Damage Reduction White Paper

advertisement

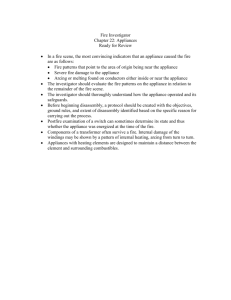

DAMAGE REDUCTION FOR APPLIANCE RETURNS Damage Reduction White Paper by Wayne Burgess & Craig Stevens If one of the main aims of Reverse Logistics is to maximize recovery value of returned products, then reducing “post-consumer” damage is paramount in ensuring this value. Organizations without dedicated reverse logistics or returns management experience significantly higher rates of damage. Because of this, 33% of surveyed companies report having damage management programs, while another 23% plan to add them within the coming two years. 1 This study is intended to examine the causes of post-consumer damage, and propose mechanisms and programs to minimize the losses. The prime focus of this paper is the appliance industry. Whereas best-in-class companies on average reclaim 64.3% of initial value from returns, appliance manufacturers without damage reduction processes on average experience a negative reclamation value. 2 There are three main areas in which damage to returned goods occurs: 1. Transportation 2. Receiving and handling Organizations without dedicated reverse logistics or returns management experience significantly higher rates of damage. 3. Storage While it may seem that these should have separate underlying problems, the causes for additional damage to returned goods are consistent throughout these three areas: packaging, returns personnel and management inattention. These causes are examined below. Packaging A seventeen-month study of over 10,000 returned appliances (case study follows) found that between twenty and thirty per cent of all returned products are typically further damaged in transport. A primary reason for this is that the majority of returned goods are brought in without protective packaging, or are poorly packaged. While return policies typically state that goods should be returned in their original packaging, the practicality of consumers retaining large empty boxes for several weeks 1 Reverse Logistics Association – April 2009 2 Revisiting Reverse Logistics – Aberdeen Group, September 2006 Damage Reduction for Appliance Returns or months after purchasing appliances is problematic. Most consumers dispose of original packaging same-day as the purchase. If they do retain packaging, the box is typically all they are concerned about, and packing braces and foam - if retained - are seldom deployed as intended. The boxes themselves have typically been opened in a manner that weakens them structurally. Even so, boxed returns remain the exception rather than the rule. Without packaging, further damage is inevitable in all areas above. Implementing a packaging-upon returns program for receivers will result in significant damage reduction across the board. This damage reduction will have its greatest effect on the 24% of returns which are found to have no fault or defect. 3 Implementing a packagingupon-returns program for receivers will result in significant damage reduction across the board. Returns personnel Both transport and warehouse staff are typically trained in handling of forward moving products. Shipping loads are designed to take the maximum amount of outbound product in a trailer, in a pre-defined configuration. Braces and straps are configured to hold packaged goods. Lifts and transporters are designed to handle balanced, configured loads. Clamps are generally designed to handle packaged goods and may need to be repositioned, cushioned or replaced with straps. The randomness of returned goods takes its toll in two ways here: 1. Returns are generally unexpected, and dealt with ad hoc. They are fitted into existing warehouse space, or transport trailers without planning. 2. Uncertain condition of the returned goods means that handling techniques, and hardware may not be suitable for unpackaged, unbalanced materials. It is not uncommon to see a lift placed directly under a returned appliance, or to see appliances topple from pallets when lifted. 3. Preparation for handling returns can greatly reduce routine handling and shipping damage. Management Inattention Apart from this lack of preparedness, there is a psychological aspect of returns which merits further attention. Returns are never a company’s main business. They are an 3 Revisiting Reverse Logistics – Aberdeen Group, September 2006 Damage Reduction for Appliance Returns | 2 unwanted afterthought. There is a tendency for staff to mentally dismiss returns as junk – even when returned in as-new condition. The result of this dismissal is lack of attention and care to maintaining the condition of returns. This is greatly exacerbated if returns are routinely placed in an otherwise unaccessed storage location, or if staff do not perceive that returns are regularly moved from this holding area in a timely fashion. Management inattention to the value of returns erodes this value in the eyes of the workers who routinely handle returns. Remedial Actions Management inattention to the value of returns erodes this value in the eyes of the workers who routinely handle returns. 1. The most important single factor is to have management focus on returns, measuring key performance indicators to maintain this focus. When a management team fully realizes that they can control the recovery value of goods, they are usually quick to respond to situations where needless damage occurs. 2. Communication to warehouse and shipping staff of this focus is a critical secondary point. If these workers are aware of the management focus, their attitude changes to encompass returns as a normal part of the job rather than an unwanted afterthought. 3. Training in specific returns handling procedures avoids having these less ‘regular’ materials treated the same as factory packaged goods. 4. Adjustment to receiving, storage and transport hardware to better accommodate unpackaged and unbalanced goods. 5. Packaging procedures upon receipt of returns. This will likely be dependent upon enforced dealer and retail policies, to ensure that goods received from the consumer are immediately dealt with in a manner to best preserve their value. 6. Implementing returns metrics and data tracking. This allows for accountability, and close monitoring of any incidents in which recovery value from returned goods erodes. 7. Communication of metrics, especially increased recovery value. This is positive reinforcement to staff of the value of their efforts in maintaining the condition of returned goods. Damage Reduction for Appliance Returns | 3 Case Study in Damage Reduction Initial situation A major appliance manufacturer received an average of 7500 returned large appliances annually. After receiving and storage, when preparing for resale, these were graded for condition using the following guidelines: 4 Case Study in Damage Reduction C l ass D e f i n iti o n s P r o du ct D e f i n iti o n s A Brand new product Scratch 'n' Dent Product damaged before it gets to customer’s home Recrate Brand new product-damaged box only FGR Used product B+ Minor hidden cosmetic flaws Scrap Product not sellable in its current state. Too much physical damage. B Minor visible cosmetic flaws C Major visible cosmetic damage-sellable D Major visible cosmetic damage-unsellable G No salvage value Definition of Surfaces A Readily visible surface on front, top, or inside of appliance when viewed from 3 to 5 feet B Sides of appliance C Surfaces not readily visible on front, top, or inside of appliance when viewed from 3 to 5 feet D Bottom and back of appliance not visible in a normal installation Baseline Determination Because existing stock had already been sorted and sold out to some extent, it was impossible to use inventory as a baseline for typical condition. In order to establish a baseline, condition was graded for each lot received at the beginning of the project. While damage reduction processes were implemented immediately, the lag between training, initial implementation and routine, allowed use of first quarter results as a baseline for metrics. This provided a conservative estimate of overall graded condition, including transportation, handling and storage. The differential between this and same quarter results the following year indicated the amount of damage reduction in these areas, as opposed to original condition. Project duration: 17 months 5 4 Annualized from 10,531 appliances over 17 months 5 01/2009 to 05/2010 Damage Reduction for Appliance Returns | 4 Total # of appliances graded: 10,531 The extended scope, and considerable volume render this sampling statistically relevant, as it represents 35% of the estimated national total. 6 Quarterly baseline: (taken from 01-03/2009) Units B+ B C D G Total 2469 11.9% 44.8% 17.7% 24.8% 0.9% 100.0% Case Study in Damage Reduction In order to account for seasonal variation in volume and condition, the same three month period was selected to chart condition after implementation of the damage reduction program. One year later results: (taken from 01-03/2010) Units B+ B C D 2194 18.9% 43.1% 28.9% 9.1% G Total 0.0% 100.0% The most statistically important changes take place at the extreme ends of the scale. Results The combined D&G categories with almost no reclamation value were reduced from 25.7% of the total to 9.1%. This marks an order of magnitude improvement of 2.82, with an increase in resalable goods of 16.6%. This shift is clearly reflected in C grade products which increased by 11.2%. Additionally all higher categories received a This marks an order of portion of this “bump” as well. The other significant increase was in B+ goods, which saw an order of magnitude increase of 1.59. This resulted in 7% more products in this highest reclamation value class. Shift Year over Year: B+ B C D G 7.0% -1.6% 11.3% -15.7% -0.9% 6 CANSIM - Table 080-0019 Damage Reduction for Appliance Returns | 5 magnitude improvement of 2.82, with an increase in resalable goods of 16.6%. This shift is clearly reflected in C grade products which increased by 11.2%.Additionally all higher categories received a portion of this “bump” as well. Waste Diversion All of the G class and D class returns were previously destined for landfill. A combination of initiatives saw the radical decrease in these grades combined with harvesting parts from the remaining D class appliances. These high volume parts were placed into service inventory. The combined tonnage of returns to landfill was decreased over this time span by 85% . 7 Case Study in Damage Reduction Prior to these damage reduction and waste diversion initiatives, an average of 1910 appliances annually went to landfill. This represented 189 tons of waste. Following the damage reduction and parts harvesting, the annual number of appliances (or parts thereof) sent to landfill was reduced to 286. The weight of the waste was reduced to 28 tons. Conclusion Implementing changes to internal transportation, handling and storage techniques for returned appliances had the effect of: • adding resale value to more than 25% of returns, which previously had no reclamation value • a 59% increase in resale value of the top This analysis indicated that damage prior to return was consistently over-reported. Understanding this offers potential further gains by more closely enforcing returns policies from field level sales outlets. grade of returned goods • an 85% increase in waste diversion. Without the addition of extensive damage in the receipt & storage of returned appliances, it became possible to compare receiving manifests to final grade of goods. This allowed a comparison of received product to the condition stated by the consumer upon return. This analysis indicated that damage prior to return was consistently over-reported. Understanding this offers potential further gains by more closely enforcing returns policies from field level sales outlets. 7 ReturnTrax Waste Diversion Study – 01-12/2009 Damage Reduction for Appliance Returns | 6