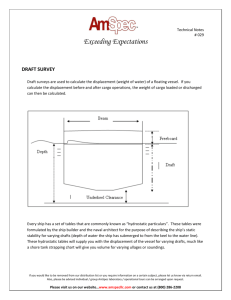

D 6.1 “Ship Structure”

advertisement