Tesis Doctoral - e-Archivo Principal

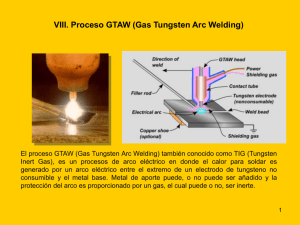

advertisement