Supervisory Control by Using Active Virtual 3D Models in-the

advertisement

Supervisory Control by Using Active Virtual 3D Models in-the-loop

T. Reichenbach, D. Miklić, Z. Kovačić

Faculty of Electrical Engineering and Computing

Department of Automatic Control, Zagreb, Croatia

tomislav.reichenbach@fer.hr damjan.miklic@fer.hr zdenko.kovacic@fer.hr

Inputs

(trajectories,

references)

Virtual Outputs

(states, events

positions,

velocities, etc)

I. I NTRODUCTION

If an assumption is made that virtual models are as close

as possible to the real ones, events in the virtual world

should reflect those from the real world. The concurrence

of real and virtual systems allows the use of virtual sensors

instead of real ones. Ordered by increasing complexity,

virtual environment (VE) can be used for visualization, collision detection and collision avoidance. Real-time collision

avoidance strategy assumes that a feedback from a collision

detection algorithm executed in VE must exist [1]. Regarding

the implementation of effective collision avoidance strategies, the main usability factor of such virtual modeling

and collision detection engine is its ability to interact with

other applications. Herein we demonstrate the concept of

supervisory control using active 3D models in-the-loop that

are effectively interacting with the Matlab+SimulinkTM simulation environment thanks to the Matlab’s built-in Component Object Model (COM) support. The examples presented

in this paper demonstrate the seamless integration of the

developed virtual modeling engine with a supplementary

Simulink models.

The paper is organized in the following way. First we

describe the concept of supervisory control using active

3D models in-the-loop. Then we describe integration of the

virtual modeling engine called L.I.S.A. and Matlab using

COM. Two examples demonstrating the applicability of the

concept are presented; implementation of a virtual sensor,

and introduction of the virtual reality feedback in the closed

control loop.

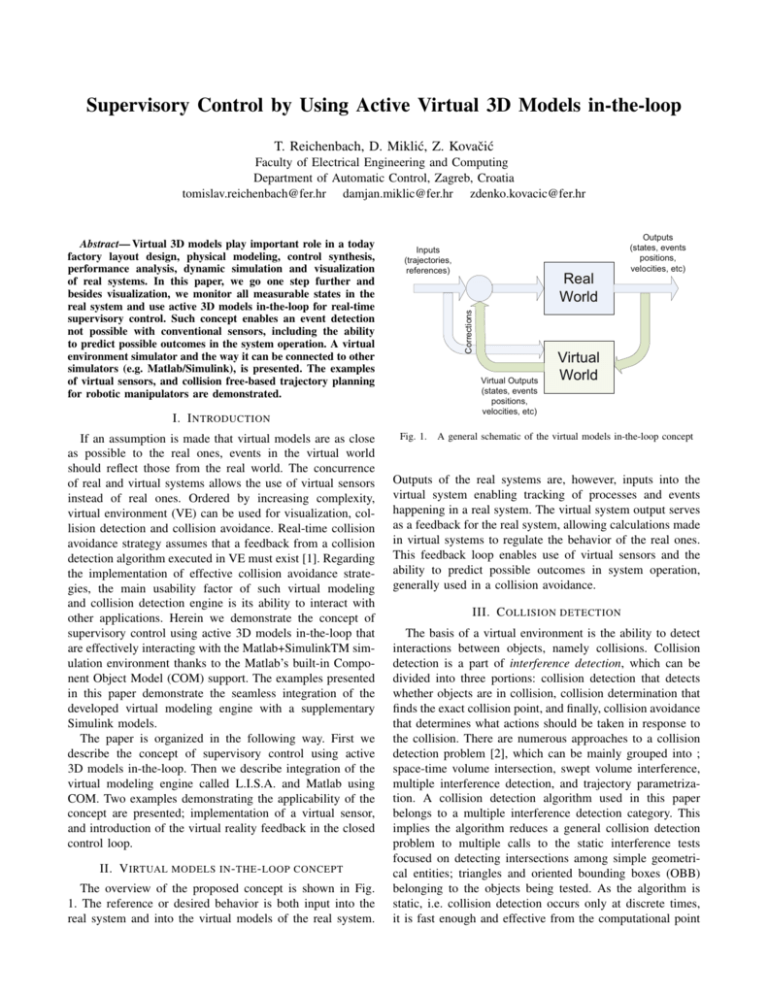

II. V IRTUAL MODELS IN - THE - LOOP CONCEPT

The overview of the proposed concept is shown in Fig.

1. The reference or desired behavior is both input into the

real system and into the virtual models of the real system.

Real

World

Corrections

Abstract— Virtual 3D models play important role in a today

factory layout design, physical modeling, control synthesis,

performance analysis, dynamic simulation and visualization

of real systems. In this paper, we go one step further and

besides visualization, we monitor all measurable states in the

real system and use active 3D models in-the-loop for real-time

supervisory control. Such concept enables an event detection

not possible with conventional sensors, including the ability

to predict possible outcomes in the system operation. A virtual

environment simulator and the way it can be connected to other

simulators (e.g. Matlab/Simulink), is presented. The examples

of virtual sensors, and collision free-based trajectory planning

for robotic manipulators are demonstrated.

Fig. 1.

Outputs

(states, events

positions,

velocities, etc)

Virtual

World

A general schematic of the virtual models in-the-loop concept

Outputs of the real systems are, however, inputs into the

virtual system enabling tracking of processes and events

happening in a real system. The virtual system output serves

as a feedback for the real system, allowing calculations made

in virtual systems to regulate the behavior of the real ones.

This feedback loop enables use of virtual sensors and the

ability to predict possible outcomes in system operation,

generally used in a collision avoidance.

III. C OLLISION DETECTION

The basis of a virtual environment is the ability to detect

interactions between objects, namely collisions. Collision

detection is a part of interference detection, which can be

divided into three portions: collision detection that detects

whether objects are in collision, collision determination that

finds the exact collision point, and finally, collision avoidance

that determines what actions should be taken in response to

the collision. There are numerous approaches to a collision

detection problem [2], which can be mainly grouped into ;

space-time volume intersection, swept volume interference,

multiple interference detection, and trajectory parametrization. A collision detection algorithm used in this paper

belongs to a multiple interference detection category. This

implies the algorithm reduces a general collision detection

problem to multiple calls to the static interference tests

focused on detecting intersections among simple geometrical entities; triangles and oriented bounding boxes (OBB)

belonging to the objects being tested. As the algorithm is

static, i.e. collision detection occurs only at discrete times,

it is fast enough and effective from the computational point

of view, thus it can provide real-time collision detection in

very complex (high polygon count) virtual environments [3].

An intersection between two OBBs, A and B is is based

on the separating axis theorem presented in [4] and [5].

According to the separating axis theorem it is sufficient to

find one axis that separates objects A and B to determine

they do not overlap. After the intersection between the

OBBs is determined an exact collision point is found with

triangle/triangle intersection test. The algorithm used for

triangle/triangle intersection test is the algorithm from in

ERIT package [6].

The collision point and the normal to the collision surface

are further used for a collision avoidance algorithm [1],

where automatically the collision-free path is generated only

by specifying the desired start and the end trajectory point.

IV. A PPLICATION I NTEGRATION U SING COM

This section specifically focuses on integration of virtual

modeling engine L.I.S.A. with Matlab/Simulink using COM

[7], an application integration framework provided by the

Microsoft Windows operating systems.

A. A COM Interface for Collision Avoidance

To enable other programs to use the virtual reality modeling engine, it was written as a COM local server. Its

functionality was encapsulated inside a COM object and

exposed through the object’s interface. The object was placed

inside an out-of-process COM server that handles the tasks

involved in providing the object to clients upon their request

(see Fig. 2).

Client application

(Simulink)

Fig. 2.

Interface

pointer

(handle)

Interface

- Method1()

- Method2()

-...

COM Object

(VR engine)

COM Out-ofProcess Server

Basic COM topology for application integration

The COM interface exposes the object’s functionality

through a set of public methods. The methods can be roughly

grouped together in four groups, by their functionality:

•

•

•

•

scene object selection

scene object manipulation

collision detection

collision free trajectory planning

Most methods come in get/set pairs. By calling the COM

object’s methods, clients can exercise complete control over

the virtual model and get feedback information on it’s states.

This enables client programs to use virtual reality models for

various control tasks, ranging from simple visualization to

soft sensors and virtual reality in-the-loop applications.

B. Integration with Simulink Models

Integrating COM objects into Simulink models is fairly

straightforward, since Matlab features built-in COM support.

The COM object must provide a type library which is a

binary description of its interface. The object’s functionality

is accessible from the Matlab command line or in m-code

through Matlab’s built-in ”COM” object.

To enable a more user friendly integration with Simulink

models, a pair of s-function blocks has been built around

the COM object, encapsulating scene manipulation and trajectory planning functionality respectively. The functionality

has been split in two blocks to reflect the fact that one part

of it deals with geometrical representations and relationships

between scene objects thus belonging to the physical description of a system, whereas the other part provides trajectory

planning capabilities and belongs to the control logic. The

usage of the blocks in simulation models can be seen in the

figures accompanying the experiments.

V. E XAMPLE 1 - COLLISION DETECTION

This example demonstrates the integration of the virtual

reality engine within a Simulink model. Simulink is used

for modeling system dynamics while a virtual reality scene

provides spatial representations and interactions between

objects. Component Object Model is the underlying technology that handles the communication between the two

applications.

The basic idea in the first example is to simulate dynamics

of a ball in simple “pong” type game (A minimalistic depiction of two player indoor soccer match). The objective of the

game is to keep the ball inside a confined environment by

controlling two slabs, representing players, positioned at the

opposite sides of the playing field. The field is constrained

in y-axis direction, bouncing the ball back; furthermore, the

playing field is cluttered with various objects that can change

the course of the ball. To keep matters simple, we assume

that the ball movement is confined to the x-y plane only and

that materials are frictionless. A discrete simulation step of

the simulation should be sufficiently small so that a collision

will be detected before the object passed completely through

the obstacle.

To control the ball, one must control the two slabs that

can move only vertically, requiring two control variables

y1ref and y2ref , representing respectively set-points of the

slabs. Additional parameters used are m1 , m2 , mball the slab

and the ball mass, v = {vx , vy } the ball velocity, and ci ,

coefficients of restitution for the i-th object.1

The block schematics in Simulink, showing system structure, are presented in Fig. 3 and the actual virtual environment in Fig. 4. The dynamics of moving objects and control

laws are modeled by ordinary differential equations and object positions are sent to the 3D scene model through custom

s-function blocks. A feedback from the 3D model block

provides collision information for the dynamical model.

1A

measure of amount of energy lost in the process of collision.

(x,y)

(x,y)

(x’,y’)

sfcn_lisa

COLLISION

BALL DYNAMICS

BRICK_1

POSITION CONTROL

sfcn_lisa

BRICK_1 VR MODEL

BRICK_1 DYNAMICS

PI

Fig. 3.

(x,y)

(x,y)

(x’,y’)

PI

BRICK_2

POSITION REFERENCE

(USER INPUT)

BALL VR MODEL

BRICK_2

POSITION CONTROL

(x,y)

(x’,y’)

(x,y)

sfcn_lisa

BRICK_2 VR MODEL

BRICK_2 DYNAMICS

“pong” type game simulation schematic in Matlab’s Simulink connected with a virtual environment simulator

3D Virtual environment

simulator

Sensor failure

detection

object position [mm]

Fig. 4.

“pong” type game simulation in a virtual environment simulator

VI. E XAMPLE 2 - VIRTUAL SENSOR

The simple example is given in Fig. 5 where the speed

of real conveyer belt is passed through RS232 connection to

the virtual conveyer belt, modeled in 3D environment. An

infrared LED sensor, at the end of the belt, signals that the

object has reached the end of the belt, and accordingly the

belt can be stopped. The analogy in virtual environments

is a virtual sensor, that detects collisions between a line,

positioned at the same place as the LED sensor, and objects

moving on a conveyer belt. Ideally, both should signal at

the same time, although some small time margin is allowed,

providing redundancy and exemption from a sensor failure.

The friction between an object and the belt is high, consequently the premise is that an object is moving with the

same speed as the belt. However, additional camera detects

if the object is moving or not because of the obstacle in its

path. Sensor fusion between the camera and conveyer belt

position sensor is used to determine object position. If the

redundancy is not a requisite, only the virtual sensors can be

RS 232

TCP/IP

Belt speed [cm/s]

Camera

CamSensor CS4

Conveyer belt

Driver

Fig. 5.

sensor failure detection

used, thus lowering the complete cost of the system.

VII. E XAMPLE 3 - COLLISION AVOIDANCE

The Rhino XR3 robot has several predefined trajectories

that are constantly traversed back and forth. The robot is

traversing the same trajectory until it encounters an obstacle

(a box). If an obstacle is hit the robot starts another trajectory,

higher or lower in the z-plane, depending on the collision

point. The Simulink schematics of the system is shown in

Fig. 6 and the corresponding virtual environment for the

simulation is shown in Fig. 7.

The z-position of the box is changed interactively during

the simulation (see top graph in Fig. 8) so it becomes the

obstacle in the traversed trajectory of the robot. First, the

collision occurs around 7s after the start (bottom graph in

Fig. 8), forcing robot to another preset trajectory, afterwards

after 12s robot is again forced upward to another trajectory.

0.65

x

Scope1

0

sfcn_lisa

y

Box

XY Graph1

0.4

Scope5

z

Scope

boolean

Data Type

Conversion

Collision signal

U U(E)

−1

Z

sfcn_lisa

Integer Delay

Rhino

x_y_z

Selector

XY Graph

Trajectory references

Scope6

Fig. 6.

Simulink schematics for the robot evading a box example

box z−pos. [m]

0.06

0.04

0.02

0

0

5000

10000

15000

0

5000

10000

15000

0

5000

10000

15000

tool y−pos. [m]

0.4

0.3

0.2

0.1

0

collision

1

0.5

0

time [ms]

Fig. 8. Box z-position, manipulator’s tool y-position, and collision state

between the manipulator and the box

Fig. 7.

Virtual reality environment for the robot evading a box example

The middle graph in Fig. 8 represents robot’s tool y-position,

and it can be observed how it has increased after each

collision. The complete tool trajectory in X-Y space is

presented in Fig. 9.

VIII. CONCLUSIONS AND FUTURE WORKS

The significance of virtual 3D models in physical modeling, control synthesis, performance analysis, dynamic simulation and visualization of real systems is very high. On the

other hand, virtual modeling tools and related applications

use passive 3D object models (like the figures in the chess).

For example, a data flow from a Simulink dynamic model of

a process to the Matlab’s Virtual Reality Toolbox is always

unidirectional. The potential of virtual models could be much

higher if their passive role on the virtual scene would be

replaced with the active one. Setting this as a design goal,

a 3D modeling engine L.I.S.A. has been developed, whose

features like collision detection and trajectory planning have

enabled closing the feedback, and thus making L.I.S.A. the

part of a closed control loop. In other words, the existence

of virtual 3D models and collision detection in L.I.S.A.

enabled implementation of a so called ”3D model in-theloop” supervisory control. ”Virtual model in-the-loop” is a

step further from the passive visualization, as we still monitor

all measurable states in the real system and visualize them,

but we also detect events and predict possible outcomes in the

system operation, turning passive 3D models into the active

ones. The paper describes control concept implementation

details on the examples of collision free-based trajectory

planning for robotic manipulators and implementation of

virtual sensors. Attention has been paid to integration of

a virtual environment simulator and the process simulation

model created in Matlab/Simulink. Regarding a future work

on the systems controlled by the ”3D model in-the-loop”

supervisory control, effective on-line collision avoidance algorithms must be developed and implemented. Performance

in dynamically reconfigurable virtual scenes and scenes with

0.25

tool y−pos. [m]

0.2

0.15

0.1

0.05

0

Fig. 9.

−0.25

−0.2

−0.15

−0.1

−0.05

0

0.05

tool x−pos. [m]

0.1

0.15

0.2

0.25

XY position of the tool (for the robot evading a box example)

stochastic movements of 3D objects (identified for example

by stereo-vision and virtual scene reconstruction) should be

thoroughly analyzed and optimal solutions should be found.

IX. ACKNOWLEDGMENTS

This work was fully supported by a grant from the Croatian Ministry of Science, Education and Sports (the project

title 0036044 ”Integrated Control of Robotized Plants”).

R EFERENCES

[1] T. Reichenbach and Z. Kovačić, Cutting Edge Robotics. Advanced

Robotic Systems (ARS), 2005, ch. Collision-free path planning in robot

cells using virtual 3D collision sensors, pp. 683–704.

[2] P. Jiménez, F. Thomas, and C. Torras, “3D collision detection:

a survey,” Computers and Graphics, vol. 25, no. 2, pp. 269–

285, Apr. 2001. [Online]. Available: http://www.elsevier.nl/gejng/10/13/20/57/29/34/article.pdf

[3] T. Reichenbach and Z. Kovačić, “Collision avoidance in virtual environment based on usage of kinematics derived from a 3d robot model,” in

Proceedings of MED2003 CD, DNBI 85/-766/5-0-/, June 2003, Rhodes,

Greece.

[4] T. Möller and E. Haines, Real-Time Rendering. A. K. Peters, 1999,

mÖL t 02:1 1.Ex.

[5] S. Gottschalk, “Collision queries using oriented bounding boxes,” Ph.D.

dissertation, University of North Carolina at Chapel Hill, 2000.

[6] M. Held, “ERIT: A collection of efficient and reliable intersection

tests,” Journal of Graphics Tools: JGT, vol. 2, no. 4, pp. 25–44, 1997.

[Online]. Available: http://www.acm.org/jgt/papers/Held97/

[7] Matlab, The External Interface Guide, Matworks.