Survey Area Layout

advertisement

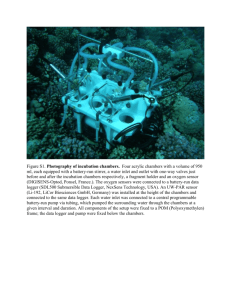

Avon Valley Archaeological Society DISCOVERING THE AVON VALLEYS PAST Geophysical Survey Manuals Garry Brisdion Jul 2010 Contents Contents............................................................................................................................ ii List of Figures .................................................................................................................. iii Section 1 – LAYING OUT THE SURVEY AREA ............................................................1 Laying out the 20 x 20 – Standard Layout ......................................................................1 Increased Accuracy Technique .......................................................................................2 Sampling Path ................................................................................................................3 Standard Layout .........................................................................................................3 Increased Accuracy Layout. .......................................................................................4 Section 2 - RESISTIVITY LOGGER .................................................................................5 Background Theory........................................................................................................5 Logger Overview ...........................................................................................................5 LCD Displays.............................................................................................................6 Resistivity Logger Switch Explanation ...........................................................................7 Output Resistance and Gain Switches .........................................................................7 Test Switch ................................................................................................................7 Mode, Up and Down ..................................................................................................7 Download...................................................................................................................7 Save switch ................................................................................................................8 Clearing the Memory .....................................................................................................8 Setting Up Prior to Survey .............................................................................................9 Data Storage Strategy .................................................................................................9 Cable and Probe Connection.......................................................................................9 Conducting the Survey ................................................................................................. 10 Potential Errors ............................................................................................................ 11 Saving Data to the PC .................................................................................................. 11 Section 3 – SAVING AND PROCESSING DATA .......................................................... 13 Saving Data to the PC .................................................................................................. 13 Data Processing ............................................................................................................ 13 ii List of Figures Figure 1 – Basic Survey Area Geometry ............................................................................1 Figure 2 – Layout of Sample lanes .....................................................................................2 Figure 3 - Increased Accuracy Sampling Rate ....................................................................3 Figure 4 - Sampling Route for Standard Layout .................................................................4 Figure 5 - Sampling Route for Increased Accuracy Layout .................................................4 Figure 6 - Layout of the Resistivity Logger ........................................................................5 Figure 7 - Suggested Survey Recording Layout ..................................................................9 Figure 8 - Position of Remote Pegs .................................................................................. 10 iii Section 1 – LAYING OUT THE SURVEY AREA 1. The standard area for survey is 20m x 20m but any shape or area size can be used. However, the size must be carefully planned in advance as this will affect how the data is stored in the Resistivity and Magnetometer Loggers. This section will cover the process for laying out and surveying a standard 20 x 20 area followed by specific instructions for recording variation in each section below. Laying out the 20 x 20 – Standard Layout 2. As per any site layout a base line should be established and used for all survey work. However, for Magnetometry this should ideally run magnetic east-west. This is to reduce the variations due to crossing lines of magnetic field. In practice small variations have little impact upon the recorded measurements. 3. Once the baseline is established, mark out the 20 x 20 using the diagonal measurement of 28.28m to give a true right angle as Figure 1 below: 28.28m 20m Baseline Reference Corner 20m Figure 1 – Basic Survey Area Geometry 4. Ideally the whole site should now be marked out using this baseline and a 20x20m grid. 5. Once the Basic Survey Area (BSA) is marked out it must be divided into columns to guide the sampler. 6. Both horizontal sides of the BSA should be marked out with pegs at 2m. These are joined across the BSA by a Guide Line which effectively divides the BSA into 1m wide strips referred to as Guide Columns. The Guide Columns are marked off at 0.5m and then at every 1m intervals as shown in Figure 2 below. These markers are referred to as Sample Markers and if laid out correctly will create two hundred 2m x 1m Sample Boxes. Two separate readings are taken from within each sample block as described below to give a total of 400 samples per a single BSA. This will equate to 1 sample for every 1m x 1m square within the BSA. 7. It is feasible to increase the sample rate to every 0.5m x 0.5m block by increasing both the number of vertical Guide Lines and the sample markers. However, this would 1 increase the number of samples to 1600 per BSA and would increase the difficulties of later processing for very little gain. This is only recommended for small areas where increased resolution is required over areas of specific interest. B C F G K L O P S T W Peg Line Marker Guide Column Sample Block Sample Location Guide Line A D E H J M N Q R T V Figure 2 – Layout of Sample lanes Increased Accuracy Technique 8. The technique described above is the standard layout used universally across the industry and will provide a perfectly adequate guide to sampling location and rate. However, the inexperienced user may experience some difficulty monitoring the logger and keeping a track of the guide line to the side at the same time. When using the magnetometer it is very easy to loose track, resulting in less samples taken per column that is required. Additionally, placing the resistivity probes or holding the magnetometer over the centre of the 1m Sample Block is subject to the obvious errors 9. As a result, we have developed a method for laying out which gives greater accuracy without the need to constantly monitor the sample position relative to the adjacent Line Markers. However, this method does require twice the number of guide lines or the need to constantly move lines across the BSR as they become free. 10. Firstly, the BSR Baseline is pegged out at 0.5m then every 1m. Secondly, the Guide Lines Markers are also located at 0.5m and then every 1m. If laid out correctly the BSR should now be broken down into 1m x 1m sample areas with the Line Marker located in the centre of that Bample Block 2 Resistivity Probe position Magnetometer position 1m 1m x 1m Sample Block 1m 0.5m A D E H Figure 3 - Increased Accuracy Sampling Rate Sampling Path 11. This section describes the path taken through the BSA in order to cover the ground in a systematic way that can be understood by the Data Loggers. Both the Magnetometer and Resistivity Meter are very specific in the way data must be recorded and so this section, which applies to both loggers, should be strictly adhered to. Specific instruction on how to take the recordings will be given in the sections on the respective instruments. 12. To ensure clarity the sample path will be described on a smaller sample area as shown in Figure 4 and 5 below. Standard Layout. 13. Figure 4 below represents the sample path to be followed if using the Standard Layout. The lines A-B, C-D, E-F etc represent the Guide Lines that should be marked at 0.5m and then every metre as described above. In order to cover the area in a systematic way, the operator will use these lines as a guide to their LEFT at all times so the walk would follow the numerical route through the area but keeping the guide line on the left at all times. 14. Each sample should be taken adjacent to the Sample Marker on the on the Guide Line. The Sample Location marker on the diagram represents the position of the Magnetometer and the mid-point between the two Resistivity probes. The exact location has to be judged by eye. If the path is followed strictly, two samples are taken from each 2m x 1m sample block, one on the way up and one on the way back. NOTE: Whilst it is possible to rotate the Resistivity Logger when changing direction it is essential that the Magnetometer is held in the same orientation with the handler moving 3 around the Logger accordingly. The reasons for this are explained in the Magnetometer section. B C 2 F 3 6 7 Line Marker Sample Location Direction of Walk 1 4 A 5 8 D E Figure 4 - Sampling Route for Standard Layout Increased Accuracy Layout. 15. Figure 5 below show the sampling route to follow if the increase accuracy layout is followed. It can clearly be seen from the diagram that there is no doubt as to where the sample position is located 16. B C F G Line Marker Sample Location Direction of Walk A D E H Figure 5 - Sampling Route for Increased Accuracy Layout 4 Section 2 - RESISTIVITY LOGGER Background Theory 17. When two conductors are place in the soil and a voltage applied across them a current will flow between them. The amount of current that flows will depend on the resistance of the soil between the two electrodes. The level of resistance is caused by a number of factors: the soil’s water content, the chemical makeup of the soil and the presence or absence of conductive material such as iron or magnetite. 18. The Resistivity Logger uses a four probe system; 2 transmitters (Tx) and 2 receivers (Rx). One pair of Tx/Rx (Reference Probes) is placed in the ground approximately 2m apart and 15-20m away from the closest edge of the sample area. This pair acts as a standard reference and should not be moved during the survey. 19. The second Tx/Rx pair (fixed to the Sample Frame) is inserted into the sample area and a reading taken. The Logger records the difference between the first and second pair of probes as the relative value at the sample location. This is the figure stored for further analysis. Logger Overview PC Connector RESISTIVITY LOGGER 510B 14C* Probe Connectors 490A 20# 16R = 49 GAIN OUTPUT RESISTANCE OFF ON TEST UP DOWN MODE DOWNLOAD SAVE Figure 6 - Layout of the Resistivity Logger 5 LCD Displays 20. The LCD has two modes: Test and Sample Mode. On switch on - the LCD will display the following: 21. The words Soil Resistivity will be quickly replaced by alphanumeric values which will differ depending upon the mode being used. 22. The bottom line refers to the sample value (extreme right) and the location in the memory to which that value is stored. C is the column and R is the row being sampled. The * indicated which is active ie which one will be changed by using the UP and DOWN switches. The MODE switch changes to active cell between C and R. NOTE: Only 128 (0 to 127) rows or columns can be sampled before the value roll over to 0 and start over-writing the original values. Surveys should be designed accordingly. In Test Mode the LCD will display: 23. During Test Mode the top line of the LCD shows the values of the probe pairs at the output. A and B refer to the two amplifiers within the Logger, one is attached to each TX/RX pair of probes. The number to the right of the top line indicates the relative difference and is for information only. This should not be saved to memory. In Survey Mode the LCD will display: 6 24. During Survey Mode the top line letters are changed to H and L referring to the high and low values of the two probe pairs and the difference shown at the right of the top line. Ideally this should be kept below a value of 500 for normal operations. 25. If a sample value has already been stored at a particular memory location, that value will be displayed on the right of the bottom line. Saving again will over-write the original data. Resistivity Logger Switch Explanation Output Resistance and Gain Switches 26. The Gain and Output Resistance rotary switches are used to control the amount of current passing from the Tx probes into the soil and the sensitivity of the system to the amount of current detected at the Rx probe. Rotation clockwise increases their values. Switches set to the twelve o’clock position means the lowest level of Gain and no added resistance to the output current (full current). The relative setting of these is by trial and error and ideally should give a sample value as large as possible and ideally in the order of 500. Moving the Reference Probes closer to the BSA can help to increase the sample value. Do not change these settings during the survey. Test Switch 27. This switch allows the microprocessor to monitor the output voltages for test purposes and would not be used under normal sampling other than to periodically check that both probes remain in connection. Mode, Up and Down 28. These control the location within the memory that the Logger stores the sample data to. The Mode switch toggles between Column and Row and the Up and Down increases or decreases the Column or Row value. Their operation will be explained later. Download 29. This switch is used only during the download of data to the PC for processing and should not be used at any other time. 7 Save switch 30. Pressing this switch saves the individual sample value to the memory location set by the Mode, Up and Down switches. Unfortunately, this has to be done for each sample taken. The LCD messages will be explained under the section explaining how to save sampled data. Clearing the Memory 31. The memory is of only limited size and should be cleared as frequently as possible to avoid running out mid survey. Maximum capacity is 128 columns with 128 rows of samples or 16384 individual sample readings (each sample uses two memory locations). Each 20x20 sample area will require 400 readings (800 memory locations) therefore only 40 surveys can be completed before clearing of the memory is necessary. In practice the data should be saved to PC and memory cleared more frequently as processing large amounts of data in the PC will be cumbersome and prone to errors. 32. Clearing the memory takes approximately 3min. 33. To clear the memory the Logger must be switched OFF. Press and hold down the SAVE button and then switch power ON. When the LCD shows the CLEARING EEPROM message on the screen the SAVE button can be released. 34. The numbers on line 2 show the progress and when complete the LCD will revert to the start-up SOIL RESISTIVITY screen and start normal operations. 35. To prevent inadvertent loss of data, clearing of the memory can only be done at start-up. 36. Saving data to the PC does not clear the memory 8 Setting Up Prior to Survey 37. To ensure no inadvertent loss or overwriting of data it is good practice to clear the memory before each survey session (each day and not each sample area). Ensure that any data is saved to the PC before clearing the memory. Data Storage Strategy 38. Plan the survey data storage strategy. Create a plan of the area and record the row and column numbers to be used for each area. Note: within the Logger the Column and Rows begin at 0. These settings should not be used as they potentially cause confusion. The diagram below gives a suggested strategy for recording a number of adjacent survey grids. 39 Rows Area 3 Column 1-20 Row 21-39 Area 4 Column 21-39 Row 21-39 Area 1 Column 1-20 Row 1-20 Area 2 Column 21-39 Row 1-20 21 20 1 1 20 21 Columns 39 Figure 7 - Suggested Survey Recording Layout Cable and Probe Connection 39. Before switching on the meter, attach the two cables via the appropriate colour probe connector sockets on the side of the meter. a. Frame Probes The crocodile clips on the short cable are then connected to the screw attachments on the probe frame. Ensure the cable is wrapped around the frame to ensure it is not inadvertently disconnected during surveying. b. Remote Pegs The crocodile clips on the long cable are connected to two steel pegs which need to be inserted into the ground in an area adjacent to the survey area and approximately 20mts away from the closest edge of the area as in the 9 diagram below. This will need to be moved as the survey progresses from Area 1 to Area 3 in Figure 7 above but may be satisfactory for both Area 1 and Area 2 as long as it is located equidistant from each area. 3-4mts 15-20mts Peg position for Area 1 only Peg position for Area 1 and 2 Area 1 Area 2 Figure 8 - Position of Remote Pegs Meter Calibration 40. Before conducting the survey the meter needs to be calibrated. This is done via the Test Mode operation and by adjusting the position of the Remote Pegs. This stage is a matter of trial and error as the final setup will vary depending on a number of factors including soil type, soil moisture content and strength of the battery. 41. Once the meter is connected and the remote pegs positioned: a. Switch on the meter with the Test mode on b. Check reading and try to maximise the value on the right of the top line of the LCD by altering the Gain and Output Resistance to ideally achieve a figure of 150-200 but well below 500. c. Varying the distance between the Remote Pegs can also increase or decrease the measured value. Conducting the Survey 42. Conducting the survey is a routine task and care should be taken to follow the sequence of activities to ensure the safely record of the sample data. DO NOT press the DOWNLOAD button during the survey. If you do it is not catastrophic and can be recovered – see below. 43. The process involves the following steps: 10 a. Before starting any new days survey activity Plan and record the Layout. b. Clear the memory c. At the start of the survey set the Column and Row numbers as per the plan set out in the previous section or as C1/R1 if this is the first survey conducted. To make the Column or Row active press the MODE button until the LCD displays C or R and press the UP button to increase the value. d. Insert the probes into the ground directly over the sample location. The LCD will change and then settle down. e. Press SAVE f. Move to the next Sample Location and insert the probes. g. INCREASE the Row location by 1 and press Save h. Repeat steps d-g until the sample column is complete. i. Move to the top of the next sample Column. j. Increase the Column number by 1. k. Insert the probes and press SAVE l. Move to the next Sample Location and insert the probes. m. DECREASE the Row location by 1 and press Save. n. Etc until the column is complete and R is down to 0 and then repeat. 44. GOLDEN RULE: INCREASE for every New Column INCREASE the ROW going up DECREASE the ROW going down Potential Errors 45. Pressing DOWNLOAD during Survey. Pressing DOWNLOAD at any time stops the current activity and instructs the Logger to speak to the PC. As the PC will not be connected at this stage the Logger will wait until it is connected. The remedy is simple and there is no risk of loss of data by following these steps: a. Switch the Logger off then on. b. Ensure the Column and Row are set to the last known sample location or reset to the beginning of the Row. c. Recommence sampling 46. Failure to SAVE or reset the C/R number. Neither of these is a problem as the data can be recaptured from the last known location: a. Examine the values stored in the Row using the MODE and UP and DOWN buttons. b. Identify the last location with a value stored. c. Move back to that location using the Guide Lines and Markers as a guide. d. Rest the Row number to that location and recommence sampling Saving Data to the PC 47. Connect the Logger to the PC using the USB-RS322 cable. 11 48. On the PC open the Magnetometer software. 49. Select the data mode button to Resistivity 50. Click ‘DOWNLOAD DATA’ button. This will start the process and ask for confirmation. Once confirmed a DOWNLOAD screen will appear. The software is now awaiting receipt of the data from the Logger. Press the Download S7 button on the Logger within 30 Seconds to send the data. 51. A bar graph on the software will show time left before S7 must be pressed otherwise the process will be aborted. 52. The LCD on the Logger will show ‘SENDING TO PC’ followed by ‘SENDING FINISHED’ when complete. Display will then return to SOIL RESISTIVITY screen. 53. If data is not received check the COM port settings via the screen options and repeat. 12 Section 3 – SAVING AND PROCESSING DATA Saving Data to the PC 54. Connect the Logger to the PC using the USB-RS322 cable. 55. On the PC open the Magnetometer software. 56. Select the ‘RESISTIVITY, data mode radio button (top right) 57. Click ‘DOWNLOAD DATA’ button. This will start the process and ask for confirmation. Once confirmed a DOWNLOAD screen will appear. The software is now awaiting receipt of the data from the Logger. Press the Download S7 button on the Logger within 30 Seconds to send the data. A bar graph on the software will appear showing the download progress 58. The LCD on the Logger will show ‘SENDING TO PC’ followed by ‘SENDING FINISHED’ when complete. Display will then return to SOIL RESISTIVITY screen. 59. If data is not received check the COM port settings via the screen options. This should be set to Com 2 for the Resistivity meter Data Processing After successful two data files will be placed on the desktop of the computer. These contain the individual sample readings but must be processed before they can be imported into the geophysics visualisation data. Data File 1 - EARTHRESORIG File Typical value = 149*126 Open the file with a Text Editor 13 Remove the *126 and *127 from each string in the TXT file. The remainder is the sample value Remove the __0*__0, (incl the comma) where __ is two spaces. These are Start and Stop recording markers and are not required. Also remove the * 0 (the gap is two spaces) Copy the remainder to Excel or Word Data File 2 - EARTHRES File The individual values are the sample value plus 32256. Therefore to obtain the true value copy the full data table into Excel and subtract 32256 from each value. As a double check, the resultant value should be the same as the number before the *126 in the EARTHRESORIG File 14