System solutions Handling technology

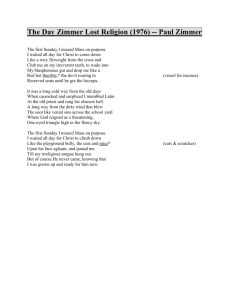

advertisement

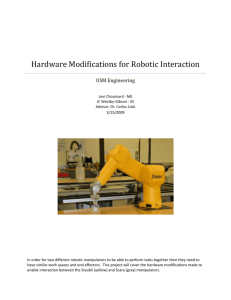

SYSTEM SOLUTIONS PROFESSIONAL EXECUTION, HIGHEST QUALITY AND FLEXIBLE SERVICE WE ARE THERE FOR YOU WHEREVER YOU NEED US WE DESIGN, ASSEMBLE, CHECK, AND DOCUMENT CONNECTION-READY SYSTEM SOLUTIONS. WE ARE NEVER SATISFIED WITH JUST FINDING ANY SOLUTION. INSTEAD, WE AIM TO FIND THE BEST SOLUTION FOR EACH CUSTOMER. ++ Connection-ready system solutions reduce your design and project-management costs. ++ Developed specifically for your application. ++ 100% tested! ++ Incl. detailed documentation. ++ Our experience from executing more than 6000 system solutions ensures that you get the functionality you need without compromising cost security. ++ Ten-million maintenance-free cycles provide maximum system availability. ++ Optimized dimensioning of components reduces gripper weight, optimizes dimensioning of the robot itself, and thereby minimizes cycle times. ++ Implementation of additional functions like cameras, sensors, measurement sensors, and screw functions reduces your costs and optimizes your application. SALES COMPANIES: China France Great Britain / Ireland Italy Switzerland / Liechtenstein Slovakia / Czech Republic Spain / Portugal South America South Korea United States / Canada / Mexico SALES PARTNERS: Zimmer Group China Ltd Zimmer Group Sarl Zimmer Group UK Ltd Zimmer Group Italia S.R.L Zimmer Group GmbH Zimmer Group Slowakei S.R. Zimmer Group Spanien S.L. Zimmer Group South America Imp. Exp.Ltda Zimmer Group Korea Ltd Europe Australia Asia Belgium, Denmark, Finland, Croatia, the Netherlands, Norway, Austria, Poland, Romania, Sweden, Slovenia, Hungary Australia / New Zealand India, Indonesia, Israel, Japan, Malaysia, Singapore, Taiwan, Thailand, Turkey System solutions Handling technology Sommer Automatic Inc. WE GIVE YOU THE GIFT OF TIME! PLEASE DO NOT HESITATE TO CALL US: Provision of connection-ready systems 100 % Initial consultation with Zimmer system sales 100 % 100 % 100 % Layout approval after technical review c ost and functional security tested Maintenance and documented service installed System solutions, Germany Jan Schaare System solutions, international Markus Böhmer T +49 7243 727 2413 M +49 151 1674 6346 jan.schaare@zimmer- group.de T +49 7243 727 2771 M +49 160 740 2335 markus.boehmer@zimmer- group.de Custom processes require intelligent solutions, perfectly tailored to the application. THE KNOW-HOW FACTORY CONTACT Obtain Simulation Select Design info compoGenerate nents concept Create and order items Fabrication Assembly Testing and of specific commisparts sioning Documentation Maintenance and service Zimmer Group Am Glockenloch 2 D-77866 Rheinau / Germany T +49 7844 9139-0 F +49 7844 9139-1199 info@zimmer-group.de www.zimmer-group.de www.zimmer-group.de PLASTICS ENGINEERING AUTOMOTIVE Gripper system for motor blocks (600 kg each) / loading and unloading of assembly stations Gripper system for aluminum rims / loading and unloading conveyors Gripper system for fuel tanks / loading of various machining stations Eight-way gripper system for metal bushings / placement for a injection molding machine FOUNDRY TOOL MACHINES ZIMMER GROUP SYSTEM SOLUTIONS ZIMMER GROUP IS ONE OF THE LEADING SPECIALISTS IN THE AREA OF GRIPPER SYSTEMS. REGARDLESS OF YOUR APPLICATION OR INDUSTRY: WE HAVE THE RIGHT SYSTEM FOR YOUR NEEDS. With more than 30 years of experience as a partner to customers in virtually every industry, we are intimately familiar with the requirements of modern manufacturing systems. Whether in mechanical engineering, the automotive and supplier industries, plastics engineering, consumer products, or foundries: The potential uses of robots are virtually unlimited. Our gripper systems will not limit your options. On the contrary, they expand your opportunities, regardless of which robot manufacturer you choose. Zimmer Group's ability to deliver effective solutions has been valued by project managers, designers, and managing directors for many years. We have been developing our gripper systems in close collaboration with integrators and end customers for more than 30 years. Gripper system, incl. tool changer for cast parts and deburring spindle / loading and unloading of machining center. Our team of twenty designers and project managers draws on more than 100 years of collective design experience in the development of custom gripper systems. The team has access to fabrication and assembly facilities that are specifically designed to execute individualized customer requirements with flexibility and speed. Zimmer Group The Know - How Factory Double grippers (unfinished / finished parts) for hollow shafts of gearwheels. Loading and unloading of a lathe. Gripper system for hot parts / removal from a forging press. SELECTED REFERENCE CUSTOMERS CONSUMER GOODS Gripper system for yogurt cups (varying diameters) / removal from deep-draw machine and packaging into boxes. Gripping / assembly system for sand core machine / removal from core shooter. Gripper system for boxes (1200 x 800 mm) / placement in a high bay warehouse in intralogistics ... and much more.