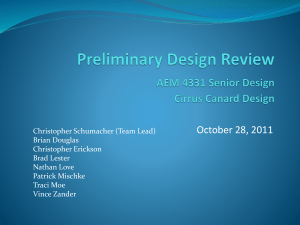

Aerodynamic and structural design of some components of an

advertisement