Experimen tt: Dehydration of an Alcohol

advertisement

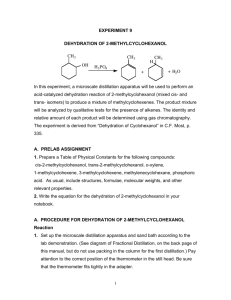

Experiment: Dehydration of an Alcohol Alcohols can undergo dehydration with a strong acid catalyst to form alkenes as shown in the equation below. C C H OH H2SO4 C C + H2O In these reactions the hydroxyl group is protonated by the acid, which then can function as a good leaving group. For protonated secondary and tertiary alcohols, dehydration proceeds by an E1 mechanism in which water is lost, forming a carbocation. This carbocation, in turn, loses a proton to form the alkene product. Tertiary alcohols undergo dehydration most easily because they form more stable carbocations. Because carbocations can rearrange to form equally stable or more stable carbocations by 1,2-hydride or alkyl shifts, dehydration can lead to a complex mix of products. Primary alcohols are the alcohols most difficult to dehydrate. Acid concentration must be high, (for instance,95% for sulfuric acid), and the reaction is slow. You will be dehydrating a secondary alcohol, 2-methylcyclohexanol, which will dehydrate under fairly mild conditions. This reaction will proceed via an E1 mechanism. In the post-lab you will be asked to write out a mechanism for the dehydration of 2-methylcyclohexanol, including all possible alkene products that could form. For now, let’s look at an E1 mechanism of another simple secondary alcohol, 2-butanol. Typical E1 Mechanism OH OH2 2o carbocation H+ This secondary carbocation can then eliminate a proton from any neighboring carbon to give mixtures of alkene products if more than one type of neighboring proton is present. H H3C H H CH H H Again, in your experiment, you will dehydrate 2-methylcyclohexanol with phosphoric acid, which is expected to form a mixture of three alkenes, all isomers having the molecular formula C7H12. These three isomers are structural isomers, and one of them forms only as a result of carbocation rearrangements. CH3 OH acid C7H12 Because this reaction, like all alcohol dehydration reactions, is reversible in acid, we must somehow shift the equilibrium to the alkene side of the equilibrium. To do this we will remove the alkene products along with water from the dehydration as they are formed. Because the nonpolar alkene products and the water that is formed have much lower boiling points than the more polar alcohol starting material, a careful distillation will remove only products, allowing the remaining alcohol to continue dehydrating in the reaction vessel. When no further product distills over below 95°, the reaction is complete. The product mixture will then be washed to remove any traces of acid, dried and purified by a final distillation. After purification, you will inject a sample into the gas chromatograph to see evidence of the three products and to calculate the ratio of these three products. Pre-lab Preparation Before coming to lab, you must do the following in your lab notebook: 1. Write structural formulas and names for the three alkene products of this reaction. Remember, one product forms as a result of rearrangement. 2. Write physical constants (boiling point, density, solubility in water ) for both the cis and the trans 2-methylcyclohexanol. In this experiment you will be reacting a mixture of both of the isomers. Also list the constants (boiling point, density, solubility in water) for the three alkene products. 3. Using your reference data from question 2, predict the order of elution from the GC. 4. This experiment uses a mixture of cis and trans 2-methylcyclohexanol for the dehydration. How would you expect the product mixture to change if you used pure trans-2-methylcyclohexanol? And for the pure cis-isomer? Explain your answer. 5. Review your lab lecture notes on gas-liquid phase chromatography, extraction and washing. Experimental Procedure ! Safety Considerations ! Phosphoric acid is harmful. Consequently, it is important not to spill any on yourself or on the container. If you spill it on yourself, wash it immediately with water. If you spill it on the container, wash it with running water so that the next student does not pick up a bottle with acid spilled down its side, burning his or her fingers in the process. ! The protonation of an alcohol by an acid is exothermic like any other acid-base reaction. Add your acid slowly and carefully so as not to splatter acid out of the reaction flask. 1. Place 15.0 mL of 2-methyl-cyclohexanol into a 50-mL round bottom flask and add several boiling stones. Add 4.5 mL of 15 M phosphoric acid directly to the round bottom flask. During the addition, swirl the mixture occasionally and check the temperature of the reaction mixture by touching the side of the flask. Have a beaker of ice water ready in case the reaction mixture becomes too hot to touch. After you have added all of the acid, swirl the flask again to be certain that the contents are thoroughly mixed. The receiver should be a 25mL round bottom flask. Heat the reaction mixture using a heating mantle set between 60 and 70. Set your Variacs higher if needed to get the alkene vapor all of the way up the column. You may reduce the voltage later, if necessary. 2. Steadily heat the reaction mixture to boiling. Observe the vapor-liquid mixture condensation line as it rises up the column. When the hot vapor-liquid mixture reaches the thermometer probe, the temperature will rise rapidly. The temperature should stabilize close to 85°C while much of the alkene product distills over. Later in the distillation, the vapor-liquid mixture will contain both the alkene products and water. The distillation temperature for this mixture may rise higher, but you should keep the temperature at the top of the column below 95ºC to minimize the co-distillation of unreacted alcohol. If it gets to more than 2-3ºC above 95ºC, reduce the Variac setting. Eventually, as more and more alkene distills off, you will notice that the starting material looks yellow. Stop the distillation when no more material distills below 95oC. The distillate will be a cloudy mixture of alkenes and water. Allow the distilling flask to cool to room temperature while you proceed to step three of the procedure. Later, when the flask is cool, you should pour the remaining liquid into the waste container in the hood. Then rinse the flask with acetone and pour the rinse into the waste as well. 3. Transfer the distillate to a separatory funnel and wash it with 2 five mL portions of 10% sodium bicarbonate solution. This will neutralize any phosphoric acid that may have been carried over during the distillation. Note: Students often get confused about the meaning of “…wash it with two 5-mL portions of…” They add 5 mL of base to the alkene product, shake the separatory funnel a few times, then incorrectly add 5 more mL, and shake again. Then they separate the organic from the aqueous layer. This is not what the directions intend for you to do. That would be the same as washing once with 10 mL of base. What you should do is add the first 5 mL of base, shake and allow the layers to separate. Remove the aqueous layer. Then with only the organic layer in the funnel, add a second 5-mL portion of base, shake and separate again. Remove the aqueous layer and wash the remaining alkene product mixture with 5 mL of water. Again remove the aqueous layer. Remove the alkene layer from the separatory funnel, place it in a dry 25-mL Erlenmeyer flask, and add a six or seven pellets of anhydrous calcium chloride to dry the product. The drying agent will stick together when it absorbs water. The correct amount of drying agent has been added when some of the added calcium chloride moves freely without sticking to other pellets. Stopper the flask to prevent the loss of product by evaporation. Allow the alkenes to dry for at least ten minutes. 4. Transfer the dry alkene to a clean, tared vial or small flask. It should be clear, not cloudy. If it is cloudy, further treatment with drying agent is required. Your sample will not be injected into the gas chromatograph unless it is completely clear. Obtain a mass of the product and let your instructor know that your sample is ready for gas chromatography. 5. Obtain an infrared spectrum of your product mixture to check for presence or absence of alcohol starting material. Post-Lab and Report Requirements This lab report will be due at the beginning of the next lab. It will contain the following information: 1. Write an equation showing all of the organic products of the reaction. 2. Write a detailed mechanism showing how all of the products formed. 3. Calculate the theoretical yield of the alkene product. Show clearly all steps that you used in your calculations. Note: From the equation for this reaction, one mole of alcohol dehydrates to form one mole of alkene. Within that one mole of alkene, there are three products having the same molecular weight. You cannot predict the percentages of each product within this alkene mixture. All you can calculate is that theoretical yield of the total mixture of alkenes. Calculate the percentage yield of your alkene product. 4. Give both physical and chemical reasons why you did not achieve a 100% yield. Your explanation should deal with both types of ways that reduce your yield. The first are losses of product through physical means, for example transfer losses or spillage. The second are ways in which the limiting reagent reacts in a way that you don’t want it to react, producing unwanted products called side products. Be thorough and detailed in your analysis by considering each step of the experiment for possible losses. This is best done as a bulleted list of losses throughout the experiment. 5. Attach the gas chromatogram of your product. Since all of the alkenes formed are isomers of C7H12, they will elute from the GC column in order of increasing boiling point. Label the identity of the three peaks (some may appear only as shoulders overlapping with a neighboring peak) as 1, 2, and 3 and give the alkene represented by each peak. 6. Which product, based on the relative areas under each peak, appear to be formed in greatest yield? Explain why. 7. Analyze your IR spectrum and explain how this spectrum proves that the desired reaction took place in this experiment.