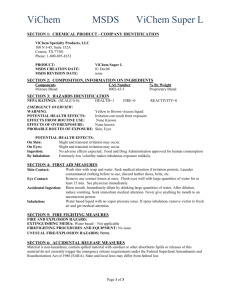

md vacuum gas oil cas 64741-57-7-str-en

advertisement