Making Soap from Nutmeg

advertisement

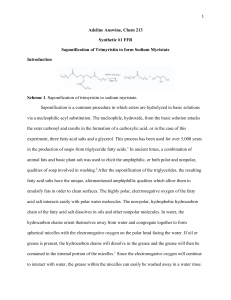

Making Soap from Nutmeg 1|ONWAEZE Introduction Saponification is the predominant process utilized in making soap. It is one of the oldest scientific methods known to man, and has enjoyed a long history of application, as it’s been used for over 5,000 years1. In general, saponification involves the alkali hydrolysis of a carboxylic ester group in a fatty acid to produce a carboxylic acid salt- the soap, and an alcohol. This idea is known to have been coveted from ancient times, where soap was produced by combining animal fat (which contains long fatty acid chains) with alkali-containing plant ash2. Soap, as mentioned previously is a fatty acid salt (usually salts of alkali metals) 1. Soap constitutes of a long- linear aliphatic carbon chains that is attached to a carboxylic acid head group. Soap is most commonly utilized as a cleaning agents in household and industries. The hydrophobic nature of its aliphatic carbon chains combined with the hydrophilic nature of its carboxylic acid head group, gives soap an amphiphillic nature that facilitates it cleaning abilities3. That is, with its hydrophobic chains it can attract and emulsify grease, and with its hydrophilic group, it can attract water. The water attached to the polar end, is thus able to rinse out the resulting emulsified grease. Over the years, soap has been able to mediate hygienic environments, which has tremendously aided in preventing the spread of infectious diseases 3. Many detergent industries have incorporated antiseptics and scents to make soap more medically and aesthetically appealing4. Figure 1: Balanced chemical equation of the synthesis of sodium myristate from trimyristin The above Figure 11 shows the balanced chemical equation of making soap from trimyristin, a certain triglyceride (containing three fatty acid chains, each connected to hydroxyl head group) extracted from nutmeg. Here trimyristin is converted to sodium myristate, the carboxylic salt of trimyristin. This saponification reaction (shown in the scheme 1 below) thus represent a classical means of making soap. 2|ONWAEZE Scheme 1: The saponification mechanism of Trimyristin to Sodium myristate In the first step of the scheme 1 mechanism, the hydroxide from the sodium hydroxide base acts as a nucleophile which attacks the carbonyl group of the trimyristin (Structure 1), causing the electrons on the C-O double bond to resonate to the oxygen atom, leading to an unstable tetrahedral intermediate (Structure 2). The tetrahedral intermediate phase occurs transiently as the electron on the negatively charged oxygen reforms a C=O bond while spontaneously displacing the adjacent ether C-O bond. The displaced structure (Structure 3a) consequently contains a negatively charged oxygen that abstracts hydrogen from the hydroxyl group of myristrate, the newly fatty acid structure (Structure 3b) that was formed in the previous step. The product of this abstraction is a newly formed myristic acid (Structure 4a) that forms an electrostatic interaction with the sodium cation of the sodium hydroxide base. The other product is a trimyristin-like structure (Structure 4b) that has lost one of its three fatty acid or myristin chains. This marks one cycle of the mechanism. The mechanism occurs for two more cycles, leading to the formation of three sodium myristate compounds and one glycerol compound. In this experiment, crude trimyristin is isolated from nutmeg in a reflux reaction, and purified by recrystallization. The presence of pure trimyristin is verified by melting point and IR spectroscopy. Pure trimyristin is converted to sodium myristrate in a saponification reaction. The sodium myristate (soap) is analyzed by TLC, melting point, IR, as well as two standard reagent tests. Experimental: Trimyristin. Ground nutmeg (10g) mixed with diethyl ether (30mL, 289mmol) was heated by reflux and stirred for 30 minutes. The reaction mixture was then cooled, vacuum filtered, and washed with ether (2 x 20mL). The combined yellow liquid filtrate was evaporated to yield yellow crude solid (2.02g). The crude solid was recrystallized with warm ethanol (95%, 20ml) and monitored with TLC (50% ethyl acetate/hexanes). The resulting crystals were separated with vacuum filtration, washed with chilled ethanol (95%, 5mL), and dried slowly to yield white solid crystals (1.82g, 18%, 2.51mmol) Rf 0.87; mp 5254°C, lit. 56-57°C; IR (ATR) Vmax (cm-1) 2914, 2848, 1731, 1113. Sodium Myristate. Ethanol (95%, 4mL), sodium hydroxide pellets (0.04g), and trimyristin (200mg, 0.28mmol) were added to a round bottom flask, stirred, and refluxed for 20 minutes. Upon cooling to room temperature, the mixture is poured into a solution of distilled water (5mL) and saturated sodium chloride (10mL), and stirred to yield a clear voluminous solid. The solid (soap) was cooled for 10 minutes, vacuum filtered from solution, and washed with cold water (30mL). The soap solid was dried to yield white solid crystals (0.18g, 94%, 0.78mmol) mp 230-235°C, lit. 245-250°C; IR (ATR) Vmax (cm-1) 2919, 2848, 1679. Test for sodium myristate. Sodium myristate (0.25g, 1.09mmol) was dissolved in distilled water (25ml) and 5ml of the solution were added to two test tubes each. To the first test tube, olive oil (10 drops) was added and the solution was mixed vigorously to yield a white homogenous mixture. To the second test tube, ferrous chloride (5 drops) was added and the solution was mixed vigorously to yield a yellow gelatinous precipitate. 3|ONWAEZE Discussion: This experiment had three stages: Isolation, synthesis, and test analysis. In the isolation portion, trimyristin was extracted from nutmeg through a reflux reaction. Diethyl ether, which shared similar polarities with trimyristin, was used to preferentially extract trimyristin from the more hydrophobic (less polar) components of nutmeg. After filtration and drying, the crude trimyristin was generated. The crude crystals were purified via recrystallization, and this purity was checked by TLC. For TLC, a spot from the purified crystals and a spot from the recrystallization solution (containing crude trimyristin and other nutmeg residues) were run on the TLC plate. The results showed that trimyristin produced a distinct spot, Rf 0.87, while the recrystallization solution produced multiple spots (reflecting the multiple components of nutmeg), thus indicating that trimyristin was pure. This Rf value was similar to Rf 0.9 value generated by past experiment1, further verifying that pure trimyristin was made. Furthermore, the purified trimyristin was analyzed with %recovery, melting point, and IR spectroscopy. The percent recovery of trimyristin isolation was 14% which was significantly higher than the 5% produced from previous experiment1. The low percent recovery is due to the fact that that trimyristin is present at very low quantities in nutmeg (about 10-20%)2. Furthermore, the melting point of the purified trimyristin was 52-54°C which was a little less than to the standard of 56-57°C 5. Depression in the melting point was most likely due to the presence of traces of the nutmeg components (that was perhaps too negligible to reflect on TLC) in the trimyristin. Lastly, key peaks characteristic of trimyristin were observed on the IR spectra (Figure 1, Supplemental information). The main functional groups on trimyristin are the C=O and the C-O bonds of the ester functional group, and the associated peaks of the bonds are to be reflected on the IR spectrum. On the IR spectra, a sharp peak at 1731cm-1 which represent the carbonyl C=O bond on the trimyristin is seen. Also a sharp peak at 1113cm-1 which represents the C-O bonds on the trimyristin is seen. These two peaks confirm the presence of the ester group on the trimyristin compound. Lastly, two peaks are seen at 2914cm-1 and 2849cm-1. Although these peaks represents the aliphatic hydrogens of the trimyristin’s long hydrophobic chains, they are less defining than the previous two peaks, as all IR spectra contain a peak within the 2900cm-1 – 2800cm-1 region. This IR spectra when compared to the standard showed great similarity. The standard showed two peaks at 2890cm-1 and 2917cm-1 representing the aliphatic C-H chains, a peak at 1750cm-1 representing the carbonyl C=O bond, and a peak at 1150cm-1, representing the C-O ester bond6. Overall, IR and melting point analysis suggests that trimyristin was present in the product. The purified trimyristin was converted to sodium myristate and glycerol in the synthetic phase of the experiment. This saponification reaction was facilitated by reflux, and the crude sodium myristate formed was purified by recrystallization. The purified sodium myristate was analyzed with % yield, melting point, and IR spectroscopy. The yield generated from purification was 94%, which suggested that the recrystallization technique was quite effective. This yield was slightly higher, but in the same range as the yield of 85% derived from a past experiment1. High yields in both experiments showed that recrystallization with ethanol was very effective for purifying sodium myristate. The next analysis on sodium myristate was the melting point determination. As sodium myristate is a salt that contains strong electrostatic forces (i.e. the interaction of the carboxylate ion and sodium), it requires very high heat energy to break the electrostatic forces. However, very high temperatures often decomposes solids. Sodium myristate is as a result seen to decompose at the high temperature of 235-240°C. This compares to the 245-250°C standard5 thus indicating that the desired myristic salt (i.e. the sodium myristate) was present in the product. Next, the functional groups present in the myristic salt was 4|ONWAEZE verified by IR (Figure 3, supplemental information). Because the synthesis of sodium myristate also led to the production of glycerol, a successful purification of sodium myristate should reflect the absence of glycerol hydroxyl peaks on the IR. Also, an absence of carboxylic ester peaks of the trimyristin starting material on the IR, will indicate isolation of pure sodium myristate. Based on this, the expected functional group to be seen on this IR includes the peaks by the C=O and O-H of the carboxylate ion group, as well as the aliphatic C-H peaks of the long hydrophobic chains of sodium myristate. On IR spectra, a sharp peaks at 2919cm-1 is seen which reflects the carboxylate O-H bond. Another sharp peak at 1679cm is seen, reflecting the carboxylate C=O bond which was formed in the place of the carbonyl C=O bond of trimyristin that shows a peak at 1735cm-1 region. Lastly, a peak at 2848cm-1 is seen, indicating the presence of the aliphatic C-H bonds of the long hydrophobic chain of sodium myristate.). No carboxylic ester peaks (1735cm-1 and 1150cm-1) of trimyristin or alcohol O-H (seen in 3300-3000cm-1) from glycerol is seen on this IR. Thus this IR shows that sodium myristate was present with little or no traces of trimyristin and glycerol. Moreover, this IR peaks is also highly similar to the standard6. The standard shows two sharp peaks at the 2918cm-1 and 2964cm-1 representing the aliphatic C-H bond, and the carboxylic O-H bond respectively, and a peak at 1700cm-1 indicating carboxylic C=O bond6. This verified the success of the experiment in producing sodium myristate. The presence of sodium myristate was further verified using two standard tests, in the analysis portion of this experiment. Dissolved sodium myristate was tested separately with olive oil and ferrous chloride. The portion sodium myristate solution mixed with olive oil produced a foamy and soluble liquid. This result is explained by the fact that amphiphilic nature of soap allows it dissolve in both oil and water. It does this by forming a micelle, that is, a spherical structure that harbors the hydrophobic components (aliphatic soap chains and olive oil) in the spherical hollow, and exposes the hydrophilic content(soaps carboxylate group) at the spherical surface, where attract and dissolve in water. The homogenous soapy solution (reminiscent of the cleaning action of soap) is thus expected and verifies the presence of sodium myristate1. The other portion of dissolved sodium myristate was mixed with ferrous chloride. This mixture produces an insoluble gelatinous precipitate. The insoluble compound is caused when the iron cations replace the sodium of the myristic salt. Ferrous myristate however, is insoluble in water and thus causes a precipitate1. This is a classic example of what happens with hard water and soap1. As hard water contains ions like Mg2+ and Ca2+, when soap (containing sodium myristate) is added to it, the aforementioned ions displace sodium, producing calcium and/ or magnesium myristate, which much like ferrous myristate, forms and insoluble complex (i.e scum) that makes washing difficult. Thus the formation of this insoluble gelatinous precipitate, verifies the presence of sodium myristate. Yields produced in this experiment were great but could be improved. The 14% recovery could be improved by using a different solvent that is more similar in polarity with trimyristin. This would extract higher quantities of trimyristin form nutmeg, thus improving the % recovery. Also, the removal of the glycerol by-product in the synthetic reflux reaction would push the equilibrium to favor the formation of more sodium myristrate, as explained by (Le Chantelier’s principle.) thus improving the soap yield. Conclusion The percent recovery of trimyristin and the percent yield of sodium myristate were great, suggesting that the isolation, purification, and reflux reactions were effective. Also proof from melting point, IR, and standard reagent tests showed that trimyristin and sodium were made and at highly purified level. 5|ONWAEZE Reference 1 De Mattos, M.C.S.; Nicodem, D.E; Making soap from nutmeg J. Chem. Educ., 2002, 79, 94-95. 2 Phansteil IV, O.; Dueno, E; Wang, Q.X. Making soap from nutmeg. J. Chem. Educ., 1998, 75, 612-614. 3 De Mull, M.N.G.; Davis, T.H.; Evans, D.F.; Bhave, A.V.; Wagner, J.R. Soap from Nutmeg: An Integrated Introductory Organic Chemistry Laboratory Experiment. J. Chem. Educ; 2000, 16, 22, 8276–8284 4 Frignani, A.; Grassi, V.; Zucchi, F; and Zanotto, F. Mono-carboylate conversion coating for Az31 Mg alloy protection. Materials and Corrosion, 2011, 62, 995- 1002 5 Vold, R.D.; Reivere, R.; McBain, J.W. A Phase Rule Study of Sodium Myristate-Water. J. Am. Chem. Soc. 1941, 63, 1293–1296. 6 Sigma-Aldrich T5141 Sigma Glycerol trimyristate. http://www.sigmaaldrich.com/ catalog/product/sigma/t5141?lang=en&region=US (accessed March 12, 2013) 6|ONWAEZE