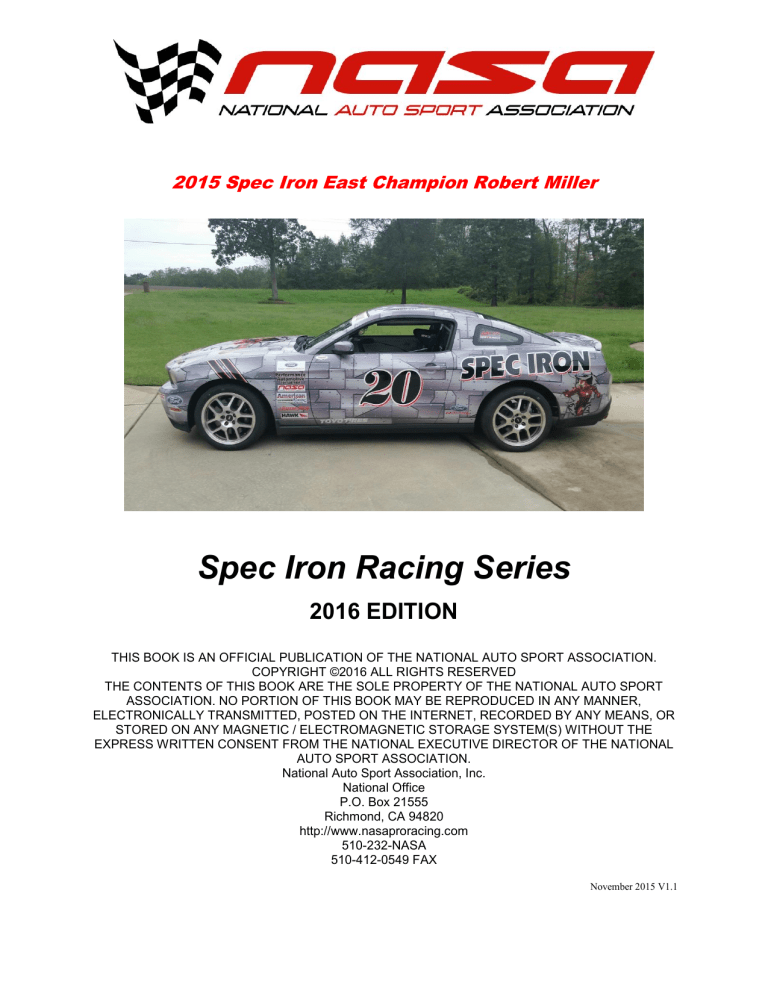

Spec Iron

2015 Spec Iron East Champion Robert Miller

Spec Iron Racing Series

2016 EDITION

THIS BOOK IS AN OFFICIAL PUBLICATION OF THE NATIONAL AUTO SPORT ASSOCIATION.

COPYRIGHT ©2016 ALL RIGHTS RESERVED

THE CONTENTS OF THIS BOOK ARE THE SOLE PROPERTY OF THE NATIONAL AUTO SPORT

ASSOCIATION. NO PORTION OF THIS BOOK MAY BE REPRODUCED IN ANY MANNER,

ELECTRONICALLY TRANSMITTED, POSTED ON THE INTERNET, RECORDED BY ANY MEANS, OR

STORED ON ANY MAGNETIC / ELECTROMAGNETIC STORAGE SYSTEM(S) WITHOUT THE

EXPRESS WRITTEN CONSENT FROM THE NATIONAL EXECUTIVE DIRECTOR OF THE NATIONAL

AUTO SPORT ASSOCIATION.

National Auto Sport Association, Inc.

National Office

P.O. Box 21555

Richmond, CA 94820 http://www.nasaproracing.com

510-232-NASA

510-412-0549 FAX

November 2015 V1.1

Spec Iron Racing Series

Copyright 2016, National Auto Sport Association

Official Rules

Rules Subject To Change

2016 Rules and Classifications

1. Introduction

The American Iron Series is a series with 3 classes: Spec Iron (SI), American Iron (AI) and American

Iron Extreme (AIX). The Spec Iron class (SI) is a road racing class under the umbrella of the American

Iron Racing series which is a road racing series featuring American “ponycars”. The American Iron Spec

Iron class was created to provide racers with the best value in amateur level road racing by combining the thunder and excitement of American style pony cars with the best possible reliability and durability of the racing platform, thereby minimizing total cost of ownership for racers.

2. Intent

The SI rules are designed to ensure parity and optimum reliability by clearly defining allowed modifications. Success in competition will come via driving skill and fine tuning of adjustable parameters.

Good sportsmanship is valued more than finishing position. This means clean, well-executed passing is to be a trademark of the series. Punting another competitor, or leaning on them to gain a position will not be tolerated. Car to car contact including bump drafting can result in an investigation and possible sanctions.

Manipulating the race start, yellow flags or race results in an unsportsmanlike manner is also unacceptable and will result in possible sanctions.

3. Sanctioning Body

The Spec Iron Series (SI) is supported and sanctioned by the National Auto Sport Association (NASA).

All race events are governed by the rules set forth by the SI Directors and NASA officials. All competitors agree to also abide by the rules set forth in NASA’s current Club Codes and Regulations

(NASA CCR) and any supplemental rules issued by the SI Directors.

4. Eligible Manufacturers/Models/Configurations

Eligible manufacturers, models, and base configurations are defined below. Additional combinations will be added in the future. a) 2005-2010 Ford Mustang, 4.6L 3V V8

5. Safety

5.1 Safety Requirements

All safety requirements will follow NASA standards as detailed in the NASA CCR. Where the SI Rules and the NASA CCR’s differ, the SI Rules will supersede the NASA CCR. All vehicles and competitors must be outfitted with proper NASA CCR-compliant safety gear including, but not limited to: legal roll cages, fire suppression systems, harnesses, window nets, safety switches, and proper driver attire.

5.2 Class Safety

The NASA Chief Scrutineer or SI Directors may exclude any car from competition for any items that the

Directors or Scrutineer deems to be unsafe. The Event Director may also exclude any car for modifications the Event Director deems to be illegal or unsafe.

5.3 Steering Wheel Lock

Steering wheel locks must be removed.

5.4 Air Bags

All air bags must either be removed or have the systems disabled.

5.5 Sunroofs/Moonroofs

Sunroofs or Moonroofs made of glass must be either: a) removed from the vehicle during competition; or b) replaced by an acceptable covering such as sheet metal, composite or carbon fiber that is securely attached to the vehicle covering the opening. Metal sunroofs may be retained if additional fasteners are used to secure them to the vehicle.

5.6 Drive Shaft/Torque Arm Safety Loops

A drive shaft safety loop is required to retain the front end of the drive shaft in the event of a universal joint failure.

5.7 Scattershield

The installation of a scattershield or explosion-proof bell housing is not required but is highly recommended.

5.8 Masterswitch

The installation of an electrical cutoff (Master Switch) is required and the switch must conform to the specifications set forth in the NASA CCR.

5.9 Fuel Safety Cell

The installation of a fuel safety cell is not required but is highly recommended. If a fuel cell is installed, it must be installed and maintained in accordance with the rules set forth in the NASA CCR.

5.10 Fire Extinguisher/Fire System

All cars must have a NASA CCR-compliant fire extinguisher installed in a manner that meets the requirements of the NASA CCR. The installation of an onboard fire system meeting the NASA CCR is not required but is strongly recommended

5.11 Convertible/T-top Cars

Convertible cars are not allowed.

5.12 Roll Cage

The roll cage must comply with the roll cage standards of the NASA CCR. However, the roll cage may also provide additional chassis stiffening by connecting the cage tubes to the chassis at points other than the main attachment points as defined in the CCR. The roll cage may NOT pass through the firewall.

Interior body panels and sheet metal may be bent, removed, or altered to accommodate the roll bar design.

5.13 Door Safety Bars

All vehicles must meet the door safety bar requirements found in the NASA CCR at Section 15.6.12 but gutting of the door beyond what is solely necessary to fit cage bars is allowed.

5.14

Seats

Seats must be of a fixed-back competition type. No reclining seats are allowed.

6. Power, Weight, and Dimensions

6.1

Power

SI has a strict 11.75:1 (11.75 pounds of vehicle weight per each horsepower) horsepower to weight ratio and 11.25:1 (11.25 pounds of vehicle weight per each foot-pound) torque to weight ratio limit as measured at the rear wheels.

All cars that compete in this class may have less than the specified amount but may not exceed the 11.75:1 HP and 11.25:1 TQ ratios.

6.2

Weight

The absolute minimum weight for SI cars is 3350 pounds with driver.

6.3 Track Width & Wheelbase

Vehicle

’05-’10 Mustang, 4.6L 3V

Maximum Wheelbase

108 “

Max Track Width

74.5”

Cars are allowed a maximum track width as noted in the table above. Track width and wheelbase are measured with driver. Wheelbase is measured from center of front hub to center of rear axle centerlines.

Track width is measured at the outside edge of the tires. The track width measurement will be taken at a point three inches from the ground by using two metal plates similar to the Longacre #7950 toe plates.

The measurement used for compliance will be the average of the front of the tire and rear of the tire width measurements at the three inch height after accounting for the width of the plates. The plates will be placed flush against the tire and not perpendicular to the ground for the measurements.

6.4 Ride Height

Minimum ride height is five (5.0) inches, to be measured with driver. Measurement to be taken at the lowest point of the rocker panel, but not to include welded seams or fasteners. This does not include exhaust, side skirts or other components. Rocker panels may not be modified from OEM. Isolated rocker panel damage may be corrected to prevent erroneous ride height readings.

7. Modifications

7.1 Permitted Modifications

No part or component may be modified, removed, or disabled unless specifically permitted by these rules.

Replacement parts must be original equipment manufacturer (OEM) for the eligible manufacturer/model/configuration defined in section 4, or the exact equivalent. Where aftermarket parts or parts kits are allowed, replacements must be those specific parts or components that make up the parts kit.

7.2 Tires/Wheels

The Toyo Tire RR and RA1 in 275/35ZR18 are the only tires permitted . Tire shaving is permitted. No other tire modifications are permitted. (i.e. - no tire grooving or chemical tire traction treatments)

Aftermarket wheels are permitted. Wheels may not be modified. Wheels must be 18x9.5 and must weigh a minimum of 26.0 lbs. The Ford Racing M-1007-S1895 wheel is strongly recommended.

7.3 Chassis

The entire tub, floorpan, firewall, and frame assemblies including the cowl and windshield frame must remain stock except for the following modifications.

7.3.1

The rear floor pan area may be modified to enable the installation of a fuel cell.

7.3.2

The floor area and OEM seat mount posts may be modified to enable the installation of racing seat mounts. Seat mount bracing may connect to the roll cage.

7.3.3

The rocker area may be modified to enable the installation of a jacking pad or jacking rail.

7.3.4

Suspension mounting points may be reinforced by welding seams or by adding sheet steel along the OEM contours as long as the mounting points remain in the OEM stock location and maintain the OEM geometry. Reinforcements may not extend beyond 12” of the center of the mounting point.

7.3.5

The Ford Racing strut tower brace M-20201-S197 may be installed.

7.3.6

The Ford Racing front lower A-arm brace M-5025-A may be installed.

7.4

Body/Interior

7.4.1

Cars must have neat and clean appearances. All panels must fit properly and be free of sharp edges. All panels must be painted. No vehicle will be able to compete in more than one event with obvious body damage or unpainted body panels.

7.4.2

Acid dipping or body panel lightening is not allowed.

7.4.3

Only ’05-’10 Mustang V6 and GT model exterior body components, including front facias, front lip spoilers, rear spoilers, and rear wings are allowed. Body components from special edition models such as the California Special are not allowed.

7.4.4

Wheel opening lips may be rolled inward for the purpose of tire clearance but must maintain the

OEM contour.

7.4.5

Exterior body trim pieces and antenna may be removed.

7.4.6

All vehicles must start with a minimum of two properly functioning rear brake lights within the

OEM rear tail light assemblies. All other OEM light assemblies may be replaced with facsimiles, plates, covers, or mesh covered cooling duct openings as long as these maintain the stock external appearance. Replacements for recessed lights must also be recessed.

7.4.7

The grill and front bumper cover may have openings enlarged or added for the purposes of routing cooling air to allowed components. However, any such modification that improves or appear to improves aerodynamic performance (increased downforce or decreased drag) are not allowed.

7.4.8

Any interior mirrors may be used.

7.4.9

The OEM dashboard and steering column must remain intact except to accommodate the installation of allowed components. Metal and plastic structure under the dash may be removed or trimmed as long as the dashboard and steering column remain in the OEM location and are properly mounted. Any unused dash or steering column mounted components such as A/C controls, air bags, etc. may be removed. Openings larger than 6 square inches that result from component removal must have a suitable metal or plastic cover. Dash trim pieces may be substituted with suitable metal or plastic pieces.

7.4.10

All interior parts, panels, and associated brackets other than as defined in 7.4.9 may be removed.

All unused brackets and trim pieces in the engine compartment may be removed. Undercoating may be removed. Floor mats, spare tire, tools, jacks, etc. must be removed. There must be no remaining sharp edges that could come in contact with the driver.

7.4.11

Hood and trunk may be “gutted” by removing structure from their underside and their struts and associated brackets may be removed.

7.4.12

Any steering wheel, steering wheel quick disconnect assembly, and shifter may be used.

7.4.13

Pedals may be modified for driver comfort.

7.4.14

The driver and passenger side door windows must be removed. The windshield and rear glass must remain OEM.

Side quarter windows may be replaced with plexiglass, lexan or similar and may be modified for air ducts to allowed components.

7.4.15

All holes in the floor and firewall must be sealed according to NASA CCR.

7.4.16

A minimum of four hood pins are required. Trunk pins or other alternate latches are recommended to secure the trunk lid. The OEM hood latch mechanism and brackets may be removed. The trunk latch mechanism and brackets may be removed if trunk pins/alternate latches are used.

7.4.17

Driver comfort items such as cool suits, windshield defogging blowers, etc. may be added as long as they have no impact on the car’s performance.

7.4.18

Ford Racing M-17954-A front and rear tow hooks must be used.

7.5 Ballast and Weight Distribution

7.5.1

Ballast can be added in order to meet the power to weight ratio provided it meets the requirements in the NASA CCR 15.20. Ballast may be placed in any location.

7.5.2

Front weight percentage of total weight must be no less than 53.5%.

7.6 Separators, Breathers, and Catch/Overflow Tanks

7.6.1

Breathers, vents, separators, and catch/overflow tanks may not be mounted inside the passenger compartment.

7.6.2

The radiator overflow vent line must run into a tank of at least one U.S. quart capacity.

7.6.3

Engine, transmission, and rear axle may have vents or breathers substituted or added including venting to a remote tank.

7.6.4

The engine may not be vented to the exhaust or any other vacuum system other than the engine air intake.

7.7 Engine Coolant

Adding antifreeze to cooling systems is not allowed. The only engine coolant used in the radiator shall be water. Water additives such as Redline Water Wetter may also be used. The intent of this rule is to avoid slick track conditions produced by spilled antifreeze.

7.8

Brakes

7.8.1

The Ford Racing M-2300-S brake upgrade kit may be used.

7.8.2

The Ford Racing ABS brake module M-2353-A may be used.

7.8.3

The hydraulic control unit, brake booster and brake master from the 2007-2009 Shelby GT500 are permitted.

7.8.4

Brake backing plates (dust shields) may be removed or modified to fit brake cooling ducts.

7.8.5

Water or other liquid cooling of brakes is not permitted. Air cooling is both allowed and recommended.

7.8.6

Brake rotors must be one piece iron with a maximum diameter of 14 inches. Rotors may be slotted or dimpled.

7.8.7

Brake pads and fluid are unrestricted.

7.8.8

Wheel studs may be replaced with Ford Racing M-1107-A (front) and M-1107-B (rear).

Alternatively, Ford Racing M-1104-A front hubs with studs may be used.

7.9

Driveline

7.9.1

Only OEM TR3650 transmissions are allowed, with no internal modifications.

7.9.2

Any single disc clutch and pressure plate of OEM stock diameter may be used provided that it is bolted directly to the unmodified OEM stock flywheel and the pressure plate is made of the same material as OEM.

7.9.3

Rear wheel negative camber may not be more than 0.50 degrees.

7.9.4

Rear axle ratio must be 3.31:1. Gear sets must be a genuine ford part and may not be modified.

7.9.5

The Ford Racing M-4204-MB or M-4204-T31H torsen differentials may be used.

7.9.6

The Ford Racing M-4033-K/KA rear differential covers may be used.

7.10

Electronics/Electrical

7.10.1

Traction control devices are expressly prohibited. Factory installed units must be disabled. See section 8.8 - Burden of proof that unit is disabled lies with the competitor. i.e.- switch disabled, computer indication, etc.

7.10.2

Data acquisition systems are permitted.

7.10.3

Two-way radio communication in the cars is encouraged and recommended.

7.10.4

The stock or Ford Racing calibration contained in part numbers M-9603-GTB (2005-2009) or M-

9603-MGT (2010) may be used and may not be altered in any way. SI and NASA officials may swap or re-flash PCMs at their discretion.

7.10.5

Removal of wiring associated with a component that may be removed by these rules is permitted.

Re-wiring of legal components is allowed as long as the modifications to the wiring do not alter or affect the original performance of the connected components.

7.10.6

Windshield wipers, wiper motor, arms, parts, windshield washer pump, washer reservoir, all lines and wiring may be removed.

7.10.7

The battery may be relocated and may be any size capable of supplying enough current to start the car.

7.10.8

The PCM may be relocated to inside the body for protection.

7.10.9

Gauges may be removed, substituted, or added.

7.11

Engine, Engine Accessories, and Exhaust

7.11.1

Engine may be rebuilt or repaired, but all internal and external components must remain within

OEM specifications and tolerances.

7.11.2

Ford Racing M-9603-GTB (2005-2009) and M-9603-MGT (2010) air intake kits are permitted.

7.11.3

Ford Racing M-19216-D46 a/c eliminator kit is permitted. All a/c and heater components and associated plumbing may be removed.

7.11.4

A restrictor between the throttle body and intake manifold may be used to reduce horsepower and torque. The diameter and thickness of the restrictor plate orifice(s) shall be noted on the Dyno

Sheet and must match at all times. No other means may be used to reduce horsepower and torque.

7.11.5

OEM exhaust manifolds may have a coating that is bonded to the parent material. This includes any paint or ceramic type coatings, but does not include header wraps.

7.11.6

Exhaust from the end of the exhaust manifolds to the exit is unrestricted other than exhaust must exit behind the driver.

7.11.7

Exhaust heat shields may be removed, substituted, or added.

7.11.8

Spark plugs are unrestricted.

7.11.9

Any readily available wet sump oil pan and pickup such as Canton 15-784 or Moroso 20548 may be used. The use of an Accusump or similar oil reservoir is permitted.

7.12

Plumbing

Plumbing, defined as hoses, hose ends, hard lines, associated fittings, and routing, is unrestricted provided it serves the same function. Filters for all fluids may be added or substituted.

7.13

Cooling and Lubrication

7.13.1

Ford Racing M-8005-MGT radiator is permitted.

7.13.2

Radiator shrouding may be removed, substituted, or added.

7.13.3

Electric cooling fans may be removed, substituted, or added.

7.13.4

Ford Racing M-8080-A de-gas bottle and cap are permitted.

7.13.5

Ford Racing M-5025-MBR transmission cooler is permitted.

7.13.6

Oil and power steering coolers of any design are permitted.

7.13.7

Engine, transmission, and differential fluids are unrestricted.

7.14

Suspension

7.14.1

Ford Racing M-3130-R4 bump steer kit is permitted.

7.14.2

Ford Racing M-18183-B or Maximum Motorsports MM5CC-7 caster/camber plates are permitted.

7.14.3

Ford Racing M-5638-B or M-5638-C front lower control arm bushings are permitted.

7.14.4

Ford Racing M-5638-R rear upper link bushings are permitted.

7.14.5

Ford Racing M-5649-R1 rear lower control arms are permitted.

7.14.6

Ford Racing M-5650-A rear lower control arm brackets are permitted.

7.14.7

Ford Racing M-4264-A adjustable panhard bar is permitted.

7.14.8

Ford Racing M-5490-A sway bar kit is permitted. Any OEM swaybar from any eligible model is permitted.

7.14.9

Motion Control Suspension Shock Package SET-1WNR-NSI-S-01 or HVT Shock Package HVT-

F1001-SI is permitted.

7.14.10

Coil springs and hardware may be of any rate, OD, ID, and free length.

7.14.11

Coil spring spacers and threaded adapters are permitted.

7.14.12

Upper 3rd link of any origin may be used but must use factory mounting holes in the factory locations on both the axle and body.

7.14.13

Any front swaybar endlinks are permitted.

7.14.14

Ford Racing M-18197-A rear upper shock mount is permitted .

8.

Rules/Procedures

8.1

Dynamometer Certification

All SI participants must have a dynamometer certification report prior to the start of the race or make arrangements to have a dyno test performed immediately after the race. (Note that one certification can be valid for an entire season provided that no performance modifications are performed to the car). Dyno test

must be performed prior to first race entered for the season and after the last race entered from the previous season.

The dynamometer certification report will consist of two parts: a completed SI Dyno Spec Sheet and

Dyno Sheet Readout Graphs. These forms must be kept with the vehicle's logbook and be ready to present to any official. The SI Dyno Spec Sheet includes instructions for performing the official dynamometer inspection, which must be followed in order for the dyno report to be valid. The Dyno Spec Sheet is available in the Appendix of these rules

8.2 Inspection and Testing

NASA tech inspectors and SI Officials have the right to inspect anything in sight at any time the vehicle is at the track. NASA tech inspectors and SI Officials have the right to request disassembly or any other procedure required to verify vehicle compliance with these rules including a dynamometer verification or be required to run monitoring equipment, such as GPS devices. The SI Official may require that a SI

Official or designee be present for any dynamometer verification.

All official SI dynamometer tests will be open. All SI competitors have the option to be present for official chassis dynamometer testing.

Prior to the chassis dynamometer inspection the competitor should top off any fluids, air the rear tires etc to ensure the engine and drivetrain are not damaged during testing and that the car is configured as required by the dynamometer inspection procedure. A NASA Technical Inspector must be present and no other modifications or adjustments may be made to the car.

To ensure fairness, an SI appointed official or an approved technician will operate any cars being inspected on the chassis dynamometer. 3 consecutive "official" dyno pulls must be performed and the average horsepower and torque value from the 3 measured runs shall be used for power to weight and torque to weight compliance. Should any run result in an erratic or non repetitive result, series officials may dismiss the result or request another dyno pull. The dyno shall use the SAE correction factor for the compliance pulls with a smoothing factor of “5”.

Any car exceeding the maximum power to weight ratio for their declared class shall be penalized in accordance with the NASA CCR and these rules.

Dynamometer tests must be conducted on a DynoJet Model in a commercial facility that offers

Dynamometer testing as part of their business and is open to the public. Each SI Director may retain the option to specify which Dyno locations will be the Approved Centers for that particular region. Please check with the Director in your area for instructions.

Appendix 2 outlines the standard procedure for dynamometer verification procedures to be used during regional events as well as the National Championships. Minor modifications may be made by the regional Series Director based on a specific events needs.

8.3 Weight Certification

All weight measurements are conducted with driver and must be done with NASA approved weight scales or with specific approval from a series director.

8.4

Appearance

8.4.1

All cars are required to display at least four official NASA racing stickers. One shall be placed on the front, rear, and each side of the vehicle.

8.4.2

Series sponsor or individual race sponsor decals or stickers may be required. Drivers must also display any series required patches and NASA patches on their driving suits.

8.4.3

All cars must display the official “American Iron” windshield banner by class across the top of the windshield unless otherwise directed by series officials. SI class cars must us a white banner background with red outlined blue letters. Banner design file can be found at

www.nasaponycars.com. Racers are responsible for having the correct windshield banner for the class they are running. The driver’s last name or first initial and last name must be displayed on the bottom right section of the windshield in white block letters between three and five inches in height.

8.4.4

Car numbers and class designation appearance is required per the CCR. All cars must display their assigned car number and class on both sides, front & rear. Side numbers must be at least 10 inches tall and front & rear numbers shall be at least 3 inches tall with a contrasting color. Class identification must be at least 3 inches tall and be located in close proximity to the number. (The series windshield banner satisfies the requirement for a front class designation.)

8.4.5

Car number availability can be obtained by contacting the SI Directors or NASA Regional

Director.

8.5 Impound

All finishing drivers must proceed to impound immediately after any race or qualifying session unless released by a NASA official. Failure to do so may result in penalties being imposed on the driver. It is purely the driver’s responsibility to report to impound with the vehicle and vehicle’s logbook at the proper time. If the vehicle is unable to report to impound, the driver must report to impound and remain until released by a NASA official.

8.6 Non-compliance/Cheating

Cheating and non-compliance are not welcome and offenders will receive harsh penalties per the NASA

CCR.

8.7 Appeals

Any decision by NASA officials during an event may be appealed per the NASA CCR.

8.8 Non-conforming Equipment

The SI Directors must approve any equipment that does not conform to the SI Rules in advance. If there are any "questionable" or "gray" area modifications, the competitor shall contact the SI Directors for clarification before competition. Limited production components and/or prototypes must be approved in writing by a Director prior to competition to ensure their use and lack of availability to all competitors will not result in a competitive advantage. For consideration, approval must be made in writing to an SI

Director thirty (30) days prior to the date of competition. Final technical compliance authority rests with the SI National Director.

8.9 Proof of Legality

It is the responsibility of the competitor to provide proof of legality of their vehicle’s modifications or components to SI Officials.

9 On Course Conduct

Per the NASA CCR, any driver displaying rough, negligent, or unsportsmanlike conduct will receive harsh penalties, which may include loss of points, suspension and/or fines at the discretion of NASA officials.

10 Points Structure

It is the intent of the American Iron Directors to have at least two qualifying points races per weekend.

Because of scheduling and other uncontrollable events, this quantity is subject to change. Please check with your region as to the number of eligible races, which will count for season points.

Points will be awarded as listed in the NASA CCR.

11.

Spec Iron Directors / Web Page

Any questions concerning the Spec Iron class should be directed to the Board of Directors or your region’s Regional Coordinator.

Jeff Demetri

Central SI Director

Demetri2@cox.net

402-672-6450

Jason Lakomiak

Great Lakes SI Director ai@nasagreatlakes.com

440-867-1808

Wesley Dearing

Mid Atlantic SI Director

Wad5122@yahoo.com

540-580-6857

Ed McGuire

Southeast SI Director

Ed_McGuire@hotmail.com

704-562-4910

Al Watson

SI National Series Director alwatson@Drivenasa.com

908-447-5788

Al Fernandez

SI National Technical Director

925-408-7303 (cell), 936-321-0331 (home) charger@consolidated.net

Marshall Mosty

Texas SI Director

Marshallmosty@hotmail.com

940-736-9043

Jason Lakomiak

Midwest SI Director ai@nasagreatlakes.com

440-867-1808

Robert Ames

Rocky Mountain SI Director

Rwa911@gmail.com

970-846-9070

Patrick Wehmeyer

Florida SI Director

Patrick.wehmeyer@gmail.com

813-361-1688

Rob Capetz

California SI Director rjccorp@aol.com

760-275-7457

AJ Hartman

Northeast SI Director

AJ@ajhartmanracing.com

609-217-8079

Additional series information, including annual schedule, track records, points race and a public message board may also be found on the American Iron Web page:

www.Americanironracing.com www.nasaforums.com www.nasaponycars.com www.facebook.com/americanironracing

APPENDIX 1

Sample Dyno Test Data Sheet & Instructions

Spec Iron

2016 Dyno Test Data and Vehicle Specification Sheet

Owner: ____________________ Car#: ______ Class: ________ Engine CID: _____

NASA Log Book # ________ Vehicle Year: _______ Make and Model: _________

Items to be certified (if applicable):

1.

Ignition Timing: _________ deg. adv. @ idle. ______Not Applicable

2.

Idle RPM: _________

3.

Fuel Pressure: _________ psi. (Fuel Injected only)

4. Carb Jet or Rod sizes: ______ Primary ______ Secondary_______ _________Not Applicable

5. Restrictor size, # of orifices, diameters, thickness: _____________________Not Applicable

6. Exhaust Configuration: a.

Primary Header pipe size: _______ inches or check if stock___________

(Check all that apply) b.

___ Single ___ Dual c. ___ X-pipe ___ H-pipe d.

Muffler Type: __________________ Inlet size: _______ inches e.

Tail Pipe location: ______________ Outlet size: _______ inches

___ Y-pipe

7. List any additional modifications and or parts to bring vehicle to recorded power listed in section 10. (Use reverse side if needed):

_____________________________________________________________________________________________

8. Altitude of dyno shop: _______ ft

9. Rear tire pressure set at 30lbs before run? ____ Yes

10. Hood closed for dyno pull? ______ Yes

11. Dynojet set to correct to SAE J1349, smoothing 5 ____ Yes

12. Reading between 165-210 degree water temp : _ _ _ HP _ _ _ Torque * all numbers rounded to whole

Reading between 165-210 degree water temp: _ _ _ HP _ _ _ Torque

Reading between 165-210 degree water temp _ _ _ HP _ _ _ Torque

Average of three runs above:

Minimum Weight as per class rules:

__________________________

Owner’s Signature Date

_ _ _ HP _ _ _ Torque

_ _ _ _ Pounds

________________________________

Dyno Operator’s signature Date

________________________________

Name

Spec Iron Dynamometer Inspection Procedures

1.

Only dyno runs on DynoJet brand dynamometers are acceptable.

2.

One dyno report may be performed and used for the entire season provided that: a.

It is performed after the last event of the prior season and before the first race entered for the season. b.

No performance modifications are made to the car.

3.

All dyno readings must be corrected to SAE J1349 Rev JUN90 (29.23 in/hg, 77F, zero humidity) and the dyno’s smoothing function must be set to 5

4.

Car must be in “ready to race” configuration with regards to engine and drivetrain. a. Spec Iron class: All engine or drivetrain components that are not stock and affect power or are adjustable (restrictors, air intakes, timing, etc.) must be explicitly allowed by the vehicle’s class rules, must be written down in section 1 - 6 of the inspection sheet, and must match at all times.

5.

Rear tires must be set to 30psi prior to the first run.

6.

Hood shall be closed for SI dyno test runs.

7.

Electric engine fans and or external cooling fans may be used.

8.

Dyno pulls will be made in 4 th

gear or at a 1:1 ratio.

9.

Altitude of the dyno shop must be recorded. Dyno runs made at locations with elevation greater than 1,500 feet higher than the track will not count as being valid at that track. Class

Officials may decide to waive this requirement for certain circumstances. Check with your local class director ahead of time.

10.

Three consecutive runs shall be made under full power. The RPM range shall be consistent for all three runs. Starting RPM shall be no higher than 2000. Ending RPM shall be clearly beyond max horsepower.

11.

Dyno runs shall be made with water temperature in the normal operating range of 165F-210F and drivetrain fluids up to a normal running temperature. (A “practice pull” is highly recommended prior to 3 consecutive runs to ensure proper drivetrain temperatures.) Water temperature may be verified using external temperature measurements such as an infrared temp gun at a thermostat housing or a metal tube section of the line returning water to the radiator.

12.

The peak horsepower and torque of each run will be noted on the inspection sheet.

13.

The average of the three consecutive runs will be calculated and noted on the inspection sheet. This average horsepower and torque number is what must be used to determine the vehicle’s required minimum weight, using the car’s specific class weight rules.

14.

One dyno certification may be valid for an entire race season as long as no performance modifications are made to the car.

15.

All HP & TQ results will be rounded to whole numbers. In the case where the measurement falls exactly on the halfway point (.50), it shall be rounded down in favor of the competitor i.e.- 260.50 = 260 and 260.51 = 261

Appendix 2

2016 Dyno Procedure at the track for NASA Spec Iron

1.

Each driver presents their declared dyno spec sheet and Dyno read out graph for the season or an updated one if a change has been made as in the Appendix of the rules. This is used to create a window sticker for impound that shows the cars HP/TQ numbers and its calculated minimum weight.

2.

Impound process for weight and dyno a.

If the car is called into impound after qualifying or race it will first be weighed. If there is no dyno at the track it will only be weighed or if there is a dyno at the track and it is not scheduled to go to the dyno it will be weighed only. Other items could also be checked in impound, track with, height, etc. b.

If the car’s weight is one pound less than its minimum weight on the window sticker the driver will be disqualified. (please check your cars weight on the scales at the track and don’t rely on the weights measured by other scales or the ones at your shop) (if the scales have a variance of 1% that could be a difference of 34 pounds on a 3400 pound car). c.

The car can be weighed up to 3 times to verify the consistency of the scales. d.

If the car’s weighs is above the minimum it heads to the dyno if scheduled. If a car is weighed it does not always go to the Dyno if not scheduled.

3.

At the track the Dyno process may be slightly simplified to save time compared to the rules

Appendix for Dynamometer Inspection Procedures such as vehicle specification on items such as

Idle RPM, Ignition Timing, Carb Jet size, Etc. However, any of these items could be checked at any time to compare to the submitted Specification sheet.

4.

Tires set at a minimum of 30 psi.

5.

Water operating temperature above 165F and below 210F. Engine or external cooling fans may be used.

6.

Hood Up (in the past we have tested with the hood down) See line 10 of the Dyno Test Data and vehicle Specification sheet in the appendix of the rules.

7.

Three pulls will be made and the numbers will be averaged. If one of the three pulls is significantly different a 4 th

pull will be made and the run with the largest discrepancy will be thrown out.

8.

The HP and TQ number from the dyno will be compared to the cars weight as just measured prior to the current dyno run.

(An example would be a car that comes across with 2900/305 on its sticker. It weighs in at 2950 so it passes there. Then it heads to the dyno and pulls 309 HP. Now, this is above the "sticker"

HP but the car weighed in at 2950 which would allow a 310 maximum and it only pulled 309 so the car is legal).

9.

The Series director or impound official can calculate these numbers.

10.

The Dyno runs are for verification of the declared dyno sheets presented by the driver and NOT for recertification. The Dyno process will be a Pass or No Pass. The Dyno test will be open to the drivers and all series competitors per rule 8.2 paragraph 3. Only the numbers will be shared and the dyno sheet will not be shared but retained by NASA.