Course syllabus

advertisement

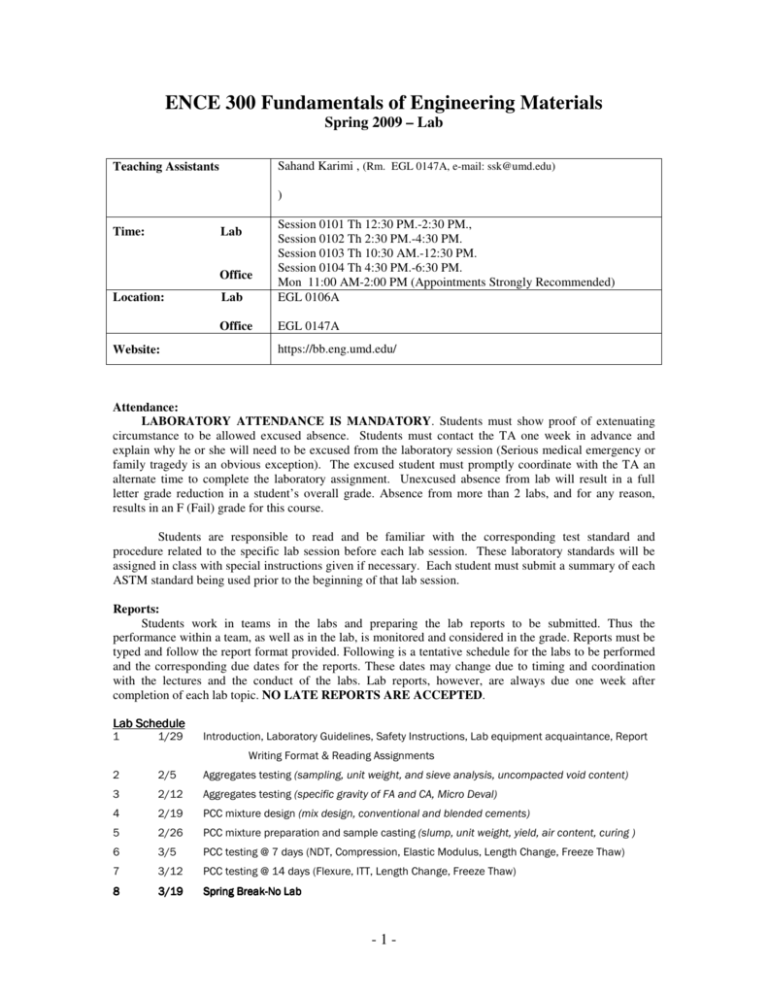

ENCE 300 Fundamentals of Engineering Materials Spring 2009 – Lab Sahand Karimi , (Rm. EGL 0147A, e-mail: ssk@umd.edu) Teaching Assistants ) Time: Lab Session 0101 Th 12:30 PM.-2:30 PM., Session 0102 Th 2:30 PM.-4:30 PM. Session 0103 Th 10:30 AM.-12:30 PM. Session 0104 Th 4:30 PM.-6:30 PM. Mon 11:00 AM-2:00 PM (Appointments Strongly Recommended) EGL 0106A Office EGL 0147A Lab Office Location: Website: https://bb.eng.umd.edu/ Attendance: LABORATORY ATTENDANCE IS MANDATORY. Students must show proof of extenuating circumstance to be allowed excused absence. Students must contact the TA one week in advance and explain why he or she will need to be excused from the laboratory session (Serious medical emergency or family tragedy is an obvious exception). The excused student must promptly coordinate with the TA an alternate time to complete the laboratory assignment. Unexcused absence from lab will result in a full letter grade reduction in a student’s overall grade. Absence from more than 2 labs, and for any reason, results in an F (Fail) grade for this course. Students are responsible to read and be familiar with the corresponding test standard and procedure related to the specific lab session before each lab session. These laboratory standards will be assigned in class with special instructions given if necessary. Each student must submit a summary of each ASTM standard being used prior to the beginning of that lab session. Reports: Students work in teams in the labs and preparing the lab reports to be submitted. Thus the performance within a team, as well as in the lab, is monitored and considered in the grade. Reports must be typed and follow the report format provided. Following is a tentative schedule for the labs to be performed and the corresponding due dates for the reports. These dates may change due to timing and coordination with the lectures and the conduct of the labs. Lab reports, however, are always due one week after completion of each lab topic. NO LATE REPORTS ARE ACCEPTED. Lab Schedule 1 1/29 Introduction, Laboratory Guidelines, Safety Instructions, Lab equipment acquaintance, Report Writing Format & Reading Assignments 2 2/5 Aggregates testing (sampling, unit weight, and sieve analysis, uncompacted void content) 3 2/12 Aggregates testing (specific gravity of FA and CA, Micro Deval) 4 2/19 PCC mixture design (mix design, conventional and blended cements) 5 2/26 PCC mixture preparation and sample casting (slump, unit weight, yield, air content, curing ) 6 3/5 PCC testing @ 7 days (NDT, Compression, Elastic Modulus, Length Change, Freeze Thaw) 7 3/12 PCC testing @ 14 days (Flexure, ITT, Length Change, Freeze Thaw) 8 3/19 3/19 Spring BreakBreak-No Lab -1- 9 3/26 Mortar and PCC testing @ 28 days (NDT, Compression, Length Change, Freeze Thaw, Mortar) 8 4/2 Superpave Mixture Design 9 4/9 Superpave materials and sample preparation (Gmb and Gmm) 10 4/16 Superpave Testing (Gmm, Gmb, and Moisture Susceptibility) 11 4/23 Metal Testing (Tension) 12 4/30 Timber Testing (Flexure and Compression) 13 5/7 Review PreLab Reading Assignments: 1 1/29 ----- 2 2/5 ASTM C29, C33, C136, C702, C1252 ((sampling, unit weight, sieve analysis, void content) 3 2/12 ASTM C127, C128, D6928 (specific gravity, FA and CA, Micro Deval) 4 2/19 ACI 211 (Concrete Mixture Proportioning) 5 2/26 ASTM C138, C143, C192 (slump, unit weight, yield, air content, curing) 6 3/5 ASTM C469, C597, C39, C157 (Compression, NDT, and Elastic Modulus, Length Change) 7 3/12 ASTM C78, C496, and C666 (Flexure, ITT, Freeze/Thaw) 8 3/19 3/19 ----- 9 3/26 ASTM C 109, C 1506, C 1437, C 305 10 4/2 ----- 11 4/9 Asphalt Volumetric Homework 12 4/16 ASTM D2041, D2726, D4867 (Gmm, Gmb, and Moisture Susceptibility) 13 4/23 ASTM A370, E8 (Tensile Testing of Metal) 14 4/30 ASTM D143 (Wood Testing) 15 5/7 ----- Lab Report Due Dates 1 2/19 Report #1 (Aggregate properties) 2 4/2 Report #2 (Mortar (Mortar and PCC mix design and behavior) behavior) 3 4/23 Report #3 (Asphalt mix design and behavior) 4 4/30 Report #4 (Metal testing and behavior) 5 5/7 Report #5 (Wood testing and behavior) *Notice: Other lab testing may be introduced as the semester progresses. All lab dates and assignment dates are not definite. Students are required to listen for modifications to the schedules and assignments during laboratory sessions. Adequate notice will be provided. Laboratory Reports Laboratory reports will be submitted two ways: -2- 1. One submission online via Blackboard’s Digital Dropbox function prior to the start of lab on the due date. 2. One hardcopy submission is also required at the beginning of lab on the due date. *Please combine all data in Microsoft Excel format and the written report sections into one printable, report-quality Microsoft Word file. Files submitted online should be saved with the following document headings Saved as Single Word File: Lab Group Number_Report Material.doc Example: Report: Group 1_Timber.doc Grading points: 1. Report - 75 % (reflecting 100% participation in the analysis and preparation of the report) (a) Format/Clarity/Neatness 5% (b) Content 25% (c) Calculations 20% (d) Summary & Conclusion 30% (e) Team Evaluation 20% Total (100%) 2. Lab attendance and class participation - 20 % (This includes pre-lab completion.) 3. Lab organization and Neatness - 5 % Additional ASTM References ASTM Standards: D 1754, D 5, D 2872, C 305, C 1437, C 185, C 109, C 1506, C 144, and C 270 -3-