Experimental Determination of Moment of Inertia

advertisement

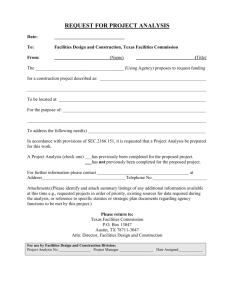

Experimental Determination of Rigid Body Parameters Prof. Raul G. Longoria October 20, 2000 Version 1.0 ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Overview • This lecture reviews the design of experiments for measuring inertia properties of rigid bodies, mainly for rotational dynamics. • A knowledge of basic pendulum dynamics is required. ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 1 Functional Types of Engineering Experiments • Determination of material properties and object dimensions • Determination of component parameters, variables, and performance indices • Determination of system parameters, variables and performance indices • Evaluation and improvement of theoretical models • Product/process improvement by testing • Exploratory experimentation • Acceptance testing • Use of physical models and analogues • Teaching/learning through experimentation ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Specific Tasks • Modeling of a rotational pendulum with either two or three suspension files. • Design of experiments using “bifilar” or “trifilar” configuration. • Perform experiments with simple rigid bodies to confirm model. ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 2 Need for Inertia Properties Suspension Puma 560 ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Moment of Inertia • The moment of inertia, J, of a rigid body about an axis is defined by, 2 J = ∫ r dm • You can interpret J as a measure of a body’s refusal to be angularly accelerated. • Parallel axes theorem J o = J CG + mlc2 ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 3 Moments of Inertia From Ogata, “System Dynamics”. ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Compound Pendulum • Equation of motion for rotation of a rigid body about a fixed axis. • Only gravity is external force (neglect any damping due to air, pivot, etc.) • Apply Newton’s law, Jθ!! = − mglc sin θ ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 4 Radius of gyration • The radius of gyration, k, is the distance from the point of suspension of the pendulum at which we must concentrate the total mass, m, in order to obtain the moment of inertia, J, of the actual mass distribution. 2 J = mk J • Equivalent simple pendulum has leq = mlc • k is the geometric mean, 2 k = lc ⋅ leq ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Experiment Design - Bifilar ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 5 Experiment Design - Bifilar Jθ!! = ∑ T = − mg sin φ × R × 2 2 L sin φ = R sin θ L ⋅ φ = R ⋅θ mg R Jθ!! + ⋅ sin θ × R × 2 = 0 2 L mgR 2 θ = 0 JL Moment of inertia θ!! + 2 2 Tn mgR J = L 2π mgR 2 2π ωn = = Tn JL ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin “Adjustable” Bifilar The torques on each file will be different here at the point of attachment, so the period depends on x. T = 2π J mgx (d − x) / l Predict a minimum period: ∂T =0 x ∂ d ME 244L Dynamic Systems and Controls Laboratory ⇒ x 1 = d 2 Department of Mechanical Engineering The University of Texas at Austin 6 Trifilar - More practical in the lab? ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Typical Drivetrain Values Ref. SAE Universal Joint and Driveshaft Manual, 1979. ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 7 Other Methods (1) Basic torsional pendulum d 2G Jd = 128π f n2 L d = wire diameter G=shear modulus of wire f n = measured natural frequency of motion in θ ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin Other Methods (2) What is the model that governs this experiment design? t 2 2 WR 2 J = − ⋅ H g 2 t = time to fall height, H H = height weight falls W = weight ME 244L Dynamic Systems and Controls Laboratory Department of Mechanical Engineering The University of Texas at Austin 8