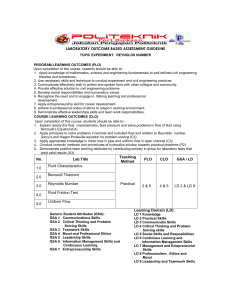

Reynolds Number & Transitional Flow: Hydraulics Lab Experiment

advertisement

CE403 Hydraulics Laboratory Experiment 11 Reynolds Number and Transitional Flow A. Introduction When a fluid flows next to a solid boundary the nature of the flow depends on the velocity relative to that boundary. At low velocities the layers of fluid move smoothly over one another and this is termed 'laminar' flow. However, as the velocity is increased small disturbances cause eddies which 'mix-­‐up' the layers of fluid and produces a different pattern of flow, which is termed 'turbulent'. This change has a marked effect on the forces acting between the fluid and the solid boundary and an understanding of the behavior is of fundamental importance in the study of hydraulics and fluid mechanics. The nature of flow over an aircraft wing affects the drag and hence determines the power required to propel the aircraft forwards. Similarly, when fluid flows along a pipe the nature of the flow determines the pressure loss and hence the power required to pump the fluid along the pipe. British physicist named Osborne Reynolds (1842 -­‐1912) first identified the variables controlling the flow and produced a rational means of predicting the nature of flow. Reynolds showed that the behavior depends on the balance between inertia and viscous forces in the fluid. This led to the definition of a non-­‐dimensional parameter, now called Reynolds number, which expresses the ratio of inertia to viscous forces and can be used to identify the conditions under which the flow changes from laminar to turbulent. By experiment it was found that the change always occurred at a similar value of Reynolds number irrespective of the fluid and the size of pipe. The Reynolds Number and Transitional Flow demonstrates the kind of experiment conducted to show the dependence of flow on Reynolds number. The apparatus enables the nature of the flow in a pipe to be studied by observing the behavior of a filament of dye injected into the fluid. The flow rate can be varied and the change, or 'transition', between laminar and turbulent flow can be clearly demonstrated. B. Equipment Reynolds Apparatus, stopwatch, graduated discharge volume measurement container. C. Procedure 1. Turn on the water supply and partially open the discharge valve at the base of the apparatus. 2. Adjust the water supply until the level in the constant head tank is just above the overflow pipe and is maintained at this level by a small flow down the overflow pipe. This is the condition required for all tests and at different flow rates through the tube; the supply will need to be adjusted to maintain it. At any given condition the overflow should only be just sufficient to maintain a constant head in the tank. 3. Measure the temperature of the water in the constant head tank and record. 4. Open and adjust the dye injector valve to obtain a fine filament of dye in the flow down the glass tube (see Figure 1a). If the dye is dispersed in the tube By Dr. İsmail HALTAŞ April 7, 15 CE403 Hydraulics Laboratory reduced the water flow rate by closing the discharge valve and adjusting the supply as necessary to maintain the constant head. A laminar flow condition should be achieved in which the filament of dye passes down the complete length of the tube without disturbance. 5. Measure the time for 200 ml discharge from the discharge pipe. Repeat the time measurements three times and record the measurements in Laminar Flow Table. 6. Slowly increase the flow rate by opening the discharge valve until disturbances of the dye filament are noted (see Figure 1b). This can be regarded as the starting point of transition to turbulent flow. Increase the water supply if required to maintain constant head conditions. 7. Measure the time for 200 ml discharge from the discharge pipe. Repeat the time measurements three times and record the measurements in Transitional Flow Table. 8. Further increase the flow rate as described above until the disturbances increase such that the dye filament becomes rapidly diffused (see Figure 1c). Small eddies will be noted just above the point where the dye filament completely breaks down. This can be regarded as the onset of fully turbulent flow. 9. Measure the time for 200 ml discharge from the discharge pipe. Repeat the time measurements three times and record the measurements in Turbulent Flow Table. 10. Close the dye injector valve and the water supply valve. Figure 1: Typical flow patterns at various flow conditions By Dr. İsmail HALTAŞ April 7, 15 CE403 Hydraulics Laboratory D. Theory Reynolds number is a dimensionless variable and defined as a function of average flow velocity, diameter of the pipe and the kinematic viscosity of the fluid for pipe flow. VD ν Equation 1 Kinematic viscosity of fluid depends on the temperature of the fluid. In Table 1 Kinematic viscosity of water at various temperatures are listed. Interpolation techniques can be used to find the kinematic viscosity of water at other temperatures. Table 1: Kinematic Viscosity of Water at various temperatures Re = Temperature) Kinematic)Viscosity) (oC) (m 2 /s))x)10:6 0 1.787 5 1.519 10 1.307 15 1.138 18 1.053 20 1.001 23 0.930 26 0.865 30 0.785 The inner diameter of glass pipe in the apparatus is D = 12 mm. Note that 1 ml = 10-­‐6 m3 It is normally accepted that below Reynolds Number of 2000 flow is laminar. Transition from laminar to turbulent is observed at Reynolds Number between 2000 and 2500. Above Reynolds Number of 4000 it is accepted that flow is fully turbulent. E. Calculations and Results Calculate the average discharge, flow velocity and Reynolds Number for each flow regime (laminar, transitional and turbulent). Tabulate your results as in the following Example Table Table 2: Flow velocities and Reynolds Numbers for laminar, transitional and turbulent flow regimes Regime Laminar Transitional Turbulent Q'(cms) 1.82E,05 1.94E,05 2.50E,05 'V'(m/s) 0.161 0.172 0.221 By Dr. İsmail HALTAŞ Re 1821 1945 2504 April 7, 15 CE403 Hydraulics Laboratory Plot a graph of Velocity V (m/s) vs. Re. as in the following Example Reynolds)Number,)Re) 3000" 2500" 2000" 1500" 1000" 500" 0" 0.150" 0.170" 0.190" Velocity)(m/s)) 0.210" 0.230" Figure 2: Flow velocity versus Reynolds Number for laminar, transitional and turbulent flow regimes F. Discussion Discuss if the Reynolds Number calculated for each flow regime is within the accepted intervals. Discuss how your discharge and Reynolds Number results are affected if you were experimenting with water at higher temperatures (i.e. 40 oC) or any other fluid with kinematic viscosity three times more than the kinematic viscosity of water. By Dr. İsmail HALTAŞ April 7, 15