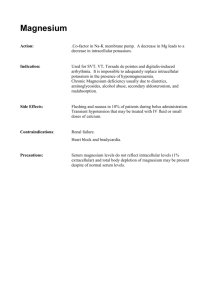

The lightest structural metal

advertisement

The lightest structural metal 1.- Introduction Since a few years ago magnesium alloys is thought as a lighter alternative to existing structural metals. However, for one reason or another, despite the advantages attributed to him, the metal has not finished breaking the force in the design of new products. One of the sectors that has promoted the use of magnesium has been the automotive sector, in fact, in 1957 a Corvette SS, designed for racing, was built with panels of magnesium. A few years before Mercedes-Benz had done the same in 300SLR model, a model that had a great success until it unfortunately became the protagonist of the most tragic accident in the history of the 24 Hours of Le Mans. In 1971 Porsche broke the distance record with a model that had reduced their weight by using a magnesium structure. However, manufacturers preferred to focus its efforts on reducing weight to the engine block and Volkswagen and -1- Porsche will be the first ones to use magnesium alloys. Recently there have been BMW, Chevrolet and Mitsubishi who have used new magnesium alloys in order to reduce engine weight. Another field of application of magnesium has been electronic devices. Because of its low weight magnesium has been used in the manufacture of casings of mobile phones, computers, cameras and other electronic components. In addition, magnesium has been one of the materials used in aerospace construction, having been incorporated into the German military planes in the first and Second World War. As a result of the flammability of dust the use of other structural metals was preferred in the evolution of aviation technology. Recently there has been a new resurgence of magnesium, the need to reduce the energy consumption of vehicles has revived the interest of companies and research centres in the possibilities of magnesium. They hope that this time the work will be fruitful and magnesium may consolidate as a real alternative to other structural metals. A comprehensive source on current uses of magnesium as a structural material can be found on page www.magnesium.com -2- 2.- Advantages and disadvantages The advantages of using magnesium alloys are: 2.1.- Low density (1.74 Kg/dm3). 35% lighter than aluminium. 2.2.- Easily cast able. Its high fluidity allows designing thin metal layers (0,8 mm), which allows designs not possible in other materials such as thermoplastics. 2.3.- Good mechanical properties with respect to plastic materials. 2.4.- It is not influenced by temperature between -20 º C and 120 º C. In contrast to plastic which suffer aging phenomena. 2.5.- Great potential for integration. Allowing the realization of multifunctional parts and therefore reducing the number of parts required for the manufacture of a set. 2.6.- Low price. It has an advantageous price with respect to engineering plastics. 2.7.- High availability in nature. This is a very abundant metal in nature, being able to extract from seawater. With regard to the limitations we find: 2.8.- Industrial processes are not robust. Due to the limited knowledge that exists on magnesium technology equipment -3- manufacturers and suppliers, generally, do not have sufficient knowledge to ensure the stability of industrial processes. 2.9.- The material has a low corrosion resistance as a consequence of their growing tendency to rust. Hence it is absolutely necessary to protect it. 2.10.- There are erroneous preconceptions about the material. In the minds of many designers and engineers is the idea that the material ignites spontaneously and is very fragile. They are erroneous ideas that prevent their use in different sectors. -4- 3.- Properties The following table shows a comparison of the properties of magnesium with the most usual structural metals. Property Fe Al Cu Ti Mg Density (Kg/dm ) 7.87 2.7 8.96 7.14 4.51 1.74 Mohs Hardness 2.5 3 6 2.5 Melting Point (ºC) 1,500 660 1,085 420 1,668 650 Electric C. (MS/m) 9.93 37.7 58.11 16.6 2.38 22.6 Thermal C. (W/mK) 80.2 237 400 116 21.9 156 Abundance Position 4º 3º 25º 23º 9º 7º Cast ability No Si No Yes No Yes Mechanized Yes Yes Yes No Yes No Welding Yes Yes Yes No Yes No Place of mining China Australia Chile EEUU Australia Seawater Brazil Guinea Australia South Africa Russia Jamaica China 3 4 Zn 2.5 Canada Australia Kazakhstan India -5- 4 .- Magnesium Alloys The following table shows the most commonly used magnesium alloys with nominal composition. Alloy Al % Zn % Mn % AM60 6 AZ31 3 1 0.2 AZ61 6 1 0.2 AZ63 6 3 0.2 AZ80 8 0.5 0.2 AZ91 9 1 0.2 Ag % Zr % Th % Re % 0.2 EZ33 2,5 0.5 2.5 ZM21 2 HK31 0.1 0.5 3 HZ32 2 0.5 3 1 QE22 2.5 0.5 QH21 2.5 0.5 2 1 1 ZE41 4.5 0.5 1.5 ZE63 5.5 0.5 2.5 ZK40 4.0 0.5 ZK60 6.0 0.5 -6- 5.- Corrosion of magnesium One of the main problems in the use of magnesium is the low corrosion resistance. This circumstance requires paying special attention to the problem of galvanic corrosion, which is the corrosion produced as a result of the contact of magnesium with another metal. Although a good surface protection of magnesium can help prevent corrosion, the best solution is avoiding a direct contact between magnesium and certain metals. Group 1 Group 2 Group 3 Group 4 Group 5 Al 5052 Al 6063 Al 2024 Galvanized steel Steel Al 5056 Al 7075 Al 2017 Cadmiate steel Stainless steel Al 6061 Al 3003 Zn Titanium Lead Copper Brass The table below shows the tendency to produce galvanic corrosion of different metals in contact with magnesium. The materials are sorted from lowest to highest tendency to cause corrosion. -7- 6.- Magnesium Treatments Magnesium surface treatments could be: 6.1.- Painting It may be in liquid or powder, the basic difference is in thickness, which usually determines the appearance and properties of the coating. The high reactivity of magnesium required to work always with primers to get a good adherence and so an acceptable corrosion resistance. 6.2.- Anodizing The anodizing is usually made in sulphuric acid; however, as a result of the high reactivity of magnesium, it is difficult to anodize in an acid medium. Hence alkaline solutions are used, and then the anodic layer formed is so insulated that plasma formation occurs during the passage of electric current, resulting in what is known as plasmachemical anodizing. 6.3.- Plating Another possibility for treating magnesium is given by plating, in which a multilayered system of copper, nickel and chromium is applied to obtain magnesium polished chrome finish or matt -8- chrome depending on the type of nickel. The difficulty of this process is to achieve good adhesion between the plate and magnesium, since the formation of insulating oxides on the surface of magnesium is very fast. These oxides provoke adherence problems between deposit and substrate. To avoid this behaviour an electroless metal interface is applied prior to the application of an electrolytic deposit of copper, nickel and chromium. As interfaces are commonly used zinc and nickel. -9-