Company magazine

advertisement

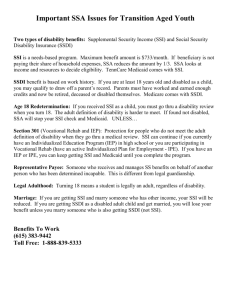

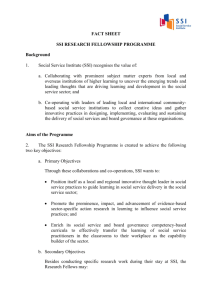

No. 26, Issue 2/2015 Company magazine Cover story – Automotive Food industry Logistics service providers Brose Group: 4 Innovative tugger train solution eliminates need for forklifts Vinamilk: 17 Vietnam’s high-tech dairy distribution centre Kühne + Nagel: Innovative combination of systems www.ssi-schaefer.com 18 Editorial Dear readers, We are committed to helping our customers maintain their competitive edge in the global marketplace. Increasing throughput, streamlining material flows and ensuring reliable processes while reducing error rates to almost zero – these are just a few of the objectives companies across multiple industries approach us with. To help them achieve their goals, we implement both manual warehousing systems and fully automated, turnkey distribution centres. Intralogistics has developed into a high-tech industry, with automated warehouse and logistics processes, and purpose-designed software. The technologies we deploy in our projects reflect this trend: they include high-throughput warehouses and storage systems, efficient picking solutions, fully automated storage and retrieval machines, sophisticated robotics, intelligent inventory data capture methods, and reliable warehouse management software. Our automotive-themed cover story on the Brose Group spotlights many of these solutions in action. Harrie Swinkels Managing Director, SSI Schaefer, Giebelstadt, Germany 2 SSI Schaefer’s warehousing and logistics systems are at the cutting edge of developments – we have a tradition of innovation. Against this background, I am pleased to introduce our new product, Navette, in this issue of Update. Our scalable, multi-level shuttle can move up to four totes, trays, or cartons at a time, by means of its two load-handling devices. As a result, it shortens travel time while doubling process efficiency. The special feature article describes our Customer Service and Support division, which offers new and established customers a broad portfolio of services. In particular, we address the growing demand for upgrading and retrofitting. Within the scope of these projects, we focus on designing solutions tailored to our customers’ specific needs – helping them create high-availability storage and maximise their productivity. Read on to learn more about the exciting world of intralogistics at SSI Schaefer. We hope you enjoy. Contents 4 14 18 4 12 20 Automotive Cover story Brose Group: Innovative tugger train solution eliminates need for forklifts Project BMW Vogl/Total/Carglass® 8 Manufacturing Project Liebherr-Aerospace/Lely/ Glenbeigh/Belimo Americas/ Klingspor/Schunk 12 Retail Food industry Logistics service providers 20 Special feature Solution Made-to-measure customer service and support Project A. Kempf/Oriflame 22 Project LANDI/NBTY 14 18 Project Kühne + Nagel Inside SSI Schaefer Interview Growing demand for upgrades Product Navette – the scalable, multi-level shuttle News Production plant expansion in Asia Project Dafgård/Nila Sea Foods/ Pistor/Tine/ Italpasta/Vinamilk 3 Cover story – Automotive Innovative tugger train solution eliminates need for forklifts Brose Group, the world’s fifth largest family-owned automotive supplier, called on SSI Schaefer’s proven expertise when constructing its new logistics centre in the Czech city of Ostrava. The one-stop solutions provider created innovative material flows managed by using a SAP EWM solution tailored precisely to the customer’s needs to supply the highly dynamic parts to Brose’s production line. Each of the four tugger train stations has a racking system comprising four levels and a total of 32 tote channels. A train with four trailers arrives at the station where loading is due to take place. 4 Cover story – Automotive Kopřivnice, Czech Republic. SSI Schaefer has constructed a new logistics centre at Brose’s manufacturing site in Kopřivnice, near the Czech city of Ostrava. By consolidating storage capacity inside the plant, the Brose Group aimed to cut shipment and external storage costs, streamline material flows, optimise production line supply processes and boost throughput. To achieve these goals, SSI Schaefer deployed a highly automated logistics solution. First, SSI Schaefer constructed a five-aisle high-bay warehouse with 9,750 pallet positions in a singledeep configuration, with the goal of increasing capacity and streamlining intralogistics. Five Exyz storage and retrieval systems ensure maximum energy efficiency during picking and putaway. A travel speed of 180 metres per minute and lifting speed of 48 metres per minute enable throughput of 200 pallets per hour. The warehouse provides storage for reserve stock, and is connected to an existing building via a bridge. It houses the goods receipt area, the conveyor systems and processing points, plus an automated small parts warehouse. Brose opted to pursue the goal of a forklift-free logistics facility. With this in mind, tugger trains are used to supply parts to the production line. All intralogistics processes are fully automated, including loading. The seven-aisle small parts warehouse can store up to 23,520 totes, each weighing up to 15 kilogrammes, in either singledeep or double-deep configurations. Seven storage and retrieval systems from the tried-andtrusted Schaefer Miniload Cranes (SMC 1) range enable throughput of up to 840 totes per hour. Totes supplying parts to the production line are loaded at four tugger train stations, located on the upstream sides of the automated small parts warehouse. Once the train has reached the correct position, the totes are released, the locking roller lowers, and the totes roll onto the trailer positions. technology, vertical conveyors and robotic arms that fully automate the depalletising process ensures high material flow efficiency. Teaching the robotic arms to perform their tasks was a particular challenge – and to solve it, SSI Schaefer combined state-of-the-art image recognition with device control technology and SAP EMW. Material flow at the logistics centre is also highly innovative. SSI Schaefer has integrated a customised SAP EWM solution into the existing SAP infrastructure. As Jürgen Hergenröther, IT/SAP Project Manager at SSI Schaefer, explains, “SAP EWM calculates where the tugger train needs to stop on its journey, and plans the routes and locations of trains, trailers and storage positions accordingly. It also organises and controls all underlying processes to ensure loading and supply processes take place exactly when and where they are needed.” The combination of pallet conveying As Claudia Vogel-Daniel, Project Manager at Brose, says, “The new solution has reduced the need for manual input and optimised material flow. What’s more, it has cut personnel costs and enhanced ergonomics. By increasing plant automation, redefining our material flows and deploying an end-to-end SAP solution, we have simplified, streamlined and increased visibility into our processes, and have boosted our throughput, too. We are extremely pleased with this intelligent solution, which has fully automated the supply of parts to the production line.” The Schaefer Miniload Cranes can collect up to two totes, depending on the type of tote. As a result, they enable throughput of up to 840 totes per hour. 5 Automotive BMW Vogl’s new storage system doubles the speed of wheel putaway and picking. An intelligent combination of technologies boosts efficiency An innovative wheel and parts storage system has created structured, accelerated processes, saved considerable space, and greatly improved ergonomics at BMW Vogl. Mühldorf am Inn, Germany. Since 2001, BMW Vogl has been one of Germany’s top 20 BMW dealerships. In 2013, a new BMW and Mini centre was opened in Mühldorf am Inn. Within the scope of this project, BMW Vogl contracted SSI Schaefer to implement a new warehouse, comprising fixed location and wheel and tyre storage systems, with pallet dollies and stackers. efficiency. This also improves working conditions, as it eliminates the need for heavy lifting during putaway and picking. The combination of dollies and pallet stackers has proven highly successful. Vertical movements are completed in just 18 seconds – offering over 50 per cent greater time efficiency than conventional systems. Moreover, there are practically no picking errors. Developing a new wheel storage system was the primary challenge; approximately 1,100 sets of wheels have to be stored on 150 square metres. “Capacity and process efficiency were not the only important factors – ergonomics is also critical. Our productivity goals shouldn’t be achieved at the cost of employees’ back pain,” explains Bernd Rupprecht, responsible for fixed location storage sales at SSI Schaefer. A typical wheel weighs 20 to 25 kilogrammes; SUV wheels tip the scales at 35 kilogrammes. Handling these heavy items is tough physical work, and places great strain on employees’ backs. Fixed location warehousing has been a mainstay of the automotive industry for many years. It offers a number of advantages: up to 50 per cent space savings, shorter picking tours due to optimised layouts, and an extremely low picking error rate, as every part has an assigned position. BMW Vogl stores approximately 4,500 spare parts on R 3000 modular shelves on a two-level mezzanine, taking up only 240 square metres of floor space. “Our new storage system enables us to provide our customers with the high-quality service they have come to expect from one of Germany’s leading BMW dealerships. It was a pleasure to work with Sets of four wheels are stored double-deep, SSI Schaefer; we have formed an excellent partwith each pair occupying one storage position. nership,” notes Jürgen Pöllner, Managing Director SSI Schaefer introduced pallet dollies to increase at BMW Vogl. 6 Efficient pallet live storage Loading and unloading take place on opposite sides of the pallet live storage system. Ertvelde, Belgium. Total supplies high-quality petrol and diesel throughout Belgium via more than 500 stations. But the company is also a global player in the energy industry, with a broad portfolio comprising fuel oil, LPG, renewables, speciality chemicals, and more. SSI Schaefer implemented a pallet live storage system at Total’s Ertvelde distribution centre in north-eastern Belgium. The solution was installed in the centre’s staging area, providing buffer storage prior to shipment. In addition, it serves as a means of conveying pallets loaded with oil drums, canisters, and cartons. The system consists of 12 aisles, three levels, and a single channel with roller tracks and 10 pallet positions. Loaded pallets – which can weigh up to 1,000 kilogrammes each – are transported on conveyor belts to the staging area, where forklifts place them on the racking system’s roller track. They are unloaded by forklifts on the opposite side of the racking – meaning putaway and retrieval pro- cantly increased our capacity, creating 360 new cesses remain independent. pallet positions,” states Peter Van Laere, Project Leader at Total. The company has already drawn Total is very satisfied with the system. up plans to replace the forklifts with automated “SSI Schaefer provided a solution that signifi- guided vehicles (AGVs). Carglass® enjoys accessible, practical storage SSI Schaefer has implemented shelving for car parts in Carglass’ European distribution centre. Hasselt, Belgium. Carglass has been Belgium’s leading automotive window specialist for over 25 years. The company’s core competency is repair and replacement – for all car makes, models, and ages. They provide 24/7 customer service, using 41 workshops and a fleet of 100 mobile technicians in Belgium. Moreover, Carglass provides a lifetime guarantee on all workmanship, including the watertight seal on replacement windscreens. To perform repairs rapidly and reliably, Carglass needs a warehouse infrastructure of the highest standard. With this goal in mind, SSI Schaefer equipped Carglass’ European distribution centre with shelving for work clothing, and R 3000 modular shelving systems for car components of a variety of types and brands – supporting picking processes for both fast and slow-moving items. For greater efficiency, repair materials and accessories are stored in Euro-Fix boxes on modular shelving systems on a mezzanine. Low-turnover car parts for various models and makes are picked daily from accessible, ergonomic storage. 7 Manufacturing Taking efficiency to a new level Within the scope of a large-scale expansion of their production plant, Liebherr-Aerospace Lindenberg has built a new logistics centre. All processes in this automated highefficiency warehouse are managed with WAMAS® software. SSI Schaefer’s WAMAS software supports the ongoing optimisation of all processes in the new logistics hall in line with actual needs, and uses graphics to visualise current inventory. Lindenberg, Germany. Liebherr-Aerospace, a leading European manufacturer of aerospace components, commenced a major expansion project for their plant in Lindenberg, Germany, in 2012. SSI Schaefer, Neunkirchen, was tasked with implementing a new warehouse management solution to streamline the plant’s intralogistics processes. The site posed a unique challenge: the new racking systems needed to be installed in a 15,700-square-metre logistics hall and assembly area for flight control systems that were 20 metres below normal ground level. Werner Grund, SSI Schaefer’s Project Leader explains, “The steep incline of the land is responsible for this unusual situation.” In other words, the floor of these zones had to be lowered to maximise the available surface area. The three-aisle high-rise racking was installed on a floor that had been lowered by 20 metres. Over the course of just a few months, SSI Schaefer succeeded in building an automated high-bay racking system and an automated small parts storage system. Both are connected by conveyor systems to repacking and picking stations that are at level “0” (i.e. 20 metres above the lowered floors). The three-aisle high-bay racking, in a single-deep configuration, offers a total of 6,714 pallet positions. These are served by Exyz storage and retrieval machines (SRMs) which put away and retrieve 39 pallets an hour, at an average speed of 220 metres per minute. Four single-mast Schaefer Miniload Cranes (SMC, type 1) – which each put away and retrieve an average of 77.5 containers an hour – are deployed in the four-aisle, double-deep small parts storage system comprising 63,440 container positions. Thanks to SSI Schaefer’s Green Crane Technology, travel speed and acceleration can be aligned precisely with actual needs, minimising both wear and electricity consumption. The introduction of WAMAS logistics software has also helped improve plant productivity. The solution supports the ongoing optimisation of all processes in the new logistics hall in line with actual needs. WAMAS is deployed within a client/server environment, and uses graphics to visualise current inventory. The software therefore offers an at-a-glance overview of plant capacity utilisation, and, in addition, enables rapid analysis and trouble-shooting. It is clear to Markus Heinrich, Head of Logistics at Liebherr-Aerospace Lindenberg, that they chose the right partner to implement these improvements. He stated: “We had a very good working relationship with SSI Schaefer throughout the entire project – they proved to be very skilled, professional and reliable.” The changes have improved the aerospace specialist’s ability to respond to fluctuating market conditions within a highly competitive, international business environment. 8 Eco-friendly intralogistics for Lely’s new campus Maassluis, the Netherlands. The Lely Group is an acknowledged pioneer in the agricultural sector. Its portfolio includes forage harvest machines, automatic livestock feeding systems, mobile barn cleaners, and robotic milking systems. SSI Schaefer installed in-line shelving at 18 assembly stations on the high-tech production lines at Lely’s new innovation campus. This shelving ensures that small parts are always easily accessible, and precisely where they need to be. SSI Schaefer also provided a pallet racking system for Lely’s warehouse, for storing materials sold by the metre. In the future, Lely will also deploy SSI Schaefer LTB containers to reduce waste packaging generated during production, and to minimise the company’s environmental footprint. Pallet racking for storing materials sold by the metre. Small parts and items available to rent are stored on modular shelving on a mezzanine, increasing efficiency. “Previously, the shelves were distributed around the workshop. Now, everything is centralised; we have saved space and have reduced picking time. What’s more, items are stored in a much more structured way,” explains Peter Boere, Workshop Team Manager at Lely Industries NV. Lely’s new campus was awarded five stars for exceptional sustainability under the BREEAM certification program. The new, eco-friendly complex was opened in January 2014 by Queen Máxima. Storage capacity doubled Dubai, United Arab Emirates. Glenbeigh Construction, a member of the Glenbeigh Group, is one of Ireland’s leading construction companies, with operations in the United Kingdom and the United Arab Emirates. The enterprise was founded in 1985, and provides project management with in-house design, response care teams, and pre-engineered low carbon off-site building solutions, for both the private and public sectors. of a significant number of cartons. The intralogistics expert implemented a multi-tier mezzanine system; the racks make full use of available headroom, and can store one million cartons. By leveraging vertical storage, SSI Schaefer eliminated the need for an increased footprint, and doubled the warehouse’s capacity. The multi-tier mezzanine system can store up to one million cartons. “SSI Schaefer’s racking systems ensured that our clients’ critical records are stored in a facility of Recently, Gleinbeigh Construction built a ware- a high standard, and provide us with prompt achouse for its sister company Glenbeigh Records cess to records; this ensures that we meet our Management. This new document management one-hour service-level delivery targets,” explains and archiving facility is located in the new aviation Declan Brady, Managing Director at Glenbeigh and logistics hub at Dubai World Central. Records Management. SSI Schaefer was contracted to provide an efficient, secure and reliable solution for the storage 9 Manufacturing Made-to-measure warehouse solution for Belimo Americas Accelerated picking improves material flows and increases throughput. The combination of manual and automated warehouse systems greatly improves process efficiency and saves time. Connecticut, USA. SSI Schaefer has implemented a 7,000-square-metre automated warehouse for Belimo Americas, a manufacturer of actuators and control valves. The scope of services included automated small parts storage with 16,320 tray and container positions, container conveyor systems, a pallet live storage system, narrow-aisle pallet racking, SSI Schaefer’s WAMAS logistics software, and goods-to-person workstations for picking, packing, and pre-assembly. The conveyor system loop serves three picking zones, including the narrow-aisle racking, the live storage system, and the picking workstations, where extremely fast-moving ‘AA’, fast-moving ‘A’, and slow-moving ‘B’ SKUs are stored, respectively. The goods are retrieved by Schaefer Miniload Cranes (SMC), and are transported from the small parts storage system via containers. The exceptionally low-noise conveyor system and highly ergonomic workstations help create a pleasant and productive working environment. Once items have been picked and placed in containers, they are sent to packing stations. If parts require pre-assembly, they are conveyed to dedicated workstations before being prepared for shipping. The decoupled workstations ensure process efficiency, and accelerate receiving-to-shipping time. “The project was delivered on time, and we were able to transition into our new facility as per schedule without interruption to our business and customer service,” explains John Coppola, Vice President of Finance and Administration at Belimo Americas. 3D-MATRIX Solution® for greater efficiency and scalability Haiger, Germany. Klingspor is a major player in abrasive technology, distributing over 200 metric tons of grinding wheels and similar materials to 80 countries daily. The enterprise has a portfolio of more than 50,000 products – and as a result, requires highly efficient storage systems. Against this background, Klingspor contracted SSI Schaefer with upgrading their existing distribution centre, with a focus on ensuring timely delivery. Design of Klingspor’s pallet racking and shuttle-served channel storage systems. At the production plant in Haiger, SSI Schaefer is installing a threeaisle, double-deep pallet racking system, with 13,400 positions, and a shuttle-served channel storage system with 36,000 container positions. The new configuration will incorporate SSI Schaefer’s innovative 3D-MATRIX Solution – which provides outstanding efficiency, flexibility, redundancy and scalability. Three energy-efficient Exyz storage and retrieval systems will streamline putaway and picking in the 2 x 120-channel pallet racking system. A pallet conveyor system with a programmable logic controller (PLC) connects the 26-metre-high racking system to three picking stations and the receiving and shipping areas. On the other side of the building, a Navette shuttle system – comprising 21 Navette vehicles and nine Navette lifts – serves a 26-metre high channel storage system. This storage system is linked by conveyors to four staging areas located in the extremely high-turnover ‘AA’ SKU zone, and to four multiorder stations and eight packing stations. In addition, Klingspor plans to introduce SAP EMW (Extended Warehouse Management) software, which will also be implemented by SSI Schaefer. The upgraded warehouse is slated to commence operation in mid-2016 – and will play a key role in the enterprise’s future growth. 10 Manufacturing A tailor-made storage solution A combination of SSI Schaefer racking components is shortening picking routes, optimising material flow, and improving ergonomics in Schunk’s new warehouse. Heuchelheim, Germany. Schunk products have become indispensable across a variety of industries. They are used, for example, in cars, ships, electronic devices, wind turbines, space shuttles, medical technology, the solar power industry, and LED lighting. To support its expanding portfolio of products, the enterprise decided to increase its efficiency and combine its warehouses for maintenance materials and equipment for water, gas, and electric installations. Schunk contracted SSI Schaefer to plan and execute the restructuring project. an integrated receiving area – and only speciallytrained warehouse staff may enter. Their task is to handle more complex requests from electricians, to pick and put away components, and to plan inventory (including placing orders for corresponding products). SSI Schaefer equipped the parts issuing desk with drawer shelving. A track-free mobile racking system with R 3000 modular shelving units allows quick access to stored items. According to Thomas Stipp, Head of Logistics at Schunk: “This is extremely important, as we need to quickly and accurately provide A new, highly efficient parts storage system has 100 to 150 employees with the right products and been created on a floor space of around 200 materials every day.” Very heavy items are moved square metres. It is designed to make full use with pallet trucks and electrically powered forklifts. of all available headroom, and has capacity for There are additional modular shelving systems 5,000 products. Particular emphasis was placed with drawers in the open self-service area, where on a compact, clearly structured layout – with short employees can take whatever components and picking routes and ergonomic processes. Stephan equipment they need. Edeling, Project Manager at SSI Schaefer, states: “It wasn’t an easy task, as the new facility had less Stipp concludes: “We enjoyed a very positive working relationship with SSI Schaefer – they tailored floor space.” everything to our exact needs. We are now planTo reduce picking errors, SSI Schaefer installed fen- ning the next step – SAP integration – to make our cing, creating an open zone and an enclosed zone. operations even more efficient.” The enclosed zone has a parts issuing desk and All inventory is now organised to maximise efficiency: fast-moving items are stored at the front of the mobile racking systems, with slow-moving items at the rear. 11 Retail Faster picking through optimised automation SSI Schaefer has implemented an automated solution for LANDI Switzerland to create high-availability storage and streamline picking of small parts. Dotzigen, Switzerland. Since 2002, SSI Schaefer has been working hand-in-glove with LANDI Switzerland to advance the enterprise’s intralogistics. Step-by-step, LANDI’s manual warehouse has been intelligently re-designed and fitted with specialised equipment and conveyors. Furthermore, WAMAS software has been implemented to manage material flows. In February 2014, SSI Schaefer installed a 60-metre long, two-aisle automated small parts storage system with a total of 24,000 container positions. Goods were previously stored in conventional modular shelving systems. In this person-to-goods configuration, pickers had to travel long distances which was timeconsuming. Today, picking is much more efficient. The new small parts storage system is served by two storage and retrieval machines, and 12 lifting beams, and is integrated into the warehouse’s existing IT and conveyor systems. Moreover, SSI Schaefer’s WAMAS logistics software optimises putaway and picking processes. The software also ensures the continuous, timely flow of goods to new multi-purpose workstations, where items are repacked after receipt, inventory data is captured, and small parts are picked to order. As Armin Kaufmann, SSI Schaefer’s Project Leader, notes “The multi-purpose configuration of these workstations and their integration into material flows ensures LANDI maximum flexibility for manual processes.” A unique feature of SSI Schaefer’s solution is a fully automated staging area for outbound items within the small parts storage system. The area comprises more than 100 storage positions, and guarantees the seamless flow of sequenced containers to the multi-purpose workstations in line with customer orders. This design enables a throughput of 1,200 containers per hour, and allows rapid picking from storage. “SSI Schaefer’s automated solution and its goodsto-person picking processes have helped us increase our throughput from 60 items per worker per hour to 300 items, in conjunction with a zero-error rate,” explains Urs Rogo, Logistics Project Leader at LANDI Switzerland. “We are very happy with how the project went, and with the results.” The new 60-metre long, two-aisle small parts storage system offers a total of 24,000 container positions. 12 Retail Medium- and slow-moving ‘B’ and ‘C’ products are stored in a modular shelving system on the second floor. Multi-tier storage solution Burton-on-Trent, United Kingdom. NBTY is a global manufacturer and distributor, specialising in high-quality nutritional supplements. The company supplies over 22,000 products under a number of its own and third-party brands. One such brand is Holland & Barrett, a Europe-wide retailer of vitamins, minerals, herbal supplements and organic health products. Holland & Barrett operates over 620 stores in the UK and Ireland, and has a successful and ever-expanding online business. tensive conveyor system connects all levels and zones, and moves order-picking and replenishment cartons to the picking floors. This conveyor leads to a series of packing benches, where documents are placed in the cartons before they are sealed and labelled. The solution combines a multi-tier mezzanine picking tower with pallet racking on the ground floor, live storage picking on the first floor and a combination of live storage picking and shelf NBTY’s high-street and online branches were picking on the top floor. originally supplied by a distribution centre in Burton-on-Trent, Staffordshire, where tasks were “The new automated system is faster, more effiperformed manually. However, there was constant- cient and more accurate, helping us meet our ly increasing pressure to keep up with daily de- online requirements. It also offers us a scalable mand. To enable NBTY to reliably serve Holland & solution to our e-commerce enterprise, enabling Barrett’s online customers, SSI Schaefer installed us to choose the level of automation to complean automated system at the existing distribution ment the level of demand”, says Mark Kendrick, centre, completely transforming the distributor’s Group Distribution Director at NBTY. e-commerce capabilities. In order to cope with NBTY’s growing product range and inventory, and to increase available storage space, SSI Schaefer built a two-storey mezzanine with pallet racking beneath it. This has enabled NBTY to store bulk and replenishment goods, both in large cartons and on pallets, at ground floor level. In addition, SSI Schaefer installed a live storage system on the first floor of the mezzanine for fast-moving ‘A’ products, and modular shelving on the second floor for mediumand slow-moving ‘B’ and ‘C’ products. In the fully flexible picking zones on both floors, shipping cartons are transported only to the zones that hold order-required products. An ex- Facts and figures Project objectives: •End-to-end automation of material flows •Improved basis for e-commerce •Constant availability •Highly precise picking Our scope of services: •Two-storey mezzanine with modular shelving system •Pallet racking, long-span racking •Eight storage and retrieval systems for pallets •Live storage system for cartons •Extensive conveyor system for cartons •WAMAS warehouse management software 13 Food industry Turnkey high-bay warehouse for frozen meatballs Dafgård’s frozen ready meals are stored at -28°C in a state-of-the-art automated warehouse. To solve the problem of limited storage space at their site in Källby, Dafgård tasked SSI Schaefer, Giebelstadt, with the construction of a new cold storage warehouse capable of storing products at -28°C. This high-bay facility will have a height of 35 metres, and be equipped with a state-ofthe-art oxygen-reduction fire prevention system. In addition, there will be six energy-efficient Exyz machines for double-deep storage and retrieval. These devices will serve a total of approximately 30,000 pallet positions. Moreover, SSI Schaefer’s scope of supply includes a new distribution zone, WAMAS logistics software, and a sophisticated conveyor system, directly linked to the production plant. 3D graphic of Dafgård’s cold storage warehouse in Källby, Sweden. Källby, Sweden. Swedish family-owned company Dafgård has been developing and supplying high-quality ready meals since the 1930s. Today, Dafgård is Sweden’s preferred brand of readymade meals, producing 40 million Billy’s pizzas every year and 400,000 meatballs every hour. Construction of the new cold storage warehouse has just commenced, and is scheduled to be completed in December 2015. It will significantly improve the efficiency of Dafgård’s logistics by enabling easy delivery date monitoring, more accurate inventory control, and faster loading of trucks. Space-saving seafood storage Tuticorin, India. Nila Sea Foods specialises in seafood products, and offers a range of over 45 SKUs, including lobster, cephalopod, crab, fish and shrimp. Until recently, Nila Sea Foods stored its frozen products in its own cold storage warehouse, and at facilities operated by third-party logistics Nila Sea Foods uses a mobile providers. However, limited storage space made racking system to store its frozen seafood products. it difficult to directly access all SKUs. Nila Sea Foods’ mission is to supply its high-quality goods on time, to ensure end-to-end product traceability, and to safeguard the cold chain at all times. For this reason, SSI Schaefer was tasked with upgrading the existing warehouse. A key role is played by a mobile racking system with a total of 1,830 pallet positions. This has enabled more efficient use of available space. “The automatic racking system helps us to increase our productivity and reduce product damage. Moreover, it consumes less electricity, takes up less space, and includes more safety measures. This allows us to easily handle and trace products,” explains Mr Chandran, General Manager of Nila Sea Foods. 14 Food industry WAMAS® streamlines operations at sub-zero temperatures Rothenburg, Switzerland. Pistor is Switzerland’s leading supplier of food products to bakeries, patisseries, and confectioners, and a key wholesaler within the restaurant industry. The business recently tasked SSI Schaefer with constructing a logistics centre for its fresh and frozen items. This is the third time Pistor has chosen SSI Schaefer to provide a state-of-the-art intralogistics solution – in 1997, it implemented WAMAS, and in 2011 it built a new distribution centre. Pistor’s new 5000-square-metre freezer warehouse, nicknamed the “Ice Cube” by the staff, is supported by WAMAS. WAMAS manages the warehouse’s operations, logistics and support processes. The software is deployed to control the flow of goods to and from more than 5,000 pallet positions and 76,000 tray positions at a temperature of - 24°C. Incoming goods arrive on pallets, and data is captured by WAMAS using handheld devices. A conveyor system then moves the items to the freezer area, where they are put away in doubledeep storage in the new two-aisle high-bay store. Trays are put away and picked by means of a Schaefer Miniload Crane (SMC 1) storage and retrieval system. The items are manually transferred from pallets to trays at repacking stations. A Schaefer Miniload Crane (SMC 1) storage and retrieval system then places the trays into a 12-aisle automated small parts storage system. The shipping area is the highlight of the new facility. The trays are automatically retrieved from the small parts storage system on trolleys in preparation for shipping. They are sent to a sorting unit via buffer conveyors, and are organised into a defined sequence by WAMAS before they arrive at the packaging area. Transfer from the small parts storage system to the ergonomic packaging area is automated from end to end. This enables packaging tasks to be performed at above zero temperatures (1°C), creating a more pleasant working environment. Due to the compact sequencing of the trolleys, the frozen products are only exposed to above-zero temperatures for a limited time. “The Rothenburg project was complex, with a high degree of automation. Products need to be stored at sub-zero temperatures, and government agencies imposed strict requirements. Despite these challenges, it was very successful,” states Richard Betschart, Head of Logistics at Pistor. WAMAS manages the warehouse’s operations, logistics and support processes. 15 The design of the high-bay warehouse with channel storage increases Tine’s storage flexibility and inventory turnover for new products. High throughput, low temperature Jæren near Nærbø, Norway. Tine processes 200 million litres of milk a year to manufacture some 300 dairy products. This creates significant storage and picking challenges, but SSI Schaefer, Giebelstadt, is up to the task. The SRMs are equipped with shuttles as loadhandling devices, enabling three- to four-deep storage in the rack channels. “The HBW’s design, with a channel storage system, improves storage flexibility and throughput of newly introduced products,” explains Ingvar Løge, manager of the new At the core of SSI Schaefer’s logistics solution is a warehouse in Jæren. A 400-metre long pallet contemperature-controlled high-bay warehouse (HBW), veyor system connects the HBW with the producwith close to 7,200 pallet positions. Due to the tion and shipping areas. sensitive nature of its goods, the cooling system is equipped with an oxygen-reduction fire prevention SSI Schaefer’s WAMAS logistics software mansystem. Putaway and picking tasks are performed ages and monitors warehouse processes. The by four storage and retrieval machines (SRMs), cold chain is maintained through a combination with a throughput of 33 pallets per hour. “The of automation, software, and storage and picking SRMs and their components are ideal for oper- systems. Furthermore, WAMAS helps streamline ation in temperature-controlled warehouses,” the entire supply chain, from farm to supermarket states Peter Lambrecht, Head of Project Manage- freezer. ment at SSI Schaefer. Pasta made in Canada Brampton, Canada. Founded in 1989, Italpasta has achieved outstanding success through its commitment to excellent service, quality, and customer satisfaction. Its team, including ten pasta specialists with extensive experience in their craft, ensure that Italpasta enjoys wide recognition in Canada’s food service sector, and is the No. 1 retail pasta brand in Ontario. A conveyor system moves cartons from the packaging zone to the buffer area. However, Italpasta’s continuous growth created real challenges for its packaging department. Space constraints in production, and poorly structured warehouse processes posed a risk to employee and food safety. For this reason, Italpasta tasked SSI Schaefer with automating and restructuring the corresponding processes – without disrupting ongoing operations. SSI Schaefer’s solution was to construct a bridge, with two integrated conveyors, to connect the manufacturing plant to the adjacent building used to hold finished goods. The conveyors move cartons from 21 packaging lines to the buffer area, where they are sorted and stacked before being sent to one of four automated palletising stations. Here, they are palletised, shrink-wrapped, labelled, and prepared for shipping. The solution has enhanced efficiency, improved staff working conditions, and increased space available for equipment – now, there is nothing standing in the way of Italpasta’s progress. 16 Food industry Vietnam’s high-tech dairy distribution centre WAMAS® software and process automation ensure high throughput for Vinamilk in Vietnam. Binh Duong, Vietnam. Vinamilk is Vietnam’s leading dairy product manufacturer, processing 400 million litres of milk annually. The company meets much of the country’s market demand, and has recently established the Ben Cat District Facility on a 200,000-square-metre site. This huge factory requires sophisticated intralogistics to ensure the smooth flow of goods. In the manufacturing department, the dairy products are packaged in Tetra Paks. These are then boxed, shrink-wrapped and palletised, before being moved to a smart warehouse, built by SSI Schaefer, via two transfer stations. The key to process automation within the warehouse is a rail-guided vehicle (RGV) system, with a total length exceeding 370 metres, and 15 vehicles. The RGV moves pallets from the manufacturing department to any required storage position within the logistics centre. “It is the first time that SSI Schaefer has installed an electrified RGV system for intralogistics flows in South-East Asia,” explains Carsten Spiegelberg, General Manager for Systems and Automation, Schaefer Systems International Pte. Ltd., Singapore. Each RGV carries two pallets simultaneously at a speed of 90 metres per minute to the transfer spurs for the automated storage and retrieval machines (SRMs). Eight Exzy SRMs serve some 28,000 pallet positions within the earthquake-proof high-bay warehouse. For the outbound process, the pallets are transferred via a conveyor to eight shipping lanes. A vertical conveyor moves pallets that require pre-picking to an upper floor. WAMAS logistics software ensures route-optimised picking while taking into account constraints imposed by the need for stable, volume-optimised pallet loads. Once picking is complete, the logistics software sequences the movement of pallets to the shipping area on the lower floor in line with customer orders. Despite highly complex goods flows, it is possible to move 188 pallets per hour to the shipping department. “SSI Schaefer’s logistics software streamlines our processes and accelerates throughput; moreover, it has reduced our error rate to almost zero. The solution as a whole provides excellent support for our growth strategy,” emphasises Trinh Quoc Dung, Vinamilk Factory Manager. Eight energy-efficient Exyz SRMs perform pallet putaway and retrieval. 17 Logistics service providers Innovative combination of systems SSI Schaefer has implemented a flexible, state-of-the-art solution that enables highly efficient processes for logistics specialist Kühne + Nagel in Utrecht in the Netherlands. Kühne + Nagel, the global logistics player, tasked SSI Schaefer with creating a highly flexible and efficient distribution centre for its business operations in the Netherlands. The result is a 12-aisle high-bay warehouse for foodstuffs, with an integrated Orbiter® shuttle system, an electrified rail-guided vehicle (RGV) system and conveyors with a total length of around one kilometre. The facility also features layer-picking robots with innovative grippers. Utrecht, the Netherlands. Worldwide, Kühne + Nagel offers its customers approximately seven million square metres of storage space – including more than 33,000 square metres in Utrecht, the Netherlands. SSI Schaefer, Giebelstadt, Germany, was contracted to create a logistics centre for storing foodstuffs for multiple customers. The result is a facility that combines a variety of highly advanced technologies. The deployment of two picking robots with innovative grippers enables the automated picking of individual pallet layers. 18 The new 12-aisle high-bay warehouse has capacity for 43,700 euro and 35,900 industrial pallets, stored four- and five-deep. The racking channels have been divided into dynamic FIFO-friendly (firstin first-out) half channels to allow direct access to front-facing pallets without the need for re-slotting. This required the installation of a non-standard load-handling device. The solution was a combination of automatic storage and retrieval machines (SRMs) and an Orbiter shuttle system. This enabled the integration of channel storage into the high-bay system. However, in comparison to conventional channel storage, there is far greater flexibility in terms of the range of products that can be stored. This is particularly advantageous for foodstuffs, with their strict sell-by dates. The SRM acts as a docking station for the Orbiter shuttle. Once the pallet has been loaded onto the SRM, the SRM travels into the corresponding aisle, and stops in front of the racking channel defined by the logistics software, enabling the Orbiter shuttle to put away the pallet in precisely the right position within the high-bay system. Logistics service providers SSI Schaefer’s WAMAS software intelligently manages all aspects of materials flow for putaway and retrieval processes, picking and crossdocking. In the receiving department, the pallets are subject to automated checks on contours, excess weight, height class, and base integrity. At the same time, a plausibility check is performed, including a weight comparison, on the basis of product master data. The electrified rail-guided vehicle system then conveys inbound pallets to the transfer stations to the SRMs. The electrified rail-guided vehicle system describes a circular route, serving the conveyors for all workstations in the distribution centre. Managed by the logistics software, this system employs 24 vehicles to move inbound goods to spurs for the SRMs or, for cross-docking, to the staging lanes ready for shipping, or to integrated picking stations. To this end, the distribution centre has six transfer stations to the roller and chain conveyors. A conveyor system of a total length of one kilometre was installed in front of the 114-metre side of the high-bay warehouse. Rotary conveyors are used to feed this system with cross-docked pallets from the receiving department, and with pallets retrieved from the high-bay warehouse. The pallets are then moved directly to the shipping area, or to the layer-picking robots. The picking robots are a key feature of the project, and make use of innovative gripper technology. They can auto-pick individual layers from one or two source pallets, and position them onto up to four target pallets. The logistics software must manage the full pallets retrieved from the high-bay warehouse in a sequence that enables each one to be used for as many target pallets as possible, but while ensuring these outbound pallets are completed rapidly – to avoid creating a bottleneck. “The design of the layer picking robots, and the configuration and management of the goods flows to and from the robots, are a vital feature of the entire distribution centre,” states John Pelzer, Technical Manager at Kühne + Nagel Netherlands. “They were key to our decision to award the contract to SSI Schaefer.” The high-bay warehouse is 34 metres high, and has a total of 43,700 positions for euro pallets, and 35,900 positions for industrial pallets. 19 Special feature SS I up lS n Te c h ica n l it / t r o f is a t e R p ti m O S y ste m io r ta por t ® ice le-Shootin Troub g e Par ts Serv Spar ice M n S er v However, there is an answer. Within the scope of a broad portfolio, SSI Schaefer’s Customer Service & Support (CSS) division offers timely advice and assistance, helping businesses to run smoothly. Customer System r er a ini tif n g ic a & tio n C Giebelstadt, Germany. Warehouses play a significant role in any logistics infrastructure. However, the components deployed in these facilities are, over a typical period of seven to 15 years, overtaken by technological advances, rendering them obsolete. They are often no longer able to effectively support the latest business processes and growth strategies. The consequences are high operating costs, inflexibility, and reduced competitiveness. Po T Maximum availability of all subsystems and responsive customer support are crucial to keeping complex logistics processes up and running. SSI Schaefer is fully committed to these objectives. e nc Made-to-measure customer service and support ive Insp ent ance ec v e ten r tio P in a ent Mainte sid na e R Its extensive range of services includes technical support, help desks, system monitoring, inspection and maintenance, on-site support, safety checks, the provision of spare parts, consulting and training. CSS works closely with its customers to develop tailor-made service offerings geared to their current requirements and potential future developments. It is not always necessary to entirely replace a legacy infrastructure. In many cases, a retrofit is sufficient to provide the required warehouse efficiency – it is a quick and cost-efficient way to upgrade intralogistics systems without interrupting ongoing operations. Often, the basic mechanical structure and key components can be retained and reused. However, older facilities often lack up-to-date control technology, energy-efficient drives, and modern conveyor components. Moreover, state-of-the-art IT systems can often bring major improvements to entire processes and goods flows, ensuring greater productivity and higher quality. SSI Schaefer provides new and established customers with expert advice on how they can best re-engineer their intralogistics – while protecting existing investments, and minimising cost, effort and disruption. This leads to greater reliability, increased uptime, and more efficient use of resources. This publication features two CSS projects that illustrate how processes and operations can be streamlined in this way. Skilled service engineers are available at all times to provide end-to-end on-site support. 20 Special feature Seven times faster with RFID tracking Conversion at A. Kempf’s distribution centre saves up to eight man-hours per day. Balingen, Germany. Beverage logistics specialist A. Kempf is a subsidiary of supermarket chain Edeka Südwest. From its warehouse in Balingen, Kempf services 125 customers per day – up to 110 delivery routes. This calls for extremely efficient processes. However, these were hampered by the legacy identification and tracking methods. For example, manual scanning of incoming pallets was very time-consuming. As a result, SSI Schaefer, Giebelstadt, converted the goods receipt processes to RFID (radio frequency identification). Each RFID transponder (also known as a tag or chip) has a unique identifier, and can store significantly richer data than barcodes. Moreover, they do not require line of sight. cards in the holders. During the shift, the warehouse management system (WMS) transmits the picking and transfer jobs directly to the onboard terminals. Both the completion of pallets for putaway and the transfer of pallets to conveyors are reported to the WMS via RFID, and coordinated via the material flow control system. The new Three industrial UHF RFID read/write devices RFID technology delivers huge time savings and were installed at the Balingen distribution centre creates seamless putaway processes. to detect the picking trucks and forklifts at the three pallet receiving stations. In addition, each “Thanks to this powerful technology and high-peremployee was given a personal identification card formance components, data collection is reliable with an RFID chip, and all trucks used for pallet and error-free,” reports Patrick Zurheide, who receipt were fitted with special card holders. manages Kempf’s distribution centre in Balingen. Thorough preparation enabled SSI Schaefer to At the start of each shift, employees log on to complete the conversion in just one week – the terminals on their trucks, and place their RFID without disrupting ongoing operations. Three industrialstrength UHF RFID read/write devices were mounted at the pallet receiving stations to track picking trucks and forklifts. Teamwork was the key to success SSI Schaefer has expanded Oriflame’s distribution centre in Poland. Piaseczno, Poland. Oriflame specialises in innovative, natural Swedish cosmetics, and markets its products via approximately three million independent Oriflame beauty consultants. With consultants securing ever-increasing order volumes, and online sales growing as well, the shipping process was experiencing significant delays. The solution was to expand the company’s logistics centre. SSI Schaefer, Graz, Austria extended the conveyor infrastructure, installed an automated carton conveyor line in the shipping department, modified the existing IT, and introduced a new labelling system. “The challenge was to enhance existing installations while the logistics centre continued to operate at full capacity,” reports Robert Ranftl, who managed the project for SSI Schaefer. To avoid disruptions in the shipping department, work was mainly carried out at night. Greater capacity has produced positive results: Oriflame can now ship products promptly and reliably, even during peak periods. “The entire project was conducted to the highest professional standards. It was the best we’ve ever been involved in – by far,” says Lukasz Kielczewski, Operations Manager at Oriflame’s logistics service provider, Logwin Air + Ocean, Poland. 21 Inside SSI Schaefer Growing demand for upgrades Klaus Reichert, Head of Fulfilment, Customer Service and Support at SSI Schaefer, Germany. Upgrades and retrofitting have become a hot topic in intralogistics. They are often advisable after about 10 years of service, depending on the industry and the type of equipment. The goal is to safeguard or raise productivity, and to ensure efficient use of resources. In an exclusive interview, Klaus Reichert answers the key questions. What does a retrofit package from SSI Schaefer entail? And how do you go about the tasks involved? We have a dedicated upgrade team within the Customer Service and Support department. They offer a comprehensive portfolio. Services include the development of customer-specific improvement plans, with detailed capital expenditure budgets, and energy-efficiency and IT solutions, for example upgrades to warehouse management and equipment control systems. We often also replace drives and mechanical components. Generally, customers approach us first, and we then assess the existing logistics infrastructure in situ. Together, we develop an upgrade plan designed to make systems ready for future challenges. We then begin with implementation – but with a focus on minimising downtime. SSI Schaefer service engineers performing upgrade work on a conveyor system serving nine aisles in an existing high-bay warehouse at Zott in southern Germany. How much demand is there for upgrades, and is it on the rise? Demand for the retrofit of state-of-the-art equipment to existing intralogistics systems remains high. It is driven by technological progress on the one side and by the age of the existing systems on the other. Hand-in-hand with the customer, we perform in-depth analysis of the legacy systems. Our goal is to make the most of available space and resources, and to maximise uptime and throughput within existing distribution centres. Do you offer upgrades and retrofits for third-party legacy equipment? We have the skills to quickly and reliably modernise both SSI Schaefer and third-party warehouse and production systems. This can entail replacing components, adding new systems, and upgrading the IT. New materials flows are tailored to existing production plants. Modernisation improves operational reliability and raises warehouse availability for both new and existing customers. Is the demand for retrofits greater in some industries than others? There does not seem to be any great variation between individual industries. We are seeing growing demand across the board. Can customers expect disruptions to ongoing operations during an upgrade project? We are very focused on working with our customers to find ways of minimising the impact of implementation projects on operations. We plan for any work that will entail downtime for mission-critical systems or the entire facility well in advance, and where necessary we schedule work for weekends or holidays. We are keenly aware that downtime can have a severe impact upon the customer’s business, but we can largely avoid it. The storage and retrieval systems at SKF in Berlin were, with the exception of the mast and the track, completely disassembled during an upgrade. 22 Inside SSI Schaefer ++++++++++++++ Production plant expansion in Asia The Navette is equipped with two load-handling devices, one positioned above the other. This enables the system to put away and retrieve items simultaneously – performing two actions in just one cycle. Navette – the scalable, multi-level shuttle Simpang Reng gam, Malaysia. SSI Schaefer’s expanded steel production plant went into operation in February 2014. A new rolling mill, the same type used by the parent company in Germany, will soon process all profiles for high-bay racking systems – which may be up to 40 metres in height. Additionally, systems for preparing special steelwork profiles will be installed. SSI Schaefer’s innovative new product, Navette, continues the enterprise’s tradition of providing efficiency-enhancing solutions for fully automated warehouses. Giebelstadt, Germany. The Navette from SSI Schaefer is an innovative, independent warehouse vehicle that combines the advantages of both a shuttle and a storage and retrieval machine. It transports totes, trays, and cartons. The Navette is integrated into the steel framework of racking aisles in automated small parts storage systems. Guided by travel and support rails, a single shuttle serves up to eight levels of storage, including two levels simultaneously. The Navette is equipped with two load handling devices (LHD), such as carton grabs, arranged one above the other so each can access a separate level. Additionally, each LHD can transport two trays, totes or cartons at a time. As a result, the Navette performs a total of two actions within a single cycle, for four items – rather than two actions consecutively without deadheading. The concurrent putaway and retrieval while the Navette shuttle remains at one position in the racking reduces travel time and doubles process efficiency. The Navette has been integrated into an end-to-end system based on SSI Schaefer’s 3D-MATRIX Solution. The shuttles are combined with Navette lifts and vehicles, and conveyors, to move goods in the X, Y and Z axes. All these components are efficiently designed to operate independently but simultaneously. Furthermore, all components can be combined in almost any number and configuration, without having to completely re-engineer the system as a whole. Subsequent expansions can be completed without disrupting normal operations. The result is a solution offering highly dynamic goodsto-person picking, and putaway, buffering and order-based sequencing. The Navette can be scaled precisely to customers’ specific needs. As a standard SSI Schaefer system, the multi-level shuttle is a secure investment. It enables access to a wide range of SKUs in storage channels, and highly efficient workflows due to its concurrent processes – it is a quantum leap forward in innovative design and warehousing technology. “We are seeing an increase in enquiries for high-rise racking systems due to rising land and labour costs. Shipping heavy steel profiles halfway around the world is obviously not cost-effective. To cater to growing demand from the Asia-Pacific Region, the Middle East and Africa, we have decided that Asia should become a competency centre for the design and supply of these systems. Our Malaysian engineers have been trained to undertake the structural designs and to prepare fabrication drawings using the German CAD program,” states Brian Miles, Regional Managing Director. In 2011, SSI Schaefer built a 5,000-square-metre plant for manufacturing conveyor systems and picking equipment. Due to rising exports, storage capacity was increased by 2,000 square metres in 2012. The site in Simpang Renggam has grown to a size of 40,000 square metres, with a headcount of approximately 500. Additional expansion – comprising a further 5,000 square metres of warehouse space plus offices – is already underway. 23 Serving up highly efficient beverage logistics In the food industry, fast and reliable delivery is a must. And that is where SSI Schaefer’s Lift & Run system comes into play. The innovative system puts theory into practice. A shuttle serves channel storage facilities, creating an exceptional, cost-effective solution for handling pallets. Highly dynamic, scalable, compact and energy efficient, the system can be tailored to specific needs. About update Published by (responsible for content): SSI SCHÄFER / FRITZ SCHÄFER GMBH • Fritz-Schäfer-Strasse 20 · 57290 Neunkirchen/Germany Public Relations / editorial team: Angelina Kuhn – email angelina.kuhn@ssi-schaefer.com www.ssi-schaefer.com SSI SCHAEFER SYSTEMS INT. INC. P. O. Box 7009 · 10021 Westlake Drive · USA-Charlotte, N.C. 28241 · Phone +1 / 7 04 / 9 44 45 00 · email general@ssimail.net update en/us 0344-042015-w 2/042015 Printed in Germany by Griebsch & Rochol • © SSI SCHÄFER • Products featured in articles may be subject to change and technical modification. Errors and omissions excepted.