10. Testing Of Welded Joints

advertisement

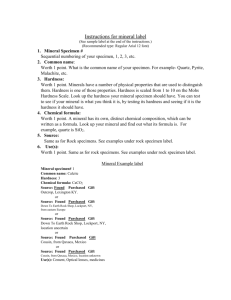

10. Testing of Welded Joints 10. Testing of Welded Joints Ls 126 The basic test for determination of material a S S S S in test area in test area S S b b1 S S Generally, it is carried out using a round L0 Lc r behaviour is the tensile test. specimen. When determining the strength of a welded joint, also standardised flat speci- Lt total length head width Lt b1 width of parallel length plates b tubes b 1 2 Lc r parallel length ) ) radius of throat depends on test unit b + 12 12 with a £ 2 25 with a > 2 6 with D £ 50 12 with 50 < D £ 168,3 ³ L S + 60 ³ 25 mens are used. Figure 10.1 shows both standard specimen shapes for that test. A specimen is ruptured by a test machine while the actual force and the elongation of the 1 d1 d S S ) for pressure welding and beam welding, L S = 0. 2 ) for some other metallic materials (e.g.aluminium, copper and their alloys) __ L c ³ L S +100 may be required r is typical for this test, Figure 10.2. L0 = measurement length (L0 = k ÖS0 with k = 5,65) Lt = total length S0 = initial cross-section within test length br-er10-01.cdr ment values, tension σ and strain ε are calculated. If σ is plotted over ε, the drawn diagram LO LC Lt d = specimen diameter d1 = head diameter depending on clamping device LC = test length = L0 + d/2 r = 2 mm specimen is measured. With these measure- Normally, if a steel with a bcc lattice structure © ISF 2002 Flat and Round Tensile Test Specimen to EN 895, EN 876, and EN 10 002 is tested, a curve with a clear yield point is obtained (upper picture). Steels with a fcc lattice structure show a curve without yield Figure 10.1 point. The most important characteristic values s which are determined by this test are: yield stress ReL, tensile strength Rm, and elongation Rm ReH Rel sf A. To determine the deformability of a weld, a e ALud Ag A bending test to DIN EN 910 is used, Figure 10.3. In this test, the specimen is put onto two s supporting rollers and a former is pressed Rm through between the rollers. The distance of RP0,2 RP0,01 sf the supporting rollers is Lf = d + 3a (former diameter + three times specimen thickness). e 0,2 % 0,01 % Ag is observed. If a surface crack develops, the A br-er10-02.cdr © ISF 2002 Stress-Strain Diagram With and Without Distinct Yield Point Figure 10.2 The backside of the specimen (tension side) test will be stopped and the angle to which the specimen could be bent is measured. The 10. Testing of Welded Joints 127 test result is the bending angle and the diameter of the used former. A bending angle of 180° is reached, if the specimen is pressed through the supporting rollers without development of a crack. In Figure 10.3 specimen shapes of this test are shown. Depending on the direction the weld is bent, one distinguishes (from top to bottom) transverse, side, and longitudinal bending specimen. The tension side of all three specimen types is machined to eliminate any influences through Specimen on the notch test effects. thickness of transverse and longitudinal specimens is thickness. Side the plate bending specimens are normally only used with very thick plates, here the specimen thickness is fixed at 10 mm. A determination of the toughness of a material or Figure 10.3 welded joint is carried out with the notched bar impact test. A cuboid specimen with a V-notch is placed on a support and then hit by a pendulum ram of the impact testing machine (with very tough materials, the specimen will be bent and drawn through the supports). The used energy is measured. Figure 10.4 represents sample shape, notch shape (Iso-V- specimen), and a schematic presentation of test results. Figure 10.4 10. Testing of Welded Joints 128 Three specimens are tested at each test tem- b Designation VWS a/b Dicke a RL VWS a/b (fusion weld) Fusion line/bonding zone perature, and the average values as well as b Weld centre Designation RL the range of scatter are entered on the impact a Dicke b b energy-temperature diagram (AV-T curve). VWT 0/b VHT 0/b This graph is divided into an area of high im- a b b pact energy values, a transition range, and an VHT a/b a area of low values. A transition temperature is VWT 0/b b a b VWT a/b VHT a/b b b VWT a/b drop of toughness values. When the tempera- a RL RL VHT a/b a RL takes place. V = Charpy-V notch W = notch in weld metal; reference line is centre line of weld H = notch in heat affected zone; reference line is fusion line or bonding zone (notch should be in heat affected zone) S = notched area parallel to surface T = notch through thickness a = distance of notch centre from reference line (if a is on centre line of weld, a = 0 and should be marked) b = distance between top side of welded joint and nearest surface of the specimen (if b is on the weld surface, then b = 0 and should be marked) br-er10-05.cdr As this steep drop mostly extends across a certain area, a precise assignment of transi© ISF 2002 Position of Charpy-V Impact Test Specimen in Welded Joints to EN 875 Figure 10.5 ture falls below this transition temperature, a transition of tough to brittle fracture behaviour a RL assigned to the transition range, i.e. the rapid tion temperature cannot be carried out. Following DIN 50 115, three definitions of the transition temperature are useful, i.e. to fix TÜ to: 1.) a temperature where the level of impact values is half of the level of the high range, 2.) a temperature, where the fracture area of the specimen shows still 50% of tough fracture behaviour 3.) a temperature with an impact energy value of 27 J. Figure 10.5 illustrates a specimen position and notch position related to the weld according to DIN EN 875. By modifying the notch position, the impact energy of the individual areas like HAZ, fusion line, weld metal, and base metal can be determined in a relatively accurate way. Figure 10.6 presents the influence of various alloy elements on the AV-T - curve. Three basically different influences can be seen. Increasing manganese contents increase the impact values in the area of the high level and move the transition temperature to lower values. The values of the low levels remain unchanged, thus the steepness of the drop becomes clearer with increasing Mn-content. Carbon acts exactly in the opposite way. An increasing carbon content increases the transition temperature and lowers the values of the high level, the steel becomes more brittle. Nickel decreases slightly the values of the high level, but increases the 10. Testing of Welded Joints 129 values of the low level with increasing con- specimen position: core longitudinal J tent. Starting with a certain Nickel content specimen shape: ISO V (depends also from other alloy elements), a 300 2% Mn steep drop does not happen, even at lowest 1% Mn 200 0,5% Mn temperature the steel shows a tough fracture behaviour. Charpy impact energy AV 100 0% Mn 27 200 In Figure 10.7, the AV-T – curves of some J 100 27 13% Ni 8,5% 5% 3,5% 2% Ni commonly used steels are collected. These 0% Ni curves are marked with points for impact en- 200 ergy values of AV = 27 J as well as with points 0,1% C J where the level of impact energy has fallen to 100 0,4% C half of the high level. It can clearly be seen 0,8% C 27 -150 -100 -50 0 Temperature 50 °C 100 © ISF 2002 br-er10-06.cdr Influence of Mn, Ni, and C on the Av-T-Curve that mild steels have the lowest impact energy values together with the highest transition temperature. The development of finegrain structural steels resulted in a clear im- Figure 10.6 provement of impact energy values and in addition, the application of such steels could be extended to a considerably lower temperature range. With the example of the steels St E 355 and St E 690 it is clearly visible that an increase of strength goes mostly hand in hand with a decrease of the impact energy level. provement Another showed imthe application of a thermomechanical treatment (con- trolled rolling during heat treatment). The application of this treatment resulted in an increase of strength and Figure 10.7 10. Testing of Welded Joints 130 impact energy values together with a parallel saving of alloy elements. To make a comparison, the AV-T - curve of the cryogenic and high alloyed steel X8Ni9 was plotted onto the diagram. The material is tested under very high P test speed in the impact energy test, thus C growth and fracture mechanisms. 1,2h ± 0,25 there are no reliable findings about crack 0,55h ± 0,25 C P a b CT - specimen L h 1,25h ± 0,13 Figure 10.8 shows two commonly used specimen height h = 2b ± 0,25 specimen width b total crack length a = (0,50 ± 0,05)h test load P specimen shapes for a fracture mechanics a h test to determine crack initiation and crack growth. The lower figure to the right shows a 2,1h 2,1h possibility how to observe a crack propaga- b S tion in a compact tensile specimen. During SENB -specimen 3PB specimen width b bearing distance S = 4h sample height h = 2b ± 0,05 total crack length a = (0,50 ± 0,05)h F,U crack initiation U F the test, a current I flows through the speci- UE,aE U men, and the tension drop above the notch is UO measured. V V br-er10-08.cdr © ISF 2002 Fracture Mechanics Test Sample Shape and Evaluation As soon as a crack propagates through the material, the current conveying cross section Figure 10.8 decreases, resulting in an increased voltage drop. Below to the left a measurement graph of such a test is shown. If the force F is plotted across the widening V, the drawn curve does not indicate precisely the crack initiation. F Analogous to the stress- F strain diagram, a decrease of force is caused by a reduction of the stressed h cross-section. If the voltage drop is plotted over the d force, then the start of d d1 2 crack initiation can be determined with suitable accuracy, and the crack br-er-10-09.cdr Hardness Testing to Brinell and Vickers Figure 10.9 propagation can be observed. 10. Testing of Welded Joints 131 Another typical characteristic of material behaviour is the hardness of the workpiece. Figure 10.9 shows hardness test methods to Brinell (standardised to DIN 50 351) and Vickers (DIN 50 133). When testing to Brinell, a steel ball is pressed with a known load to the surface of the tested workpiece. The diameter of the resulting impression is measured and is a magnitude of hardness. The hardness value is calculated from test load, ball diameter, and diameter of rim of the impression (you find the formulas in the standards). The hardness information contains in addition to the hardness magnitude the ball diameter in mm, applied load in kp and time of influence of the test load in s. This information is not required for a ball diameter of 10 mm, a test load of 3000 kp (29420 N), and a time of influence of 10 to 15 s. This hardness test method may be used only 0,200 mm 6 2 7 10 3 6 7 7 0 8,9 reference level for measurement 10 3 10 specimen surface 6 130 30 0 hardness scale hardness scale 100 6 4 5 3 8 130 30 0 specimen surface 0,200 mm Instead of a ball, a diamond pyramid is 1 3 100 0 Hardness testing to Vickers is analogous. This method is standardised to DIN 50133. 4 5 3 8 0,200 mm Hardness Number). 3 1 0,200 mm on soft materials up to 450 BHN (Brinell 8,9 reference level for measurement 7 10 pressed into the workpiece. The lengths of the two diagonals of the impression are Terms Abbreviation ball diameter = 1,5875 mm ( 1/16 inch) - cone angle = 120° 2 - radius of curvature of cone tip = 0,200 mm 3 F0 test preload 4 F1 test load lated from their average and the test load. 5 F total test load = F0 + F1 6 t0 penetration depth in mm under test preload F0. This defines the reference level for measurement of tb. The impressions of the test body are always 7 t1 total penetrationn depth in mm under test load F1 8 tb resulting penetration depth in mm, measured after release of F1 to F0 geometrically similar, so that the hardness 9 e resulting penetration depth, expressed in units of 0,002 mm: tb / 0,002 10 HRC HRA measured and the hardness value is calcu- 1 value is normally independent from the size of the test load. In practice, there is a hard- HRB HRF Rockwell hardness = 130 - e br-er10-10.cdr ness increase under a lower test load be- © ISF 2002 Hardness Test to Rockwell cause of an increase of the elastic part of the deformation. Rockwell hardness = 100 - e e = Figure 10.10 Hardness testing to Vickers is almost universally applicable. It covers the entire range of materials (from 3 VHN for lead up to 1500 VHN for hard metal). In addition, a hardness test can be carried out in the micro-range or with thin layers. Figure 10.10 illustrates a hardness test to Rockwell. In DIN 50103 are various methods standardised which are based on the same principle. 10. Testing of Welded Joints 132 With this method, the penetration depth of a penetrator is measured. At first, the penetrator is put on the workpiece by application of a pre-test load. The purpose is to get a firm contact between workpiece and penetrator and to compensate for possible play of the device. Then the test load is applied in a shock-free way (at least four times the pre-force) and held for a certain time. Afterwards it is released to reach minor load. The remaining penetration depth is characteristic for the hardness. If the display instrument is suitably scaled, the hardness value can be read-out directly. All hardness test methods to Rockwell use a ball (diameter 1.5875 mm, equiv. to 1/16 Inch) or a diamond sphero-conical penetrator (cone angle 120°) as the penetrating body. There are differences in size of pre- and test load, so different test methods are scaled for different hardness ranges. The most commonly used scale methods are Rockwell B and C. The most considerable advantage of these test methods compared with Vickers and Brinell are the low time duration and a possible fully-automatic measurement value recognition. The disadvantage is the reduced accuracy in contrast to the other methods. Measured hardness numbers are only comparable under identical conditions and with the same test method. A comparison of hardness values which were determined with different methods can only be carried out for similar materials. A conversion of hardness values of different methods can be carried out piston for steel and cast steel according to a table in DIN 50150. A relation of hardness and tensile strength is also given in that table. All the hardness test methods described above require a coupon which must be taken from the reference bar workpiece and whose hardness is then determined in a test machine. If a workpiece on-site is to be tested, a dynamical hardness test specimen method will be applied. The advantage of these methods is that measurements can be taken br-er10-11.cdr on completed constructions with handheld © ISF 2002 Poldi - Hammer Figure 10.11 10. Testing of Welded Joints 133 units in any position. Figure 10.11 illustrates a hardness test using a Poldi-Hammer. With this (out of date) method, the measurement is carried out by a comparison of the workpiece hardness with a calibration piece. For this purpose a calibration bar of exactly determined hardness is inserted into the unit, which is held by a spring force play-free between a piston and a penetrator (steel ball, 10 mm diameter). The unit is put on the workpiece to be tested. By a hammerblow to the piston, the penetrator penetrates the workpiece and the calibration pin simultaneously. The size of both impressions is measured and with the known hardness of the calibration bar the hardness of the workpiece can be determined. However, there are many sources of errors with this method which may influence the test result, e.g. an inclined resting of the unit on the surface or a hammerblow which is not in line with the device axis. The major source of errors is the measurement of the ball impression on the workpiece. On one hand, the edge of the impression is often unsharp because of the great ball diameter, on the other hand the measurement of the impression using magnifying glasses is subjected to serious errors. Figure 10.12 shows a modern measurement method which works with ultrasound and combines a high flexibility with easy handling and high accuracy. Here a test tip is pressed manually against a workpiece. If a defined test load is passed, a spring mechanism inside the test tip is triggered and the measurement starts. The measurement principle is based on a Test force measurement of damping characteristics in 5 kp 5.0 the steel. The measurement tip is excited to kp emit ultrasonic oscillations by a piezoelectric 4.0 crystal. The test tip (diamond pyramid) pene3.0 trates the workpiece under the test pressure 2.0 caused by the spring force. With increasing Federweg penetration depth the damping of the ultrasonic oscillation changes and consequently the frequency. This change is measured by the device. The damping of the ultrasonic os- - little work on surface preparation of specimens (test force 5 kp) - Data Logger for storage of several thousands of measurement points - interfaces for connection of computers or printers - for hardness testing on site in confined locations br-er10-12.cdr © ISF 2002 cillation depends directly on penetration depth thus being a measure for material hardness. The display can be calibrated for all commonly used measurement methods, a meas- Figure 10.12 10. Testing of Welded Joints 134 urement is carried out quickly and easily. Measurements can also be carried out in confined pulsation range (compression) Application Dye penetrant method σm = σa σm > σ a crack is free, surface is clean σm < σa compression - + tension Description σm = 0 σ m < σa σm = σa σ m > σa spaces. This measurement method is not yet standardised. time crack and surface with penetrant liquid cleaned surface, dye penetrant liquid in crack pulsation range (tension) alternating range all materials with surface cracks surface with developer shows the crack by coloring Wöhler line Magnetic particle testing II A workpiece is placed between the poles of a magnet or solenoid. Defective parts disturb the power flux. Iron particles are collected. I III σD Stress σ failure line Surface cracks and cracks up to 4 mm below surface. However: Only magnetizable materials and only for cracks perpendicular to power lines 0 1 10 102 103 104 105 106 Fatigue strength (endurance) number lg N 107 I area of overload with material damage II area of overload without material damage III area of load below fatigue strength limit br-er10-13.cdr © ISF 2002 br-er10-14.cdr © ISF 2002 Fatigue Strength Testing Figure 10.13 Figure 10.14 To test a workpiece under oscillating stress, the fatigue test is standardised in DIN 50100. Mostly a fatigue strength is determined by the Wöhler procedure. Here some specimens (normally 6 to 10) are exposed to an oscillating stress and the number of endured oscillations until rupture is determined (endurance number, number of cycles to failure). Depending on where the specimen is to be stressed in the range of pulsating tensile stresses, alternating stresses, or pulsating compressive stresses, the mean stress (or sub stress) of a specimen group is kept constant and the stress amplitude (or upper stress) is varied from specimen to specimen, Figure 10.13. In this way, the stress amplitude can be determined with a given medium stress (prestress) which can persist for infinite time without damage (in the test: 107 times). Test results are presented in fatigue strength diagrams (see also DIN 50 100). As an example the extended Wöhler diagram is shown in Figure 10.13. The upper line, the Wöhler line, indicates after how many cycles the specimen ruptures under tension amplitude σa. The 10. Testing of Welded Joints 135 Application Description X-ray or isotope radiation penetrate a workpiece. The thicker the workpiece, the weaker the radiation reaching the underside. W ire diameter Mainly for defects with orientation in radiation direction. Tolerated deviation mm 3,2 2,5 2 1,6 1,25 1 0,8 0,63 0,5 0,4 0,32 0,25 0,2 0,16 0,125 0,1 ¬ - W ire number mm 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 ± 0,03 ± 0,02 ± 0,01 ± 0,005 ° Abbreviation ® W ire number to Table 1 FE 1/7 1 to 7 FE 6/12 FE 10/16 CU 1/7 ¬ radiation source - ¯ CU 10/16 AL 1/7 AL 6/12 workpiece ® film (displayed in distance from workpiece) ¯ defect in radiation direction; difficult to identify (flank lack of fusion) ° defect in radiation direction; easy to identify br-er10-15.cdr AL 10/16 © ISF 2002 50 6 to 12 50 or 25 10 to 16 50 or 25 1 to 7 CU 6/12 W ire length mm 6 to 12 10 to 16 Material groups to be tested mild steel iron materials copper copper, zink, tin and its alloys aluminium aluminium and its alloys 50 50 50 or 25 1 to 7 50 6 to 12 50 10 to 16 W ire material 50 or 25 br-er10-16.cdr © ISF 2002 Determination of Picture Quality Number to DIN 54105 Non-Destructive Test Methods Radiographic Testing Figure 10.16 Figure 10.15 damage line indicates analogously, when a Description US-head generates high-frequency sound waves, which are transferred via oil coupling to the workpiece. Sound waves are reflected on interfaces (echo). Application Mainly for defects with an orientation transverse to sound input direction. damage to the material starts in form of cracks. Below this line, a material damage does not occur. à Test À methods described above require specimens taken out of the workpiece and a Á partly very accurate sample preparation. A testing of completed welded constructions is  impossible, because this would require a deÄ À sound head Á oil coupling  workpiece à defect Ä ultrasonic test device Å radiation pulse Æ defect echo ³ backwall echo Å Æ ³ br-er10-17.cdr © ISF 2002 Non-Destructive Test Methods Ultrasonic Testing II Figure 10.17 struction of the workpiece. This is the reason why various non-destructive test methods were developed, which are not used to determine technological properties but test the workpiece for defects. Figure 10.14 shows 10. Testing of Welded Joints 136 two methods to test a workpiece for surface defects. Figure 10.15 illustrates the principle of radiographic testing which allows to identify also defects in the middle of a weld. The size of the minimum detectable defects depends greatly on the intensity of radiation, which must be adapted to the thickness of the workpiece to be radiated. As the film with documented defects does not permit an estimation of the plate thickness, a scale bar must be shown for estimation of the defect size. For that purpose, a plastic template is put on the workpiece before radiation which contains metal wires with different thickness and incorporated metallic marks, Figure 10.16. The size of the thinnest recognisable wire indicates the size of the smallest visible defect. Radiation Figure 10.18 testing provides information about the defect position in the plate plane, but not about the position within the thickness depth. A clear advantage is the good documentation ability of defects. Figure 10.18 An information about the depth of the defect is provided by testing the workpiece with ultrasound. The principle is shown in Figures 10.17 and 10.18 (principle of a sonar). The display of original br-er10-19.cdr pulse, backwall and defect Ultrasonic Testing of Fillet Welds echo is carried out with an oscilloscope. Figure 10.19 10. Testing of Welded Joints 137 This method provides not only a perpendicular sound test, but also inaccessible regions can be tested with the use of so called angle testing heads, Figure 10.19. Pores between 10 and 20 mm depth provide an unbroken echo sequence across the entire display starting from 10mm. The backwall echo sequence of 30 mm is not yet visible. 30 Wall thickness is below 40 mm. The roughness provides smaller and wider echos. Echo sequence of 20 mm depth. The backwall is completely screened. The perpendicular crack penetrating the material does not provide a display because the reflecting surface (tip of crack) is too small. 40 The oblique and rough defect from 20 to 30 mm provides a wide echo of 20 to 30 mm. Starting with SKW 4, an unbroken echo sequence follows. The inclination of the reflector is recornised by a change of the 1st echo when shifting the test head. The oblique backwall reflects the soundwaves against the crack. this is the reason why an ‘impossible’ depth of 65 mm is displayed. Echo sequence of 10 mm depth. The reflector in 30 mm depth is completely screened. br-er10-20.cdr © ISF 2002 br-er10-21.cdr Defect Identification with Ultrasound © ISF 2002 Defect Identification With Ultrasound Figure .10.20 Figure 10.21 Figures 10.20 and 10.21 show macro section base material schematically the display of various defects 50 µ ferrite + perlite coarse grain zone bainite on an oscilloscope. A correct interpretation of all the signals requires great experience, 2,5 mm fine grain zone ferrite + perlite fusion line weld metal cast structure Steel: S355N (T StE 355) bainite because the shape of the displayed signals is often not so clear. br-er10-22.cdr Metallographic Examination of a Weld Figure 10.22 illustrates the potential of metallographic Figure 10.22 examination. Grinding and 10. Testing of Welded Joints 138 etching with an acid makes the microstructure visible. The reason is that depending on structure and orientation, the individual grains react very differently to the acid attack thus 100 25 Fe % Fe % Cr 80 Cr 20 15 20 10 a complete survey about the weld and fusion line, size of the HAZ, and sequence of solidification. Under adequate magnification, these 0 areas can still not be distinguished precisely, 10 8 Ni however, an assessment of the developed 6 4 macrosection, i.e. without magnification, gives 60 40 % Ni reflecting the light in a different way. The 5 microstructure is possible. 2 0 0 200 mm 100 0 An assessment of the distribution of alloy 100 Distance from fusion line br-er10-23.cdr elements across the welded joint can be car- © ISF 2002 Micro-Analysis of the Transition Zone Base Material - Strip Cladding ried out by the electron beam micro-analysis. An example of such an analysis is shown in Figure 10.23 Figure 10.23. If a solid body is exposed to a focused electron beam of high energy, its atoms are excited to radiate X-rays. There is a simple relation between the wave length of this radiation and the atomic number of the chemical elements. As the intensity of the radiation depends on the concentration of the elements, the chemical composition of the solid body can be concluded from a survey of the emitted X-ray qualitatively and spectrum quantita- tively. A detection limit is 50 50 20 20 about 0.01 mass % with this 20 20 50 0 10 method. Microstructure areas of a minimum diameter 50 1. weld 2. weld weld of about 5 µm can be ana- axis of bending former weld Agents: - electrolytic copper in the form of chips (min. 50 g/l test solution) - 100 ml H2SO4 diluted with 1 l water and then . 110 g CuSO 5 H2O are added lysed. If the electron beam is Test: The specimens remain for 15 h in the boiling test solution. Then the specimens are bent across a former up to an angle of 90° and finally examined for grain failure under a 6 to 10 times magnification. moved across the specimen (or the specimen under the br-er-10-24.cdr beam), the element distribu- Strauß - Test tion along a line across the Figure 10.24 axis of bending former 10. Testing of Welded Joints 139 solid body can be determined. Figure 10.23 presents the distribution of Ni, Cr, and Fe in the transition zone of an austenitic plating in a ferritic base metal. The upper part shows the related microsection which belongs to the analysed part. This microanalysis was carried out along a straight line between two impressions of a Vickers hardness test. The impressions are also used as a mark to identify precisely the area to be analysed. The so called Strauß test is standardised in DIN 50 12 914. it serves to determine web 80 the resistance of a weld measurement points tack welds against intergranular corro- base plate weld1 40 40 20 sion. Figure 10.24 shows the specimen shape which is normally used for that a a a 20 aa a a 12 weld2 120 80 aa test. In addition, some debr-er-10-25.cdr Test of Crack Susceptibility of Welding Filler Materials to DIN 50129 tails of the test method are explained. Figure 10.25 Figure 10.25 presents a specimen shape for testing the crack susceptibility of welding consumables. For this test, weld number 1 is welded first. The 2. weld is welded not later than 20 s in reversed direction after completion of the first weld. Throat thickness of weld 2 must be 20% below of weld 1. After cooling down, the beads are examined for cracks. If tensioning bolt hexagon nut min. M12 DIN 934 guidance plates a tensioning plate specimen base body cracks are found in weld 1, the test is void. If weld 1 is free from cracks, weld 2 is examined for crack with magnifying glasses. Then weld 1 is machined off and weld 2 is cracked by bend- br-er-10-26.cdr Tensioning Specimen for Crack Susceptibility Test Figure 10.26 ing the weld from the root. Test results record any 10. Testing of Welded Joints 140 surface and root cracks together with information about position, orientation, number, and length. The welding consumable is regarded as 'non-crack-susceptible' if the welds of this test are free from cracks. Figure 10.26 presents two proposals for self-stressing specimens for plate tests regarding their hot crack tendency. Such tests are not yet standardised to DIN. thermo couple electrode cross-section groove shape 60° 60° welding direction weld metal support plate Wd./2 H Wd. 2 implant Hc Wd./2 2 load temperature in °C specimen shape load in N Tmax start end crater 150 crack coefficient C= c x 100 (in %) 800 500 1 2 3 4 5 sections 60 anchor weld 80 test weld 150 100 60 anchor weld br-er10-27.cdr t8/5 © ISF 2002 rupture time br-er10-28.cdr Tekken Test Figure 10.27 time in s © ISF 2002 Implant Test Figure 10.28 There are various tests to examine a cold crack tendency of welded joints. The most important ones are the self-stressing Tekken test and the Implant test where the stress comes from an external source. In the Tekken test which is standardised in Japan, two plates are coupled with anchor joints at the ends as a step in joint preparation see Figure 10.27. Then a test bead is welded along the centre line. After storing the specimen for 48 hours, it is examined for surface cracks. For a more precise examination, various transverse sections are planned. The value to be determined is the minimum working temperature at which cracks no longer occur. The specimen shape simulates the conditions during welding of a root pass. 10. Testing of Welded Joints 141 The most commonly used cold crack test is the Implant test, Figure 10.28. A cylindrical body (Implant) is inserted into the bore hole of a support plate and fixed by a surface bead. After the bead has cooled down to 150°C the implant is exposed to a constant load. The time is measured until a rupture or a crack occurs (depending on test criterion 'rupture' or 'crack'). Varying the load provides the possibility to determine the stress which can be born for 16 hours without appearance of a crack or rupture. If a stress is specified to be of the size of the yield point as a requirement, a preheat temperature can be determined by varying the working temperature to the point at which cracks no longer appear. As explained in chapter 'cold cracks' the hydrogen content plays an important role for cold crack development. Figure 10.29 shows results of trials where the cold crack behaviour was examined using the Tekken and Implant test. Variables of these tests were hydrogen content of the weld metal and preheat temperature. The variation of the hydrogen content of the weld metal was carried out by different exposure to humidity (or rebaking) of the used stick electrodes. Based on the hydrogen content, the preheat temperature was increased test by test. Consequently, the curves of Figure 10.29 represent the limit curves for the related test. Specimens above these heat input: 12 kJ/cm basic coated stick electrode plate and support plate thickness: 38 mm °C cracks, below these curves °C Implant-Test 150 Tekken-Test 100 50 cracks are present. Evi- 150 Rcr = Rp0,2 = 358 N/mm² Preheat temperature Preheat temperature curves remain free from fractured starting cracks crack-free 20 dent for both graphs is that with 100 temperature 50 starting cracks crack-free 20 0 10 20 30 ml/ 40 100 g increased 0 10 Diffusible hydrogen content br-er-10-29.cdr Test Result Comparison of Implant and Tekken Test 20 30 ml/ 40 100 g preheat considerably higher hydrogen contents are tolerated without any crack development be- cause of the much better hydrogen effusion. Figure 10.29 If both graphs are compared it becomes obvious that the tests produce slightly different findings, i.e. with identical hydrogen content, the determined preheat temperatures required for the avoidance of cracking, differ by about 20°C. 10. Testing of Welded Joints 142 Figure 10.30 illustrates a method to measure the diffusible hydrogen content in welds which is standardised in DIN 8572. Figure a) shows the burette filled with mercury before a specimen is inserted. The coupons are inserted into the opened burette and drawn with a magnet through the mercury to the capillary side (density of steel is lower than that of mercury, coupons surface). Then the burette is closed and evacuated. The hydrogen, which effuses of the coupons but does not diffuse through the mercury, collects in the capillary. The samples remain in the evacuated burette 72 hours for degassing. To determine the hydrogen volume the burette is ventilated and the coupons are removed from the capillary side. The volume of the effused hydrogen can be read out from the capillary; the height difference of the two mercury menisci, the air pressure, and the temperature provide the data to calculate the norm volume to pump hydrogen under reduced pressure under VT air pressure B evacuated standard conditions. This capillary side volume and the coupons M meniskus1 weight are used to calculate, as measured value, the hy- meniskus2 mercury coupons drogen volume in ml/100 g weld metal. This is the most a) starting condition commonly used method to determine the c) ventilated after degassing Burettes for Determination of Diffusible Hydrogen Content hydrogen content in welded joints. b) during degassing br-er-10-30.cdr Figure 10.30