Condition Assessment Program (CAP)

Raising Safety, Opportunity and Values

IR-CAP - GUIDELINES

for “Tankers”

Published By:

Indian Register of Shipping

Marine Advisory Services

52A, Adi Shankaracharya Marg,

Opp. Powai Lake,

Mumbai – 400 072

IR-CAP- GUIDELINES for “TANKERS”

Published – November 2013

All rights reserved. No part of this publication may be reproduced or transmitted in any

form or by any means, including photocopying and recording, without the prior written

consent of INDIAN REGISTER OF SHIPPING

nkers”

IR-CAP – GUIDELINES FOR TANKERS

Index

Section 1. GENERAL .......................................................................................................4 A. Indian Register of Shipping Condition Assessment Programme (IR-CAP) ...........4 B. IR-CAP Ratings ......................................................................................................4 C. Industry Requirements for CAP ............................ Error! Bookmark not defined. D. Transparency, Interface with classification and flag state .....................................5 E. IR-CAP Procedures ...............................................................................................6 Section 2. HULL STRUCTURE .......................................................................................8 A. General ..................................................................................................................8 B. Scope of CAP Hull structure surveys.....................................................................8 C. CAP Hull Rating Methodology ............................................................................ 14 D. Guidelines for overall Hull Structural condition rating ......................................... 16 E. Final CAP Rating for Hull Structure ..................................................................... 18 F. CAP Hull Structure Reporting ............................................................................ 18 Section 3. MACHINERY AND CARGO SYSTEMS ................................................... 20 A. General ............................................................................................................... 20 B. Operational Condition Surveys, Scope and Rating Criteria ............................... 20 C. Machinery and Cargo Systems Groups, Machinery Sub Groups and Machinery

Elements ............................................................................................................. 24 D. Operational Condition Ratings Assessment ....................................................... 24 E. CAP Rating Guidelines for Rating of Machinery and Cargo Systems & Fittings 26 F. Global Rating for Maintenance ........................................................................... 26 G. CAP Rating for Machinery and Cargo System & fittings .................................... 27 Section 4. “IR CAP Thickness Measurements Guidelines”

(Annexure – I)...... 28 A. Requirement for standard extent of Thickness Measurements .......................... 28 B. Standard Extent of Thickness Measurements .................................................... 28 C. Reduced Extent of Thickness Measurements .................................................... 28 D. Important Notes: ................................................................................................. 28 Page 3 of 29

IR-CAP – GUIDELINES FOR TANKERS

speed, fuel oil consumption rate or cargo and

ballast pump capacities

Section 1. GENERAL

A. Indian Register of Shipping Condition

Assessment Programme (IR-CAP)

1.

General

• IR-CAP is a voluntary and independent

verification of the actual technical condition of

a ship’s Hull structure, Machinery and Cargo

system

• IR-CAP can be applied to all types of

Tankers.

• Is supplementary to the scope of classification

• Provides a comprehensive survey report in

an easily accessible and understandable

format, which includes observations, ratings

and photographic records

• Is application of 4 point rating system that

easily identifies the condition, reliability and

maintenance standard associated with the

vessels , Hull structure , Machinery and

Cargo systems or sub-system,

being

assessed

• Confirm the ship’s condition to interested

parties like charters, shippers and terminal

operators as an important

tool for risk

assessment

• It is an independent assessment of the

vessel's condition, which can be used to

advertise the vessel to prospective buyers,

charterers, terminal receivers, underwriters

or other parties

• Is not limited to IR classed vessels. IR-CAP

services can be applied to any other classed

vessels.

• Is not an endorsement or negation of

classification

• Is not a substitute for Class Surveys of ships

• Will not affect the classification process

• Will not alter or interfere with the application

of the Class Society’s rules and/or of the

applicable Statutory Requirements

• Does not cover assessment of items and

systems covered by statutory regulations

such as life saving appliances, navigational

equipment, communication equipment etc

• Does not make any judgment pertaining to

other possible charter party items such as

B. IR-CAP Ratings

IR-CAP rates the vessel in accordance with a

rating scale from 1(very good) to 4 (poor).

1.

CAP Hull structure ratings

The CAP Hull structure ratings have the

following description:

a.CAP 1 – Very Good Condition

Items examined and measured found with only

superficial reductions from "as new" or current

rule scantlings. No maintenance or repair

required.

b.CAP 2 – Good Condition

Items examined and measured found to have

deficiencies of a minor nature not requiring

correction or repair and/or found to have all

thicknesses significantly above class limits.

c. CAP 3 - Acceptable Condition

Items examined and measured either found to

have deficiencies, which do not require

immediate corrective action, or found to have

thicknesses, which although generally above

class renewal levels, do exhibit substantial

corrosion.

d.CAP 4 - Poor Condition

(Below Class minimum standard)

Items examined and measured either found to

have a deficiency or deficiencies which may

affect the ship's potential to remain in class, or

found to have, in some areas, thicknesses

which are at or below the class renewal levels.

Page 4 of 29

IR-CAP – GUIDELINES FOR TANKERS

2.

the owners/management

standards.

CAP Machinery and Cargo system ratings

a. CAP 1 – Very Good Condition

company’s

own

Components and systems found with no

deficiencies affecting the safe operation and/or

normal

performance.

Maintenance

and

documentation found in very good order. No

maintenance or repair considered necessary.

b. CAP 2 – Good Condition

Components and systems found with minor

deficiencies not affecting the safe operation

and/or normal performance. Maintenance and

documentation found to be good. No immediate

maintenance or repair considered necessary.

c. CAP 3 - Acceptable Condition

Components and systems found with

deficiencies but not affecting the safe operation

and/or normal performance, Maintenance and

documentation considered to be satisfactory.

No

immediate

maintenance

or

repair

considered necessary.

D. Transparency, Interface with classification

and flag state

1.

The CAP is designed to be highly transparent

with the onus on clear and detailed report,

photographic records and certification.

(Below Class minimum standard)

2.

Components and systems found with

deficiencies affecting the safe operation and/or

normal performance. Documentation and

maintenance found to be poor. Maintenance

and repair required to reinstate serviceability

The CAP is a consultancy service and is

independent,

yet

complementary,

to

classification

3.

The CAP service is offered according to a

contract with the client and rendered to ships

with or without IR Class.

4.

Class is a continuous service based on regular

inspection and the issuing of class certificates

with specified validity periods. The CAP

declaration is issued documenting the condition

of the vessel at the time of the inspection

5.

The main purpose of CAP is to evaluate and

report the vessel’s condition above minimum

class standard and the scope for CAP is more

comprehensive than for class surveys.

6.

CAP is also independents from CAS, which is

regulatory survey on behalf of the flag state.

7.

The CAP service is offered according to a

contract with the client and rendered to ships

with or without IR Class.

8.

Class is a continuous service based on regular

inspection and the issuing of class certificates

with specified validity periods. The CAP

declaration is issued documenting the condition

of the vessel at the time of the inspection

9.

The main purpose of CAP is to evaluate and

report the vessel’s condition above minimum

d. CAP 4 - Poor Condition

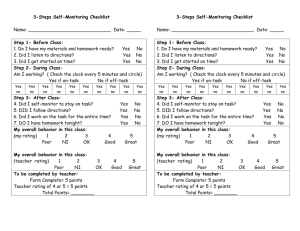

Table 1: CAP Ratings

C. Industry Requirements for CAP

1.

2.

3.

The CAP report is mainly used as a tool for

documenting the technical condition towards

cargo owners and/or authorities in connection

with renewal of or entry into new charters.

The CAP report can be used for other purposes

as well, such as in connection with refinancing

and sale of the vessel, termination of

management

agreements

or

towards

underwriters.

The CAP report can also be used to establish a

sound basis for decisions on repair or

investments in order to extend the lifetime of

Page 5 of 29

IR-CAP – GUIDELINES FOR TANKERS

critical machinery or system may be assessed

by the surveyor as being CAP 3 but the client’s

aim is CAP 1 for Machinery and cargo system.)

class standard and the scope for CAP is more

comprehensive than for class surveys.

10. CAP is also independents from CAS, which is

regulatory survey on behalf of the flag state.

E. IR-CAP Procedures

1.

Request for CAP Survey

a. A request for a vessel condition assessment

needed by the client concerning CAP Survey is

to be submitted using the “Survey Request

Form” provided by IRS.

b. All the defects are informed to the client’s

representative in writing and photographic

records are to be kept. If these items are

upgraded / rectified then a follow up inspection

is made and photographic records taken.

These records form a part of the final CAP

report.

b. The request can be made directly to the IRS

Head Office or any branch office.

2.

Planning of CAP Survey

a. On receipt of a request for CAP, the IRS Head

Office will contact the client to discuss his

requirement and expectation for CAP Rating.

b. On acceptance of quotation, the IRS Head

Office representative shall contact with the

client’s representative(s) to draft out the CAP

planning document (As per Survey Request

Form filled by client) which sets out the scope

and extent of CAP surveys that are to be

carried out.

c. The planning document is finalised onboard the

vessel during meetings between the CAP

surveyor and the client’s representative.

3.

Opening Meeting

a. CAP surveys begin with an opening meeting

held onboard the vessel. This meeting is held to

familiarise all the concerning parties with Indian

Register Condition Assessment Programme for

the subject vessel.

b. Following points are to be discussed during the

meeting:

4.

•

Contents of the CAP planning document

•

Scope of CAP surveys

•

Inspection arrangements

•

Safety requirements

•

CAP defects list

•

Other relevant issues.

CAP Defect List

a. During the condition assessment inspections,

IRS surveyor may find areas of Hull structure,

machinery and cargo system and their fittings

that are either defective or have been assessed

at a rating below client’s expectation. (E.g. a

5.

Closing Meeting

a. On the completion of CAP surveys, closing

meeting is held and the results of the surveys

and inspection are advised to the client’s

representative in the form of visit report.

b. If the CAP survey is carried out over several

visits, then for each time that the surveyor

completes his inspections, a meeting is held

with the client’s representative. The findings of

each survey carried out are discussed and a

defect list, where applicable, is presented at this

meeting.

c. Preliminary ratings for surveyed parts may be

presented during the closing meeting(s)

however the final CAP rating shall only be

determined after final review in IRS Head

Office.

d. It is recommended that CAP inspections are

completed in stipulated time. However, this may

not be possible due to the vessel's schedule, or

due to the type of vessel being surveyed.

Should several visits be necessary, then the

timeframe between the first inspection and the

Page 6 of 29

IR-CAP – GUIDELINES FOR TANKERS

last inspection may not exceed 3 months.

Where a vessel is in lay-up, subjected to an

elongated repair timeframe or is being specially

modified, then the CAP timeframe between the

first and the last visit may be extended on

application to an agreement by IRS Head

Office.

6.

fittings and piping are to be cleaned, including

removal from surfaces of all loose accumulated

corrosion scale. Spaces are to be sufficiently

clean and free from water, scale, dirt, oil

residues, etc.

Condition Assessment Certification

Indian Register of Shipping does not assign any

validity period to the Condition Assessment

Program Certificate. They are issued to certify

that the vessel, or vessel sub-system, has a

specific CAP rating on a specific date.

Charterers may, however, choose to apply their

own acceptance periods for the certificate.

7.

Condition Assessment Reporting

a. On the completion of the condition assessment

surveys, the CAP surveyor provides a report

that details the extent of surveys carried out,

the condition of the vessel and vessel subsystems at the time of survey, details of repairs

and upgrades together with photographic

records.

b. The CAP report shall normally be issued within

the period of one month to three months from

the end of the survey, depending on the scope

of the client’s requirements for CAP survey and

certification. The CAP report is provided with

both paper and electronic copies according to

the client’s needs and requirements for

reporting.

c. The CAP report includes a summary of Hull

Structure, Machinery and Cargo System

Assessment which gives an overview of the

surveys carried out, the surveys’ findings and

the CAP rating(s) awarded.

8.

Safety during Surveys

a. The client is responsible for providing the

necessary facilities for the safe execution of the

CAP surveys.

b. The client will assume, with respect to the IRS

CAP surveyor(s), all the responsibility of an

employer for his workforce, such as to meet the

provision of applicable legislation. As a rule, the

surveyor(s) have to be constantly accompanied

during surveys by the client’s personnel.

c. Adequate ventilation and lighting is also to be

provided

for

machinery

spaces

and

accommodation areas if they are under survey.

d. In preparation for survey and to allow a

thorough examination, all spaces, machinery,

Page 7 of 29

IR-CAP – GUIDELINES FOR TANKERS

Section 2.

HULL STRUCTURE

A. General

1. Concept of condition assessment of hull

structure

a.IR-CAP Condition Assessment Programme for

hull structure identifies and reports on the

actual condition of the vessel’s structure. CAP

structural surveys may be carried out either in

dry-dock or with the vessel afloat.

b.The concept of condition assessment

programme for hull structure combines the full

scale modeling of the vessel obtained from

drawings on a in-house software platform along

with an extensive vessel structural survey to

produce a thorough

assessment

of the

vessel’s condition and the assignment of a

CAP rating. This concept is unique in its own

way for IR-CAP.

c. The extent of surveys required to be carried out

and the subsequent reporting requirements are

discussed and agreed with the client and forms

an input to scope of survey for the CAP

Planning document (PLAN DOC)

identified and paid particular attention by the

attending CAP surveyor.

•

Valid certificates of the ship (All statutory

certificates and class certificates)

•

Survey records of the ship (special survey,

annual survey, intermediate survey and

docking Survey)

•

Repair history of the ship (including

alterations or modifications, deficiencies

and repair methods)

•

The

latest

measurement

•

Previous CAP reports, if any

report

of

thickness

b.Plans and documents required for Hull

Structural modelling and strength assessment

of hull structures:

•

General arrangement

•

Midship Section

•

Transverse section plan

•

Construction profile

•

Longitudinal & Transverse bulkheads

•

shell expansion

•

Deck, Bottom &Inner Bottom

•

Loading manual

•

Stability Booklets

•

Records of thickness measurement at the

time of assessment

•

Other necessary plans

2. Structural Condition Assessment by Visual

Surveys

a.General

B. Scope of CAP Hull structure surveys

The scope of CAP Hull Structural survey will

cover following aspects

1. Check of documents and records onboard

a.Verification of the following documents and

records are carried out prior to the

commencement of CAP Survey in order to

clearly indicate defects found during the past

surveys, especially recurring defects, such as

fractures, cracking, excessive wastage, fatigue

damage etc. so that they can be clearly

The main purpose of the Close up, Overall and

External Survey is to detect and report

deficiencies, local corrosion and to evaluate &

report the general visual condition of the vessel.

All main structural elements in tanks and

spaces are rated independently.

b.Overall Survey, Close Up Survey and external

survey

Visual inspection of the condition of structures

are carried out, the surveyor inspect for

evidence of deformation, indents, buckling,

Page 8 of 29

IR-CAP – GUIDELINES FOR TANKERS

pitting, grooving, coatings, anodes,

cracks, leakages etc.

wastage,

An overall survey of the hull structure is a

survey intended to assess and report on the

overall condition of the vessel’s hull.

A close-up survey is a survey where the details

of structural components are within the close

visual inspection range of surveyor i.e. normally

within the reach of hand. On the analysis of

UTM Report, the areas with reduced scantling

must be specially examined and subjected to

close-up survey. Close-up surveys require

access to parts of a tank/hold/void space which

are normally not within reach and this means

that safe access is to be provided for

inspection.

External Survey of Hull Structure is a survey to

assess and report on the structural condition of

vessels external envelops. Mainly it covers

examination of shell plate, bottom plate and

Deck Plate from outside.

c. Requirement for Visual Surveys (Close Up,

Overall & External Surveys)

1. The following divisions of main structural

elements cover all types of tanks and spaces

(not all elements are applicable to all tanks)

•

Deck

•

Side

•

Bottom

•

Inner bottom

•

All Longitudinal bulkheads

•

All Transverse bulkheads

• Internal structures (stringers, web frames,

girders, swash bulkheads, etc)

2. All main structural elements should be rated

independently for all tanks and Spaces (Ballast,

Cargo, Fore Peak, Aft Peak, Engine Room,

Pump Room, Void Tank etc.)

3. All Internal structures (stringers, web frames,

girders, swash bulkheads, etc) should be rated

together with plating of the main structural

element and to be covered for all types of

Tanks.

4. Longitudinal and vertical stiffeners etc. should

be rated together with plating of the main

structural element they are attached to.

5. Only visual condition as observed from inside

the tank which is rated should be taken into

account for that tank.

6. Visual condition from the other side of the main

structural element should be described and

rated in connection with other tanks or with

external structural examination.

7. All main structural elements should be rated

independently for all tanks and Spaces (Ballast,

Cargo, Fore Peak, Aft Peak, Engine Room,

Pump Room, Void Tank etc.)

8. All Internal structures (stringers, web frames,

girders, swash bulkheads, etc) should be rated

together with plating of the main structural

element and to be covered for all types of

Tanks.

9. Longitudinal and vertical stiffeners etc. should

be rated together with plating of the main

structural element they are attached to.

10. Only visual condition as observed from inside

the tank which is rated should be taken into

account for that tank.

11. Visual condition from the other side of the

main structural element should be described

and rated in connection with other tanks or with

external structural examination.

12. Survey of “Hot spots” identified from the CAP

fatigue strength assessment, if applicable.

13. Possible problem areas identified from

examination of class records and historical data

of structural failures such as cracks, buckling,

etc

Page 9 of 29

IR-CAP – GUIDELINES FOR TANKERS

14. Any Additional Main and Internal Structural

Elements as considered necessary by the

attending Surveyor

15. The following areas deserve special attention

during the survey:

• End of main girders, stringers and struts with

associated brackets.

Particular attention

should be paid to the toes of brackets,

bracket ends of shell, deck and bulkhead

stiffeners.

• Connections of shell, deck and bulkhead

longitudinals to transverse web frames.

• Discontinuities in the form of misalignment or

abrupt change of section.

• Plating in way of cut or openings.

• Areas of substantial corrosion or other

suspect areas.

close up survey to illustrate an example of

vessel Compartment and individual Panel.

Similar assessment is carried out towards

external and overall surveys.

Defects found during the overall, external and

close up survey are advised to the owner's

representative using the onboard survey

document.

Should defects be found during the close-up

surveys, then these defects will be advised to

the client’s representative in writing using

survey report and photographic records will be

made. If these items are upgraded / rectified, a

follow- up inspection will be made and

photographs are taken to show the

rectifications. These defects/rectifications are

part of the final CAP report and will be taken

into consideration within the structural CAP

ratings issued at the completion of the surveys.

• Areas which show signs of damage or

buckling.

• Areas

identified

for

regular

inspection/monitoring as per vessel's critical

structure area monitoring plan.

Figure 1: Example of assessment of close up

Survey for Compartment and Panel

3. Visual Structural Condition Rating Criteria

During survey the CAP surveyor will take

representative photographs of the structural

condition to enable the client to gain an

overview and insight into the general hull

condition. These photographs are attached to

the hull structure report.

The Visual Surveys data is to be reported by

using the Survey Template created through IR

CAP Software. An example is given in figure 1

below.

Figure 1 shows a hypothetical assessment of

a.Surveys are undertaken to assess the condition

of structure as regards to deformation, indents,

buckling, pitting, grooving, coatings, anodes,

wastage, cracks, leakages and other defects.

b.Visual structural condition of the panels is

assessed during external, overall and close-up

surveys and a rating from 1 to 4 are given to

each panel in each vessel Compartment.

c. The rating for Close up, Overall and External

Surveys are based on the following parameters

•

General Condition

•

Wastage

Page 10 of 29

IR-CAP – GUIDELINES FOR TANKERS

•

Coating condition

•

Anode Condition

In accordance with the rating criteria given for

hull Structure, the ratings for visual structural

condition are defined in Table 2

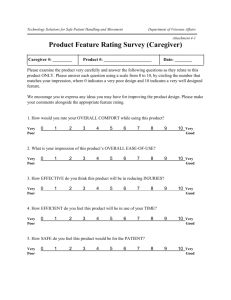

.Table 2: Visual Survey ratings Criteria

The allowable margin for defects is defined by

IRS minimum class requirements for ships in

Service. (Refer Survey Procedures B01-06(3),

B-08 and B-10-01&02). Acceptance criteria for

other deficiencies are divided and rated in a

similar manner.

Note: Crack of structural elements found in the

survey is to be repaired. Once the crack is

found, the rating of the structural element is not

to be higher than CAP 2

4. Wastage of Structure - Ultrasonic Thickness

Measurements (UTM)

a.General

Ultrasonic thickness measurements form a

major element in the CAP surveys of hull

structure and the analysis of these

measurements is a prominent factor to

determine the amount of wastage of each

structural element and subsequent assessment

of CAP ratings.

the CAP Surveyor.

The scope may be extended further where

substantial corrosion is found and as deemed

necessary by the surveyor, after consideration

of findings during overall and close-up surveys.

Failure to carry out thickness measurements in

accordance with this specification may prevent

completion of CAP Survey.

For areas in tanks where coatings are found to

be in GOOD condition, the extent of thickness

measurements required may be specially

considered but not less than Reduced Extent of

Thickness Measurements (Refer Annexure - I).

However, sufficient thickness measurements

shall be taken, in all cases, to confirm the actual

average condition and the maximum observed

diminution of the structure.

Towards Longitudinal Strength Calculation,

minimum three transverse sections shall be

chosen where the maximum diminution are

expected to occur or are revealed from deck

plating thickness measurements. At least one

transverse section shall include a ballast tank

within 0.4L amidships.

The thickness measurement data are to be

reported by using the UTM Template created

through IR CAP Software. An example is given

in figure 2 below.

Figure 2: UTM Template

b.Scope for thickness measurement

The requirements for thickness measurement

are to be carried out in accordance with “IR

CAP Thickness Measurements Specification”

(Ref. Annexure - I).

Thickness measurement is to be carried out by

an IRS or any other IACS member Class

Society approved UTM Firm.

The thickness measurements shall be carried

out either prior to or, concurrently with the

close- up survey. The results of thickness

measurement carried out by the approved

Company within 6 months prior to the

commencement of CAP survey may be

acceptable after the review and assessment by

Table 3: UTM Ratings for wastage of structure

Page 11 of 29

IR-CAP – GUIDELINES FOR TANKERS

The full scope of the UTM measurement

requirements is to be included in the CAP

Planning Document (PLAN DOC).

5. Assessment of Structural Wastage Rating

Criteria

A statistical analysis of thickness diminutions is

generally carried out against original “as-built”

scantlings available on the reference drawings

provided by the ship owner / operator.

All UTM readings in way of panels are to be

reviewed against permissible diminution of

structure in accordance with the acceptance

criteria for wastage of structure as defined in

Table 3.

Wastages observed during Visual surveys and

wastage in accordance with UTM report are

mutually supporting towards assessment of

rating calculation.

coatings for the various Panels/ area under

consideration are defined and ratings are

awarded towards coating condition as per

Criteria given in table 4.

8. Assessment of Anode Condition (Cathodic

Protection)

Condition of anodes fitted in ballast tanks,

cargo tanks and other areas of the vessel hull is

to be reported.

During overall and close-up surveys, corrosion

protective anodes (if fitted) are to be assessed

for each panel/ each area under consideration.

Rating for condition of anode is given

depending on the amount of wastage of anode

observed during visual survey as per criteria

given in table 5

Table 4: Coating condition ratings criteria

The ratings for structural wastage applied for

each Panel are then combined with ratings for

visual Survey rating.

Note : Due to various circumstances such as

inaccurate measurement, stray pits, etc., then

there will be some deviations in UTM

readings which means that some flexibility in

assessment

is required.

Therefore an

allowance of 10% of 'errant' readings may be

allowed as long as these are randomly

scattered and no repairs are deemed necessary

by the surveyor.

6. Areas of substantial corrosion

Substantial corrosion is an extent of corrosion

such that the assessment of the corrosion

pattern indicates wastage in excess of 75% of

allowable margins, but within acceptable limits.

i.e. a CAP 3.

Table 5: Anodes condition assessment ratings criteria

If any individual panel of the vessel shows a

rating of 3 then the overall CAP rating awarded

for the vessel’s structure cannot be higher than

CAP 2.

Note: Some charterers make the stipulation

that any areas of substantial corrosion must be

repaired prior to their chartering a vessel i.e.

they only accept a vessel with all assessed

Panels of rating 2 or better.

7. Assessment of Structural Coating Condition

During the overall and close-up surveys, the

vessel's structural protective coatings are

surveyed and reported upon.

9. Strength assessment of hull structures

a.General requirements

The structural strength assessment consists of

three

parts,

i.e.

longitudinal

strength

Calculation, Buckling Strength verification and

fatigue assessment.

During Visual surveys the condition of the

Page 12 of 29

IR-CAP – GUIDELINES FOR TANKERS

Fatigue strength assessment may be carried

out according to the applicant’s request.

b.Longitudinal strength calculation

Minimum three representative Transverse

sections within Midship 0.4L will be selected in

the cargo hold area for longitudinal strength

calculations, so as to carry out bending strength

and buckling strength calculations.

The ship’s approved allowable still water

bending moments used in the calculations are

to be obtained from loading manual. The

representative cross sections used in this

Section are in accordance with the requirement

of Standard Extent of thickness measurement

(refer Annexure-I)

The following items will be calculated at Deck

and Bottom.

(1) Hull girder section modulus of as Built

Scantling = ‘Zo’

(2) The actual section modulus = ‘Za’

The section modules are rated according to the

criteria given below.

The lowest of the deck and bottom rating is

decisive towards the rating of the buckling

strength.

The lowest of the Longitudinal Strength rating

and buckling strength rating is decisive towards

the rating of the final Structural strength rating

d.Fatigue Assessment (optional)

Fatigue assessment is an optional service

offered in addition to the CAP whenever

requested by the client. It is an evaluation of the

fatigue performance of hull structural details

based on the “as-built” scantling design.

A simplified fatigue analysis is to be carried out

for the end connections of longitudinal stiffeners

to transverse bulkheads and web frames within

the cargo area, located on the strength deck,

side shell, bottom shell, inner bottom and

longitudinal bulkheads using IR_FLA Software.

All areas with longitudinal stiffener end

connections estimated to have fatigue life less

than the current age of the ship + 3 years have

been identified as “hot spots” where fatigue

problems may occur and close-up surveyed as

part of the CAP survey.

The lowest of the deck and bottom rating is

decisive towards the rating of the section

modulus.

c. Buckling strength calculation

The buckling capacities of panels (plate and

stiffeners combined) in deck and bottom of a

representative “as-measured” cross sections

are calculated by using the strength calculation

software.

Fatigue strength assessment is to be carried

out and completed prior to the CAP site survey

to enable the “hot spots” to be subject to closeup inspection during CAP survey. There might

be a possibility of requiring reinforcement for

“hotspots” after the close up inspection.

Rating of the buckling capacity is based on the

buckling utilization factor

‘η = σc /σcr ‘

σc - hull girder compressive stress at deck or

bottom, in N/mm2;

σcr - critical compressive buckling stress at

deck or bottom, in N/mm2.

The Buckling strength is rated according to the

criteria given below.

Page 13 of 29

IR-CAP – GUIDELINES FOR TANKERS

e.Tank Testing

Tank testing, usually undertaken during the

vessel’s renewal survey or when tank

boundaries have been repaired.

Where tank testing has been carried out this is

to be reported in the CAP report. The surveyor

examines the bulkheads under test in the

adjacent tanks or holds, voids or cofferdams.

Tank testing is to be performed in compliance

with IRS Rules.

Satisfactory

tightness

is

an

essential

requirement for CAP Survey. Rating will not be

computed if this is ‘Not Satisfactory’

2. Structural Condition rating for panels and

Compartments

a.During the UTM rating calculation, individual

assessment of each panel is calculated and

given a rating towards thickness measurement.

b.The UTM rating for each panel consists of the

detailed average thickness calculation of each

element in the respective panel.

c. During External, close-up and overall surveys,

each Panel is individually assessed and given a

rating for General condition, wastage, coating

and anode conditions.

d.UTM rating and External, close-up and overall

Survey ratings are then formulated with

application of weightage factor to get individual

panel rating with the help of IR CAP Software.

e.All individual panel ratings are evaluated and

lowest panel rating will be assigned towards

structural condition rating of the Compartment

f. An overall Structural Condition rating is then

computed by averaging the ratings attributed to

the different Compartments.

Figure 3 shows a hypothetical assessment to

illustrate an example of vessel’s Compartment

and individual Panel.

Figure 3 Example of vessel’s Compartment

and Panel‘s rating Calculation

C. CAP Hull Rating Methodology

1. Vessel’s Compartments and Panels

a.To facilitate the assessment, review and

reporting of the vessel's structural condition, the

vessel structure is divided into different

“Compartments” such as cargo tanks, ballast

Tanks, Machinery Spaces, slop tanks,

cofferdams, void spaces, etc.

b.Each “Compartment” is divided into several

“panels” which are small enough to be readily

examined and evaluated by the surveyor

c. The number of Panels incorporated into a

vessel Compartment will usually be depending

on the layout of the ship and Compartment wise

Hull modelling created through IR-CAP

Software.

3. Rating Aspects for panel and Compartment

a. The IR-CAP rating system for hull structure

surveys is broadly defined in above para. to

arrive at an overall rating for the vessel’s

structure, the following aspects are rated

individually and collectively during visual survey

(Close Up, Overall and External Survey) for

panels in the compartment.

• Visual inspection of structural general conditionfor deformation, indents, buckling, cracks,

leakages, pitting, grooving, etc.

Page 14 of 29

IR-CAP – GUIDELINES FOR TANKERS

• Wastage of structure- Assessment based on

ultrasonic thickness measurements (UTM) and

the percentage diminution of structure.

overall structural condition rating of 1.

Figure 5 - Illustration of overall structural

condition rating Calculation

• Visual inspection of protective coatings- For

coating breakdown, cracking, flaking, blistering,

detachment, etc.

• Visual Inspection of Anode Condition- for

wastage of anodes, etc (if applicable)

b. Individual ratings are awarded for each of the

above aspects. These individual ratings are

formulated with application of weightage factor

to compute an individual Panel rating and

further Compartment Rating through IR-CAP

Software

Figure 4: Example of Panel rating assessment

in close up Survey for Panels

The example described in Figure 6 shows the

final Overall Structural Condition rating cannot

be better than one rating grade better than the

lowest rating.

Figure 6: Illustration of revised

structural condition rating

overall

Figure 4 shows a hypothetical assessment of

close up survey to illustrate an example of

vessel Compartment and individual Panel.

Similar assessment are carried out towards

external and overall surveys

4. Overall Structural Condition Rating

To arrive at an overall structural condition rating

for the vessel’s Hull structure, the ratings

awarded for each vessel compartment are

combined and an average rating is computed.

Figure 5 shows the table of overall structural

condition rating Calculation for the vessel. The

average rating is calculated as 1.40 which is

then rounded to the nearest integer to an

The average Overall Structural condition rating

is calculated as 1.43 which is then rounded

Page 15 of 29

IR-CAP – GUIDELINES FOR TANKERS

down to an overall structural condition rating of

1, however, as 'Cargo Oil Tank No. 5 (Center)'

has been awarded a rating of 3, an overall

rating of 1 cannot be awarded. This is because

the final rating cannot be better than one rating

grade better than the lowest rating. In this case,

the best Overall Structural Condition rating that

can be applied to the vessel is a rating of 2.

Note: Some charterers would not charter this

hypothetical vessel because there is existence

of a Compartment with a rating 3. If this

Compartment [Cargo Oil Tank No. 5(Center)] is

subsequently repaired/upgraded to a rating 2 or

better during survey then the overall structural

condition rating, for this hypothetical vessel,

would be updated by the surveyor to a rating 1.

5. Rating

Calculation

Cumulative Diminution

by

Note: Rating from these graphs are for information

and general overview of the whole ship

structure only, however these ratings are not

computed towards final rating of hull structure.

6. Longitudinal Strength Rating

Figure 8 shows the illustration of the

Longitudinal Strength rating Calculation through

IR-CAP Software.

Rating will be derived as per the longitudinal

strength criteria described in section 9 b above.

Longitudinal strength assessment will be

carried out within Midship 0.4 L at Minimum

three representative Transverse sections which

include at least one Ballast tank.

Figure 8: illustration of the Longitudinal

Strength rating Calculation

Percentage

a.Ratings by Percentage Cumulative Diminution

for the following Structural envelop will be

provided for general structural condition

overview of complete vessel at a glance and

will not form the basis for the final

computation of the vessels structural rating.

b.Ratings will be computed for Main Deck, Side

shell, Bottom, Inner bottom, longitudinal

bulkheads, and Transverse bulkheads. It

includes plating and its attached longitudinals

and Transverse members

Figure 6: Rating Calculation by Percentage

Cumulative Diminution.

. The lowest of the deck and bottom rating will be

assigned towards the final rating of each

Transverse Section.

The lowest of the final rating of each transverse

Section will be assigned towards the final

longitudinal strength rating of the vessel.

Structural strength rating 3 indicates that minimum

class requirements for ships in operation are

fulfilled. Structural strength rating 4 indicates

that the vessel does not fulfill IR Class

Requirement for ships in operation.

D. Guidelines for

condition rating

overall

Hull

Structural

1. The vessel structure is divided into different

“Compartments” such as cargo tanks; ballast

Tanks, Machinery Spaces, slop tanks,

cofferdams, void spaces, etc.

2. Each “Compartment” is divided into several

“panels” which are small enough to be readily

examined and evaluated by the surveyor

3. During External, close-up and overall surveys,

each Panel is individually assessed and given a

rating for General condition, wastage, coating

and anode conditions. (E.g. applicable coating

Page 16 of 29

IR-CAP – GUIDELINES FOR TANKERS

condition rating 1 is for Good, 2 is for Fair and 3

is for Poor. There is no rating 4.)

4. The UTM rating for each panel consists of the

detailed average thickness calculation of each

element in the respective panel.

5. UTM, External, close-up and overall Survey

ratings are then formulated with application of

weightage factor to get individual panel rating

with the help of IR CAP Software.

6. All individual panel ratings are then evaluated

and lowest panel rating will be assigned

towards structural condition rating for the

vessel’s Compartment

7. An overall rating for the Hull structure surveys is

then computed by averaging the ratings

attributed to the different Compartments of the

hull structure.

8. Rating awarded to a Compartment is then

rounded to the nearest integer e.g. 1.42 is

rounded to 1, 1.60 is rounded to 2 and special

note 1.50 is rounded to 2

9. The rating applied

to Panel for General

condition, wastage, coating and anode

conditions will be an integer, either 1, 2, 3, or 4.

If no rating can be given then a comment is

required to be made e.g. N/F (not fitted), N/S

(not surveyed) or N/A (not applicable) etc.

10.

Where indents are prominent enough

that

they

are

mentioned in class

notes/memorandum then the rating awarded

for visual Surveys within the Panel cannot be

better than rating 2.

than one rating grade better than the lowest

rating applied to Panel for UTM, Close Up,

External and Overall Survey within that

Compartment. (e.g. if one Panel is awarded a

rating 3 for Close Up then the maximum rating

that can be applied to that Compartment is a

rating of 2.)

14.

Irrespective of the average structural rating

calculated for a Panel, the rating awarded for

that Panel cannot be better than one rating

grade better than the lowest rating applied to

Panel for General condition, wastage, coating

and anode conditions within that Panel. (E.g.

rating 3 is awarded for coating condition then

the maximum rating that can be applied to that

Panel is a rating of 2.)

15.

Irrespective of the average structural rating

calculated for the vessel as a whole, the overall

vessel structural rating awarded cannot be

better than one rating grade better than the

lowest rating applied to any vessel

Compartment (e.g. rating 3 is awarded for any

Compartment then the maximum rating that can

be applied to the vessel will be rating of 2.)

16.

Irrespective of the average

rating

calculated for a vessel Compartment, a final

overall structural rating of 4 is given to the

vessel if there is an panel that is awarded a

rating of 4 for UTM, Close Up, External and

Overall Survey and it is left un repaired.

11.

Any Panel within ballast tanks which is

awarded a coating rating of 3 shall be included

in surveyor’s onboard visit report to the client

for regular inspection

12.

Damage to plating and stiffening such as

cracking and buckling caused by in line stress

or fatigue shall automatically lead to a rating of

4 for the Panel. Depending on the structure

detail, cause of defect and complementary

aspects such as age of the vessel; repairs of

such defects may not be sufficient for some

charterers unless design modification is carried

out.

Suitable

repairs/modifications

are

discussed with the client on a case to case

basis in conjunction with the structural and

fatigue assessment.

13.

Irrespective of the average structural rating

calculated for a Compartment, the rating

awarded for that Compartment cannot be better

Page 17 of 29

IR-CAP – GUIDELINES FOR TANKERS

E. Final CAP Rating for Hull Structure

1. The finalised CAP rating awarded for the

vessel’s Hull structure is based on a

comparison between the rating awarded for the

overall Hull structural Condition rating and the

rating awarded to Structural Strength Rating

b.The document gives no period of validity, but

charterers

have

introduced

their

own

acceptance periods

The finalised CAP rating for Vessel’s hull structure

shall be the Lowest of the rating values as per

the example given in Table 6.

Table 6: Final CAP Rating for Hull Structure

F. CAP Hull Structure Reporting

1. CAP Survey Defects

a.All defects which would result in Condition of

Class when performing a class survey are

included in the Defects List. These defects must

be repaired.

b.When CAP Surveys are carried out

Independently of class surveys, the CAP

surveyor will ensure that all findings below class

requirements are being repaired.

c. Defects found during the overall, external and

close up survey are advised to the owner's

representative using the onboard survey

document.

d.Should defects be found during the close-up

surveys, then these defects will be advised to

the client’s representative in writing using

survey report and photographic records will be

made. If these items are upgraded / rectified, a

follow- up inspection will be made and

photographs are taken to show the

rectifications.

e. These defects/rectifications are part of the final

CAP report and will be taken into consideration

within the structural CAP ratings issued at the

completion of the surveys.

2. CAP Certificate

a.A CAP Certificate is to be issued at completion

of the CAP project. The overall CAP Hull Rating

is stated in the Certificate along with date of

inspection and ship information

3. CAP Hull Structure Report

The CAP hull report consist the following points

•

Declaration

•

Particulars of the vessel

•

summary of findings from inspection and

Analysis

•

CAP rating summary

•

Structural strength analysis and rating

•

Descriptions, observations and ratings for

each main structural element in each tank /

space

•

Summary of visual surveys and rating

•

Descriptions of defects and repairs

•

Statistical analysis of UTM data for each

Panel in each tank / space

•

Photographic evidence of the condition in

each tank / space

•

Longitudinal strength calculation

•

Report for fatigue strength assessment if

applicable

•

Hull assessment by percentage cumulative

diminution

4. CAP Upgrade Report

a.It is the client’s decision to upgrade the

structure beyond the minimum acceptable

standard to achieve the CAP rating objective.

b.In addition to the defects included in the Survey

Report, findings considered above class

minimum requirements may affect the UTM and

Page 18 of 29

IR-CAP – GUIDELINES FOR TANKERS

visual Survey rating. It is up to the owner to

decide if such findings are to be repaired.

Various levels of upgrading above class

minimum requirements may be necessary in

order to reach the client’s local or overall CAP

rating objective. Such items requiring upgrading

are described in a CAP Upgrade Report.

c. The level of detail in the CAP Upgrade Report

will vary depending of the size of the gap

between the observed condition and the client’s

desired CAP rating. In cases of considerable

deviation it will not include lengthy, specific

repair proposals. It should be noted that

upgrading is voluntary, and that it is expected

that the client takes responsibility for it. IRS and

the CAP surveyor will assist in every way

possible in order to achieve a successful

outcome of the project.

d.The rating methodology involves averaging of

several factors, and

it may be

complicated to give exact advice regarding the

level of upgrading necessary to obtain a

specific overall CAP rating. The CAP Upgrade

Report may therefore be seen as an overview

of items that must be upgraded in order to avoid

local ratings below the client’s objective, and

not as a guarantee of a specific overall rating

following upgrading of the described items. This

is particularly the case for an overall CAP rating

of 1. Achieving a CAP 2 rating overall will in

most cases be obtained by repairing defects in

the CAP survey report and upgrading of

findings in the CAP Upgrade report

5. Completion and follow-up

a.A CAP report describes the condition of the

vessel at the time of the inspection, the repair of

defects,

any

upgrading

carried

out,

Photographic evidence and the condition at the

end of the process.

b.In order to update the report and to re-evaluate

of the CAP rating for the upgraded area after

repairs and upgrading, IRS needs to re-inspect

the vessel.

c. Similarly, the UTM analysis and rating in the

CAP report must be updated if steel renewals

due to low thickness have been carried out. In

such cases the UTM report is to be updated by

the UTM company and re-submitted.

d.The final CAP Hull Structure report will be

completed based on the documented condition

of the ship at the end of the CAP process.

Page 19 of 29

IR-CAP – GUIDELINES FOR TANKERS

Section 3.

MACHINERY AND CARGO

SYSTEMS

A. General

1. Condition Assessment Program for Machinery

& Cargo Systems - Concept

a.IR-CAP for Machinery & Cargo Systems and

fittings is a risk-management tool designed to

assess the overall maintenance condition as

well as the actual operational condition of the

onboard Machineries & Cargo Systems and

fittings.

b.The IR-CAP surveyors assess and make use

of the records of condition monitoring and

planned maintenance systems, analyses and

reports which are already part of the day to

day maintenance management. The vessel’s

records, vibration analysis, lubricating oil

analysis, Insulation resistance test, Infrared

Thermography and other systems’ analyses are

reviewed during this process.

also be supplemented by insulation testing and

infrared Thermography.

c. In general the surveyor will not request to open

up equipment for inspection of component

parts, however, where equipment is found

disassembled for maintenance during CAP

surveys, and then this should be documented

within the Machinery and Cargo Systems &

Fittings report and a photographic record taken.

d.During the operational surveys, the surveyor

may determine to extend the scope of the

surveys e.g. the surveyor may request that a

unit be disassembled for inspection where the

item show signs of deterioration in external

condition or during function testing.

e.Defects found during operational surveys are

advised to the owners’ representative using the

onboard visit report / defect list.

2. Condition Assessment of Machinery & Cargo

Systems - Ratings

The IR-CAP rating system is broadly defined in

Section 1, para B 2, and Table 1. The CAP

rating is awarded for the vessel’s Machinery

and Cargo systems and fittings based on a

comparison between the rating awarded for the

overall operational condition of the equipment

and the global rating for maintenance which is

awarded based on an audit of the vessel’s

planned maintenance system (PMS). The CAP

rating shall be the worst of these rating values.

B. Operational Condition Surveys, Scope and

Rating Criteria

1. General

a.Indian Register of Shipping does not make use

of any weighting factors in order to calculate

final ratings but instead, it uses a group

approach whereby similar Machinery Elements

i.e. Equipment and systems are amalgamated

into ‘Machinery Groups’. This makes it easy for

reporting as well as providing a logical method

for assessment of ratings whereby each group

has equal weight in the calculation of the overall

operational condition rating.

b.Operational condition surveys consist of a

visual condition inspection, a function test and

depending on the equipment type, a review of

vibration analysis and/or a hydraulic or

lubricating oil analysis. These surveys may

2. Visual Inspection

a.Visual inspections are carried out to assess the

overall condition of each machinery unit

together with its appurtenances, bed plates and

supports. The surveyor inspects (depending on

the type of unit) for evidence of damage,

deformation,

cracks,

leakages,

coatings

breakdown, corrosion, pitting, erosion, etc.

b.During these inspections, the CAP surveyor

takes representative photographs which are

attached to the Machinery and Cargo Systems

Report to provide photographic record of the

general condition of the machinery and cargo

systems & fittings. The rating of visual

inspection is done according the criteria in

Table 7.

Page 20 of 29

IR-CAP – GUIDELINES FOR TANKERS

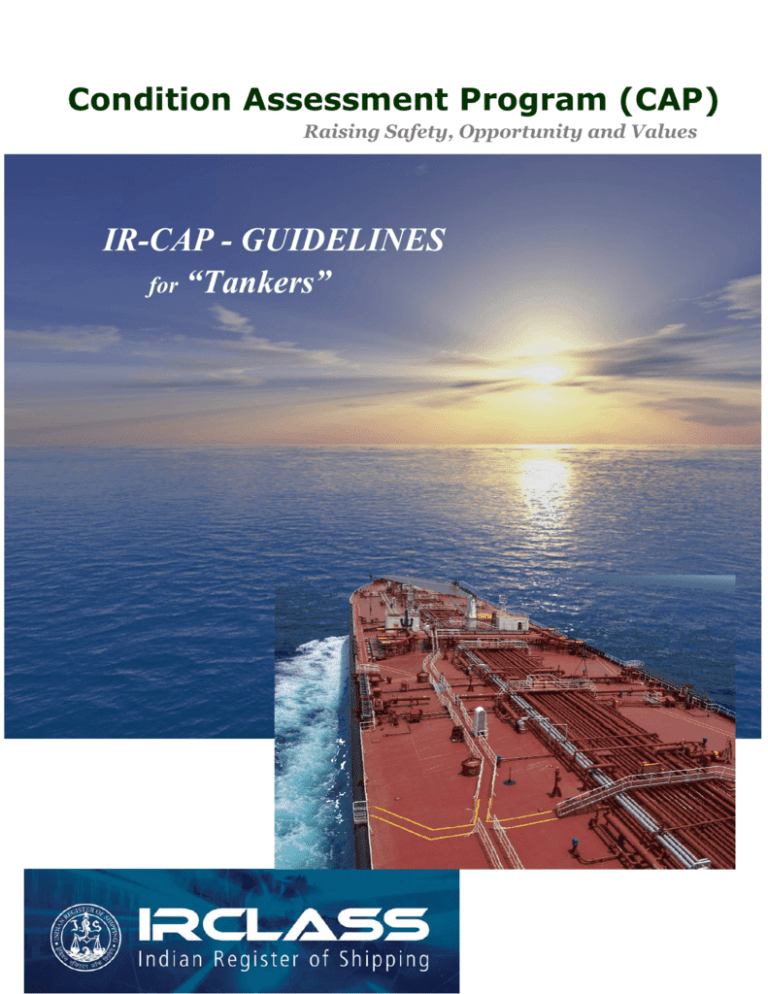

Table 7: Visual Inspection Rating Criteria

Table 8: Function Test Rating Criteria

3. Function Test

a.Function tests are carried out on equipment

under working conditions with the results

assessed against the operational criteria from

manufacturer, e.g. pumps and compressors are

to be tested run and their performance

assessed, closing appliances are to be tested

for full range of movement, machinery safety

devices are to be tested and proved, alarms

and instrumentation are to be actuated and

inspected, pipelines are to be pressure tested,

etc.

b.All propulsion and auxiliary machinery, fittings

and systems' equipment is required to undergo

function test and to be rated according to Table

8. It is recognised that some vessel's systems

such as CO2 flooding, foam systems, etc. will

not be able to have their performance fully

tested however these can be assessed by

supplemental means such as simulation, level

testing and chemical analysis.

4. Vibration Analysis

a.Vibration measurements on rotating and

reciprocating machineries will be carried out by

IRS Surveyor during vessels voyage/at

anchorage or during cargo operation as per

vessel’s availability.

b.When the vibration evaluation criteria of

machinery and equipments are provided by

manufacturers and measurements are normally

performed under the same operating and

loading conditions as per manufacturer’s

recommendation. Refer Table 9.

c. If there are excessive vibration levels that infer

significant deterioration of the equipment, then

the unit should be opened for examination of

the rotating components.

d. Where no vibration analysis is carried out for

an item of rotating machinery then the best

average rating that may be applied to that Item

is a rating 2, i.e. irrespective of the results of

any visual test, function test or lube analysis, a

rating of 1 cannot be awarded for an item of

rotating machinery if vibration analysis is not

carried out.

Page 21 of 29

IR-CAP – GUIDELINES FOR TANKERS

Table 9: Vibration Analysis Ratings Criteria

Table 10: Vibration Analysis Rating Criteria for

Rotating Machinery

(Where Manufacturer’s Vibration evaluation criteria are not

available)

e.In case manufacturer’s vibration evaluation

criteria of machinery and equipments are not

available, then the applicable criteria’s for the

evaluation of machine vibrations are specified

in each of the following Groups. The evaluation

criteria relate to acceptance testing and apply

only to the vibration produced by the machine

itself and not to vibration transmitted from

outside. The magnitude of observed broadband

vibration is considered to assess vibration

severity of various machines.

Groups for Rotating Machinery

Group 1: Large machines with rated power

above 300 kW; electrical machines with shaft

height ≥ 315 mm from the base.

Typical machines include turbo generators,

alternators, large electrical motors etc. These

machines normally have sleeve bearings and

an operating speed range from 120 r.p.m to

15,000 r.p.m.

Group 2: medium sized machines with rated

power above 15 kW and up to and including

300 kW; electrical machines with shaft height

160 H < 315 mm.

Typical machines are electrical motors. These

machines normally have rolling element

bearings and operating speed above 600 r.p.m.

Group 3: Pumps with multivane impellers and

with separate driver (centrifugal, mixed flow and

axial flow) with rated power above 15 kW.

Typical machines are steam turbine driven

cargo pumps, electrical driven auxiliary pumps,

forced draft fans, I.G. blowers etc. These

machines normally may have sleeve or roller

element bearings.

Group 4: Pumps with multi vane impellers and

with integrated driver (centrifugal, mixed flow

and axial flow) with rated power above 15 kW.

Page 22 of 29

IR-CAP – GUIDELINES FOR TANKERS

Note: Different and/or higher values may be

permissible for specific machines and operating

conditions. All such cases are subject to special

consideration.

These values apply to radial measurements on

all bearings, bearing pedestals, or housings of

machines and to axial vibration measurements

on thrust bearings.

Groups for Reciprocating Machinery

Table 11: Vibration Analysis Rating Criteria for

Reciprocating Machinery

(Where Manufacturer’s Vibration

criteria are not available)

evaluation

Note:

1. Where generators are coupled to the

flange housing of the engine the values

measured at the engine end of the generator

shall meet the values for generators

2. For vertically mounted motors the vibration

level may be increased by 50% for the top of

the motor.

5. Lubricating Oil / Hydraulic Oil Analysis

a. Where appropriate, lubricating and hydraulic

oil samples are collected from respective

systems and are to be tested for evidence of

deterioration of the oil or of equipment parts

and for suitability of the oil for continuous

usage.

Systems and equipment that would be normally

expected to have oil analysis carried out are

usually fitted with sumps or 'top up' or 'header'

tank. The result of the analysis then is then

rated according to the Table 12.

Table 12: Lubrication Analysis Ratings Criteria

b.Where hydraulic oil or lubricating oil analyses

are not carried out, for a system or for

equipment which would normally be expected

to have such analyses, then the best average

rating that may be applied to that system or

equipment is a rating 2, i.e. irrespective of the

results of a visual test, function test or vibration

analysis, a rating of 1 cannot be awarded if an

oil analysis is not carried out.

c. In general lube oil sample reports may be

accepted if they are carried out within three

months prior to the start date of CAP survey.

6. Ultrasonic Thickness Measurement

a. Although there is no requirement for UTM

measurements for Machinery and Cargo

Systems & Fittings, the CAP surveyor may

request UTM measurements for machinery

items that show evidence of deterioration during

visual examination or are subject to leaks

during pressure testing.

( e.g. - Sea Water System, Fresh Water

Systems, Machinery Foundation, Steam pipe

lines, Crude oil Cargo Lines, Heat exchangers,

Boiler and its Associated Systems, Hydrophore

Page 23 of 29

IR-CAP – GUIDELINES FOR TANKERS

Systems, Ballast and fire lines, Sewage Tanks

and Systems, etc.)

equipment being assessed, however, the

results of the IRT assessment will not be rated.

b. The surveyor may also request that pipeline

sections or machinery items be disassembled

for internal visual inspection depending on

measurement results.

C. Machinery and Cargo Systems Groups,

Machinery Sub Groups and Machinery

Elements

7. Insulation Testing

a.Insulation Megger testing is to be carried out in

accordance with class requirements and the

rating criteria, in Table 13 should be applied.

Note: The overall rating assigned for an item

cannot be higher than the Megger test rating if

a rating 4 is assigned for the megger results.

Table 13: Insulation Megger Testing Ratings

Criteria

1. General

To facilitate the assessment and reporting on

the vessel's Machinery and Cargo systems &

fittings,

The Following Subdivisions have been created:

• Machinery Groups are

Machinery Sub Groups and

divided

into

• Machinery Sub Groups Are Divided into

Machinery Elements.

This makes it easier for reporting as well as

providing a logical method for assessment of

ratings where each group has equal weight in

the calculation of the overall operational

condition rating.

D. Operational Condition Ratings Assessment

1. Operational Condition Rating of Machinery

Groups

a.During the CAP Survey of Machinery and

Cargo Systems and fittings, individual

Machinery Element ratings are awarded for

visual condition, function test, vibration

analysis, lubricating oil analysis and Insulation

Resistance as applicable. These ratings are

then combined to give an average rating,

rounded to the nearest first decimal point, for

each Machinery Element.

b.Each Machinery Element average rating is then

combined to give an overall average rating,

which is then rounded to the nearest whole

number to give an operational condition rating

for the Machinery Sub Group that is being

surveyed.

8. Infrared Thermography

Infrared Thermography assessment of the

operational condition of electrical equipment

and cabling may be included as part of the

condition assessment as a supplement to

function testing if the client requests, this to be

included in the CAP report. Where this is

carried out, a summary IRT report is to be

attached to the Machinery and Cargo Systems

& fittings report for additional information on the

c. Each Machinery Sub group average rating is

then combined to give an overall average

rating, which is then rounded to the nearest

whole number to give an operational condition

rating for the Machinery Group that is being

surveyed.

Figure: 9 shows, how the operational condition

rating for a Machinery Sub Group: 1. Auxiliary

Generators/Emergency

Generators/Shaft

generators is tabulated and computed from the

Sub Group Machinery/Element ratings. In given

Example hypothetical rating for Machinery sub

group is assigned as 2.

Page 24 of 29

IR-CAP – GUIDELINES FOR TANKERS

Figure: 10 Shows how the operational

condition rating for Machinery Group:

3.

Electrical Power Generation & Distribution

System is tabulated and computed from the

each Sub Group ratings (For Example

Hypothetical ratings of Machinery group that is

being rated is Machinery Group: 3. Electrical

Power Generation & Distribution System.

Additionally there are two more subgroups are

under consideration for Machinery Group 3)

In the above examples the average operational

rating for this hypothetical Sub groups is given

as 1.7 and revised overall operational rating is

2.

Figure 9: Illustration of Machinery Sub Group

Operational Condition Rating

Note 2: Where analyses are not required to be

carried out, then these are left unrated and N/A

has been entered instead of a rating. N/A = Not

Applicable. Where N/A is entered then this

‘rating’ is omitted from the calculation for the

average rating.

2. Overall Operational Condition Rating

a.To arrive at an overall operational condition

rating for the Machinery and Cargo systems &

fittings the individual

operational condition

ratings awarded for each Machinery group are

combined. An average operational condition

rating is then computed and a final rating

formulated.

b.The example described in Figure 11, shows the

table which is normally used to show the ratings

awarded to individual Machinery groups

together with the overall operational condition

rating awarded. In this example the average

rating is calculated as 1.6 which is then

rounded upwards to an overall operational

condition rating of 2.

Figure: 11 Illustration of overall operation

condition Rating

Figure 10: Illustration of Machinery Group

Operational Condition Rating

Note 1: Where there are no sub groups in the

Machinery group then the Average Operational

Ratings of Machinery Elements will be directly

applicable to the Machinery group.

Page 25 of 29

IR-CAP – GUIDELINES FOR TANKERS

E. CAP Rating Guidelines for Rating of

Machinery and Cargo Systems & Fittings

1. General

a. The rating applied to an Machinery Element

visual condition, function

test, vibration

analysis,

oil analysis

and

Ultrasonic

Thickness Measurement (UTM) shall be an

integer, either 1, 2, 3, or 4. If no rating can be

given then a comment is required to be made

e.g. N/F (not fitted), N/T (not tested) or N/A (not

applicable), etc.

b.Each average rating calculated for an

Machinery Elements and Machinery Sub

groups, is to be rounded (For Example-.an

average of 1.01 to 1.49 is to be rounded down

to 1 and 1.50 to 1.99 is rounded up to 2)

c. The operational condition rating for each

Machinery group, or for the overall operational

condition rating for 'Machinery and Cargo

Systems & Fittings’ and as a whole, is also

assigned by rounding to the nearest integer, as

above.

d.Where there are no sub groups in the

Machinery group then the Average Operational

Ratings of Machinery Elements will be directly

applicable to the Machinery group.

e. Where no function test or required analysis

are carried out for an Machinery Element then

the best average rating that can be applied to

that specific Machinery Element is a rating of 2,

i.e. irrespective

of the results of other

tests/analyses a rating of 1 cannot be awarded

for any item if a function test or an required

analysis is not carried out. Where no function

test or required analysis is carried out then this

is to be highlighted in the Machinery and Cargo

System & fittings report.

f. Where no function test and required analysis is

carried out for any Machinery Element, then the

best average rating that can be applied to that

specific Machinery Element is a rating of 3. This

is also to be highlighted in that Machinery group

part of the Machinery and Cargo System &

fittings report.

g.Irrespective of the average rating calculated

for an Machinery group, the rating awarded for

that Machinery group as a whole, cannot be

better than one rating grade better than the

worst rating applied to an Machinery Element

for a function test or a required analysis (e.g. if

one Machinery Element is awarded a rating 3

for function test then the maximum rating that

can be applied to that Machinery group is a

rating of 2.) This is also to be highlighted in that

‘Machinery Group’ as part of the Machinery and

Cargo System & fittings report.

h.If ‘Machinery and Cargo System & fittings’

Machinery Elements, that are critical to the safe

operation of the vessel or for the safety of the

crew, have been awarded a rating of 4, then the

rating awarded for that machinery group will

also

be

a

4,

except

where

the

Machinery/element is covered by redundancy

and the secondary unit has a rating of 2 or

better.

(Critical items are Machinery Elements such

as main

engine, Steering Systems,

generators, fuel pumps, boilers, main cooling

water pumps, lube oil pumps, fire alarm

systems, fire fighting systems, anchors, anchor

chains, windlasses, rudder, PV valves etc.)

F. Global Rating for Maintenance

1. General

The global rating for maintenance for the

Machinery and Cargo System & fittings is

awarded based on the results of an audit of

the vessel's planned maintenance system

(PMS). The requirements for a PMS are

reviewed and the scope of the audit of the PMS

is discussed.

2. Scope of Audit

a.The surveyor will audit that part of the PMS

system that covers the Machinery and Cargo

System & fittings.

b.The audit is to cover the timely implementation,

frequency, scope and results of the

maintenance. Postponements and overdue

Page 26 of 29

IR-CAP – GUIDELINES FOR TANKERS

items are to be included in the audit and

reporting and follow-up actions are to be

identified and reviewed.

3. Global Rating for Maintenance

The global rating for maintenance for the

vessel’s Machinery and Cargo System & fittings

is awarded as per the criteria in Table 16.

Table 16: Global Rating Criteria for planned

maintenance system (PMS)

G. CAP Rating for

System & fittings

Machinery

and

and reports, complete

records of the surveys.

with

photographic

3. Update Analysis and Report

All Machinery Element or components of

Machinery are awarded a rating lower than the

minimum rating expected by the client, then

these are analyzed and a report is forwarded to

the client.

Cargo

1. Final Rating

a.As stated in below para b, the CAP rating

awarded for the vessel’s Machinery and Cargo

System & fittings is based on a comparison

between the rating awarded for the overall

operational condition and that awarded for the

global rating for maintenance.

b.The finalised CAP rating for Machinery and

Cargo System & fittings, shall be the worst of

these rating values as the example in Table 17.

Table 17: Final CAP Ratings for Machinery and

Cargo System & fittings

2. Machinery and Cargo System & fittings Report with Photographs

On the completion of the CAP survey, the

surveyor compiles a report for each Machinery

Group, Machinery Sub Group and Machinery

Element surveyed. The report includes the table

for compilation and computation of the overall

operational condition rating to be awarded for

Machinery and Cargo System & fittings and a

set of individual Machinery group rating tables

Page 27 of 29

IRCAP –GUIDELINES For “TANKERS”

Section 4.

Annexure - I

Spaces (Ballast, Cargo, Fore Peak, Aft Peak,

Engine Room, Pump Room, Void Tanks, etc.)

“IR CAP Thickness

Measurements Guidelines”

(Annexure – I)

A. Requirement for standard

Thickness Measurements

extent

of

1. Ultrasonic thickness measurement is required

to establish the extent of corrosion for all tanks,

spaces and structures to be rated. Thickness

measurement gives representative data for all

main and internal structural elements of all

required tanks and spaces. The UTM data is