Mikron Writing Instruments English

advertisement

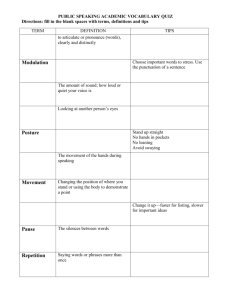

Writing Instruments Mikron leader in writing instruments machinery 2 Cost efficient tip manufacturing equipment from Mikron Tip manufacturing Mikron Machining Technology’s past is closely linked to the history of the ball point pen. Since the early stages of the ballpoint pen, Mikron has developed machinery to make writing tips and to assemble refills. As the cost of pens has been reduced over the years, Mikron has developed more and more productive machines. Ballpen tips, whether made from brass, nickel-silver or stainless steel are efficiently produced on the Mikron Multistar LX-24 and Multistar LX-12 Writing machines. Tips can be made automatically from coldformed blanks or directly from wire stock. Production output ranges from 80 to 300 finished tips per minute. Various tips produced on Mikron Multistar transfer systems Mikron Multistar machines work to the most demanding tolerances in the industry and are thus ideally suited to produce not only the ordinary ballpen tips but also close tolerance rollerball and jel ink tips. In fact, most of the leading ballpen brands use writing tips made on Mikron equipment. 11 10 9 Unloading 12 8 7 6 4 1 2 5 3 Stations 1 to 12 of a machining cycle on a Multistar LX-24 Loading & collet closing 3 Cold heading press Mikron RP-32: The metal is straightened, placed in the die and cut to the desired length Wire cutting machine Mikron TR-42 WRI The Mikron TR-42 is a machine for the economical and straight shearing of wire metal. Cold heading press Mikron RP-32 As a single stroke cold header the Mikron RP-32 is most suitable for small plain parts working directly from coil. 4 Tip manufacturing Mikron RP-32/3 (or TR-42) deburring Mikron Multistar centrifuge washing machine Multistar LX-24 Writing The Multistar LX-24 with 24 work stations and up to 44 working spindles is the guarantor for a smooth mass production. With the Multistar LX-24 machining is possible from below and above. Other additional features are the 24 intermediate stations, which allow measuring, controlling and cleaning procedures during the same run. That way you can quadruplicate your productivity It is unique! A run produces up to 600 simple workpieces per minute. Separating the fields of work doubles, triples or quadruplicates the amount of production at the same high processing speed. Factors of success at one glance • Fastest rotary transfer machine worldwide • High precision and repeatability • Simultaneous machining at two sides at each station • Multiple cycles for extremely high amounts • Parallel production of two parts • Load / unload time parallel to the machining process • Quick and simple tool changes 5 Refill manufacturing High precision refill tips machined on Mikron Multistar LX-24 and assembled with IMPI 34 Mikron IMPI-34 centrifuge Mikron ATW-10 balance hand pump hand centrifuge Multistar LX-12 Writing offers economic high volume machining at a low investment level. The Multistar product line, with over 600 machines sold world wide in the writing instruments field, has been completed with the model Multistar LX-12 Writing. This rotary transfer machine is particularly suitable for the high-speed machining of brass and NiSi tips in a single working cycle. Compared with today’s traditional production methods, the Multistar LX-12 Writing will considerably improve the writing quality of brass and BNP tips. The spindles, clamping collets and cutting tools are interchangeable with the same components used on the Multistar LX-24, thus stock keeping of spare parts is reduced and running the Multistar LX-12 Writing is economic and easy. IMPI-34 The Mikron IMPI-34 refill assembly machine has proven to be a highly reliable, easy to operate and extremly productive refill assembly machine. This machine is especially suited for economical capillary refills. It assembles the writing tip to the point, does crimping and plug assembly. Blind hot stamping is also possible. 6 Quality Control and Support Equipment Mikron supplies equipment which meets the specific requirements of the writing instrument manufacturer and is renown for planning and implementing costefficient manufacturing facilities for tips and refills. The automatic production machines made by Mikron cover the complete range of tip and refill manufacturing. • • • • Coldforming machines TR-42 and RP-32 Rotary transfer machine Multistar LX-24 Ink joiners and assembly machines IMPI-34 Write test machine ATW-10 To guarantee a continuous, premium quality and outstanding productivity, the very best quality control and support equipment is a must. Writing test machine ATW-10 The machine tests simultaneously 10 refills in different writing angles between 90° and 60° under a load of 80 - 120 gr (0.176 - 0.265 lbs). It assists in investigating flow character, affinity, lay-down and wear rate at different writing speeds. Starting abilities, sphericalness of balls, and other details may be checked. The registering mechanism allows the reading of the writing distance in meters. Adjustable paper feed and writing speed allow most efficient testing. Test of writing quality on a Mikron ATW-10 7 Cutting tools and aggregates suggested by Mikron Precision tools One of the key elements when producing steel or brass tips on Mikron’s Multistar machine, are cutting tools. Mikron has recognized the importance of high performing tools many years ago and has thus established it’s own in-house tool manufacturing facility. We are able to provide standard and special cutting tools from small special production to large volume series all within the most demanding quality standards. Consult us for your tooling needs; our specialists are ready to help you. AE-100 Analytical Balance Electronic Analytical Balance used to control ink consumption. Special features: • Weighing range 0-109 g (0-0.24 lbs.) • Readout 0.1 mg (2 x 10 -7 lbs.) M-112 Measuring Microscope Instrument for dimensional inspection of the tip. Offers an optimum of brightness and clarity of the image. Special features: • Magnification 50 x • Vertical illuminator • Stage with X-Y movements and reading on vernier 0.001 mm (.0001”) • Rotating goniometric head, 360° vernier with 10° reading Hand Pump / Hand Centrifuge Auxiliary equipment to fill and centrifuge refills by hand for samples and laboratory tests. SM-5 Stereo Microscope High resolution stereo microscope for quality inspection. A sharp three-dimensional image is produced and even for prolonged periods, accurate and efficient work without eye strain is guaranteed. MM-10 Drill Grinder Special features: • Magnification 30 x • Eye pieces inclined 45° • Vertical illumination 6V - 15W Special features: • Point angle adjustable 90 - 180° • Cutting and clearance angle 0 - 45° • Grinding range 0.2 - 6.4 mm (0.008 - 0.25”) • Max. drill length 160 mm (6.3”) Precision, small drill grinding machine used for regrinding and point-thinning of right and left hand drills. Incorporated microscope with magnification 15 x allows rapid monitoring of grinding operation. Mikron Machining Your contacts 0811 Headquarter Mikron SA Agno Via Ginnasio 17 CH-6982 Agno Tel. +41 91 610 61 11 Fax +41 91 610 66 80 mag@mikron.com Mikron SAS Nerviano Via S. Ambrogio 16 I-20015 Parabiago (MI) Tel. +39 0331 55 12 22 Fax +39 0331 55 12 86 mnv@mikron.com Mikron Tool SA Agno Via Campagna 1 CH-6984 Bioggio Tel. +41 91 610 40 00 Fax +41 91 610 40 10 mto@mikron.com Mikron Corp. Monroe 200 Main Street P.O. Box 268 Monroe, CT 06468 / USA Tel. +1 203 261 31 00 Fax +1 203 268 47 52 mmo@mikron.com Mikron GmbH Rottweil Berner Feld 71 D-78628 Rottweil Tel. +49 741 5380 0 Fax +49 741 5380 580 mro@mikron.com Mikron Taiwan Office P.O. Box 91-251 Taipei, Taiwan R.O.C. Tel. +886 2 2231 07 07 Fax +886 2 2231 01 07 mtw@mikron.com www.mikron.com Mikron® is a trademark of Mikron Holding AG, Biel (Switzerland)