Epigallocatechin-3-gallate Immediate Release Tablets

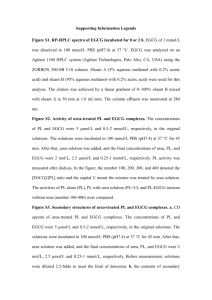

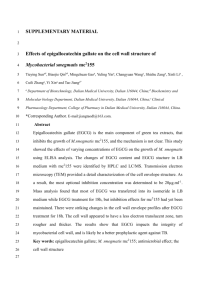

advertisement