Slinky Stretch:

advertisement

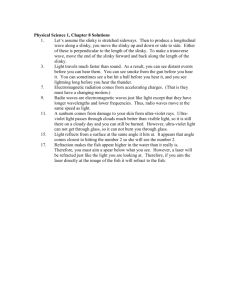

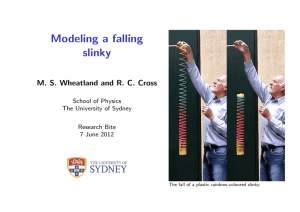

Slinky Stretch: Effect of Spring Resting Length on Maximum Stretch of Spring When Allowed to Decompress Under Force of Gravity Ryan LaPointe Section B December 18, 2015 Lab Partners: Patrick Lei, Dany Alkurdi Introduction The purpose of this experiment was to demonstrate the law of conservation of energy using a spring, namely a slinky children’s toy. How does increasing the resting length of a spring affect the maximum stretched length of the spring that occurs when the spring is allowed to decompress vertically under the force of gravity? If the resting length of the spring is increased, it is hypothesized that the maximum stretched length of the spring when allowed to decompress vertically under the force of gravity will increase linearly, because the resting length of a spring is inversely proportional to the spring constant. Methodology The slinky was held against the bottom of a horizontal surface. A number of turns of the slinky were then held in place as the rest of the slinky was allowed to fall under the force of gravity. Using a camera, the maximum stretched length of the spring was determined through video analysis. This procedure was repeated with various numbers of turns of the slinky held in place. Both before and after this experimentation, force measurements were taken from the slinky in order to determine the coefficient of friction of the entire slinky. The slinky was placed horizontally on a table and one end was attached to a force measuring device. The slinky was then stretched to the lengths of 0.00, 0.10, 0.20, 0.30, and 0.50 meters and the force exerted by the slinky on the force sensor was recorded. The slinky was also massed. Diagram 𝐶𝑀 𝑍0 𝐿0 𝐿𝑡𝑜𝑡𝑎𝑙 𝑍 𝐿 𝐶𝑀 Constants and Equations Equations Constants 𝑀 = 64.2 g 𝐿𝑡𝑜𝑡𝑎𝑙 = 16.4 cm 𝑔 = 9.8 m/s 2 4 𝑚𝑔 3 4 𝑚𝑔 3 ∆𝐿 𝑘 or ∆𝐿 = 𝑀 (𝐿 ) 𝑚= 𝐿𝑡𝑜𝑡𝑎𝑙 0 2 ∆𝑍 = ∆𝐿 3 𝑘= (See Appendix A for derivations) Summarized Data Setting AVG L (m) STDEV %RSD Ltheo %err k ktheo %err L0 m Z ΣEi ΣEf of L of L (m) of L (N/m) (N/m) of k (m) (kg) (m) (J) (J) % change of ΣE 0.33 0.14 0.008 1.149 0.220 58.80 3.49 1.26 64.02 0.05 0.0212 0.16 0.034 0.034 0.000 0.50 0.30 0.007 0.769 0.506 67.89 2.44 0.83 65.96 0.08 0.0321 0.35 0.111 0.111 0.000 0.67 0.52 0.010 0.918 0.909 75.98 1.91 0.62 67.53 0.11 0.0430 0.60 0.254 0.254 0.000 0.83 0.78 0.007 0.499 1.394 78.01 1.56 0.50 67.90 0.14 0.0533 0.91 0.477 0.477 0.000 0.91 0.92 0.011 0.729 1.676 82.15 1.45 0.46 68.63 0.15 0.0584 1.07 0.615 0.615 0.000 Avg. 0.813 Avg. 72.57 Avg. 66.81 Graphs L vs Amount of Slinky Used L (m) Measured Theoretical 1.8 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 L = 2.521s - 0.6925 R² = 0.9837 L = 1.3595s - 0.3489 R² = 0.9869 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Amount of Slinky Used, s Spring Constant vs Amount of Slinky Used Calculated Theoretical Spring Constant, k (N/m) 4.0 3.5 k[s] = 1.3345s-0.868 R² = 0.9997 3.0 2.5 2.0 k[s] = 0.4145s-1 R² = 1 1.5 1.0 0.5 0.0 0.3 0.4 0.5 0.6 0.7 Amount of Slinky Used, s 0.8 0.9 1.0 Analysis The average percent relative standard deviation (%RSD) of the collected data was 0.813%, indicating high precision in the data collection. All theoretical and calculated models have a high coefficient of determination (r2), denoting that the models fit the data with high fidelity. The models are only valid in the first quadrant, because a spring of negative or zero length cannot exist and neither 𝑘 nor ∆𝐿 can be negative. The theoretical and calculated models strongly differ. Regarding ∆𝐿 vs amount of slinky used, the average error of the theoretical model with respect to the calculated model was 72.57%; for 𝑘 vs amount of slinky used, the average error was 66.81%. A possible source of error in this experiment is the friction between the slinky and the table when the force of the spring was being measured in order to generate the theoretical 𝑘 model. This source of error would influence the theoretical 𝑘 model in a direction consistent with that present in the graph. Conclusion The results of this experiment do support the hypothesis that the maximum stretched length of a spring when allowed to decompress vertically under the force of gravity will increase linearly as the resting length of the spring is increased, because a linear trend line fits a graph of ∆𝐿 vs amount of slinky used with an r2 of 0.99. Further research should be conducted to develop a method for determining the coefficient of the function without using approximations. Appendix A: Equation Derivations Calculating 𝑘 of the entire spring: Hooke’s law: 𝐹 = 𝑘∆𝑥 𝐹 𝑘= ∆𝑥 Obtaining theoretical 𝑘 for each setting using the 𝑘 of the entire spring: 𝑠 is the amount of spring used (between 0 and 1). 1 𝑃𝐸𝑠 = 𝑘 (∆𝑥 )2 2 First, we know the following: 1 1 2 𝑃𝐸𝑠𝑠𝑚𝑎𝑙𝑙 = 𝑘𝑠𝑚𝑎𝑙𝑙 (∆𝑥 )2𝑠𝑚𝑎𝑙𝑙 = 𝑘𝑠𝑚𝑎𝑙𝑙 (𝑠∆𝑥𝑙𝑎𝑟𝑔𝑒 ) 2 2 𝑃𝐸𝑠𝑠𝑚𝑎𝑙𝑙 = (𝑠)𝑃𝐸𝑠𝑙𝑎𝑟𝑔𝑒 Combining these two equations, we get: 1 2 𝑘𝑠𝑚𝑎𝑙𝑙 (𝑠∆𝑥𝑙𝑎𝑟𝑔𝑒 ) = (𝑠)𝑃𝐸𝑠𝑙𝑎𝑟𝑔𝑒 2 1 1 2 2 𝑘𝑠𝑚𝑎𝑙𝑙 (𝑠∆𝑥𝑙𝑎𝑟𝑔𝑒 ) = (𝑠)𝑘𝑙𝑎𝑟𝑔𝑒 (∆𝑥𝑙𝑎𝑟𝑔𝑒 ) 2 2 1 1 2 2 𝑘𝑠𝑚𝑎𝑙𝑙 (𝑠 2 )(∆𝑥𝑙𝑎𝑟𝑔𝑒 ) = (𝑠)𝑘𝑙𝑎𝑟𝑔𝑒 (∆𝑥𝑙𝑎𝑟𝑔𝑒 ) 2 2 2 𝑘𝑠𝑚𝑎𝑙𝑙 (𝑠 ) = (𝑠)𝑘𝑙𝑎𝑟𝑔𝑒 𝑘𝑠𝑚𝑎𝑙𝑙 (𝑠) = 𝑘𝑙𝑎𝑟𝑔𝑒 Calculating ∆𝑍 for each setting: (Derivation from Finding the Center of Mass of a Soft Spring by Juan D. Serna) 𝑁 is the amount of the slinky measured in number of turns. 𝜃 is the amount of the slinky measured as an angle. 𝑐 ≡ 𝐿0 /2𝜋𝑁 𝑚𝑔(2𝐿0 − 𝑐𝜃 )𝑐𝜃 ∆𝑧 = 2𝑘𝐿20 2𝜋𝑁 1 𝑚𝑔(2𝐿0 − 𝑐𝜃 )𝑐𝜃 𝐿0 𝑚𝑔 ∫(𝑧)𝑑𝑚 𝑍= = ∫ [𝑐𝜃 + ] 𝑑𝜃 = + 𝑚 2𝜋𝑁 0 2 3𝑘 2𝑘𝐿20 𝐿0 2 + ∆𝐿 2 3 2 ∆𝑍 = ∆𝐿 3 𝑍= Calculating 𝑘 for each setting: ∆𝑃𝐸𝑔 = ∆𝑃𝐸𝑠 1 𝑚𝑔∆𝑍 = 𝑘 (∆𝐿)2 2 2𝑚𝑔∆𝑍 𝑘= (∆𝐿)2 2 2𝑚𝑔 ( ∆𝐿) 3 𝑘= (∆𝐿)2 4 𝑚𝑔 3 𝑘= ∆𝐿 Calculating theoretical ∆𝐿 for each setting: 4 𝑚𝑔 3 ∆𝐿 = 𝑘 Appendix B: Collected Data Before Distance (m) 0.00 0.10 0.20 0.30 0.50 Force (N) -0.01548 0.04260 0.10900 0.14050 0.30600 k 0.000 0.426 0.545 0.468 0.612 Average 0.410 Average Average Setting Trial 0.33 0.50 0.67 0.83 0.91 1 2 3 0.700 0.870 1.067 1.348 1.472 0.704 0.877 1.088 1.357 1.493 0.722 0.877 1.086 1.350 1.481 After Force (N) 0.01233 0.04859 0.11320 0.14860 0.27300 k 0.000 0.486 0.566 0.495 0.546 0.419 0.414 Lowest position of bottom of slinky (m) 4 5 6 7 0.708 0.870 1.099 1.358 1.494 0.716 0.880 1.092 1.363 1.504 0.714 0.879 1.093 1.360 1.496 0.710 0.881 1.092 1.364 1.504 8 9 10 0.724 0.882 1.093 1.358 1.502 0.717 0.863 1.101 1.354 1.503 0.723 0.885 1.102 1.371 1.503