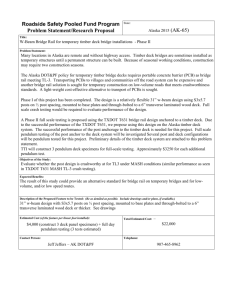

VT Development of a Lightweight Steel Bridge

advertisement

Project Title: PIs: Institution: Cost: Development of a Lightweight Steel Bridge Deck System Suitable for Rapid Construction Bill Wright, Tommy Cousins, Carin Roberts-Wollmann, and Mike Stallings Virginia Tech and Auburn University $151,300 Background Statement This project will develop a steel sandwich panel bridge deck system suitable for rapid deck replacement and rapid construction of new bridges. The concept utilizes prefabricated modular panels that can be easily transported and erected using modest capacity lifting equipment. The basic panels consist of a top and bottom steel plate separated by rectangular HSS steel tubes as core elements. This results in a non-proprietary system involving standard offthe-shelf components that can be fabricated at conventional bridge fabrication facilities. The system utilizes the newly developed hybrid laser arc welding (HLAW) technology to produce "stake" welds to connect the plates to the HSS core elements. It is estimated that the steel deck panel system can be installed and made ready for traffic in approximately one week. The system weight is about half that for a conventional concrete deck allowing increased live load capacity for bridge rehabilitation projects. An added benefit is that the panels provide lateral bracing to the beams as they are placed eliminating the need for cross frames between the beams. Early projections indicate significant project cost savings are possible due to the substantial reduction in construction time. The system is suitable for mass production in a factory-type environment using robotic welding equipment potentially resulting in large savings. Objectives & Work Description The objective of this project is to prepare the steel sandwich panel bridge deck system for implementation. Preliminary results indicate that the system has sufficient strength and can be designed for infinite fatigue life under truck loads. However, several barriers remain to implementation. The tasks itemized below are meant to address the most significant of these barriers: 1) 2) 3) Perform an optimization study to determine the best combination of plate thickness and HSS sections for a typical girder bridge application. Fabricate and test full scale deck panels in the laboratory. This includes both cyclic tests under simulated wheel loads and strength overload tests. Develop and fatigue test the panel-to-panel field connections for rapid construction. Other barriers to implementation that need to be addressed in future research are a girder to deck connection that will result in composite action, a durable wearing surface for application to the top deck surface, and a crash tested barrier rail system. Why is your team best for this project? The project team brings a wealth of experience in the steel bridge arena. All of the PIs listed above have been active in the bridge research community since the 1980s. Prof. Wright is the inventor of this sandwich panel concept and has already performed an initial feasibility study including fatigue testing of the proposed HLAW welded connections used to form the panels. Virginia Tech and Auburn both have extensive experience evaluating the performance of innovative deck systems and have facilitated numerous installations of deck systems on actual bridges. In addition, both institutions have mutually compatible structural and fatigue testing capabilities, which will aid in timely completion of this project. Therefore, this team has the ideal capabilities to fully develop details of the deck system and insure that it is ready for implementation in actual bridges.