Modified Critical Fractile Approach for a Class of Partial

advertisement

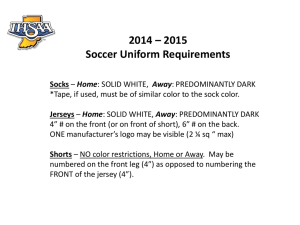

Critical Fractile Approach for a Class of Partial Postponement problems Qi Fu ∗ Chung-Yee Lee † Chung-Piaw Teo ‡ August 26, 2008 Abstract We consider a group of regular products each facing random demand. There are two stocking options. The first option is to procure the regular products. The second option is to stock a common component which can be customized later to any one of the regular products, after demand realization. This captures the trade-offs in several apparel supply chain, where the common component represents the basic design (e.g. blank shirts) which can be customized later to other designs (printed shirts). This model is also similar to a single period one-warehouse multi-retailer model, where the stock at the warehouse (i.e., the common component) can be sent to the retailers (at an added cost) as and when necessary. Our goal is to obtain insightful rules of thumb that practitioners can incorporate into their inventory models to determine the stocking levels to minimize the supply chain cost. Instead of proposing a numerical procedure to obtain the optimal solution, we propose an adaptation of the classical critical fractile approach for this class of partial postponement problem. The closed-form formula obtained are surprisingly effective. Our preliminary numerical results suggest that this simple approach to inventory planning often comes close to the performance of the optimal solution obtained from numerical method. Subject Classifications: Newsvendor Problem; Critical Fractile; Partial Postponement; Delayed Customization ∗ Department of Industrial Engineering and Logistics Management, HKUST. Email: fuqi@ust.hk Department of Industrial Engineering and Logistics Management, HKUST. Email: cylee@ust.hk ‡ Department of Decision Sciences, NUS Business School. Email: bizteocp@nus.edu.sg † 1 1 Introduction Postponement is a product design, manufacturing, and delivery strategy that retains the product in a neutral and non-committed status, and delays the point of consumer specification as much as possible along the supply chain. There are many advantages of such strategy: companies can (i) reduce the amount of inventory investment due to the risk pooling effect of holding customizable components, and (ii) respond quickly to demand shifts among the family of products, leading to less stock out situations. Moreover, (iii) the salvage value of non-customized component can be higher than the customized products. Postponement is best suited for situations when the products share a common platform, and the demands are highly affected by consumers’ perception and thus have large forecast variability. Many companies in a wide variety of industries have adopted and successfully implemented various postponement strategies in their manufacturing, assembly, packaging and delivery processes. Practical application of the concept can be traced back to the 1920’s. The first detailed empirical descriptions appeared in the 1960’s [4]. The strategy is now used by companies such as Burger King, General Motors, Honda, Embraer, Dade Behring, Reebok, McGraw-Hill, Imation, etc. Readers may refer to Rietze [6] for a thorough review of postponement case studies. In the academic literature, the concept was originally proposed by Alderson [1] and later expanded by Bucklin [3]. Afterwards, there has been a stream of literature addressing various type of postponement problems. Readers may refer to Aviv and Federgruen [2] and Swaminathan and Lee [8] for an overview of concepts and models of postponement. A partial postponement problem arises in the situation that a family of similar products share a common platform and differ only in some minor features (for example, color of apparels, taste of foods, flavor of drinks, etc). Parsons [5] provides a thorough description of the partial postponement strategy used in Reebok’s NFL replica jersey supply chain: Blank jerseys were stored and later printed with appropriate design depending on the popularity of the players in the season. Siver and Minner [7] studied a similar inventory replenishment problem for a pizza store: demand for a particular type of pizza is first met with the finished pizzas (end products), and then upon stock out of the finished pizzas, met by appropriately adding toppings to the common unfinished shells (customizable product). Note that under a partial postponement strategy, part of the stock is customized only after the realization of demands for the various 2 end products. This problem can be viewed as an inventory substitution problem. Bassok et al. [10] presented structural results for such problem when the products can be ordered and higher ranked products can be used as substitute for lower ranked products. Tibben-Lemke and Bassok [9] used these results to develop several new insights to the class of problems we studied in this paper - when one generic component can be customized to susbtitute for any one of the n regular products. They derived necessary and sufficient conditions for (i) not keeping inventory of the generic component, and (ii) keeping only the generic component. Furthermore, based on the optimality conditions, they developed an efficient routine to obtain the optimal procurement quantities for the generic component and the n regular products. Unfortunately, these papers assume that demand distribution is well specified in advance and focused mainly on developing numerical methods (cf. Siver and Minner [7], Tibben-Lemke and Bassok [9]) to obtain the theoretical optimal solution. This does not fit the approaches used by many practitioners, who often have to determine the replenishment decision using only simple rules of thumb. For instance, Parsons [5] indicated the retailers in the Reebok’s Supply Chain were replenishing their inventory based on simple rules such as “order up to 30% of the demand in a season” for printed jerseys, relying on the blank jerseys to meet additional demands. Given the ambiguity and difficulty in obtaining reliable demand forecasts, it is easy to understand why these rules of thumb seem to be the preferred approach used by the retailers in their inventory replenishment decisions. In this paper, we investigate this type of partial postponement problem for the case when the cost structure of the n regular products are identical, although the demand distribution could differ. This situation holds, for instance, in the Reebok supply chain, where the n regular products refer to the jerseys of n different players. It also includes as special case the inventory replenishment problem in a one-warehouse-multi-retailer system, where we need to determine jointly the inventory levels at the warehouse and at the retailers, assuming that the inventory at the warehouse can be used to replenish the demand of the retailers at an added cost (but identical for all retailers). In this case, the inventory at the warehouse plays the role of the blank jersey in the Reebok’s supply chain. We show that the optimality conditions for the partial postponement problem simplify dramatically in the case when all products are identical, into something that resemble the critical fractile formula for the simple newsvendor model. We exploit the new optimality conditions to 3 develop practical rules of thumb for retailers to obtain near optimal procurement quantities. The rest of this paper is organized as follows. In section 2, we provide a detailed description of the problem studied in this paper. Section 3 discusses the solution approach and the main results obtained. Section 4 presents the numerical results, using the Reebok NFL replica jersey case as the background for the experiments. 2 Model Specification Consider the following partial postponement problem: a family of regular products can be acquired either in the form of finished goods from the manufacturer, or in the form of a common component, which can be customized later to one of the regular products. This is a problem encountered, for instance, in the Reebok’s supply chain as shown in Figure 1: The contract manufacturers cut, sew and assemble the jerseys. Some jerseys are printed with player name and number (dressed jerseys), while other jerseys are left blank, according to the orders from Reebok. Then both the blank jerseys (common component) and the dressed jerseys (regular products) are shipped to the distribution center (DC) of Reebok located in Indianapolis. The distribution center owns on-site screen printing facility, which can burn blank jerseys to meet customer orders on time after demand is observed. Our objective is to maximized the expected system profit which consists of 3 components, the expected revenue from selling the products, the cost of procurement and production, and the salvage value of leftover inventory. The sequence of events can be described as follows. The company faces random demands Di , i = 1, · · · , m for the m regular products. The company needs to determine the procurement quantities Qi , i = 1, · · · , m for the regular products at a unit cost of c01 , and the procurement quantity Qo for the common component at a unit cost of c02 . The selling price of each unit of the regular products is p. If the stock of one or more regular products is depleted, additional demands are satisfied by customizing the common component based on a first-come-first-serve rule. The unit customization cost is r2 (c02 < c01 < c02 + r2 ). At the end of the season, leftover inventory of regular products can be salvaged at a discount price of s1 , and common component can be salvaged at a discount price of s2 (s2 ≥ s1 ). We formulate the partial postponement problem as follows. max Qi ,i=1,··· ,m,Qo Π(Q1 , . . . , Qm , Qo ), 4 blank jerseys raw m aterials contract m anufacturers 2 -16 w eeks screen printing blank jerseys R eebok D C retailers dressed jerseys dressed jerseys 8 w eeks 1 w eeks Figure 1: Reebok supply chain where Π(Q1 , . . . , Qm , Qo ) := ( m m i h i h X X + − c02 Qo p E min(Qi , Di ) + (p − r2 )E min Qo , (Di − Qi ) i=1 − c01 i=1 m X i=1 m m i i+ h h X X Qi + s 1 E (Qi − Di )+ + s2 E Qo − (Di − Qi )+ i=1 ) i=1 This is clearly a convex optimization problem (cf. [9]). Our focus in this paper is to derive insights on the optimal ordering quantities. Note that without the common component (i.e. Qo = 0), the above reduces to the classical newsvendor problem, with Qi chosen so that c 0 − s1 P Di > Qi = 1 . p − s1 5 On the other hand, for any procurement decision Q̄ = (Q1 , · · · , Qm , Qo ), it is easy to show that m m m i h i h X X X + 0 Π(Q̄) = p − c1 E min(Qi , Di ) + (p − r2 )E min Qo , (Di − Qi ) Qi − c02 Qo i=1 i=1 i=1 m m i i+ h h X X +s1 E (Qi − Di )+ + s2 E Qo − (Di − Qi )+ i=1 = p m X E(Di ) − p i=1 −s1 i=1 m X m hX (Di − Qi )+ − Qo i=1 i+ − (c01 − s1 ) m X Qi − (c02 − s2 )Qo i=1 m i h X + . E min(Qi , Di ) − (r2 + s2 )E min Qo , (Di − Qi ) h i i=1 In the above expression p i=1 Pm i=1 E(Di ) C(Q̄) := (c01 − s1 ) m X is a constant independent of the ordering decisions. Let m hX Qi + (c02 − s2 )Qo + p i=1 +s1 m X h (Di − Qi )+ − Qo i+ i=1 i h E min(Qi , Di ) + (r2 + s2 )E min Qo , i=1 m X (Di − Qi ) + i . i=1 The expression C(Q̄) can be interpreted as the procurement cost of m + 1 option contracts: reservation cost of c1 := c01 − s1 , and execution cost of h1 := s1 for product i = 1, . . . , m; reservation cost of c2 := c02 − s2 and execution cost of h2 := r2 + s2 for the common component; any leftover demand is met by a spot market with cost p. The decisions Qi ’s and Qo are now merely the number of option contracts to purchase. The first two terms in the expression refers to the option reservation costs, and the other terms refer to the execution cost, based on demand realization. Thus the two problems can be linked by the following equation: max Π(Q̄) = p m X E(Di ) − min C(Q̄). i=1 That is, maximizing the expected profit of a partial postponement problem is equivalent to minimizing the expected cost of a option procurement problem under the above transformation. In the following we will provide solution approaches based on the equivalent option procurement problem instead of the original partial postponement problem. 3 Solution approach We first consider the case when the demands for the m types of products are independent of each other, as the exposition is simpler. The same argument can be extended to the general case. In the following theorem, we present the optimality conditions. 6 Theorem 1 For a partial postponement problem with multiple independent demand sources stated above, the optimality condition on the optimal procurement quantity of the customized products Qi , i = 1, · · · , m, is: P (Di > Qi ) = P c1 − c2 + (p − h2 )P ( Pk6=i h2 − h1 + (p − h2 )P ( (Dk − Qk )+ > Qo ) k6=i (Dk − Q k )+ > Q o ) , (1) and the optimality condition on the optimal procurement quantity for the common component Qo is: P m X (Di − Qi )+ > Qo = i=1 c2 . p − h2 (2) Proof : If the optimal solution Qo does not satisfy the optimality condition (1), say “<” instead of “=” holds, then we can perturb the optimal solution, changing Qo by ( > 0). The objective value will change by the following amount: • Reservation cost will change by c2 . • In the event Pm i=1 (Di − Qi )+ < Qo , the change does not affect the execution cost and hence has no impact on the total cost. • When Pm i=1 (Di − Qi ) + > Qo , since we have more units of the common component. The execution cost will change by (h2 − p). Then change of expected total cost can be expressed as m X + c2 − (p − h2 )P < 0. (Di − Qi ) > Qo i=1 Thus, the objective value can be reduced, contracting the optimality of the solution. On the other hand, if “>” instead of “=” holds, perturbing Qo by −, we arrive at the same contradiction. If the optimal solution Qi does not satisfy the optimality condition (2), for example “<” instead of “=” holds, then we can perturb the optimal solution, changing Qi by ( > 0). The objective value will change by the following amount: • Reservation cost will change by c1 . 7 • In the event Di ≤ Qi , no impact on the execution cost. • When Di > Qi , savings on execution cost can be realized since we have more units of product i. The cost will change by (h1 − h2 ) if m X (Dk − Qk )+ < Qo , and m X (h1 − p) if k=1 (Dk − Qk )+ > Qo . k=1 The change of expected total cost can be expressed as note p − h1 = (p − h2 ) + (h2 − h1 ) : m m X X + + c1 − (h2 − h1 )P Di > Qi , (Dk − Qk ) < Qo − (p − h1 )P Di > Qi , (Dk − Qk ) > Qo k=1 k=1 m X + = c1 − (h2 − h1 )P (Di > Qi ) − (p − h2 )P Di > Qi , (Dk − Qk ) > Qo k=1 Since P Di < Qi , m X + (Dk − Qk ) > Qo = P k=1 m X k=1 = P X + (Dk − Qk ) > Qo |Di < Qi P (Di < Qi ) (Dk − Qk )+ > Qo P (Di < Qi ), (3) k6=i where the second equality comes from the independency of the demands, we have m X P Di > Qi , (Dk − Qk )+ > Qo k=1 =P m X X (Dk − Qk )+ > Qo − P (Dk − Qk )+ > Qo P (Di < Qi ). k=1 k6=i Substituting the above equation into the change of expected total cost, the change of the expected cost can be expressed as m X c1 − (h2 − h1 )P (Di > Qi ) − (p − h2 )P (Dk − Qk )+ > Qo + (p − h2 )P X k=1 (Dk − Qk )+ > Qo P (Di < Qi ) k6=i 8 By equation (2) the above expression can be rewritten as c1 − (h2 − h1 )P (Di > Qi ) − c2 + (p − h2 )P X + (Dk − Qk ) > Qo P (Di < Qi ) k6=i = c1 − c2 + (p − h2 )P − X (Dk − Qk )+ > Qo k6=i (h2 − h1 ) + (p − h2 )P X + (Dk − Qk ) > Qo P (Di > Qi ) <0 k6=i Thus, the objective value can be reduced, contracting the optimality of the solution. The case of “>” can be analyzed by perturbing Qi by − similarly. As an immediate corollary, since P m X X (Di − Qi )+ > Qo ≥ P (Di − Qi )+ > Qo for all j = 1, . . . , n, i=1 i6=j we have P (Di > Qi ) = ≤ = c1 − c2 + (p − h2 )P [ P Pk6=i (Dk − Qk )+ > Qo ] h2 − h1 + (p − h2 )P [ k6=i (Dk − Qk )+ > Qo ] P c1 − c2 + (p − h2 )P [ m (Dk − Qk )+ > Qo ] Pk=1 + h2 − h1 + (p − h2 )P [ m k=1 (Dk − Qk ) > Qo ] c2 c1 − c2 + (p − h2 ) p−h c1 2 . c2 = h2 − h1 + (p − h2 ) p−h2 c2 + h 2 − h 1 Similarly, X X c2 =P (Di − Qi )+ > Qo ≤ P (Dk − Qk )+ > Qo P (Di < Qi ) + P (Di > Qi ). p − h2 m i=1 k6=i Using the optimality condition, we can rewrite P X (h − h )P (D > Q ) − (c − c ) 2 1 i i 1 2 (Dk − Qk )+ > Qo = . (p − h2 )P (Di < Qi ) k6=i We can re-arrange terms to have c2 (h2 − h1 )P (Di > Qi ) − (c1 − c2 ) ≤ + P (Di > Qi ). p − h2 p − h2 i.e., P (Di > Qi ) ≥ 9 c1 . p − h1 It also follows directly from the optimality condition that P (Di > Qi ) ≥ c 1 − c2 . h2 − h 1 Thus we have the following corollary: Corollary 1 c1 c2 +h2 −h1 ≥ P (Di > Qi ) ≥ max c1 −c2 c1 h2 −h1 , p−h1 for each i = 1, . . . , m. In a nutshell, the rule of thumb for the replenishment quantity of jersey i is thus given by Rule of Thumb 1: Order enough printed jerseys so that the chances of stock out c1 2 is between max( hc12 −c −h1 , p−h1 ) × 100% and c1 c2 +h2 −h1 × 100%. In the Reebok’s case, the two ratios are close to each other if (i) c2 + h2 ≈ p. i.e., the sum of procurement and customization cost c02 + r2 of the blank jersey is close to the selling price p, or (ii) c2 = c02 − s2 ≈ 0, i.e., the salvage value of the blank jersey is close to the procurement cost. In the case when m = 1, our result simplifies to the following: Corollary 2 For a partial postponement problem with a single type of product, the optimal procurement quantity for the customized product Q1 satisfies the following condition P (D1 > Q1 ) = c 1 − c2 h2 − h 1 (4) and the optimal procurement quantity for the standard component can be determined by the following optimality condition P (D1 > Q1 + Qo ) = c2 . p − h2 (5) In the rest of this section, we assume that the demand of the products are independent normally distributed with mean µi and standard deviation σi . In the classical newsvendor model, the critical fractile depends only on the cost parameters, and all products with the same cost parameters will have the same stock out probability in the optimal solution. In the 10 partial postponement case, with the incorporation of the postponement option (blank jerseys), interestingly this may not be the case. We discuss next how the incorporation of σi changes the stocking decisions. Theorem 2 Let Q∗i denote the optimal ordering quantity for product i. If σi ≥ σj , then P (Di > Q∗i ) ≤ P (Dj > Q∗j ). In particular, if the demands have identical standard deviation, then all optimal stock out probabilities are identical. Proof : Suppose P (Di > Q∗i ) > P (Dj > Q∗j ). Since demands are normally distributed, Q∗j − µj Q∗i − µi ≤ . σi σj Note that P (Di > Q∗i ) = P c1 − c2 + (p − h2 )P [ Pk6=i,j h2 − h1 + (p − h2 )P [ (Dk − Q∗k )+ + (Dj − Q∗j )+ > Q∗o ] k6=i,j (Dk − Q∗k )+ + (Dj − Q∗j )+ > Q∗o ] , (6) . (7) and P (Dj > Q∗j ) = P c1 − c2 + (p − h2 )P [ k6=i,j (Dk − Q∗k )+ + (Di − Qi )+ > Q∗o ] k6=i,j (Dk − Q∗k )+ + (Di − Q∗i )+ > Q∗o ] P h2 − h1 + (p − h2 )P [ Hence P[ X (Dk − Q∗k )+ + (Dj − Q∗j )+ > Q∗o ] > P [ k6=i,j X (Dk − Q∗k )+ + (Di − Qi )+ > Q∗o ]. k6=i,j Note that for all x ≥ 0, P (Di > Q∗i + x) = = ≥ ≥ = D i − µi Q∗i + x − µi P > σi σi ∗ Dj − µj Qi + x − µ i P > σj σi ∗ Qj − µj Dj − µj x P > + σj σj σi ∗ Qj − µj Dj − µj x P > + σj σj σj ∗ P (Dj > Qj + x). 11 (8) Thus whenever P[ X P k6=i,j (Dk − Q∗k )+ ≤ Q∗o , X (Dk − Q∗k )+ + (Dj − Q∗j )+ > Q∗o ] = P [(Dj − Q∗j )+ > Q∗o − k6=i,j (Dk − Q∗k )+ ] k6=i,j = P [Dj − Q∗j ≤ P [Di − Q∗i > Q∗o > Q∗o − X (Dk − Q∗k )+ ] k6=i,j = P[ X − X (Dk − Q∗k )+ ] k6=i,j (Dk − Q∗k )+ + (Di − Q∗i )+ > Q∗o ]. k6=i,j On the other hand, when P[ X P k6=i,j (Dk − Q∗k )+ ≥ Q∗o , (Dk − Q∗k )+ + (Dj − Q∗j )+ > Q∗o ] = P [ k6=i,j X (Dk − Q∗k )+ + (Di − Q∗i )+ > Q∗o ]. k6=i,j This is a contradiction to (8). This can be translated to the following rule of thumb: Rule of Thumb 2: If printed jersey i has higher variability than printed jersey j, then in the optimal ordering solution, jersey i has lower stock out1 probability than jersey j. The optimality conditions can be rewritten as nP( o + i (Dk −Qk ) >Qo ) c1 − c2 + c2 P ( k6=(D + k −Qk ) >Qo ) n P ( k (D −Q )+ >Q ) o . P (Di > Qi ) = o k k i h2 − h1 + c2 P ( k6=(D + k −Qk ) >Qo ) P P P P (9) k To evaluate the optimal ordering quantity, we need to understand the behavior of the ratio P X m X (Dk − Qk )+ > Qo /P (Dk − Qk )+ > Qo . k6=i k=1 It is difficult to find a closed form formula to the above expression. By Markov’s inequality, P X m X X X (Dk −Qk )+ > Qo ≤ E (Dk −Qk )+ /Qo , E (Dk −Qk )+ ≤ E (Dk −Qk )+ /Qo . k6=i 1 k6=i k=1 k We say that jersey i has a stock out if Di > Q∗i , i.e., without consider the possibility of converting blank jerseys into printed one. 12 We compare the two expressions on the right hand side instead to obtain P X m X (Dk − Qk )+ > Qo /P (Dk − Qk )+ > Qo k6=i k=1 X X ≈ E (Dk − Qk )+ /E (Dk − Qk )+ = X k6=i k X σk L (Qk − µk )/σk / σk L (Qk − µk )/σk k6=i k where Z L zk = ∞ (x − zk )f (x)dx zk is the unit loss function for standard normal r.v., and f (·) is the pdf of the standard normal distribution. We use this to propose a simple rule-based heuristic for the partial postponement problem: 1. Initially, for each product i, order Qi such that P σ c 1 − c2 + c2 P σ P σ P (Di > Qi ) = h2 − h 1 + c 2 P σ k k6=i k k k6=i . (10) k k k 2. Let zi = (Qi − µi )/σi . Calculate L(zi ), where L(·) corresponds to the unit loss function of the standard normal r.v. Refine the ordering quantity to satisfy: P σ L(z ) c1 − c2 + c2 P σ L(z ) P σ L(z ) . P (Di > Qi ) = h2 − h1 + c2 P σ L(z ) k k6=i k k k k6=i k k k k (11) k k 3. Order Qo such that P m X (Di − Qi )+ > Qo = i=1 4 c2 . p − h2 (12) Numerical Results In this section, we use the Reebok’s case and data described in Parsons [5] to conduct our numerical experiments. Based on forecast, the jerseys of six key players, listed in Table 1, are the most popular in terms of jersey sales. The demands for the key players are satisfied first by the stock of dressed jerseys and then by decorating the blank jerseys. The demands for other players are met solely by decorating blank jerseys. 13 Desc Mean Stdev NEW ENG PATRIOT Total 87680 19211 BRADY,TOM #12 30763 13843 LAW,TY #24 10569 4756 BROWN,TROY #80 8159 3671 VINATIERI,ADAM #54 7270 4362 BRUSCHI,TEDY #04 5526 3316 SMITH,ANTOWAIN #32 2118 1271 23275 10474 Other Players Table 1: Demand forecasting of New England Patriots 2003 Parsons [5] studied the above problem using the newsvendor model in his thesis. Two approaches are discussed and compared, assuming the demands are normally distributed. Approach 1 uses the newsvendor solution for each demand class independently, where dressed jerseys are for the key players and blank jerseys are for the rest of the players. Approach 2 uses a complicated modified newsvendor solution to determine the amount of dressed jerseys for each key player, by incorporating the information on the availability of blank jerseys. The data used in his experiments is as shown in Table 2. Wholesale Price, (p) = $24.00 Cost of a Dressed Jersey (c01 ) = $10.90 Cost of a Blank Jersey (c02 ) = $9.50 Cost of Decorating a Blank Jersey to a Dressed Jersey (r2 ) = $2.40 Salvage Value of a Dressed Jersey (s1 ) = $7.00 Salvage Value of a Blank Jersey (s2 ) = $8.46 Table 2: Parameters used for the computational experiments Using Corollary 1 and the above parameters, the stock out probabilities (i.e., P (Di > Qi )) for regular products are confined in the tight range [0.741, 0.796] in the optimal solution. The critical ratios (i.e., 1-P (Di > Qi )) are thus in the range [0.204, 0.259]. Note that the demands of jerseys for other players are met solely by the stock of blank jerseys. Let Dr denote this portion 14 of demand. The portion of demand to be satisfied by blank jerseys is P k6=i (Dk − Q k )+ + D r . We could view Dr as demand for a product with Qr fixed at 0. Thus we should modify the optimality equations in Theorem 1 as follows. The optimal procurement quantity for dressed jerseys Qi , i = 1, · · · , 6 satisfies the following condition P c1 − c2 + (p − h2 )P [ k6=i (Dk − Qk )+ + Dr > Qo ] P P (Di > Qi ) = , h2 − h1 + (p − h2 )P [ k6=i (Dk − Qk )+ + Dr > Qo ] (13) and the optimal procurement quantity for blank jerseys Qo satisfies the following condition P 6 X (Di − Qi )+ + Dr > Qo = i=1 c2 p − h2 (14) To search for the optimal solution, we need to know the distribution of the following two terms: X (Dk − Qk )+ + Dr and 6 X (Di − Qi )+ + Dr . i=1 k6=i Parsons approximates these distributions by first finding the mean of each random term, then multiplying it by the original coefficient of variance to obtain its variance. We use however the heuristic (ignoring the impact of Dr ) to find the order quantities for the printed jerseys, and then use monte-carlo simulation (with Qi fixed by the heuristic, while incorporating the demand due to Dr ) to find the appropriate level of the blank jerseys (Qo ) needed to maintain the service level stipulated in the optimality condition. We compare the performance of the 4 solution approaches, i.e., Parsons’s approaches (denoted by P-1 and P-2), our approach (the ratios from both step 1 and step 2), and the optimal solution. The results are presented in Table 3. For our approach, we tabulate the order quantities, the stock-out probabilities in step 2 of our heuristic, followed by the stock-out probabilities obtained in step 1. From the table, we can see that the performances of the several approaches are rather close. This is due to the choice of cost and profit structure in the problem setting: the cost of obtaining a dressed jersey by decorating a blank one is only slightly higher than the cost of procuring a dressed jersey. Moreover, the unit shortage cost (net margin) is at least $12.10 = $24 − $9.5 − $2.4 and the unit overage cost is at most $3.9 = $10.9 − $7.0, so the risk of Reebok NFL replica jerseys is quite low and therefore the differences among the several approaches are not significant. Furthermore, the stock out probabilities obtained from step 1 15 is already extremely close to the ratios from step 2. Desc Solution P-1 P-2 Our Paper Optimal sol. (Stock-Out Prob.) BRADY,TOM #12 Q1 41018 24852 20375 (0.7735, 0.7747) 21696 (0.7440) LAW,TY #24 Q2 14092 8538 6744 (0.7893, 0.7890) 6871 (0.7755) BROWN,TROY #80 Q3 10879 6591 5187 (0.7909, 0.7907) 5401 (0.7806) VINATIERI,ADAM #54 Q4 10501 5407 3753 (0.7899, 0.7896) 3972 (0.7778) BRUSCHI,TEDY #04 Q5 7983 4110 2853 (0.7914, 0.7912) 3055 (0.7823) SMITH,ANTOWAIN #32 Q6 3059 1575 1074 (0.7942, 0.7941) 1106 (0.7905) Table 3: Comparison of solutions We also conduct another numerical study by altering the system parameters. Specifically, we decrease the selling price and set the salvage values to zero to increase the risk level. The results are shown in Table 4. Note that Corollary 1 pins the critical ratios to the range [0.044, 0.208], i.e., stock out probabilities in the range [0.792, 0.956]. We observe that for this case with a higher business risk, the ratio of the quantity of blank jerseys to the total quantity of dressed jersey in the optimal solution increase significantly. Note that in this more risky environment, the system can result in negative profit under some demand scenarios, yet the probability of such an outcome is also reduced under the optimal solution. Desc BRADY,TOM #12 Solution P-1 P-2 Our Approach Optimal sol. (Stock out Prob.) Q1 17084 16156 10959 (0.9237, 0.9325) 10022 (0.9304) LAW,TY #24 Q2 5869 5550 2693 (0.9511, 0.9501) 2649 (0.9505) BROWN,TROY #80 Q3 4531 4285 2029 (0.9525, 0.9516) 2062 (0.9521) VINATIERI,ADAM #54 Q4 2960 2667 24 (0.9516, 0.9507) 64 (0.9511) BRUSCHI,TEDY #04 Q5 2249 2027 0* 6 (0.9525) SMITH,ANTOWAIN #32 Q6 862 777 0* 0 (0.9549) Table 4: Comparison of solutions: p = 13, c01 = 10.9, c02 = 9.0, r2 = 2.4, s1 = s2 = 0. (*) denote negative value in our order quantity. We conduct a more comprehensive comparison of the performance of 5 different approaches, i.e.,the previous four approaches, and an approach storing only blank jerseys (denoted by BL). 16 The latter reduces to a simple newsvendor problem. In reporting our results, we use only step 1 of our heuristic to obtain the critical ratios. This in part is due to the observation that the modification from step 2 does not have much effect on the critical ratios in our method, for this set of parameters in our problem. Figure 1(a) to 4(b) show the result of a sensitivity analysis study based on the benchmark problem. interestingly, the proposed heuristic performs quite well in all instances: its performance in terms of expected system profit is extremely close to the optimum. Specifically, Figure 1 (a) shows that as the cost of a dress jersey c01 increase, the expected system profit exhibits a downward trend except under the pure blank jersey policy, which is not affected by c01 . Moreover, with c01 increasing, the performance of BL improves and can even be near optimal, because unit cost of blank jerseys plus unit decorating cost is only slightly higher than the cost of dressed jerseys. Figure 2 (a) to 4 (a) show that the expected system profits are decreasing in c02 and r2 while increasing in s2 , which are intuitive. The numerical results show that the heuristic always outperform P-1, P-2 and BL, and none of these three approaches always works well. Figure 1 (b) to 4 (b) depict the critical ratios for dressed jersey under the 4 approaches, P-1, P-2, the optimal solution and the heuristic, except BL (the ratio is zero and is therefore not depicted). P-1 and P-2 use the same critical ratio for all dressed jerseys, whereas for the optimal solution and the proposed heuristic, each type of dressed jerseys has a distinct critical ratio, so here we only plot the maximum and minimum values. From these graphs, we can observe that P-1 and P-2 tend to overestimate the critical ratio for dressed jerseys. For our heuristic, the critical ratios are rather close to the optimal ones, especially for those ratios with relatively smaller values. The numerical study validates the effectiveness of our simple heuristic. Its performance is almost as good as the optimal solution. In addition, we observe that most of the critical ratios for dressed jerseys are close to the lower bound, except for the maximum critical ratios, which is more sensitive to the change of system parameters. The reason can be found from the demand distribution information (cf. Table 1) that the largest standard deviation dominates the others. This observation is also consistent with our approach. 17 5 x 10 0.4 P−1 P−2 BL Opt. Sol. Heuristic 1.6 Average Profit 1.4 1.2 1 0.8 0.6 0.4 P−1 P−2 Optimal (Max) Optimal (Min) Heuristic (Max) Heuristic (Min) 0.35 Critical Ratio of Dressed Jerseys 1.8 0.3 0.25 0.2 0.15 0.1 0.05 9 9.5 10 10.5 11 0 11.5 9 9.5 10 c’1 10.5 11 11.5 c’1 1(a) Performance of the solutions 1(b) Critical Ratio of dressed jerseys 4 x 10 0.25 P−1 P−2 BL Opt. Sol. Heuristic 10 Critical Ratio of Dressed Jerseys 12 Average Profit 8 6 4 0.15 0.1 P−1 P−2 Optimal (Max) Optimal (Min) Heuristic (Max) Heuristic (Max) 0.05 2 0 0.2 8.8 9 9.2 9.4 9.6 c’ 9.8 10 10.2 0 10.4 8.8 9 9.2 9.4 2 9.6 c’ 9.8 10 10.2 10.4 2 2(a) Performance of the solutions 2(b) Critical Ratio of dressed jerseys 4 x 10 P−1 P−2 BL Opt. Sol. Heuristic 12 0.2 0.18 Critical Ratio of Dressed Jerseys 14 Average Profit 10 8 6 4 0.16 0.14 0.12 0.1 0.08 P−1 P−2 Optimal (Max) Optimal (Min) Heuristic (Max) Heuristic (Min) 0.06 0.04 2 0.02 0 2 2.2 2.4 2.6 2.8 r2 3 3.2 3.4 0 3.6 3(a) Performance of the solutions 2 2.2 2.4 2.6 2.8 r2 3 3.2 3.4 3.6 3(b) Critical Ratio of dressed jerseys 18 5 x 10 1.3 1.2 Average Profit 0.2 P−1 P−2 BL Opt. Sol. Heuristic 0.18 Critical Ratio of Dressed Jerseys 1.4 1.1 1 0.9 0.8 0.7 0.6 0.16 P−1 P−2 Optimal (Max) Optimal (Min) Heuristic (Max) Heuristic (Min) 0.14 0.12 0.1 0.08 0.06 2 3 4 5 6 s 7 8 0.04 9 2 3 4 5 6 s 2 4(a) Performance of the solutions 7 8 9 2 4(b) Critical Ratio of dressed jerseys References [1] W. Alderson. Marketing efficiency and the principle of postponement. In Cost and Profit Outlook. 1950. [2] Y. Aviv and A. Federgruen. The benefits of design for postponement. In R. Ganeshan S. Tayur and M. Magazine, editors, Quantitive models for Supply Chain Management, pp 553-584. Kluwer, Boston, 2003. [3] L. P. Bucklin. Postponement, speculation, and the structure of distribution channels. Journal of Marketing Research, 2(1):6, 1965. [4] J. D. Pagh and M. C. Cooper. Supply chain postponement and speculation strategies: How to choose the right strategy. Journal of Business Logistics, 19(2):21, 1998. [5] J. C. W. Parsons. Using a newsvendor model for demand planning of nfl replica jerseys. 2004. Master Thesis, Massachusetts Institute of Technology. [6] S. M. Rietze. Case studies of postponement in the supply chain. 1970. Master Thesis, Department of Civil and Environmental Engineering, Massachusetts Institute of Technology Massachusetts Institute of Technology. [7] E. A. Silver and S. Minner. A replenishment decision involving partial postponement. OR Spectrum, 27:1–19, 2005. [8] J. M. Swaminathan and H. L. Lee. Design for postponement. In S. Graves and T. De Kok, editors, Supply Chain Management - Handbook of Operations Research and Management Science, vol 11, pp 199-226. North-Holland, Amsterdam, 2003. 19 [9] R. S. Tibben-Lembke and Y. Bassok. An inventory model for delayed customization: A hybrid approach. Eurpoean Journal of Operational Research, 165:748–764, 2005. [10] R. Anupindi Y. Bassok and R. Akella. Single period multi-product inventory models with susbstitution. Operations Research, 47:632–642, 1999. 20