instead of reducing the peaks, it reduces the rate at which power is demanded. A 7495 shovel can switch from regenerating 2.5 MW of power to demanding 3.7 MW of power in less than a second. This is a very difficult ramp rate for a generator to supply. The system uses the energy stored in the ultra-capacitors to allow the generators to ramp up more slowly while still supplying all of the necessary power to the machine. Likewise, when power demand of the machine decreases quickly, the generators ramp down slowly and the excess energy recharges the ultra capacitors. The Cat Power Demand Management System in testing uses a skid with two 2-MW gensets and associated hardware, and the energy storage components are mounted on the roof of the shovel. The system will be available as a retrofit for 7495s. Caterpillar also displayed its new dynamic hoist brake with optional Smart Controller for Cat 7495 and 7495HF electric rope shovels. The dynamic hoist brake is designed to stop the dipper from dropping during an uncontrolled event such as a power drop or an emergency stop. The new brake is designed to perform and survive a full speed dynamic brake event with a fully loaded dipper and, as a result, to minimize the risk of an uncontrolled dipper drop. The dynamic hoist brake is a drop-in replacement for the standard hoist brake, which was designed to be applied when the hoist motor was not rotating. The new brake offers a www.miningengineeringmagazine.com number of advantages including friction material that eliminates burnishing requirements and reduces variations in brake torque, increased thermal capacity, increased life, mechanical wear indication and simplified, on-machine rebuild procedures. “The heavy-duty dynamic brake has undergone a rigorous design, development and validation process,” said Jim Ryan, new product introduction program lead, electric rope shovels. “We started with full bench testing to simulate the application, and we’ve proven its performance on our 7495 working at the Arizona Proving Grounds.” Caterpillar also has developed a smart controller, available as an option, to continuously monitor the applied torque, energy input and wear of the dynamic hoist brake. The controller also includes hardware that will apply additional brake torque, if necessary, by a secondary pneumatic piston. The smart controller helps ensure that brake torque levels do not drop below specified levels even as a result of temperature extremes, improper maintenance or other abnormalities. The system also monitors brake energy levels to anticipate thermal overload. It is easily fitted to all 7495 and 7495HF shovels using the Cat dynamic hoist brake. n Mınıng engıneerıng A Cat 7495 electric shovel loads a haul truck. DECEMBER 2013 3