MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

PETROLEUM SCIENCE AND TECHNOLOGY

Vol. 21, Nos. 1 & 2, pp. 275–282, 2003

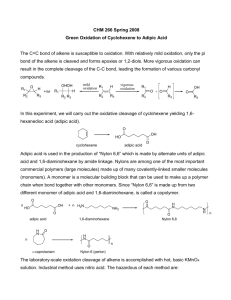

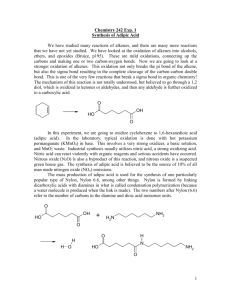

Green Catalytic Oxidation of Cyclohexanone

to Adipic Acid

Shi-gang Zhang, Heng Jiang,* Hong Gong,

and Zhao-lin Sun

Department of Materials Science, Fushun Petroleum

Institute, Fushun, P.R. China

ABSTRACT

Synthesis of adipic acid by catalytic oxidation of cyclohexanone with

30% hydrogen peroxide in the presence of sodium tungstate catalyst

can be well performed under reflux temperature. The adipic acid

isolated yield reaches to 82.1%, and the purity of the product is also

very high. The catalytic oxidation reaction takes place without any

organic solvent and phase-transfer agent. The effects over different

acidic ligands and the amount of the ligand on the catalytic oxidation

were investigated. The catalysts exhibit high activity for the catalytic

oxidation reaction of the mixture of cyclohexanone and cyclohexanol

to adipic acid by 30% hydrogen peroxide under reflux temperature.

*Correspondence: Heng Jiang, Department of Materials Science, Fushun

Petroleum Institute, Fushun 113001, P.R. China; E-mail: hjiang78@hotmail.

com.

275

DOI: 10.1081/LFT-120016948

Copyright & 2003 by Marcel Dekker, Inc.

1091-6466 (Print); 1532-2459 (Online)

www.dekker.com

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

276

Zhang et al.

Key Words: Adipic acid; Green catalytic oxidation; Cyclohexanone; Hydrogen peroxide.

INTRODUCTION

Adipic acid is an important chemical mainly used for manufacture of

nylon-6,6, whose production is up to 2.2 million metric tons per year

(Xuan, 1999). Currently the industrial production of adipic acid uses

nitric acid oxidation of cyclohexanol or a tow-step oxidation of cyclohexane process by nitric acid. The nitrous oxide is the inevitable stoichiometric waste produced by this process. Despite the efforts made to decrease

the emission of this waste by recovering or recycling of the nitrous oxide,

about 400,000 metric tons are still emitted into the environment each year,

which corresponds to 5–8% of the worldwide anthropogenic emission of

N2O (Noyori et al., 1998). As it is well known that the nitrous oxides cause

the ozone depletion as well as acid rain and smog which are harmful

for our earth. Together with the development of the environmental

legalization and the environmentally conscious of the common people,

to find a new clean way to produce adipic acid has become very necessary.

Many attempts have been made to substitute the classical process, such as

the direct oxidation of cyclohexane to adipic acid by molecular oxygen

(Schulz and Onopchenko, 1981) or by air (Park and Goroff, 1993),

manufacture of adipic acid by hydrocarboxylation of pentenic acid

(Denis et al., 1995; Bruner et al., 1998), and synthesis of adipic acid

from biomass-derived carbon sources (Frost and Draths, 1996) or from

D-glucose (Draths and Frost, 1994). But these processes would not be the

ideal one because of the low yield or the terminal products are too complex

for the isolation of the wanted product.

Aqueous hydrogen peroxide as an ideal clean oxidant also achieves

great interest. Noroyi et al., reported a practical method of oxidation

cyclohexene with 30% hydrogen peroxide in presence of small amounts

of Na2WO4 and [CH3(n-C8H17)3N]HSO4 as a phase transfer catalyst.

A novel clean peroxy tungstate-organic complex catalyst was also used

to catalyze oxidation of cyclohexene by 30% hydrogen peroxide to

produce adipic acid at a high yield (Ma et al., 2001). Long chain carbon

alkyl ammonium sulfate was used to substitute the expensive phrase

transfer catalyst to produce adipic acid and obtained a yield of 81.7%

(Gong et al., 2000). The industrial production of cyclohexene is mainly

by partially hydrogenation of benzene or by dehydration of cyclohexanol.

As the process needs critical conditions, the price of cyclohexene is very

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

Cyclohexanone Oxidation

277

high which cause much effect on the production cost of the adipic acid.

However the industrial process of oxidation cyclohexane to cyclohexanol

and cyclohexanone has become quite efficient. In this paper, we chose

Na2WO42H2O as catalyst to oxidize cyclohexanone to adipic acid by

30% hydrogen peroxide in the presence of different acidic ligands. The

effects of the kinds of the ligands, the amounts of the ligand and the reaction time on the catalytic reaction are studied. Further researches show

that the catalytic system also gives a well catalytic ability for the oxidation

of mixture of cyclohexanone and cyclohexanol. Based on these works,

we discuss the catalytic mechanism of this kind of catalysis oxidation.

EXPERIMENTAL

The reagents used in the reaction are analytical purity reagents.

0.825 g Na2WO4H2O (2.5 mmol), desired amounts of acidic ligand

and 44.5 mL 30% hydrogen peroxide (440 mmol) were placed in an

100 mL flask, stirred for 10–15 min to get a clear solution at room

temperature. Then 10.5 mL cyclohexanone (100 mmol) was added into

it without stopping stirring. Continue stirring the reaction mixture at a

reflux temperature for 8 h. After reaction was completed the reaction

mixture was cooled in the refrigerator for 12 h. Then white crystalline

product was obtained after filtration, washed with ice water and dried

in the air. The product was weighted and the isolated yield of the adipic

acid was calculated which was based on the cyclohexanone that was put

in the reaction flask. A melting point tube was used to measure the

melting point of the product (the thermometer is not justified). The

melting point of the product is mainly between 149 and 151 C (the

reported result is 152 C).

RESULTS AND DISCUSSION

The effect of different acidic ligands on the reaction is showed in

Table 1. It can be seen that there is no adipic acid crystalline obtained

when no acidic ligand is added into the reaction mixture. The isolated

yield increases noticeably when acidic ligand is present. It can be

explained that when the ligand is added into catalytic system, it can

coordinate with the water soluble sodium tungstate to form a water

soluble complex, which is easily to contact with the oil phase, thus the

reaction speed is accelerated. The highest yield showed in the Table 1

—

9.45

9.44

10.0

—

4.09

5.10

4.17

1.23

3.22

2.90

2.85

4.21

—

—

25 C pKa

0

74.8

72.1

71.1

23.7

62.4

74.3

67.0

58.6

59.7

15.9

70.1

20.4

55.2

44.8

Isolated yield (%)

Anthranilic acid

Phthalic acid

Benzoic acid

Hydroxylamine hydrochloride

Diaminehydrochloride

Hydrazine sulfate

Phosphoric acid

Phosphorous acid

Metaphosphoric acid

NaH2PO42H2O

NaHSO4

Sulfosalicylic acid

Salicylic acid

Sulfamic acid

p-Toluenesulfonic acid

Acidic ligand

2.05

2.95

4.21

—

—

—

2.12

2.15

—

—

—

—

2.98

—

—

25 C pKa

The effect of different acidic ligand on the catalytic reaction.

66.3

77.6

1.8

66.7

48.3

61.7

75.0

73.4

3.4

0

73.7

71.2

75.4

66.3

18.1

Isolated yield (%)

278

Reaction conditions: Na2WO42H2O, 2.5 mmol; catalyst/acid ligand ¼ 1/1 (mol ratio); 30% H2O2, 44.5 mL; cyclohexanone,

100 mmol; reaction time, 8 h; reflux temperature.

None

Pyrocatechol

Resorcinol

Hydroquinone

o-Phenylenediamine

2,4-Dinitrophenol

8-Quinolinol

L(þ)Ascorbic acid

Oxalic acid

Tartaric acid

Bromoacetic acid

Malonic acid

Succinic acid

Nicotinic acid

i-Nicotinic acid

Acidic ligand

Table 1.

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

Zhang et al.

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

Cyclohexanone Oxidation

279

is 77.6% when phthalic acid is used as the acidic ligand. It also can be

seen from Table 1 that for the same kind of ligands, the isolated yield of

adipic acid increases with the increasing acidity of the acidic ligand. The

acid condition is favored for the oxidation when hydrogen peroxide

is used as oxidant, but this is not the only factor. Although the acidity

of 8-quinolinol, pyrolatechol, resorcinol and hydroquinone is low, their

isolated yield of adipic acid is much higher than that of 2,4-dinitrophenol,

and bromoacetic acid. There may be something to do with the coordinate

effect of the ligand when it coordinates with sodium tungstate. The pKa

value of pyrocatechol, resorcinol and hydroquinone is in the range of 9–

10, however, the isolated yield of adipic acid is very high. Since these

phenolic compounds are radical inhibitors, we can infer that the oxidation reaction is not a free radical mechanism but coordination catalysis

mechanism.

The effect of different amounts of ligands on the reaction is showed

in Table 2. Phosophoric acid, sulfosalicylic acid, hydroquinone,

Table 2.

Acidic ligand

Phosphoric acid

Sulfosalicylic acid

Hydroquinone

Pyrocatechol

The effect of acidic ligand amount.

Ligand amount (mmol)

Product isolated

yield (%)

1.014

1.523

2.567

5.22

10.22

0.675

1.25

2.5

5.0

10.0

2.5

5.0

10.0

2.5

5.0

10.0

9.6

29.1

75.0

65.7

60.4

27.4

82.1

71.2

71.4

59.6

71.1

76.3

71.1

74.8

78.6

71.7

Reaction condition: Na2WO42H2O, 2.5 mmol; cyclohexanone,

100 mmol; 30% H2O2, 44.5 mL; reaction time, 8 h; reflux

temperature.

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

280

Zhang et al.

pyrocatechol are used with different amounts to study these effects.

Table 2 shows that the isolated yield of adipic is low if the amount of

acidic ligand is too little and too much. Using sulfosalicylic acid as ligand,

the isolated yield of adipic acid reaches the highest when the mole ratio of

the catalyst and the ligand is 2/1. When the amount of ligand is too little,

sodium tungstate cannot form coordinate complex with ligand

thoroughly, which will affect the catalyst to contact with the oil

phase. When the ligand is too much, the ligand will form with the

Na2WO42H2O to multiple chelate, thus the peroxide bonds in the catalyst structure may be destroyed. This also can be partly proved by the

phenomena of using tartaric acid as ligand. Though acid ability of

tartaric acid is high, the isolated yield is very low as Table 1 showed

because the tartaric acid can coordinate with the catalyst to form multiple

chelate. Furthermore, too much ligand dissolved in the reaction mixture

will increase the solubility of the product that will decrease the isolated

yield, too.

Effect of the reaction time on the reaction is showed in Table 3. From

Table 3 we can see that the isolated yield of adipic acid increase at first

when the reaction time prolonged and reaches the highest isolated yield

at 10 and 6.5 h, respectively. Long reaction time leads to the decreasing

Table 3.

The effect of reaction time on the catalytic oxidation.

Acidic ligand

Reaction time (h)

Product isolated

yield (%)

Hydroquinone

4

6

8

10

12

14

2

3

4.5

5

6.5

8

70.1

73.5

71.1

76.9

76.4

70.1

9.30

18.8

47.0

59.5

63.7

39.5

L(þ)ascorbic

acid

Reaction condition: Na2WO42H2O, 2.5 mmol; catalyst/acid

ligand ¼ 1/1 (mole ratio); 30% H2O2, 44.5 mL; cyclohexanone,

100 mmol; reflux temperature.

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

Cyclohexanone Oxidation

281

yield of adipic acid slightly. The further oxidation of the adipic acid to

soluble products such as succinic acid and -valeroactone may be the

probable reason.

Based on the above researches, we investigate the catalytic behavior

of catalysis system for the mixture of cyclohexanone and cyclohexanol.

The results are summarized in Table 4. The results indicate that the

catalysis system exhibit the highest catalytic activity for the oxidation

of mixture of cyclohexanol and cyclohexanone with the mole ratio of

cyclohexanol and cyclohexanone being 1/2. The isolated yield reaches

to 79.1% when sulfosalicylic acid was used as the ligand, but it is still

lower than 82.1% isolated yield of adipic acid when pure cyclohexanone

is used as substrate. It also shows that the oxidation of cyclohexanol is

not easier than that of cyclohexanone.

According to the research of Noyori et al., (1998) the oxidation

reaction of cyclohexene to obtain adipic acid catalyzed by Na2WO42H2O

Table 4.

Catalytic oxidation of the mixture of cyclohexanone and cyclohexanol.

Ligand

Sulfosalicylic acid

Hydroquinone

Pyrocatechol

Ligand

amount

(mmol)

1

2.5

1.25

2.5

2.5

62.3

68.6

37.5

45.9

Cyclohexanol/cyclohexanone (mol ratio)

4/1

68.6

71.4

44.8

46.2

2/1

72.0

74.8

52.7

50.2

1/1

73.3

76.6

58.3

53.9

1/2

74.3

79.4

61.9

60.3

1/4

73.2

78.2

63.2

52.2

0

71.2

82.1

71.1

74.8

Reaction conditions: Na2WO42H2O, 2.5 mmol; 30%H2O2, 44.5 mL; cyclohexanone þ cyclohexanol ¼ 100 mmol; reaction time, 8 h; reflux temperature.

Scheme 1.

The proposed reaction mechanism.

MARCEL DEKKER, INC. • 270 MADISON AVENUE • NEW YORK, NY 10016

©2003 Marcel Dekker, Inc. All rights reserved. This material may not be used or reproduced in any form without the express written permission of Marcel Dekker, Inc.

282

Zhang et al.

should follow multiple steps involving three kinds of oxidation

reactions (olefin epoxidation, two alcohol oxidation, and Baeyer–

Villiger oxidation) and hydrolyses. The oxidation of cyclopentanone to

obtain -valeroactone by hydrogen peroxide reported by Fischer and

Hölderich, (1999) also shows that glutaric acid is one of side product.

According to these facts and our research results, the proposed reaction

mechanism is depicted in Sch. 1.

REFERENCES

Bruner, H. S., Lane, S. L., Murphree, B. E. (1998). Manufacture of adipic

acid. US Patent 5,710,325.

Denis, P., Grosslin, J., Metz, F. (1995). Preparation of adipic acid by

hydrocarboxylation of pentenic acids. US Patent 5,420,346.

Draths, K. M., Frost, J. W. (1994). Environmentally compatible synthesis of adipic acid from D-glucose. J. Am. Chem. Soc. 116:399.

Fischer J., Hölderich, W. F. (1999). Baeyer–Villiger-oxidation of cyclopentanone with aqueous hydrogen peroxide by acid heterogeneous

catalysis. Appl. Catal. A: General 180:435.

Frost, J. W., Draths, K. M. (1996). Synthesis of adipic acid from biomass-derived carbon sources. US Patent 5,487,987.

Gong, H., Jiang, H., Lu, Z. B. (2000). A new green route to the adipic

acid. Chem. J. Chinese Universities 21(7):1121.

Ma, Z. F., Deng, Y. Q., Wang, K., Cheng, J. (2001). Clean catalytic

oxidation to adipic acid. Chemistry Bulletin (Chinese) 2:116.

Park, C. M., Goroff, N. S. (1993). One step air oxidation of cyclohexane

to produce adipic acid. US Patent 5,221,800.

Sato, K., Aoki, M., Noyori, R. (1998). A green route to adipic acid:

direct oxidation of cyclohexanes with 30 percent hydrogen peroxide. Science 281:1646.

Schulz, J. G. D., Onopchenko, A. (1981). A process for converting cyclohexane to adipic acid. US Patent 4,263,453.

Xuan, E. F. (1999). The production and market analysis of adipic acid.

Chemical Production and Technology (Chinese) 6(4):59.

Received December 31, 2001

Accepted February 23, 2002