isoPro® type sBm - J & P – Bautechnik Vertriebs GmbH

advertisement

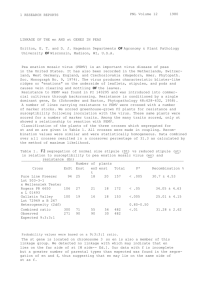

for better solutions... ISOPRO® STEEL CONNECTION SBM/SBQ Thermal insulating panel for connecting steel or timber beams ISOPRO® – Made in Germany ISOPRO® – Insulation at the highest level www.h-bau.com Contact Helsinki Oslo Moscow Warsaw London Kiev Paris H-BAU Bucharest Rome Madrid H-BAU Technik GmbH Am Güterbahnhof 20 79771 Klettgau Germany Phone +49 (0) 77 42 | 92 15-30 Telefax +49 (0) 77 42 | 92 15-90 info.klettgau@h-bau.de www.h-bau.de 2 www.h-bau.com Ankara Production and Delivery North-east Brandenburger Allee 30 14641 Nauen OT Wachow Germany Phone +49 (0) 3 32 39 | 7 75-20 Telefax +49 (0) 3 32 39 | 7 75-90 info.berlin@h-bau.de Production Chemnitz Beyerstraße 21 09113 Chemnitz Germany Phone +49 (0) 371 | 400 41-0 Telefax +49 (0) 371 | 400 41-99 ISOPRO ® for better solutions Steel connection Contents ISOPRO® Steel connection General Type overview 4 Component catalogue & test certificates 5 Type SBM General 6 Examples of use 7 Design & dimensions 8 Dimensioning 10 Deflection & elevation 11 Planning notes 12 Installation tolerances 13 On-site reinforcement 14 On-site face plate 16 Type SBQ General 18 Examples of use 19 Design & dimensions 20 Dimensioning22 Planning notes 23 On-site reinforcement & face plate 24 3 Insulation at the highest level ISOPRO type SBM & SBQ ® Type overview ISOPRO® type SBM - Page 6 - Cantilever steel or wood Structures with reinforced concrete structural components. Bending moments, lateral and horizontal forces are transferred. ISOPRO® type SBQ - Page 18 - Propped cantilever steel or timber structures with reinforced concrete structural components. Lateral and horizontal forces are transferred. 4 www.h-bau.com ISOPRO type SBM & SBQ ® for better solutions Component catalogue & test certificates ISOPRO® type SBM and SBQ component catalogue Reinforcing steel: B500B Stainless steel: S275 - mat. no. 1.4571, 1.4062, 1.4362 S460 - mat. no. 1.4571 as per general building control approval Z-30.3-6 Structural steel: S235 Insulating body: NEOPOR® poly hard foam ʎ = 0.031 W/mK Connecting components Concrete: Normal concrete as per EC2 and DIN EN 206-1 Minimum concrete strength of internal components: C20/25 Reinforcing steel: B500B Structural steel: in terms of the balcony, according to data published by the structural engineer Test certificates Approval: DIBt Berlin General building control approval No. Z-15.7-313 Technical information about our ISOPRO thermal insulation panels can be downloaded at www.h-bau.com ® Project-related insulation ratings on request. www u. a b .h com click... * NEOPOR® is a registered trade-mark of BASF, Ludwigshafen 5 Insulation at the highest level ISOPRO type SBM ® General information The product The ISOPRO® type SBM thermal insulation panel connects cantilever constructions statically with reinforced concrete structural components. At the same time, its excellent thermal properties resolve the structural problems of thermal bridging at this junction. The element comprises an EPS insulating body with extremely low thermal conductivity and a statically effective stainless steel truss construction. Depending on type, positive and negative bending moments and both lateral and horizontal forces can be transferred. 6 www.h-bau.com Features Building control approval No. Z-15.7-313 Dimensioning values embedded in the approval Reduction of thermal bridging as per DIN 4108-2 and EnEV Simple and secure assembly by means of continuously variable height adjustment The application As a solution to the interface between steel and reinforced concrete construction, ISOPRO® steel connectors fit perfectly into the ISOPRO® family. ISOPRO® type SBM elements were developed specially for connecting cantilever balconies and canopies. The elements are installed in the shell as part of reinforcement and concreting work. Assembly of the steel construction is carried out at a later date by the steel workers. ISOPRO type SBM ® for better solutions Application examples ISOPRO® type SBM connecting situations Formwork erection brick work: Formwork erection brick work with external thermal insulation material: Special design for connection to a wall: Please contact our application technologies department for further special constructions. Tel.: +49 (0) 77 42 / 92 15-70 Fax: +49 (0) 77 42 / 92 15-96 Email:technik@h-bau.de Corner area for h ≥ 200 mm: Notes: The following applies for connection in the corner area: Only for slab thickness h ≥ 200 mm. Element bearing capacity for h - 20 mm. You must observe the 20 mm height difference on the on-site face plate. 7 Insulation at the highest level ISOPRO type SBM ® Design & dimensions (10 mm steps) ISOPRO® type SBM 14 Q8 / SBM 14 Q10 Assembly plate Adjustment plate Pressure plate 65x40x15 *Values for Q10 (10 mm steps) ISOPRO® type SBM 14 QQ Assembly plate Adjustment plate 8 www.h-bau.com ISOPRO type SBM ® for better solutions Design & dimensions (10 mm steps) ISOPRO® type SBM 20 Q10 / SBM 20 Q12 Assembly plate Adjustment plate C(1:5) *Values for Q12 C Timber assembly plate Sample illustration 9 Insulation at the highest level ISOPRO type SBM ® Dimensioning System length The system length is measured from the trailing edge of the top plate Cleat on-site Cleat on-site Load case for uplift loads Load case for down loads Dimensioning table for concrete ≥ C20/25 Material ISOPRO® type SBM 14 ISOPRO® type SBM 20 SBM 14 Q8 SBM 14 Q10 h = 180 [mm] 10.1 9.0 10.1 - 9.2 22.2 - 11.3 20.6 - 11.3 h = 200 [mm] 11.9 10.5 12.0 - 10.8 26.3 - 13.5 24.4 - 13.5 h = 220 [mm] 13.7 12.1 13.8 - 12.4 30.4 - 15.6 28.2 - 15.6 h = 240 [mm] 15.5 13.7 15.6 - 14.0 34.5 - 17.7 32.0 - 17.7 h = 250 [mm] 16.4 14.5 16.5 - 14.9 36.5 - 18.7 34.0 - 18.7 h = 260 [mm] 17.3 15.3 17.4 - 15.7 38.6 - 19.8 35.9 - 19.8 h = 280 [mm] 19.1 16.8 19.2 - 17.3 42.7 - 21.9 39.7 - 21.9 Vertical force VRd [kN] 18.0 30.0 18.0 - 12.0 30.0 - 12.0 45.0 - 12.0 Horizontal force HRd [kN] ± 2.5 ± 4.0 Bending moment MRd [kNm] SBM 14 QQ ± 2.5 SBM 20 Q10 ± 4.0 SBM 20 Q12 ± 6.5 See approval for intermediate sizes. Product definition ISOPRO®: e.g. SBM 14 Q10 h200 Element height Lateral force load-bearing capacity Load-bearing capacity Type designation Note: The steel construction is to be elevated to minimize deflection; see P. 11. For maximum expansion joint distances, see P. 12. For maximum installation tolerances, see P. 13. 10 www.h-bau.com ISOPRO type SBM ® for better solutions Deflection & elevation Deflection factors tanα and maximum expansion joint distances ISOPRO® type SBM 14 Material Deformation factor tanα ISOPRO® type SBM 20 SBM 14 Q8 SBM 14 Q10 SBM 14 QQ SBM 20 Q10 SBM 20 Q12 h = 180 mm 0.6 0.6 1.0 1.3 1.3 h = 200 mm 0.5 0.5 0.8 1.1 1.1 h = 220 mm 0.5 0.4 0.7 1.0 0.9 h = 240 mm 0.4 0.4 0.6 0.9 0.8 h = 250 mm 0.4 0.4 0.6 0.8 0.8 h = 260 mm 0.4 0.3 0.6 0.8 0.7 h = 280 mm 0.3 0.3 0.5 0.7 0.7 See approval for intermediate sizes. Deflection and elevation To determine the vertical displacement of the steel construction, the deformation of the steel connection ISOPRO® type SBM is to be superimposed with the deformation of the connected steel construction. We recommend providing proof in the limit state of suitability for use (quasi-continuous load combination). The steel construction is to be elevated for the deformation identified. It is worth noting that the results in accordance with scheduled drainage are rounded up or down. The proportion of elevation derived from the element deformation is determined as follows: w [mm] = tanα · (MEd/MRd) · l [m] · 10 k tanα See table above for deformation factor. MEd Bending moment for determining the elevation as a result of the ISOPRO® element. The decisive load combination will be determined by the planners. MRd Design moment of the ISOPRO® element in accordance with the dimensioning table. lk System length [m]. Note: The values indicated are approximations. These may deviate depending on the installation situation and assembly. It may then be necessary to take other deformation influences into consideration. 11 Insulation at the highest level ISOPRO type SBM ® Planning notes Expansion joint distances For determining the maximum permissible expansion joint distances, a balcony plate which is firmly connected with the steel girders is decisive. If the connection between steel girders and balcony plate is designed to be relocatable, the distances of the non-relocatable connections become decisive. Material ISOPRO® type SBM 14 SBM 14 Q8 Maximum expansion joint distances SBM 14 Q10 ISOPRO® type SBM 20 SBM 14 QQ ≤ 6.0 m Element and edge distances Notes: The following applies for connection in the corner area: Only for slab thickness h ≥ 200 mm. Element bearing capacity for h - 20 mm. You must observe the 20 mm height difference on the on-site face plate. Reduced expansion joint distances. 12 www.h-bau.com SBM 20 Q10 SBM 20 Q12 ≤ 4.0 m ISOPRO type SBM ® for better solutions Installation tolerances Installation tolerances Initial position = Upper tolerance slotted hole Initial position = Centre slotted hole Initial position = Lower tolerance slotted hole Tolerance: +12 / -0 mm Tolerance: ±6 mm Tolerance: +0 / -12 mm Adjustability The adjustment plate ensures simple and continuously variable height adjustment. Notes: The executables should indicate these accuracies in the detail and working drawings. The actual shell dimensions shall be tested by the responsible construction management and forwarded to the steel workers. The dimension tolerances shall be observed according to DIN 18201, 18202 and 18203. 13 Insulation at the highest level ISOPRO type SBM ® On-site reinforcement ISOPRO® type SBM 14 Q8 / SBM 14 Q10 Assembly plate Connection reinforcement of tensile rods 2 Ø 14, design as per DIN EN 1992-1-1. Constructive transverse reinforcement as per DIN EN 1992-1-1. ISOPRO® type SBM 14 QQ Assembly plate Bracket Connection reinforcement of tensile rods 2 Ø 14, design as per DIN EN 1992-1-1. Constructive transverse reinforcement as per DIN EN 1992-1-1. Arrange stirrups on element at least Ø 6 from edge banding. Required connection reinforcement of compression struts for scheduled uplift loads according to details provided by the structural engineer. Additional reinforcement in the area of the slot according to details provided by the structural engineer. 14 www.h-bau.com ISOPRO type SBM ® for better solutions On-site reinforcement ISOPRO® type SBM 20 Q10 / SBM 20 Q12 Assembly plate Connection reinforcement of tensile rods 4 Ø 14, design as per DIN EN 1992-1-1. Bracket reinforcement dependent on slot length. Variant 1 Pos. 1, Pos. 2 Variant 2 Pos. 1 Pos. 2 2x 21 Ø 6/6 Variant 3 Pos. 3, Pos. 4 Pos. 1: 2x 15 Ø 6/6 Pos. 2: 2x 6 Ø 6/6 Variant 4 Pos. 3 Pos. 4 21 Ø 6/6 Pos. 3: 15 Ø 6/6 Pos. 4: 6 Ø 6/6 Connection reinforcement of compression struts for scheduled uplift loads according to details provided by the structural engineer. For uplift loads, arrange stirrup on element at least Ø 6 from edge banding (cf. P. 14). Additional reinforcement in the area of the slot according to details provided by the structural engineer. 15 Insulation at the highest level ISOPRO type SBM ® On-site face plate Notes: Support cleat for lateral force transfer is mandatory! Perform corrosion protection following welding. Material, dimensions (1), t) according to details provided by the structural engineer. Observe open grip length for max. top plate strength. DXF files may be downloaded at: www.h-bau.com. ISOPRO® type SBM 14 Q8 / SBM 14 Q10 Welded tight Element height [mm] 180 200 220 240 250 260 280 Hole distance x [mm] 113 133 153 173 183 193 213 Open grip length 30 mm. ISOPRO® type SBM 14 QQ Welded tight Element height [mm] 180 200 220 240 250 260 280 Hole distance x [mm] 113 133 153 173 183 193 213 Open grip length 30 mm. 16 www.h-bau.com ISOPRO type SBM ® for better solutions On-site face plate ISOPRO® type SBM 20 Q10 / SBM 20 Q12 Welded tight leat for taking on uplift loads Element height [mm] 180 200 220 240 250 260 280 Hole distance x [mm] 108 128 148 168 178 188 208 Open grip length 35 mm. 17 Insulation at the highest level ISOPRO type SBQ ® General information The product The ISOPRO® type SBQ thermal insulation panel connects supported steel constructions statically with reinforced concrete structural components. At the same time, its excellent thermal properties resolve the structural problems of thermal bridging at this junction. The element comprises an EPS insulating body with extremely low thermal conductivity and a statically effective stainless steel truss construction. Both positive lateral forces and horizontal forces can be transferred. 18 www.h-bau.com Features Building control approval No. Z-15.7-313 Dimensioning values embedded in the approval Reduction of thermal bridging as per DIN 4108-2 and EnEV Simple and secure assembly by means of continuously variable height adjustment The application As a solution to the interface between steel and reinforced concrete construction, ISOPRO® steel connectors fit perfectly into the ISOPRO® family. ISOPRO® type SBQ elements were developed specially for connecting supported steel constructions such as balconies and canopies. The elements are installed in the shell as part of reinforcement and concreting work. Assembly of the steel construction is carried out at a later date by the steel workers. ISOPRO type SBQ ® for better solutions Application examples ISOPRO® type SBQ connection situations For formwork erection brick work: For formwork erection brick work with external thermal insulation material: Special design for connection to a wall: Please contact our application technologies department for further special constructions. Tel.: +49 (0) 77 42 / 92 15-70 Fax: +49 (0) 77 42 / 92 15-96 Email: technik@h-bau.de Corner area for h ≥ 200 mm: Note: The following applies for connection in the corner area: Only for slab thickness h ≥ 200 mm. You must observe the 20 mm height difference on the on-site face plate. 19 Insulation at the highest level ISOPRO type SBQ ® Design & dimensions (10 mm steps) ISOPRO® type SBQ 8 Assembly plate Adjustment plate Pressure plate 40x40x15 (10 mm steps) ISOPRO® type SBQ 10 Assembly plate Adjustment plate Pressure plate 40x40x15 20 www.h-bau.com ISOPRO type SBQ ® for better solutions Design & dimensions (10 mm steps) ISOPRO® type SBQ 12 B Assembly plate Adjustment plate B(1:5) Pressure plate 40x40x15 Timber assembly plate Sample illustration 21 Insulation at the highest level ISOPRO type SBQ ® Dimensioning System length The system length is measured from the trailing edge of the top plate Cleat on-site Load case for down loads Dimensioning table for concrete ≥ C20/25 Material ISOPRO® type SBQ 8 Height h [mm] ISOPRO® type SBQ 10 ISOPRO® type SBQ 12 180 - 280 Vertical force VRd [kN] 30.4 51.8 62.5 Horizontal force HRd [kN] ± 2.5 ± 4.0 ± 5.5 Product definition ISOPRO®: e.g. SBQ 10 h200 Element height Load-bearing capacity Type designation Note: For maximum expansion joint distances and maximum installation tolerances, see P. 23. 22 www.h-bau.com ISOPRO type SBQ ® for better solutions Planning notes Expansion joint distances For determining the maximum permissible expansion joint distances, a balcony plate which is firmly connected with the steel girders is decisive. If the connection between steel girders and balcony plate is designed to be relocatable, the distances of the non-relocatable connections become decisive. Material ISOPRO® type SBQ 8 / SBQ 10 ISOPRO® type SBQ 12 Maximum expansion joint distances ≤ 6.0 m ≤ 4.0 m Element and edge distances Installation tolerances Initial position = Upper tolerance slotted hole Initial position = Centre slotted hole Initial position = Lower tolerance slotted hole Tolerance: +12 / -0 mm Tolerance: ±6 mm Tolerance: +0 / -12 mm Adjustability The adjustment plate ensures simple and continuously variable height adjustment; see P.13. Notes: The executables should indicate these accuracies in the detail and working drawings. The actual shell dimensions shall be tested by the responsible construction management and forwarded to the steel workers. The dimension tolerances shall be observed according to DIN 18201, 18202 and 18203. 23 Insulation at the highest level ISOPRO type SBQ ® On-site reinforcement & face plate On-site reinforcement ISOPRO® type SBQ Assembly plate The constructive stirrup 2 Ø 8 is available ex-works. On-site face plate ISOPRO® type SBQ Welded tight Notes: Support cleat for lateral force transfer is mandatory! Perform corrosion protection following welding. Material, dimensions (1), t) according to details provided by the structural engineer. Observe open grip length of 30 mm for max. top plate strength. DXF files may be downloaded at: www.h-bau.com. 24 www.h-bau.com Notes for better solutions 25 Insulation at the highest level Notes 26 www.h-bau.com Notes for better solutions 27 Insulation at the highest level Concreting with system... 120-mm thermal insulation panel 80-mm thermal insulation panel Sealing technology Shuttering tubes Rebending connections Sealing technology Shear dowels Masonry fixings Sound insulation elements Sealing technology Rustproof stainless steel Shuttering elements Shuttering elements Quick connectors Transport anchors Spacers H-BAU Technik GmbH Am Güterbahnhof 20 79771 Klettgau Telephone +49 (0) 77 42 | 92 15-20 Fax +49 (0) 77 42 | 92 15-90 info.klettgau@h-bau.de Production and Delivery North-East Brandenburger Allee 30 14641 Nauen OT Wachow Telephone +49 (0)3 32 39 | 7 75-20 Fax +49 (0)3 32 39 | 7 75-90 info.berlin@h-bau.de Production Chemnitz Beyerstrasse 21 09113 Chemnitz Telephone +49 (0) 37 1 | 400 41-0 Fax +49 (0) 37 1 | 400 41-99 www.h-bau.com 07/2014 ISOMAXX® ISOPRO® PENTAFLEX® RAPIDOBAT® FERBOX® KUNEX® HED GRIPRIP® SCHALL-ISO PLURAFLEX® RIPINOX® WARMBORD SCHALBORD UNICON® KE III ACCESSORIES