3 Product Groups - BRC Global Standards

advertisement

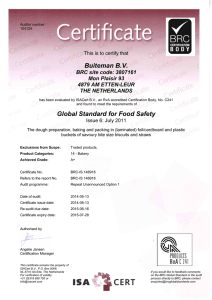

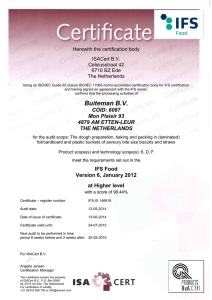

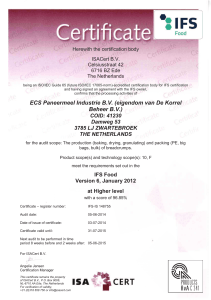

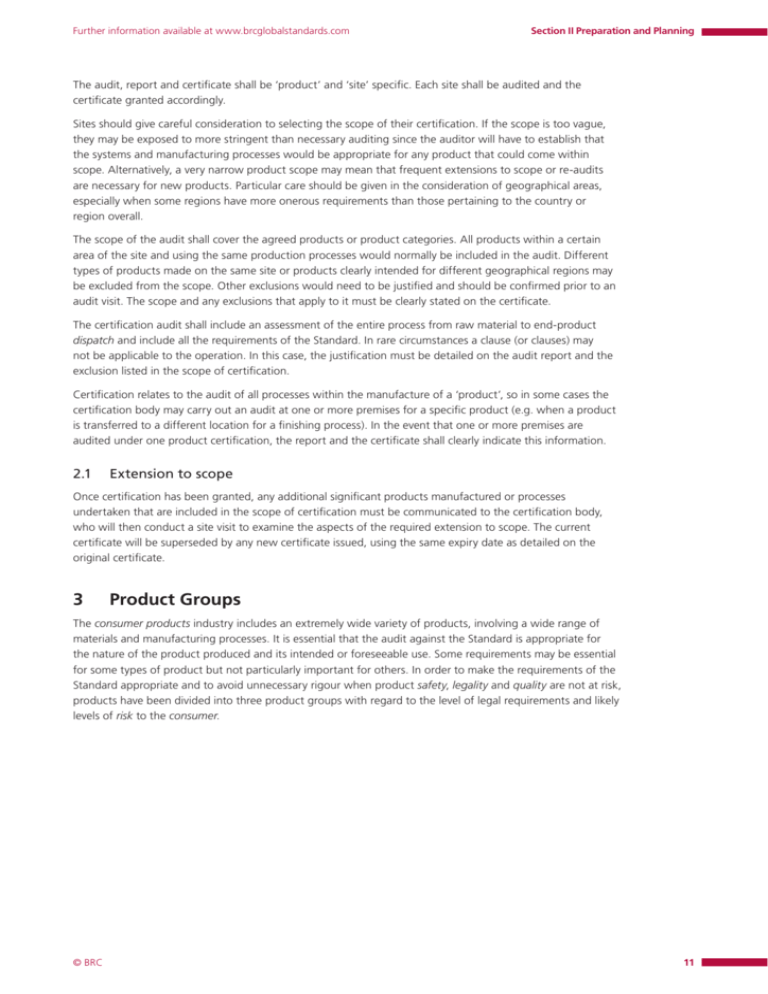

Further information available at www.brcglobalstandards.com Section II Preparation and Planning The audit, report and certificate shall be ‘product’ and ‘site’ specific. Each site shall be audited and the certificate granted accordingly. Sites should give careful consideration to selecting the scope of their certification. If the scope is too vague, they may be exposed to more stringent than necessary auditing since the auditor will have to establish that the systems and manufacturing processes would be appropriate for any product that could come within scope. Alternatively, a very narrow product scope may mean that frequent extensions to scope or re-audits are necessary for new products. Particular care should be given in the consideration of geographical areas, especially when some regions have more onerous requirements than those pertaining to the country or region overall. The scope of the audit shall cover the agreed products or product categories. All products within a certain area of the site and using the same production processes would normally be included in the audit. Different types of products made on the same site or products clearly intended for different geographical regions may be excluded from the scope. Other exclusions would need to be justified and should be confirmed prior to an audit visit. The scope and any exclusions that apply to it must be clearly stated on the certificate. The certification audit shall include an assessment of the entire process from raw material to end-product dispatch and include all the requirements of the Standard. In rare circumstances a clause (or clauses) may not be applicable to the operation. In this case, the justification must be detailed on the audit report and the exclusion listed in the scope of certification. Certification relates to the audit of all processes within the manufacture of a ‘product’, so in some cases the certification body may carry out an audit at one or more premises for a specific product (e.g. when a product is transferred to a different location for a finishing process). In the event that one or more premises are audited under one product certification, the report and the certificate shall clearly indicate this information. 2.1 Extension to scope Once certification has been granted, any additional significant products manufactured or processes undertaken that are included in the scope of certification must be communicated to the certification body, who will then conduct a site visit to examine the aspects of the required extension to scope. The current certificate will be superseded by any new certificate issued, using the same expiry date as detailed on the original certificate. 3 Product Groups The consumer products industry includes an extremely wide variety of products, involving a wide range of materials and manufacturing processes. It is essential that the audit against the Standard is appropriate for the nature of the product produced and its intended or foreseeable use. Some requirements may be essential for some types of product but not particularly important for others. In order to make the requirements of the Standard appropriate and to avoid unnecessary rigour when product safety, legality and quality are not at risk, products have been divided into three product groups with regard to the level of legal requirements and likely levels of risk to the consumer. © BRC 11 BRC Global Standard for Consumer Products Further information available at www.brcglobalstandards.com The Standard divides products into three product groups: Group 1 Products that have product-specific safety legislation and are required to be manufactured under hygienic conditions either by law or to prevent microbiological or other contamination that has the potential to cause serious injury or death during normal or foreseeable use of the product Group 2 Products that have product-specific safety legislation or mandatory/harmonised product standards and/or Products that have the potential to cause serious injury or death if they fail during normal or foreseeable use Group 3 Products that have no product-specific safety legislation or products where the only specific legislation is concerned with the toxicity resulting from consumer exposure to chemicals in articles, thus requiring the use of appropriate raw materials The Standard contains decision trees (see Figures 2 and 3) which identify to which of the three product groups a product belongs. 3.1 Assigning product groups The company must first determine whether it is a manufacturer, contract or assembly packer by referring to the definitions in the glossary (Appendix 7) prior to using the decision tree to determine the product group. The chosen group needs to be verified and agreed by the certification body that will carry out the audit. In the case of a novel product type or one on which there has been disagreement between parties, the certification body or retailer should refer the item to the BRC who will present it to the Technical Advisory Committee (see Section V for details about the committee) for adjudication concerning the appropriate product group. Once agreed, the outcome will be published on the website. In urgent cases BRC technical staff will determine the product group to be used for a specific audit and then refer to the Technical Advisory Committee for a definitive decision, which must be followed in subsequent audits and for other products of the same type. 3.2 Audit level It is not acceptable, in any circumstances, for a company to be audited to a lower product group than that into which the product falls when the assessment has been carried out. For example, a company cannot choose to have a Group 1 product audited to Group 3 requirements. Sometimes a specific product can be demonstrated (by means of a risk assessment and following the decision tree) to be in a lower group than that which would usually be expected. In such a case, the reason for this decision should be recorded on the certificate. There are occasions when companies may decide to be audited to the requirements of a higher product group than the one defined using the decision tree. This is acceptable, although not encouraged. If this approach is taken, then the certificate must show both the level to which the factory was audited and the product group resulting from the decision tree. This enables the product group assigned via the decision tree to be listed on the BRC directory in order to help maintain consistency. For further guidance, consult the decision trees (see Figures 2 and 3) and the BRC Global Standards website. It is recognised that many manufacturers may produce products that fall into more than one group. In these circumstances they may either choose to use the highest group for the entire site or ensure that suitable segregation methods are in place to separate different products by areas. It is not acceptable for more than one product group to be applied to the same area. 12 © BRC Further information available at www.brcglobalstandards.com Section II Preparation and Planning Where there is any doubt, the category for higher risk products as expressed above should be adopted. 3.3 Who determines the product group? The company shall follow the decision tree and determine the product group for the products being manufactured and supplied. This product group shall be validated by the certification body, which will confirm or reject the manufacturer’s decision. If the product group is determined by the certification body as being higher than the manufacturer’s determined product group, the certification body can seek the manufacturer’s agreement to be evaluated as the higher-risk product group. If agreement cannot be reached after consulting the BRC Global Standards website www.brcglobalstandards.com for any guidance or position statements that may be available, the matter can be referred by either party to the BRC Technical Advisory Committee for adjudication by contacting the BRC technical services team via email at brcglobalstandards@brc.org.uk. The company may also be required to provide the certification body with background information on the site concerned, through the completion of either a pre-audit questionnaire or pro-forma information sheet. 3.4 Guidelines for the use of the product group decision tree for the manufacture of consumer products The purpose of the decision tree is to enable the user to determine the product group of any product in the scope of the Standard. It is important to note that the product group is based on the risk to the consumer for whom the finished product is intended or by whom it is likely to be used. When using the decision tree, sources of contamination or other factors that could be introduced during the production and distribution process, and which could potentially affect the safety, legality and quality of the finished product, shall also be considered. When evaluating the risk, the primary effect should be considered. For example, if a product can produce a small abrasion then the injury is slight. The possibility that such injury could subsequently become infected should not be taken into account unless the product itself is likely to cause the infection or it is specifically intended for a user group with reduced immunity. When evaluating the possibility of serious injury or death, the approach should generally be to consider the individual product/products received by a consumer. For example, although the presence of trace carcinogenic materials in a product may contribute to long-term illness, the individual product received by the consumer will not itself cause serious injury or death. The control or avoidance of the toxic substance would still be an essential part of the risk assessment and the use of such materials may be illegal. For each product manufactured or assembled, each question is answered sequentially from the beginning, until a ‘yes’ answer is reached. The first ‘yes’ determines the product group. Questions should be answered based upon the risks and the legislation in the market where the finished product is intended to be sold to the consumer. In the case where a product intended for multiple markets falls into different product groups, the higher group shall be used. The decision trees are detailed in Figures 2 and 3. © BRC 13 BRC Global Standard for Consumer Products Further information available at www.brcglobalstandards.com Is this product defined as a pharmaceutical or a cosmetic, or is it used invasively? Yes Product group 1 No Yes Does the product have productspecific legislation requiring hygienic manufacture (e.g. GMP)? Product group 1 No Is there potential for contamination of the product which could cause major injury or harm? Yes Biological contamination or radiation Yes Product group 1 Yes Chemical or physical contamination No Does the product have any product-specific legal requirements concerning safety or any harmonised or mandatory standards? Product group 2 Yes Product group 2 No Yes Does the product require risk or safety warning on the product packaging, labelling or instructions? Product group 2 No Is the product in contact with skin during foreseeable use and/or does the product contain nanomaterials? Yes Is the product subject to mandatory labelling of ingredients or components? Yes Are there significant physical, chemical, electrical, flammability, magnetic, acoustic or radiation risks? Yes Product group 2 No No Can this product type cause death or major injury if it fails during foreseeable use? Yes Product group 2 No Is the product designed or clearly intended for vulnerable or very vulnerable user groups? Yes Product group 2 No Product group 3 Figure 2 Product group decision tree – manufacturer 14 © BRC Section II Preparation and Planning Further information available at www.brcglobalstandards.com Finished components from manufacturer delivered to packer Yes Use the manufacturer’s decision tree Yes Bulk or unwrapped material for contract packing No Use the manufacturer’s decision tree Product group 2 Is the finished component subject to change? No Major Yes Product group 3 Yes Could the introduced hazard cause injury or harm? Minor Yes Can the assembly process introduce more risks? No No Product group 2 Yes Does the assembly packing operation affect the requirements? (e.g. warnings, labelling) Yes Does the product have any product-specific legislation/ harmonised or mandatory standards? No No Product group 3 Figure 3 Product group decision tree – assembly packer © BRC 15