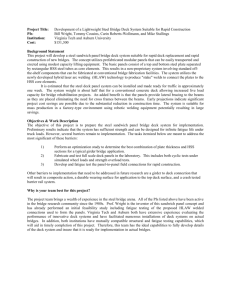

ROOF DECK - Bushwick Metals

advertisement