Part 3

advertisement

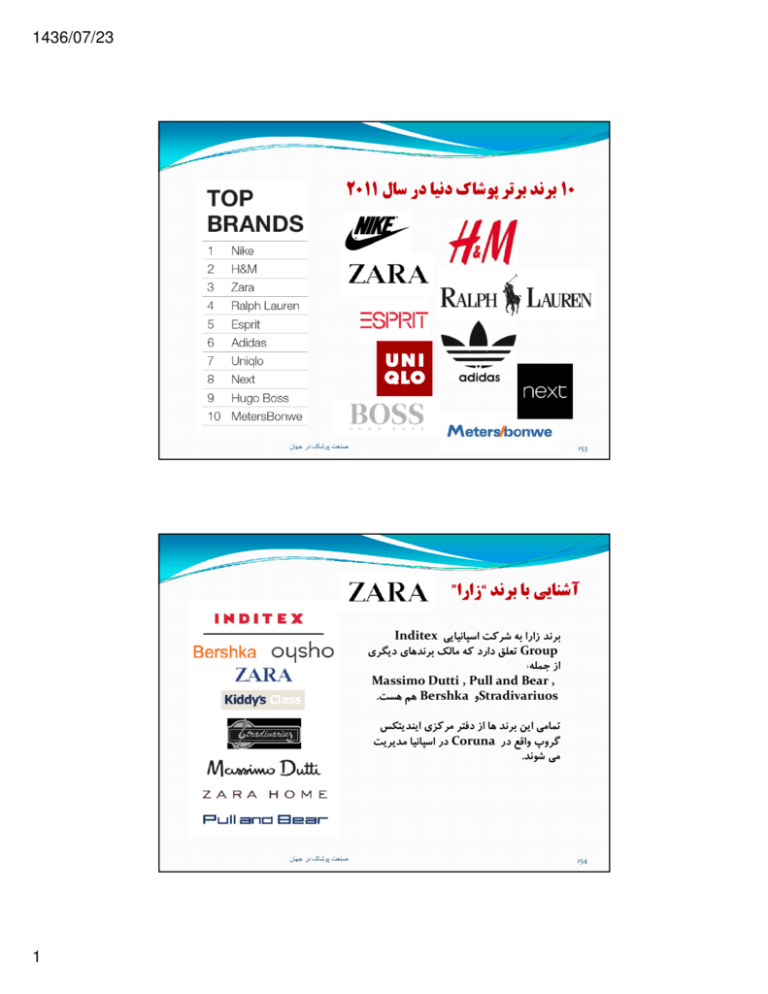

1436/07/23 10ﺑﺮﻧﺪ ﺑﺮﺗﺮ ﭘﻮﺷﺎك دﻧﻴﺎ در ﺳﺎل 2011 در ن 153 آﺷﻨﺎﻳﻲ ﺑﺎ ﺑﺮﻧﺪ “زارا” ﺑﺮﻧﺪ زارا ﺑﻪ ﺷﺮﻛﺖ اﺳﭙﺎﻧﻴﺎﻳﻲ Inditex Groupﺗﻌﻠﻖ دارد ﻛﻪ ﻣﺎﻟﻚ ﺑﺮﻧﺪﻫﺎي دﻳﮕﺮي از ﺟﻤﻠﻪ: Massimo Dutti , Pull and Bear , Stradivariuosو Bershkaﻫﻢ ﻫﺴﺖ. ﺗﻤﺎﻣﻲ اﻳﻦ ﺑﺮﻧﺪ ﻫﺎ از دﻓﺘﺮ ﻣﺮﻛﺰي اﻳﻨﺪﻳﺘﻜﺲ ﮔﺮوپ واﻗﻊ در Corunaدر اﺳﭙﺎﻧﻴﺎ ﻣﺪﻳﺮﻳﺖ ﻣﻲ ﺷﻮﻧﺪ. 154 در ن 1 1436/07/23 Amancio Ortega Gaonaﻣﺆﺳﺲ ﮔﺮوه Inditexﻣﻌﺘﻘﺪ اﺳﺖ ﻣﺸﺘﺮي ﺑﻪ ﻟﺒﺎس ﺑﻪ ﭼﺸﻢ ﻣﻮاد داراي ﺗﺎرﻳﺦ اﻧﻘﻀﺎ ﻣﺎﻧﻨﺪ ﻣﺎﺳﺖ ،ﻧﺎن و ﻳﺎ ﻣﺎﻫﻲ ﻧﮕﺎه ﻣﻲ ﻛﻨﺪ ﻛﻪ ﺑﺎﻳﺪ ﺑﻪ ﺳﺮﻋﺖ ﻣﺼﺮف ﺷﻮد ﻧﻪ اﻳﻨﻜﻪ در ﻗﻔﺴﻪ ﻫﺎ اﻧﺒﺎر ﮔﺮدد. ﻟﺬا ﺑﺎﻳﺪ ﺑﺘﻮان اﻟﺒﺴﻪ را ﺑﻪ ﺻﻮرت داغ و ﺗﺎزه! ﺑﻪ ﻣﺸﺘﺮي ﺗﺤﻮﻳﻞ داد. !Freshly backed clothes 3ﻓﺮﻣﻮل ﻣﻮﻓﻘﻴﺖ زارا ﺑﺮاي اﻳﻦ ﻛﺎر: 155 • زﻣﺎن اﻧﺘﻈﺎر ﻛﻮﺗﺎه )(short lead time اﻟﺒﺴﻪ ﻣﺪي ﺑﻴﺸﺘﺮ • ﻛﻤﻴﺖ ﭘﺎﻳﻴﻦ )(low quantity ﻋﺮﺿﻪ ﻛﻢ • ﺗﻨﻮع ﻃﺮح ﺑﺎﻻ )(more styles ﻗﺪرت اﻧﺘﺨﺎب ﺑﻴﺸﺘﺮ و اﺣﺘﻤﺎل ﺑﺎﻻﺗﺮ اﺻﺎﺑﺖ ﺑﻪ ﻫﺪف در ن در ﺣﺎﻟﻲ ﻛﻪ ﻧﺎم ﻫﺎي ﻣﻌﺮوف دﻧﻴﺎي ﻣﺪ ،ﺑﻴﻦ 4اﻟﻲ 12ﻣﺎه زﻣﺎن ﻧﻴﺎز دارﻧﺪ ﺗﺎ ﻃﺮحﻫﺎي ﺟﺪﻳﺪﺷﺎن را ﺑﻪ ﺑﺎزار ﻋﺮﺿﻪ ﻛﻨﻨﺪ ،زارا ﺑﻴﻦ دو ﻫﻔﺘﻪ ﺗﺎ 1ﻣﺎه ﻫﻤﺎن ﭘﺮوﺳﻪ را ﻃﻲ ﻣﻲ ﻛﻨﺪ. ﺑﺎ اﻳﻦ روش ،زارا ﺳﺎﻻﻧﻪ ﺣﺪود 12000ﻃﺮح ﺟﺪﻳﺪ ﺑﻪ ﺑﺎزار ﻣﺪ ﻋﺮﺿﻪ ﻣﻲﻛﻨﺪ ﻛﻪ رﻗﻢ ﺑﻲ ﻧﻈﻴﺮي اﺳﺖ. 156 در ن 2 1436/07/23 ارزﻳﺎﺑﻲ دﻗﻴﻖ ﺑﺎزار زارا ﻫﺮ روز ﮔﺰارش ﻓﺮوش اﻗﻼم ﺧﻮد را از ﺗﻤﺎم ﻓﺮوﺷﮕﺎه ﻫﺎﻳﺶ درﻳﺎﻓﺖ ﻣﻲ ﻛﻨﺪ ﺗﺎ اﻗﻼم ﭘﺮ ﻓﺮوش و ﻛﻢ ﻓﺮوش را ﺷﻨﺎﺳﺎﻳﻲ ﻛﻨﺪ .ﻣﺪﻳﺮان ﻓﺮوﺷﮕﺎه ﻫﺎ و ﻓﺮوﺷﻨﺪه ﻫﺎ ﻧﻈﺮات و اﻳﺪه ﻫﺎي ﺧﻮد را ﻣﻨﺘﻘﻞ ﻣﻲ ﻛﻨﻨﺪ. ﺑﺮرﺳﻲ ﻧﺤﻮه ﭘﻮﺷﺶ و ﺗﻤﺎﻳﻼت اﻗﺸﺎر ﺗﺄﺛﻴﺮﮔﺬار ﻣﺮدم در داﻧﺸﮕﺎه ﻫﺎ ،ﺟﺸﻦ ﻫﺎ و ﺗﺠﻤﻌﺎت روش دﻳﮕﺮ Zaraﺑﺮاي ارزﻳﺎﺑﻲ ﺑﺎزار اﺳﺖ. ﻳﻚ ﺗﻴﻢ ﻃﺮاﺣﻲ ﻗﻮي ﻣﺘﺸﻜﻞ از ﺣﺪود 200ﻧﻔﺮ در ) Curunaﺷﻤﺎل ﻏﺮﺑﻲ اﺳﭙﺎﻧﻴﺎ( در ﻛﻞ ﻃﻮل ﺳﺎل در ﺣﺎل ﻛﺎر و اراﺋﻪ ﻃﺮح ﻫﺎي ﺟﺪﻳﺪﻧﺪ .ﻫﺮ ﻃﺮاح ﺑﻪ ﻃﻮر ﻣﺘﻮﺳﻂ 60ﻃﺮح در ﺳﺎل )ﺣﺪود 1ﺗﺎ 2ﻃﺮح در ﻫﻔﺘﻪ( اراﺋﻪ ﻣﻲ دﻫﺪ. 157 در ن اﺳﺘﺮاﺗﮋي ZARA ﭘﺎﺳﺨﮕﻮﻳﻲ ﺳﺮﻳﻊ ﺑﻪ روﻧﺪ ﻣﻮﺟﻮد ﺑﻪ ﺟﺎي اﻳﺠﺎد ﻳﻚ روﻧﺪ ﺟﺪﻳﺪ 158 در ن 3 1436/07/23 ﺗﻮﻟﻴﺪ در ﻧﺰدﻳﻜﻲ دﻓﺘﺮ ﻣﺮﻛﺰي ﺑﺮ ﺧﻼف ﺑﺴﻴﺎري از ﺧﺮده ﻓﺮوﺷﺎن ﻣﻌﺘﺒﺮ ﻣﺎﻧﻨﺪ H&M ،Gapو ...ﻛﻪ ﺗﻮﻟﻴﺪ اﻗﻼم ﺧﻮد را ﺑﻪ ﺗﻮﻟﻴﺪﻛﻨﻨﺪﮔﺎن ﻛﺸﻮرﻫﺎي دور )ﻋﻠﻲ اﻟﺨﺼﻮص آﺳﻴﺎي ﺷﺮﻗﻲ( ﻣﻲ ﺳﭙﺎرﻧﺪ ،در ﺣﺪود %80اﻗﻼم Zaraدر اروﭘﺎ و در ﻧﺰدﻳﻜﻲ اﺳﭙﺎﻧﻴﺎ ﺗﻮﻟﻴﺪ ﻣﻲ ﺷﻮد .در ﺣﺪود ﻧﻴﻤﻲ از ﻣﺤﺼﻮﻻت در ﻛﺎرﺧﺎﻧﺠﺎت ﺷﺮﻛﺖ و ﻳﺎ ﻛﺎرﺧﺎﻧﺠﺎت واﺑﺴﺘﻪ ﺑﻪ آن ﺗﻮﻟﻴﺪ ﻣﻲ ﮔﺮدد. در ن 159 اﻧﺠﺎم ﺑﺮﺧﻲ ﻋﻤﻠﻴﺎت و ﺑﺮون ﺳﭙﺎري ﺑﺮﺧﻲ دﻳﮕﺮ! ﮔﺮوه Inditexﺳﺮﻣﺎﻳﻪ ﮔﺬاري ﺑﺎﻻﻳﻲ ﺑﺮ روي ﻣﺎﺷﻴﻦ آﻻت ﺑﺎ ﺗﻜﻨﻮﻟﻮژي ﺑﺎﻻ در زﻣﻴﻨﻪ رﻧﮕﺮزي ،ﺑﺮش و ﺗﻜﻤﻴﻞ ﻧﻤﻮده اﺳﺖ .ﭘﺎرﭼﻪ ﺧﺎم از اﺳﭙﺎﻧﻴﺎ ،ﺷﺮق دور ،ﻫﻨﺪ و ﻣﺮاﻛﺶ ﺗﻬﻴﻪ ﻣﻲ ﺷﻮد و ﻋﻤﻠﻴﺎت رﻧﮕﺮزي و ﺗﻜﻤﻴﻞ ﺗﻮﺳﻂ ﻛﺎرﺧﺎﻧﺠﺎت ﺷﺮﻛﺖ اﻧﺠﺎم ﻣﻲ ﺷﻮد. ﻋﻤﻠﻴﺎت ﻛﺎرﮔﺮﺑﺮ دوﺧﺖ ﺑﻪ ﻛﺎرﮔﺎه ﻫﺎي ﺗﻮﻟﻴﺪي در اﺳﭙﺎﻧﻴﺎ و ﺷﻤﺎل ﭘﺮﺗﻐﺎل ﻛﻪ در ﺣﺪود 350ﻛﺎرﮔﺎه ﻫﺴﺘﻨﺪ ،ﺳﭙﺮده ﻣﻲ ﺷﻮد. ﭘﺲ از دوﺧﺖ وﺗﻜﻤﻴﻞ ﻛﺎﻻﻫﺎ ﺑﻪ ﺳﺮﻋﺖ ﺑﻪ ﻓﺮوﺷﮕﺎه ﻫﺎي ﺷﺮﻛﺖ ﻓﺮﺳﺘﺎده ﻣﻲ ﺷﻮﻧﺪ .ﻫﺮ ﻓﺮوﺷﮕﺎه 2ﺑﺎر در ﻫﻔﺘﻪ ﻛﺎﻻﻫﺎي ﺗﻮﻟﻴﺪي را درﻳﺎﻓﺖ ﻣﻲ ﻛﻨﺪ و اﻧﺘﻘﺎل ﻫﺮ ﻛﺎﻻ ﺑﻴﺶ از ﻳﻚ ﻫﻔﺘﻪ ﻃﻮل ﻧﻤﻲ ﻛﺸﺪ. 160 در ن 4 1436/07/23 ﺑﻪ ﺟﺎي ﭘﻴﺶ ﺑﻴﻨﻲ ﺑﺮاي ﻃﺮح ﻫﺎي ﻫﺮ ﻓﺼﻞ از ﻣﺎه ﻫﺎ ﭘﻴﺶ )ﻫﻤﺎﻧﻨﺪ آﻧﭽﻪ اﻛﺜﺮ ﺧﺮده ﻓﺮوﺷﺎن اﻧﺠﺎم ﻣﻲ دﻫﻨﺪ( Zaraﻧﻮع و ﻣﻴﺰان ﭘﺎرﭼﻪ ﻣﻮرد ﻧﻴﺎز ﺧﻮد را ﭘﻴﺶ ﺑﻴﻨﻲ ﻣﻲ ﻛﻨﺪ و ﻃﺮح ﻫﺎ را ﺑﺮ اﺳﺎس ﻧﻴﺎز ﺑﺎزار ﺑﺎ ﺳﺮﻋﺖ ﺑﺎﻻ اراﺋﻪ ﻣﻲ دﻫﺪ. •ﺿﺮر ﻧﺎﺷﻲ از ﻟﺒﺎس ﻓﺮوش ﻧﺮﻓﺘﻪ ﺑﻴﺸﺘﺮ از اﻧﺘﺨﺎب ﻏﻠﻂ ﭘﺎرﭼﻪ اﺳﺖ. •اﻣﻜﺎن اﺳﺘﻔﺎده از ﭘﺎرﭼﻪ در ﻃﺮح ﻫﺎي دﻳﮕﺮ وﺟﻮد دارد. در ن 161 ﻧﻘﺶ ﻓﻨﺎوري اﻃﻼﻋﺎت در زﻧﺠﻴﺮه ﺗﺄﻣﻴﻦ Zara ﺗﺼﻤﻴﻢ ﮔﻴﺮي ﺳﺮﻳﻊ رﺻﺪ ﻧﺰدﻳﻚ روﻧﺪ ﺑﺎزار و رﻓﺘﺎر ﺧﺮﻳﺪ ﻣﻄﺎﻟﻌﻪ ﻧﺤﻮه ﭘﻮﺷﺶ در ﻛﻤﭗ ﻫﺎي داﻧﺸﺠﻮﻳﻲ، ﺗﺠﻤﻌﺎت و ... ﺑﺎزﺧﻮرد از ﻓﺮوﺷﮕﺎه ﻫﺎ: • ﮔﺰارش ﻓﺮوش • ﻧﻈﺮات ﻓﺮوﺷﻨﺪه ﻫﺎ ﺟﻤﻊ آوري و ﺗﺤﻠﻴﻞ اﻃﻼﻋﺎت در دﻓﺘﺮ ﻣﺮﻛﺰي ﻃﺮاﺣﻲ ﺑﺮ ﻣﺒﻨﺎي اﻃﻼﻋﺎت ﺗﺼﻤﻴﻢ ﮔﻴﺮي در ﻣﻮرد ﻣﻮاد ﻣﻮرد اﺳﺘﻔﺎده ﺗﻮﻟﻴﺪ •ﻛﻨﺘﺮل ﻣﻮﺟﻮدي ﭘﺎرﭼﻪ و ﻣﻠﺰوﻣﺎت در اﻧﺒﺎر •رﻧﮕﺮزي ،ﭼﺎپ و ﺗﻜﻤﻴﻞ )در ﺻﻮرت ﻧﻴﺎز( • ﺗﻮﻟﻴﺪ ﺗﻮزﻳﻊ •ارﺳﺎل ﺑﻪ ﻓﺮوﺷﮕﺎه ﻫﺎ •ﻗﺮار دادن در رﮔﺎل ﻫﺎ 162 در ن 5 1436/07/23 ﭘﺎﻳﻴﻦ ﻧﮕﺎه داﺷﺘﻦ ﻫﺰﻳﻨﻪ ﻫﺎ Zara -1ﺑﺨﺶ ﻛﺎرﮔﺮﺑﺮ دوﺧﺖ را ﺑﻪ ﺗﻮﻟﻴﺪ ﻛﻨﻨﺪه ﻫﺎي دﻳﮕﺮ ﻣﻲ ﺳﭙﺎرد. ﺑﻴﺸﺘﺮ ﻛﺎرﮔﺮان اﻳﻦ ﺗﻮﻟﻴﺪي ﻫﺎ ﻣﺎدران ،زﻧﺎن ﻣﺴﻦ و ﻳﺎ دﺧﺘﺮان ﻧﻮﺟﻮاﻧﻲ ﻫﺴﺘﻨﺪ ﻛﻪ ﺑﺮاي ﺑﻪ دﺳﺖ آوردن ﻛﻤﻚ ﺧﺮج ﻛﺎر ﻣﻲ ﻛﻨﻨﺪ. دﺳﺘﻤﺰد ﻳﻚ ﻛﺎرﮔﺮ ﺻﻨﻌﺘﻲ اﺳﭙﺎﻧﻴﺎﻳﻲ در ﺳﺎل 2001در ﺣﺪود 1300دﻻر آﻣﺮﻳﻜﺎ در ﻣﺎه ﺑﻮده اﺳﺖ .در ﺻﻮرﺗﻲ ﻛﻪ ﻛﺎرﮔﺮان ﻏﻴﺮ رﺳﻤﻲ ﻣﺸﻐﻮل ﺑﻪ ﻛﺎر در ﻛﺎرﮔﺎه ﻫﺎي ﭘﻮﺷﺎك درآﻣﺪي ﻛﻤﺘﺮ از ﻧﺼﻒ آن ﻳﻌﻨﻲ در ﺣﺪود 500دﻻر آﻣﺮﻳﻜﺎ داﺷﺘﻨﺪ. -2در ﻣﻮرد ﻫﺰﻳﻨﻪ ﻫﺎي ﺑﺎزارﻳﺎﺑﻲ Zara ،ﺑﻴﺸﺘﺮ ﺑﺮ روي اﻧﺘﺨﺎب ﻣﺤﻞ ﻣﻨﺎﺳﺐ ﺑﺮاي ﻓﺮوﺷﮕﺎه ﻫﺎﻳﺶ ﺗﺄﻛﻴﺪ دارد ﺗﺎ ﻫﺰﻳﻨﻪ ﻛﺮدن ﺑﺮاي ﺗﺒﻠﻴﻎ. در ﺳﺎل 2001ﺗﻨﻬﺎ 0/3درﺻﺪ از ﻓﺮوﺷﺶ را ﺑﻪ ﺗﺒﻠﻴﻐﺎت اﺧﺘﺼﺎص داد در ﺻﻮرﺗﻴﻜﻪ اﻳﻦ ﻣﻘﺪار ﺑﺮاي رﻗﺒﺎي او در ﺣﺪود 3/8درﺻﺪ اﺳﺖ. 163 در ن -3ﻫﻤﭽﻨﻴﻦ ﻋﺮﺿﻪ ﺳﺮﻳﻊ ﭘﻮﺷﺎك ﻣﺪي و ﺗﻮﻟﻴﺪ ﻛﻢ از ﻫﺮ ﻃﺮح ﺳﺒﺐ ﺷﺪه ﺗﺎ ﻫﺰﻳﻨﻪ ﻫﺎي ﻧﺎﺷﻲ از ﺣﺮاج اﺟﻨﺎس ﻓﺮوش ﻧﺮﻓﺘﻪ ﻛﺎﻫﺶ ﻳﺎﺑﺪ .ﺗﻨﻬﺎ در ﺣﺪود %18 اﻗﻼم ﮔﺮوه Inditexدر ﻇﺮف زﻣﺎﻧﻲ ﺧﻮد ﺑﻪ ﻓﺮوش ﻧﻤﻲ رود و ﺷﺎﻣﻞ ﺗﺨﻔﻴﻒ ﻣﻲ ﺷﻮد .در ﺻﻮرﺗﻲ ﻛﻪ اﻳﻦ ﻣﻘﺪار ﺑﻪ ﻃﻮر ﻣﺘﻮﺳﻂ ﺑﺮاي ﺧﺮده ﻓﺮوﺷﺎن دﻳﮕﺮ در ﺣﺪود %35اﺳﺖ. -4از آﻧﺠﺎ ﻛﻪ Zaraﺑﻴﺸﺘﺮ از ﻃﺮح ﻫﺎي ﻣﻮرد ﭘﺴﻨﺪ و ﻣﺪﻫﺎي راﻳﺞ اﻳﺪه ﻣﻲ ﮔﻴﺮد ،و ﻛﻤﺘﺮ ﻃﺮح ﻫﺎي ﺻﺮﻓﺎً اﺑﺘﻜﺎري اراﺋﻪ ﻣﻲ دﻫﺪ ،ﻫﺰﻳﻨﻪ ﻛﻤﺘﺮي ﻫﻢ ﺑﺎﺑﺖ ﻃﺮاﺣﻲ و ﺗﻮﺳﻌﻪ ﻣﺤﺼﻮل ﻣﻲ ﭘﺮدازد. ﻛﭙﻲ ﻛﺮدن از ﻃﺮح ﻫﺎي ﻃﺮاﺣﺎن ﻣﻌﺘﺒﺮ از ﺷﻴﻮه ﻫﺎي Zaraﻣﻲ ﺑﺎﺷﺪ. 164 در ن 6 1436/07/23 ﺑﺮﻧﺪ ﺳﺎزي در ﭘﻮﺷﺎك ﺑﺮﻧﺪ ﻧﺎم ﻳﺎ ﻧﻤﺎدي اﺳﺖ ﻛﻪ ﺳﺎزﻣﺎن آن را ﺑﺎ ﻫﺪف ارزش آﻓﺮﻳﻨﻲ ﺑﺮاي ﻣﺤﺼﻮﻻت ﺧﻮد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﻣﻲدﻫﺪ ﺑﺮﻧﺪ ارزﺷﻤﻨﺪ ﺗﺮﻳﻦ داراﻳﻲ ﻳﻚ ﺳﺎزﻣﺎن اﺳﺖ در ن 165 ﻣﺮاﺣﻞ ﺳﺎﺧﺖ ﺑﺮﻧﺪ -1ﺗﺸﺨﻴﺺ ﻧﻴﺎز ﻣﺸﺘﺮي ﺟﻤﻊ آوري اﻃﻼﻋﺎت ﺑﺎ ﻣﻄﺎﻟﻌﻪ ﺑﺎزار •ﺗﺸﺨﻴﺺ ﻧﻴﺎزﻫﺎي ﺑﺎﻟﻔﻌﻞ ﻣﺸﺘﺮﻳﺎن •ﺗﺸﺨﻴﺺ ﻧﻴﺎزﻫﺎي ﺧﻔﺘﻪ و ﺗﻼش در ﺟﻬﺖ ﺑﻴﺪار ﻛﺮدن آﻧﻬﺎ -2ﺳﺎﺧﺖ ﺗﺼﻮﻳﺮ ﺑﺮﻧﺪ ﻧﺎم ،ﻃﺮح ،ﻟﻮﮔﻮ ،رﻧﮓ ،ﺷﻌﺎر ﺗﺒﻠﻴﻐﺎﺗﻲ و ... •ﺗﻮﺟﻪ ﺑﻪ ﺳﻼﺋﻖ ﺑﺎزار ﻫﺪف •ﺗﻮﺟﻪ ﺑﻪ ﺗﻨﺎﺳﺐ ﺗﺼﻮﻳﺮ ﺑﺎ ﻣﺎﻫﻴﺖ ﻛﺎر •اﻳﺠﺎد ﺗﻤﺎﻳﺰ و اﻳﺠﺎد ﻣﺎﻧﺪﮔﺎري در ذﻫﻦ ﻣﺸﺘﺮي 166 در ن 7 1436/07/23 -3ﺗﻮﺳﻌﻪ و آزﻣﺎﻳﺶ ﻣﺤﺼﻮل •ﺑﺮاي ﭼﻪ ﻗﺸﺮي ﻃﺮاﺣﻲ ﺷﺪه اﺳﺖ؟ •ﭼﻪ ﻧﻴﺎزي را ﭘﺎﺳﺦ ﻣﻲ دﻫﺪ؟ •وﺟﻪ ﺗﻤﺎﻳﺰ آن ﺑﺎ ﻣﺤﺼﻮﻻت رﻗﻴﺐ ﭼﻴﺴﺖ؟ •ﺑﺎزﺧﻮرد ﺑﺎزار ﻧﺴﺒﺖ ﺑﻪ ﻣﺤﺼﻮل و ﻧﺎم و ﻧﺸﺎن آن ﭼﮕﻮﻧﻪ اﺳﺖ؟ -4اﻧﺘﺨﺎب ﺑﻬﺘﺮﻳﻦ ﺗﺮﻛﻴﺐ 167 در ن -5ﺛﺒﺖ ﻧﺎم و ﻧﺸﺎن ﺗﺠﺎري ﺑﺮاي ﻣﺤﺎﻓﻈﺖ ﻗﺎﻧﻮﻧﻲ از آﻧﻬﺎ -6ﻣﻌﺮﻓﻲ ﺑﺮﻧﺪ ﺑﻪ ﺑﺎزار ﺑﺎ اﺳﺘﻔﺎده از ﺗﻜﻨﻴﻚ ﻫﺎي ﺑﺎزارﻳﺎﺑﻲ ﻫﺪف ﺗﺒﻠﻴﻐﺎت و ﺗﻜﻨﻴﻚ ﻫﺎي ﺑﺎزارﻳﺎﺑﻲ ﺗﺮﻏﻴﺐ ﻣﺸﺘﺮﻳﺎن ﺟﺪﻳﺪ ﺑﺮاي اﺳﺘﻔﺎده از ﻣﺤﺼﻮل ﺑﺮاي ﺑﺎر اول اﺳﺖ .ﺧﺼﻮﺻﻴﺎت ﻣﺤﺼﻮل ﻣﻲ ﺑﺎﻳﺴﺖ ﺑﺘﻮاﻧﺪ ﻣﺸﺘﺮﻳﺎن را ﺑﻪ اﺳﺘﻔﺎده ﻣﺠﺪد ﺗﺮﻏﻴﺐ ﻛﻨﺪ 168 در ن 8 1436/07/23 ﻛﺪام ﺗﻜﻨﻴﻚ ﺑﺮاي ﺗﺒﻠﻴﻐﺎت و ﺑﺎزارﻳﺎﺑﻲ ﻣﺤﺼﻮﻻت ﭘﻮﺷﺎك ﻣﻨﺎﺳﺐ اﺳﺖ؟ • ﺗﺒﻠﻴﻐﺎت در رﺳﺎﻧﻪ ﻫﺎ • اﺳﺘﻔﺎده از ﻣﺤﺼﻮل ﺗﻮﺳﻂ اﻓﺮاد ﻣﺸﻬﻮر • اراﺋﻪ ﻧﻤﻮﻧﻪ راﻳﮕﺎن • اراﺋﻪ ﺑﻦ ﺗﺨﻔﻴﻒ )(voucher • ﺗﺨﻔﻴﻒ ﻫﺎي ﻓﺼﻠﻲ )ﺣﺮاج( • ﺧﺮﻳﺪ ﺑﺎ ﺟﺎﻳﺰه ... ﺑﺮاي ﺗﺮﻏﻴﺐ ﻣﺸﺘﺮي ﺑﻪ ﺧﺮﻳﺪ ﻣﺠﺪد از ﭼﻪ روﺷﻬﺎي ﻣﻲ ﺗﻮان اﺳﺘﻔﺎده ﻛﺮد؟ در ن 169 -7ﻛﻨﺘﺮل و ﻧﻈﺎرت ﺑﺮ ﺑﺮﻧﺪ در ﺑﺎزار • ﺧﻼﻗﻴﺖ ،ﻃﺮح اﻳﺪه ﻫﺎي ﺟﺪﻳﺪ ﻳﺮاي ﺣﻔﻆ و ﮔﺴﺘﺮش ﺑﺎزار • آﻣﺎدﮔﻲ ﭘﺎﺳﺨﮕﻮﻳﻲ در ﺑﺮاﺑﺮ اﺳﺘﺮاﺗﮋي ﻫﺎي رﻗﺒﺎ 170 در ن 9 1436/07/23 ﺻﻨﻌﺖ ﭘﻮﺷﺎﮎ ،ﺣﺮﮐﺘﯽ ﺑﺴﻮﯼ ﻓﺮﺩﺍ ﺑﺮرﺳﻲ ﻧﻤﻮﻧﻪ ﻫﺎي ﻣﻮﻓﻖ در ﺻﻨﻌﺖ ﭘﻮﺷﺎك • ﺗﺎرﻳﺨﭽﻪ • رﻣﺰ ﻣﻮﻓﻘﻴﺖ • وﺿﻌﻴﺖ ﺻﺎدرات ﭼﻴﻦ )اﻣﭙﺮاﺗﻮري ﻧﻮﻳﻦ( • ﺑﺎزارﻫﺎي ﻫﺪف ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف ﺳﺎل 1870ﻣﻴﻼدي:آﻏﺎز ﻓﻌﺎﻟﻴﺖ ﺻﻨﻌﺘﻲ؛ اﺣﺪاث اوﻟﻴﻦ ﻛﺎرﺧﺎﻧﻪ ﭘﻮﺷﺎك؛ دوره 1870ﺗﺎ :1949ﺗﻮﺳﻌﻪ ﻛﺎرﺧﺎﻧﺠﺎت؛ ﺑﻜﺎرﮔﻴﺮي 745000ﻧﻔﺮ؛ﻋﺪم اﺳﺘﻔﺎده از اﺗﻮﻣﺎﺳﻴﻮن؛ دوره 1950ﺗﺎ :1955ﺑﺮﻧﺎﻣﻪ 5ﺳﺎﻟﻪ دوﻟﺖ ﺑﺮاي ﺑﺮآورده ﻧﻤﻮدن ﺗﻤﺎﻣﻲ ﻧﻴﺎزﻫﺎي اﻳﻦ ﺻﻨﻌﺖ؛ ﺳﺎل 1979ﻣﻴﻼدي:آﻏﺎز دوره دوم ﺗﻮﺳﻌﻪ؛ ﻣﺪرن ﺳﺎزي ﻛﺎرﺧﺎﻧﺠﺎت ﭘﻮﺷﺎك؛ دوره 1997ﺗﺎ :2002ﺗﺒﺪﻳﻞ ﺷﺪن ﺑﻪ ﺑﺰرﮔﺘﺮﻳﻦ ﺗﻮﻟﻴﺪﻛﻨﻨﺪه و ﺻﺎدرﻛﻨﻨﺪه ﭘﻮﺷﺎك ﺟﻬﺎن؛ ﻛﺎﻫﺶ اﺷﺘﻐﺎل از 10.6ﻣﻴﻠﻴﻮن ﻧﻔﺮ ﺑﻪ 7.89ﻣﻴﻠﻴﻮن ﻧﻔﺮ؛ 10 1436/07/23 ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف ﭼﻴﻨﻲ ﻫﺎ رﻣﺰ ﻣﻮﻓﻘﻴﺖ ﺧﻮد را در ﭘﻴﺮوي از 4اﻟﮕﻮ ﻣﻲ داﻧﻨﺪ: اﻟﮕﻮي-1ﻛﺎﻫﺶ ﺻﺎدرات ﻛﺎﻻي ﻣﻴﺎﻧﻲ و اﻓﺰاﻳﺶ ﺻﺎدرات ﻛﺎﻻي ﻧﻬﺎﻳﻲ ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف اﻟﮕﻮي -2ﺗﻤﺮﻛﺰ ﺑﺮ روي ﻳﻚ ﺳﺮي ﻣﺤﺼﻮﻻت ﻣﺸﺨﺺ ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ ﭘﺘﺎﻧﺴﻴﻞ ﻣﻮﺟﻮد ﺟﻬﺖ ﺻﺎدرات 11 1436/07/23 ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف اﻟﮕﻮي -3ﺑﻜﺎرﮔﻴﺮي ﻗﺎﻧﻮن واردات ﺑﺪون ﺣﻘﻮق ﮔﻤﺮﻛﻲ ﻣﻮاد اوﻟﻴﻪ در ازاي ﺻﺎدرات ﻣﺤﺼﻮل ﻧﻬﺎﻳﻲ)ﻗﺎﻧﻮن ﻓﺮآﻳﻨﺪ ﺻﺎدرات( ﺣﺠﻢ اﺳﺘﻔﺎده از ﻗﺎﻧﻮن ﻓﺮآﻳﻨﺪ ﺻﺎدرات]ﻣﻴﻠﻴﺎرد دﻻر[ ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف اﻟﮕﻮي -4ﺗﻌﻴﻴﻦ ﺑﺎزارﻫﺎي ﻋﻤﺪه واردات ﻣﻮاد اوﻟﻴﻪ و ﺻﺎدرات ﻣﺤﺼﻮل ﺟﻬﺖ ﺗﻤﺮﻛﺰ و ﺑﺮﻧﺎﻣﻪ رﻳﺰي ﺑﺮ روي آﻧﻬﺎ ﺣﺠﻢ ﺻﺎدرات ﺑﻪ ﺑﺎزارﻫﺎي ﻫﺪف ]ﻣﻴﻠﻴﺎرد دﻻر[ 12 1436/07/23 ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف ﺣﺠﻢ ﺗﻮﻟﻴﺪ ﭘﻮﺷﺎك ﭼﻴﻦ]ﻣﻴﻠﻴﺎرد ﺛﻮب ﻳﺎ ﻗﻄﻌﻪ[ اﻓﺰاﻳﺶ ﺣﺠﻢ ﺗﻮﻟﻴﺪ ﭘﻮﺷﺎك در اداﻣﻪ ﻣﻮﻓﻘﻴﺖ در ﺻﺎدرات آن ﺑﻮد. ﺻﺎدرات از %40در ﺳﺎل1980ﺑﻪ %70در ﺳﺎل 2001اﻓﺰاﻳﺶ ﻳﺎﻓﺖ. -ﺣﺠﻢ ﺻﺎدرات در ﺳﺎل 2002ﺑﻪ 41/3ﻣﻴﻠﻴﺎرد دﻻر رﺳﻴﺪ. ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف ﺑﺎزارﻫﺎي ﻫﺪف ﺗﻮﻟﻴﺪات ﭘﻮﺷﺎك ﭼﻴﻦ ﺑﻪ ﻫﻤﺮاه ﺳﻬﻢ ﻫﺮﻳﻚ از آﻧﻬﺎ از ﻛﻞ ﺻﺎدرات 13 1436/07/23 ﺻﻨﻌﺖ ﭘﻮﺷﺎﮎ ،ﺣﺮﮐﺘﯽ ﺑﺴﻮﯼ ﻓﺮﺩﺍ • ﺗﺎرﻳﺨﭽﻪ • رﻣﺰ ﻣﻮﻓﻘﻴﺖ ﺗﺮﻛﻴﻪ )ﻗﺪرﺗﻲ ﻧﻮﻇﻬﻮر( ﺗﺎرﻳﺨﭽﻪ • وﺿﻌﻴﺖ ﺻﺎدرات • ﺑﺎزارﻫﺎي ﻫﺪف رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف دوره 1923ﺗﺎ 1962ﻣﻴﻼدي:آﻏﺎز ﻓﻌﺎﻟﻴﺖ ﺻﻨﻌﺘﻲ ﭘﻮﺷﺎك در ﺗﺮﻛﻴﻪ؛ دﻫﻪ ﻫﻔﺘﺎد ﻣﻴﻼدي):(1970sﺗﻮﺳﻌﻪ ﻛﺎرﺧﺎﻧﺠﺎت و ﻣﺪرن ﺳﺎزي ﺗﻜﻨﻮﻟﻮژي ﺗﻮﻟﻴﺪ ﭘﻮﺷﺎك؛ دﻫﻪ ﻫﺸﺘﺎد ﻣﻴﻼدي):(1980sآﻏﺎز ﺷﺘﺎب ﺻﺎدرات ﭘﻮﺷﺎك و روﻧﺪ روﺑﻪ رﺷﺪ آن در اﻳﻦ دﻫﻪ دﻫﻪ ﻧﻮد ﻣﻴﻼدي):(1990sدوره ﺑﻬﺮه ﺑﺮداري و ﻛﺴﺐ ﺳﻬﻢ %20از ﻛﻞ ﺻﺎدرات ﺗﺮﻛﻴﻪ 14 1436/07/23 ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف ﺗﺮك ﻫﺎ رﻣﺰ ﻣﻮﻓﻘﻴﺖ ﺧﻮد را در ﺻﻨﻌﺖ ﭘﻮﺷﺎك در ﻣﻮارد زﻳﺮ ﻣﻲ ﺑﻴﻨﻨﺪ: -1ﺑﻬﺮه ﻣﻨﺪي از ﻣﻮاد اوﻟﻴﻪ ارزان و ﻣﻨﺎﺳﺐ -2ﻧﺰدﻳﻜﻲ ﺑﻪ ﺑﺎزارﻫﺎي ﻋﻤﺪه ﻣﺎﻧﻨﺪ اﺗﺤﺎدﻳﻪ اروﭘﺎ -3زﻣﺎن ﺗﺤﻮﻳﻞ) (Delivery timeﻛﻮﺗﺎه ﺑﻪ ﺧﺎﻃﺮ ﻣﻮﻗﻌﻴﺖ ﺟﻐﺮاﻓﻴﺎﻳﻲ -4ﺑﺎﻻ ﺑﻮدن ﺗﻮان ﭘﺎﺳﺨﮕﻮﻳﻲ ﺳﺮﻳﻊ)(Quick Response -5ﭘﻴﺮوي از ﺳﻴﺎﺳﺖ ﻫﺎي ﺗﺠﺎرت آزاد اﺗﺤﺎدﻳﻪ اروﭘﺎ -6ﺑﻬﺮه ﻣﻨﺪي از ﺻﻨﺎﻳﻊ ﺗﻮﻟﻴﺪﻛﻨﻨﺪه ﻣﻠﺰوﻣﺎت ﺻﻨﻌﺖ ﭘﻮﺷﺎك -7ﺑﺎﻻ ﺑﻮدن ﺗﻮان ﻃﺮاﺣﻲ و ﻧﻮآوري در ﻣﺪ -8ﺣﺴﺎﺳﻴﺖ ﻧﺴﺒﺖ ﺑﻪ آراﻣﺶ روﺣﻲ و وﺿﻌﻴﺖ زﻧﺪﮔﻲ ﻛﺎرﮔﺮان ﺗﻮﻟﻴﺪ ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف 15 1436/07/23 ﺗﺎرﻳﺨﭽﻪ رﻣﺰ وﺿﻌﻴﺖ ﺑﺎزارﻫﺎي ﻣﻮﻓﻘﻴﺖ ﺻﺎدرات ﻫﺪف ﻋﻮاﻣﻞ ﻣﺆﺛﺮ ﺑﺮ ﻗﺪرت رﻗﺎﺑﺖ در ﺻﻨﻌﺖ ﭘﻮﺷﺎك • ﻫﺰﻳﻨﻪ ﻫﺎي دﺳﺘﻤﺰدي و ﻏﻴﺮ دﺳﺘﻤﺰدي ﻛﺎرﮔﺮ 184 در ن 16 1436/07/23 Garment Workers Wages across the World, 2010 Country United States United Kingdom Venezuela Costa Rica Guatemala Colombia Honduras Philippines China Peru El Salvador Jordan Malaysia Hourly Wage 8.25-14.00$ 7.58-9.11$ 2.73$ 2.19$ 1.21$ 1.20$ 1.02$ 0.94-1.00$ 0.93$ 0.92$ 0.92$ 0.74$ 0.73$ Iran? در ن Country Nicaragua Bahrain Thailand India Mauritius Vietnam Egypt Mexico Sri Lanka Pakistan Indonesia Cambodia Bangladesh Hourly Wage 0.65$ 0.57$ 0.56$ 0.55-0.68$ 0.55-0.65 0.52$ 0.50-0.87$ 0.50-0.53$ 0.46$ 0.37$ 0.35$ 0.24$ 0.21$ 0.7 - 1 $ 185 ﻣﻬﺎرت و ﻛﺎراﻳﻲ ﻛﺎرﮔﺮ،• ﺳﻄﺢ ﺳﻮاد ، آب،• زﻳﺮﺳﺎﺧﺖ ﻫﺎي ﻛﺸﻮر )در دﺳﺘﺮس ﺑﻮدن و ﻫﺰﻳﻨﻪ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ (ﻣﺨﺎﺑﺮات و ﺣﻤﻞ و ﻧﻘﻞ در ن 17 186 1436/07/23 Global electricity price comparison 2011-2012 Country Argentina Australia Belgium Bhutan Brazil Canada China Chile Croatia Denmark Dubai Finland France Germany Guyana Hungary US cents/1kWh 05.74 25 29.06 01.88 to 04.40 34.18 10.78 16.0 23.11 17.55 40.38 07.62 20.65 19.39 36.48 26.80 23.44 Country Hong Kong Iceland Ireland Italy US cents/1kWh 12.04 03.93 28.36 28.39 Jamaica 07.35 up to 100 kWh, 16.80 beyond 15.40 Latvia 07.42 Malaysia 11.11 Moldova Netherlands 28.89 02.06 up to 50 kWh, for a maximum of Pakistan 14.62 beyond 700 kWh 10.44 Perú Philippines 30.46 25.25 Portugal 09.58 Russia Singapore 22.83 در ن 187 Global electricity price comparison 2011-2012 Country Spain South Africa Sweden Taiwan Thailand Tonga Turkey Iran UK Ukraine Uruguay USA Uzbekistan Vietnam در ن 18 US cents/1kWh 27.06 05.37 27.10 07 up to 17 04.46 up to 09.79 57.95 13.1 02.00 to 06.00 21.99 03.05 (first 150kWh), 03.95 14.47 to 22.89 11.20 04.95 06.20 to 10.01 188 1436/07/23 • دﺳﺘﺮﺳﻲ ﺑﻪ ﺑﺎزار ﻓﺮوش -زﻣﺎن اﻧﺘﻈﺎر )(lead time زﻣﺎن ﻣﺎﺑﻴﻦ ﺳﻔﺎرش ﻛﺎﻻ ﺗﺎ درﻳﺎﻓﺖ آن Lead time: • ﻧﺮخ ﺗﻌﺮﻓﻪ ﮔﻤﺮﻛﻲ ﺣﻘﻮق ورودي اﻟﻴﺎف ﭘﻨﺒﻪ%15 : ﺣﻘﻮق ورودي ﻧﺦ ﭘﻨﺒﻪ اي%30 : ﺣﻘﻮق ورودي ﭘﺎرﭼﻪ %70 :ﻳﺎ ﻛﻴﻠﻮﻳﻲ 37000رﻳﺎل )ﻫﺮ ﻛﺪام ﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ( ﺣﻘﻮق ورودي ﭘﻮﺷﺎك %100 :ﻳﺎ ﻛﻴﻠﻮﻳﻲ 250000رﻳﺎل )ﻫﺮ ﻛﺪام ﺑﻴﺸﺘﺮ ﺑﺎﺷﺪ( ﻃﺒﻖ آﻣﺎر ﻏﻴﺮ رﺳﻤﻲ در ﺣﺎل ﺣﺎﺿﺮ ﺣﺪود 70درﺻﺪ ﭘﻮﺷﺎك در ﺑﺎزار اﻳﺮان ﺧﺎرﺟﻲ اﺳﺖ ﻛﻪ ﺑﻴﺶ از 90درﺻﺪ آن ﺑﻪ ﺻﻮرت ﻗﺎﭼﺎق وارد ﻛﺸﻮر ﻣﻲ ﺷﻮد. 189 در ن • ﻣﻮاﻓﻘﺘﻨﺎﻣﻪ ﻫﺎي ﺗﺠﺎرت ﺗﺮﺟﻴﺤﻲ ﺑﺎ ﺗﺄﻣﻴﻦ ﻛﻨﻨﺪﮔﺎن ﻣﻨﻄﻘﻪ اي ﻣﻮاﻓﻘﺘﻨﺎﻣﻪ ﻫﺎي ﺗﺠﺎرت ﺗﺮﺟﻴﺤﻲ وآزاد ﻛﻪ در زﺑﺎن اﻧﮕﻠﻴﺴﻲ ﺗﺤﺖ ﻋﻨﻮان ) Preferential Trade Agreements(PTAﺷﻨﺎﺧﺘﻪ ﺷﺪه اﺳﺖ ،در واﻗﻊ ﺗﻮاﻓﻖ ﻫﺎي ﺑﻴﻦ اﻟﻤﻠﻠﻲ ﻣﻴﺎن ﻛﺸﻮرﻫﺎ ﺑﻪ ﻣﻨﻈﻮر ﺗﺴﻬﻴﻞ ﺗﺠﺎرت ودر ﻧﺘﻴﺠﻪ اﻓﺰاﻳﺶ ﺣﺠﻢ ﺗﺠﺎرت ﻣﻴﺎن ﻛﺸﻮرﻫﺎي ﻃﺮف ﺗﺠﺎري اﺳﺖ.در اﻳﻦ ﻗﺒﻴﻞ ﻣﻮاﻓﻘﺘﻨﺎﻣﻪ ﻫﺎ ،دوﻟﺘﻬﺎ ﺗﺴﻬﻴﻼﺗﻲ را در ﻓﺮاﻳﻨﺪ ﺗﺠﺎرت ﺑﻴﻦ اﻟﻤﻠﻠﻲ ﺑﺮاي ﻳﻜﺪﻳﮕﺮ ﺑﻪ وﺟﻮد ﻣﻲ آورﻧﺪﻛﻪ درﻣﻮرد ﺳﺎﻳﺮ ﻛﺸﻮرﻫﺎ ﻗﺎﺋﻞ ﻧﻤﻲ ﺷﻮﻧﺪ. اﻳﺮان ﭼﻨﺪ ﻣﻮاﻓﻘﺘﻨﺎﻣﻪ ﺗﺠﺎرت ﺗﺮﺟﻴﺤﻲ در ﺣﺎل اﺟﺮا ﺑﺎ ﻛﺸﻮرﻫﺎي زﻳﺮ دارد: ازﺑﻜﺴﺘﺎن ،ﺗﻮﻧﺲ ،ﺳﻮرﻳﻪ ،ﭘﺎﻛﺴﺘﺎن ،ﻛﻮﺑﺎ ،وﻧﺰوﺋﻼ ،ﻗﺮﻗﻴﺰﺳﺘﺎن ،ﺗﺮﻛﻴﻪ ،ﺑﻮﺳﻨﻲ و ﻫﺮزﮔﻮﻳﻦ، ﻛﺸﻮرﻫﺎي ﻋﻀﻮ ﺳﺎزﻣﺎن ﻫﻤﻜﺎري ﻫﺎي اﻗﺘﺼﺎدي ﻣﻨﻄﻘﻪ اي )اﻛﻮﺗﺎ( 190 در ن 19 1436/07/23 • ﻓﺮاﻳﻨﺪ ﮔﻤﺮك • دﺳﺘﺮﺳﻲ ﺑﻪ ﻣﻮاد اوﻟﻴﻪ )ﻧﺦ ،ﭘﺎرﭼﻪ و ﻣﻠﺰوﻣﺎت( ﺑﺎ ﻗﻴﻤﺖ رﻗﺎﺑﺘﻲ • ﺷﺮاﻳﻂ اﻗﺘﺼﺎدي و ﺳﻴﺎﺳﻲ ﻛﺸﻮر • ﺗﻮان ﺟﺬب ﺳﺮﻣﺎﻳﻪ ﻫﺎي ﺧﺎرﺟﻲ در ن 191 • ﺗﺠﺮﺑﻪ ﻣﺪﻳﺮﻳﺘﻲ و ﺑﺎزارﻳﺎﺑﻲ • ﺗﻮاﻧﺎﻳﻲ اراﺋﻪ ﺑﺴﺘﻪ ﻛﺎﻣﻞ ﺧﺪﻣﺎت )(full package ﺑﺎزارﻳﺎﺑﻲ و ﺗﺤﻘﻴﻘﺎت +ﻃﺮاﺣﻲ +ﺗﻮﻟﻴﺪ +ﺗﻮزﻳﻊ 192 در ن 20 1436/07/23 Role of apparel engineers Simple industrial engineering applied specifically to the apparel industry. Main activities of an industrial/apparel engineer: •Plant layout •Production flow system •Machines and adjustments •Operator performance •Operator training •Production control system •Cutting room •Quality control •Distribution •Payroll system / incentives •Plant safety •Maintenance در ن 193 ﺑﺨﺶ ﻫﺎي ﻣﺨﺘﻠﻒ ﻳﻚ واﺣﺪ ﺗﻮﻟﻴﺪي ﭘﻮﺷﺎك :ﻳﻚ واﺣﺪ ﺗﻮﻟﻴﺪي ﭘﻮﺷﺎك ﺑﺴﺘﻪ ﮔﺴﺘﺮدﮔﻲ و ﺣﺠﻢ ﻓﻌﺎﻟﻴﺖ ﻫﺎي آن ﻣﻲ ﺗﻮاﻧﺪ ﺷﺎﻣﻞ ﺑﺨﺶ ﻫﺎي زﻳﺮ ﺑﺎﺷﺪ Designing room Cutting room واﺣﺪ ﻃﺮاﺣﻲ ﺳﺎﻟﻦ ﺑﺮش ﺳﺎﻟﻦ ﻻﻳﻲ ﭼﺴﺐ زﻧﻲ Fusing Sewing room Pressing room Storekeeping room ﺳﺎﻟﻦ دوﺧﺖ ﺳﺎﻟﻦ ﭘﺮس اﻧﺒﺎر ، ﺑﺎزرﮔﺎﻧﻲ،ﺗﻘﺴﻴﻢ ﺑﻨﺪي ﻣﺮاﺣﻞ ﻓﻮق ﺑﺮ اﺳﺎس ﻣﺮاﺣﻞ ﻓﻨﻲ و ﺗﻜﻨﻮﻟﻮژﻳﻜﻲ اﺳﺖ و از ﺑﻴﺎن واﺣﺪﻫﺎي ﻣﺎﻟﻲ . ﺻﺮﻓﻪ ﻧﻈﺮ ﺷﺪه اﺳﺖ... ﭘﺸﺘﻴﺒﺎﻧﻲ و در ن 21 194 1436/07/23 Apparel production systems A- Individual system/whole garment system In this system the entire garment operation process is done by an individual. From cutting to packing the individual person performs the entire job. With this production system the operator would be given a bundle of cut work and would proceed to sew it according to his or her own method of work. Of necessity, the labour required by this system must be highly skilled and versatile, a combination which is becoming exceedingly rare and increasingly expensive. This type of system is effective when a very large variety of garments have to be produced in extremely small quantities. A typical application would be in the sewing room of a boutique, which produces its own merchandise. در ن 195 B- Group system This is a development of the individual system, with the difference that the operators specialize in one major component and sew it from beginning to end. For example, an operator specializing in backs would assemble the back and yoke, label attaching, etc., and performs all the operations required to finish that particular component. The sewing room would have a number of sections, each containing multitalented operators capable of performing all the operations required for a specific component. در ن 22 196 1436/07/23 در ن 197 This is a very efficient system for producing a variety of styles in reasonable quantities. Advantages: 1. As the labour of all levels, i.e. semi-skilled, skilled, trainee, can be used in this system, the labour cost is less compared to individual system. 2. Productivity is higher compare to individual system, because of use of special machine and all types of labour. 3. This system is very efficient for producing a variety of styles in reasonable quantities. 4. Automation and specialization can be done. 5. Absenteeism and machine breakdown problems will not cause serious problems در ن 23 198 1436/07/23 Disadvantages: 1. All the operators are involved in the work to maintain the quality of garment. 2. Even though productivity is high still the highly skilled operators required to perform simple operation within the section. 3. Group of people are involved in each section, so we require more WIP which increases the inventory cost. 4. As this is not a bundling system, there are more chances of shade and size variation; hence quality and production are affected. در ن 199 C- Progressive bundle synchro straight line system – batch system As the name suggests, this system is based on a synchronized flow of work through each stage of producing a garment. Time-synchronization is the most important factor of this system because the flow of work cannot be synchronized if there are considerable variations in the standard times allowed for all the operations performed on the line. The synchro system by its very nature is rigid and particularly vulnerable to absenteeism and machine breakdowns. In addition, this system requires a sufficient volume of the same type of garment to keep the line in continuous operation. To be effective, this system requires: Volume production Accurate line balancing Skilled supervision Reserve operators Reserve machinery and equipment در ن 24 200 1436/07/23 Advantages: 1. Laboursof all levels, i.e., unskilled, skilled, semi-skilled labours, are involved in this system where the operations are broken into small simple operation. Hence the cost of labour is very cheap. 2. Here the quantity of each component is checked during the individual operation itself, so the quality is good. 3. The components are moved in bundles from one operation to next operation, so there is less chance for confusion like, lot mix-up, shade variation, size variation, etc. 4. Specialization and rhythm of operation increases productivity. 5. As the WIP is high in this system, it is a stable system. Because of the buffer, the breakdown, absenteeism, balancing of line, change of style can be easily managed. 6. An effective production control system and quality control system can be implemented. (a) Time study, method study techniques; (b) Operator training programme; (c) Use of material handling equipments, such as centre table, chute, conveyor, trolley, bins, etc. 7. Bundle tracking is possible, so identifying and solving the problems becomes easy. در ن 201 Disadvantages: 1. Balancing the line is difficult and this problem is solved by effective supervisor. 2. Proper maintenance of equipment and machinery is needed. 3. Proper planning is required for each batch and for each style, which takes lot of time. 4. Improper planning causes labour turnover, poor quality, less production, etc. 5. Increase in WIP in each section increases the inventory cost. 6. Planned and proper layout should be made to make the system effective, i.e. smooth flow of material. 7. Variety of styles, less quantity is not effective in this system. 8. Shuttle operators and utility operators are needed in every batch to balance the line effectively. در ن 25 202 1436/07/23 D- Unit production system (UPS) As a mechanical system this has been in use for many years, but a major advance was made in 1983 when computers were first used to plan, control and direct the flow of work through the system. The essential feature of this type of system is as follows: 1. The unit of production is a single garment and not in bundles. 2. The garment components are automatically transported from work station to work station according to a pre-determined sequence. 3. The work stations are so constructed that the components are presented as close as possible to the operator’s left hand in order to reduce the amount of movement required to grasp and position and component to be sewn. 26 در ن 203 در ن 204 1436/07/23 The operational principles are as follows: All the components for one garment are loaded into a carrier at a work station especially designed for this purpose. The carrier itself is divided into sections, with each section having a quick-release clamp which prevents the components from falling out during movement through the system. When a batch of garments has been loaded into carriers it is fed past a mechanical or electronic device which records the number of the carrier and addresses it to its first destination. Some of the more intelligent systems address the carriers with all the destinations they have to pass through to completion در ن 205 The loaded carriers are then fed on to the main powered line, which continually circulates between the rows of machines. This main, or head, line is connected to each work station by junctions that get opened automatically if the work on a carrier is addressed to that particular station. The carrier is directed to the left side of the operator and waits its turn along with the other carriers in the station. When the operator has completed work on one carrier, a push button at the side of the sewing machine is pressed and this actuates a mechanism, which transports the carrier back to the main line. As one carrier leaves the station, another is automatically fed in to take its place. When the carrier leaves the station, it is recorded on the data collection system, and then is addressed to its next destination. در ن 27 206 1436/07/23 Advantages: 1. Bundle handling is completely eliminated. 2. The time involved in the pickup and disposal is reduced to minimum. 3. Output is automatically recorded, hence eliminates the operator to register the work. 4. The computerized systems automatically balance the work between stations. 5. Up to 40 styles can be produced simultaneously on one system. Disadvantages: 1. Unit production system requires high investments. 2. The payback period of the investment takes long time. 3. Proper planning requires being effective. در ن 28 207