the Stainless Steel Product Catalogue

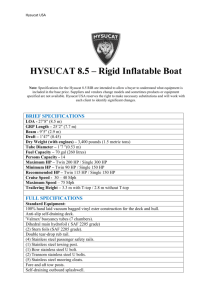

advertisement