Air Flow Measurements

advertisement

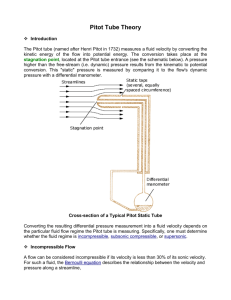

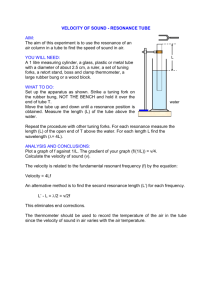

ME-EM 3220 ENERGY LABORATORY Air Flow Measurements Pitot Static Tube A slender tube aligned with the flow can measure local velocity by means of pressure differences. It has sidewall holes to measure the static pressure ps in the moving stream and a hole in the front to measure the stagnation pressure po, where the stream is decelerated to zero velocity. The pitot static tube may also be of the modified ellipsoidal-nose type. The tube has a very small diameter compared to that of the duct diameter, but the resultant error caused by the additional blockage effect is considered minimal for this investigation. Instead of measuring po and ps separately, it is customary to measure their difference with, say, a transducer, as in Figure 1. Fluid flow V ps po ps ps po Figure 1 po po Pitot Tube Configuration Pitot tubes are affected by Reynolds number at low fluid velocities. The minimum Reynolds number for total pressure measurements is approximately 30. This is the point where the characteristic length of the pitot tube is equal to the diameter of the impact hole. Below this value, the indicated impact pressure is higher than the stream impact pressure due to viscosity effects. For air at standard atmospheric conditions, the error due to low Reynolds number is only apparent for air velocities less than 12 ft./sec. (3.66 m/sec.). And this is for pitot tubes with impact hole diameters of 0.010 inches (0.2543 mm) or less. For low-velocity for example, U = 1 ft./sec. in standard air, p0-p equal to only 0.001 lbf/ft2 (0.048 Pa). This is beyond the resolution of most pressure gages. The accuracy of pitot tubes is also affected if the sensor head is not parallel to the fluid. The total and static pressure measurement error due to yaw and pitch angles increase rapidly above angles of 5 o. Fortunately, they cancel each other out so velocity pressure measurements are 2% accurate up to angles of attack of 30o. 1 The measurements of static pressure is also sensitive to the presence of fluid boundaries. The presence of a pitot tube in a pipe also affects the static pressure. The pitot tube partially blocks the flow passage which increases the flow velocity in the vicinity of the device. This results in an indicated static pressure which is less than the actual static pressure. The speed of response of pitot tubes is also geometry dependent. The diameter of the air passage within the probe, the diameter and length of the interconnecting tubes, and the displacement volume of the manometer determines the time constant. For tubes diameters greater than 1/8 inches (3.175 mm) and ordinary manometer connections, the time constant is very short. However the time constant increases rapidly for smaller diameter tubes, with a response time of approximately 15 to 60 seconds for tubes having a 1/16 inches (1.59 mm) diameter. Because of the slow response of the fluid-filled tubes leading to the pressure sensors, it is not useful for unsteady-flow measurements. One common problem with pitot tubes that have very small diameters is that they tend to choke up easily if there is fine dirt in the fluid. The pitot static tube is useful in liquids and gases; for gases a compressibility correction is necessary if the stream Mach number is high. If ReD > 1000, where D is the probe diameter, the flow around the probe is nearly frictionless and Bernoulli’s relation applies with good accuracy. p2 – p1 1 2 2 ----------------+ --- ( V 2 – V 1 ) + g ( z 2 – z 1 ) = 0 2 ρ [1] p p 1 2 1 2 -----1 + --- V 1 + gz 1 = -----2 + --- V 2 + gz 2 = const ρ 2 ρ 2 [2] or For an incompressible flow 1 2 1 2 p s + --- ρV + ρgz s ≈ p 0 + --- ρ ( 0 ) + ρgz 0 2 2 Assuming that the elevation pressure difference V th = [3] ρg ( z s – z 0 ) is negligible, this reduces to 2 ( p0 – ps ) -----------------------ρ [4] Here ρ is the air density in kg/m3; p ρ = -------s , RT [5] p s is the static pressure in Pascal, R is the gas constant and the value is 287 m2/(s2.K), T is the absolute temperature in Kelvin. The velocity measured by the pitot tube needs to be corrected due to geometry and flow interactions. It is done as follows V = αV th where [6] α = f ( Re D ) , and the Reynolds number, ρVD Re D = -----------µ [7] 2 Table below gives the range of α as a function of Reynolds numbers., Re D 3 × 10 α 0.986 4 1 × 10 0.988 5 3 × 10 0.990 5 1 × 10 6 0.991 Since V is not known, process is one which requires iteration, as described next; • STEP 1: - guess your α values anywhere from 0.986 to 0.991 Hint: Start from the lowest value. • STEP 2: - plug in the α values and calculate V • STEP 4: - Evaluate Re D • STEP 5: - Look up your guess α values whether it matches with the calculated Re D or not • STEP 6: - If the assumed α values is not in the calculated Re D range, repeat Steps 1 - 5. NOTE: Different sensors will require a calibration data generated for that particular case. If such information is not available use the table above as valid for the pitot tube you are using. Depending on the application you have, you may also be advised to delete velocity correction altogether, α = 1. For channel flow where an average velocity is required, ( p 0 – p s ) can also be determined by evaluating the effective pressure (or average) for the channel after multiple measurements as follows: ∆P eff 1 = ---N 2 j=N ∑ 0.5 ∆P j [8] j=1 where N is the number of measurements. 3 Calculating the Flow Rate from the Velocity Profile The volumetric airflow rate can be directly determined from the velocity profile across the duct. Recall that a fluid of velocity u passing across an infinitesimal area dA with outward unit normal vector n̂ . u n dA Figure 2 Velocity Profile Denoting the cross sectional area of the duct as A, the volume flow rate through any given cross section of the duct can be found from integration Q = ∫ –( u • n̂ ) d A [9] A For a flow which is axisymmetric, the velocity is only a function of radial distance from the tube axis (centerline) as it is in the case of circular cross-section but it will have also have an azimuthal angle dependency otherwise. What follows is a discussion for a channel of circular cross-section area only. In this instance, u = u(r ) [10] and the infinitesimal area element dA = 2πrdr [11] where r is the radial distance from centerline, which varies from r=0 to r=R (the tube wall). The vector dotproduct can be simplified by recognizing the flow velocity is always perpendicular to the cross section of the tube. Thus u ( r ) • n̂ = – u ( r ) [12] where u is the magnitude of the velocity. With these simplifications, the volumetric flow-rate in the circular tube is given by r=R Q = ∫ 2πu ( r )r dr [13] r=0 Knowing the velocity profile u(r) then allows us to calculate the volumetric flow rate by integration. Since the data set is usually limited to a finite number of values u(r), we cannot perform the exact analytic integral. We can, however, use a numerical estimate to approximately evaluate the flow rate. This numerical estimate is best understood by recognizing that integration is the process of calculating the area underneath a curve. The curve in Figure 3 represents the true function u(r), for which the discrete values u 1 = u ( r 1 ) , u 2 = u ( r 2 ) , etc. are available. We can approximate the integration by summing the areas represented by the shaded rectangles. In this case, the flow rate can be estimated from 4 u(r) u1 u2 dr1 dr2 r1 r2 r3 r4 r5 r6=R Figure 3 Approximating an Analytic Integral With Discrete Numeric Values 6 Q ≈ 2π ∑ un r n dr n [14] n=1 Q ≈ 2π ( u 1 r 1 dr 1 + u 2 r 2 dr 2 + u 3 r 3 dr 3 + u 4 r 4 dr 4 + u 5 r 5 dr 5 + u 6 r 6 dr 6 ) [15] Mass flow rate can be evaluated as ṁ = ρQ [16] An analysis similar to above can be performed for rectangular cross-sections as well. 5 Air Flow Measurements Bernoulli Obstruction Theory Consider the generalized flow obstruction shown in Figure 4. Figure 4 Velocity and Pressure Change through a Generalized Bernoulli Obstruction Meter The energy grade line (EGL) shows the height of the total Bernoulli constant 2 p V h 0 = z + --- + -----γ 2g [17] The hydraulic grade line (HGL) shows 2 V -----2g [18] where the height corresponding to elevation and pressure head 6 p z + --γ [19] that is, the EGL minus the velocity head. The HGL is the height to which liquid would rise in a piezometer tube attached to the flow. In an open-channel flow the HGL is identical to the free surface of the water. The flow in the basic duct of diameter D is forced through an obstruction of diameter d; the β is a key parameter of the device, d β = ---D [20] After leaving the obstruction, the flow may neck down even more through a vena contracta of diameter D2 < d, as shown. Apply the continuity and Bernoulli equations for “incompressible steady frictionless flow” to estimate the pressure change: Continuity: π 2 2 Q = --- D V 1 = D 2 V 2 4 [21] Bernoulli 1 2 1 2 p 0 = p 1 + --- ρV 1 = p + --- ρV 2 2 2 Eliminating [22] V 1 , we solve these for V 2 or Q in terms of the pressure change ( p 1 – p 2 ) : 2 ( p1 – p2 ) Q ------ = V 2 ≈ ---------------------------------4 4 A2 ρ ( 1 – D2 ⁄ D ) 1⁄2 [23] But this is surely inaccurate because we neglected friction in a duct flow, where we know friction will be very important. Nor do we want to get into the business of measuring vena contracta ratios D2/d for use in Equation 23. We assume that D 2 ⁄ D ≈ β and then calibrate the device to fit the relation. 2 ( p1 – p2 ) Q = A t V t ≈ C d A t ------------------------4 ρ(1 – β ) 1⁄2 [24] where subscript t denotes the throat of the obstruction. The dimensionless discharge coefficient Cd accounts for the discrepancies in the approximate analysis. By dimensional analysis for a given design we expect C d = f ( β, Re D ) [25] ρV 1 D Re D = -------------µ [26] where The geometric factor involving β in Equation 24 is called the velocity-of-approach factor 4 –1 ⁄ 2 E = (1 – β ) [27] One can also group Cd and E in Equation 24 to form the dimensionless flow coefficient Cd α = C d E = -------------------------4 1⁄2 (1 – β ) α [28] 7 Thus, 2 ( p1 – p2 ) Q = α A t -------------------------ρ 1⁄2 [29] Obviously the flow coefficient is correlated in the same manner: α = f ( β, Re D ) [30] Occasionally one uses the throat Reynolds number instead of the approach Reynolds number ρV t d Re = ---------DRe D = -----------β µ [31] Since the design parameters are assumed known, the correlation of α or of C d is the desired solution to the fluid-metering problem. Figure 5 shows three basic devices recommended for use by the International Organization for Standardization (ISO): the orifice, nozzle, and venturi tube. Figure 5 Orifice, Nozzle, and Venturi Tube Configurations 8 Thin-Plate Orifice. An orifice plate is nothing but a flat plate with a hole in it. Once placed in the duct, it restricts flow and causes an increase in velocity similar to a venturi. Directly behind the orifice plate an area of low pressure exists. By measuring the difference in pressure from this point to the-free flowing duct, the volumetric flow rate can be found using the following equation: 2 πd 2∆P 3 Q = αε --------- ----------- m ⁄ s 4 ρu [32] where α flow coefficient, ε expansibility factor, d diameter of orifice, m, ∆P pressure drop over orifice plate, Pa, ρ u density upstream of the device (i.e. at atmospheric pressure) kg/m3. The values of α for the orifice plates are as follows: 65 mm orifice: α = 0.599 95 mm orifice: α = 0.596 The value of ε for an inlet orifice is given by the following expression ∆P ε = 0.42 ------Pu where [33] P u = pressure upstream of the device (atmospheric), Pa. Nozzle. The flow nozzle, with its smooth rounded entrance convergence, practically eliminates the vena contracta and gives discharge coefficients near unity. The volumetric flow rate is determined from the following expression; 2 πd 2∆P 3 Q = αε --------- ----------- m ⁄ s 4 ρu [34] The values of the dimensionless compound coefficient is given by the expression αε = 0.986 – ( 0.0055 × 10 –3 × ∆P ) [35] Nozzle Inlet Venturi Flow-Rate Measuring Device. A venturi is just a gradual constriction in the duct. Since the mass flow rate is constant, the velocity must increase as the area decreases. A change in static pressure occurs, and that change in pressure can be used to find the flow rate using the following formula and dimensions (same as the nozzle). 2 πd V 2∆P 3 Q = αε ---------- ----------- m ⁄ s 4 ρu [36] The values of the dimensionless compound coefficient is given by the expression αε = 0.986 – ( 0.0055 × 10 –3 × ∆P ) [37] 9 Conical Inlet Venturi Flow-Rate Measuring Device. This device is mounted on the inlet side of the fan ducting. The volume flow the expressions Q relationship is given by 2 πd V 2∆P 3 Q = αε ---------- ----------- m ⁄ s 4 ρu [38] where – 0.2 αε = 1.0 – 0.5Re d 4 when 2 × 10 < Re d < 30 × 10 4 [39] and αε = 0.960 when Re d ≥ 30 × 10 4 [40] Note that conical inlet flow measurement should not be used when Red<2x104. Here, d diameter of constant diameter duct section (meters) = 0.095, ρI is density of air upstream device - (kg/m3), ∆P differential pressure measured in pascals [kg/(m.s2)]. Flow Rate Measurements: Cusson Wind Tunnel On/Off switch large and small manometers Start button Fan outlet valve venturi Off button Pitot tube Fan Place the orifice or nozzle here nozzle conical inlet 65 mm orifice 95 mm nozzle 95 mm orifice 10 Experimental setups and Apparatus. (Cusson - For orifice plate) Apparatus Air Flow Bench, Manometers (small & large scale), Orifice (65 mm & 95 mm), Nozzle (95 mm), Conical Inlet cone, Venturi, Pitot tube Procedure: (Emperiments I, and III) 1. Couple the 1 meter long ducting to the flow straightening section positioned at the inlet of the fan using the toggle catches 2. Attached the orifice inlet adapter housing to that 1 meter duct 3. Support the overhanging section of the assembly to a suitable height using the stand 4. Ensure that the flow straightening honeycomb disc is positioned squarely within the orifice inlet adapter housing 5. Insert the 65 mm orifice plate into the inlet adaptor housing. (The orifice plate is positioned with the counter sunk side downstream from the inlet, i.e. facing into the housing) 6. Fit the pitot static tube and scale to the 1 meter ductwork at any of the three radial positions. (Blank off the pitot static tube tappings if not in use) 7. Connect the pitot static tube to the smaller manometer (Total Pressure to the back of the small manometer inlet) (Static Pressure to the limb of the smaller adapter 8. Connect the orifice adapter housing tapping to the larger manometer limb. 9. Set each manometer limb in the upright position, level and zero the manometer 10. Fully close the fan outlet valve and then switch on the fan 11. Set the orifice plate manometer limb to the most sensitive position possible and re-zero it again (after disconnecting the pressure taping tube). Record the reading in kPa Note: The readings should be multiplied with the multiplier written on that manometer. Experimental setups and Apparatus. (Hampden) Apparatus Standard test section, pitot-static probe, probe positioner, Manometers Procedure: (Experiment II) 1. Install the standard test section in the wind tunnel 2. Install a pitot-static probe, in the probe positioner and through the duct access hole in the test section 3. Connect pressure tubing from the static and total pressure taps on the pitot-static tube to one of the appropriate manometers 4. Using the variable frequency drive control to adjust fan speed and the pitot tube positioner to locate the pitot tube vertical location in the duct, read and record velocity pressures at various locations Note: The lab instructor will show how to turn on/off the drive control and monitor the speed. Area of the inside duct (standard test section) is 0.444 ft2 (0.0413 m2) inside dimensions. 11 EXPERIMENT I Pitot-Tube Based Velocity Profile and Flow Rate Measurements Cusson Wind Tunnel (D = 147 mm) Trial # Pitot Tube Locations Almost closed ∆p M=1 + 6 cm M=2 + 5 cm M=3 + 4 cm M=4 + 3 cm M=5 + 2 cm M=6 + 1 cm M=7 CENTER: 0 cm Effective ∆p Average Velocity Volume Flow Rate Mass Flow rate V Valve Outlet Positions Center ∆p V Almost open ∆p V ∆P eff = Eq ( 8 ) (Pascal) V av (m/s) Q = AV av ṁ = ρQ (kg/s) For air at 20oC and 1 atm; ρ = 1.20 kg/m3, µ = 1.8 E-5 kg/(m.s), ν = 1.51 E-5 m2/sec 1. Traverse the pitot static tube across the diameter of the ductwork, noting the manometer reading at each position and record them in Data Sheet. (The manometer should be in the most sensitive position possible, bearing in mind that the maximum values will be obtained at the central positions) 2. Repeat the experiments again by adjusting the fan outlet to the “center” and almost open” position and record your data in Data Sheet. Assignments: • Complete the table above. • Plot the velocity across the diameter. • Calculate the entrance length required to establish a fully developed boundary layer at inlet (refer to Chapter 6 of your text book). • Discuss the velocity profile within the light of the entrance length. 12 EXPERIMENT II Pitot-Tube Based Velocity Profile and Flow Rate Measurements Hampden Wind Tunnel (Test section Inside area 0.0413 m2) Trial # Pitot Tube Locations N = 800 rpm ∆p M=5 + 8 cm M=4 + 6 cm M=3 + 4 cm M=2 + 2 cm M=1 CENTER: 0 cm Effective ∆p Average Velocity Volume Flow Rate Mass Flow Rate V Valve Outlet Positions N = 1600 rpm ∆p V N = 2400 rpm ∆p V ∆P eff = Eq ( 8 ) (Pascal) V av (m/s) Q = AV av ṁ = ρQ (kg/s) For air at 20oC and 1 atm; ρ = 1.20 kg/m3, µ = 1.8 E-5 kg/(m.s), ν = 1.51 E-5 m2/sec 1. Traverse the pitot static tube across the cross section of the test chamber, noting the manometer reading at each position and record them in Data Sheet. (The manometer should be in the most sensitive position possible, bearing in mind that the maximum values will be obtained at the central positions) 2. Repeat the experiments again by adjusting the fan outlet to the “center” and almost open” position and record your data in Data Sheet. Assignments: • Complete the table above. • Plot the velocity across the plane. • Calculate the entrance length required to establish a fully developed boundary layer at inlet (refer to Chapter 6 of your text book). • Discuss the velocity profile within the light of the entrance length. 13 EXPERIMENT III Cusson Wind Tunnel (D = 147 mm) Orifice Plate For Flow Rate Measurements Valve Positions) ∆P kPa αε Q m3/s αε Q m3/s Almost closed Center Almost Open Nozzle For Flow Rate Measurements Valve Positions) ∆P kPa Almost closed Center Almost Open Conical Inlet Venturi For Flow Rate Measurements Valve Positions) ∆P kPa αε Q m3/s Almost closed Center Almost Open Nozzle Inlet Venturi For Flow Rate Measurements Valve Positions) ∆P kPa αε Almost closed Center Almost Open 14 Q m3/s Bernoulli Equation Demonstrator Background Pressure Measurements In Moving Fluids Pressure measurements in moving fluids deserve special considerations. Consider the flow over the bluff body shown in Figure 1. Figure 6 Streamlines over a bluff body Assume that the upstream flow is uniform and steady. Points along the two streamlines labeled as A are to be studied. Along streamline A, the flow moves with a velocity, V 1 , such as at point 1 upstream of the body. As the flow approaches point 2 it must slow down and finally stop at the front end of the body. Point 2 is known as the stagnation point and streamline A the stagnation streamline for this flow. Along streamline B, the velocity at point 3 will be V 3 and because the upstream flow is considered to be uniform it follows that V 1 = V 3 . As the flow along B approaches the body, it is deflected around the body. From conservation of mass principles, V 4 > V 3 . Application of conservation of energy between points 1 and 2 and between 3 and 4 yields 2 2 2 2 p 1 + ( ρV 1 ) ⁄ ( 2g ) = p 2 + ( ρV 2 ) ⁄ ( 2g ) [41] p 3 + ( ρV 3 ) ⁄ ( 2g ) = p 4 + ( ρV 4 ) ⁄ ( 2g ) [42] However, because point 2 is the stagnation point, V 2 = 0 , and 2 p 2 = p total = p 0 = p 1 + ( ρV 1 ) ⁄ ( 2g ) [43] 2 Hence, it follows that p 2 > p 1 by an amount equal to V 2 ⁄ 2g , an amount equivalent to the kinetic energy per unit mass of the flow as it moves along the streamline. If the flow is brought to rest in an isentropic manner (i.e., no energy lost through irreversible processes such as through a transfer of heat1), 15 this translational kinetic energy will be transferred completely into p2 is known as the stagnation or total pressure and will be noted as p0. The “total pressure” can be determined by bringing the flow to rest at a point in an isentropic manner. The flow at 1, 3, and 4 are known as the stream or static pressures2 of the flow. Because the flow is uniform, V 1 = V 3 , so that p 3 = p 1 . The static pressure and velocity at points 1 and 3 are known as the freestream pressure and freestream velocity. However, as the flow accelerates around the body its velocity increases such that, from Eq (1), p 4 ≠ p 3 . The pressure, such as at point 4, is called a local static pressure. The “static pressure” is that pressure sensed by a fluid particle as it is moves with the same velocity as the local flow. Background Closely related to the steady-flow energy equation is relation between pressure, velocity, and elevation in a frictionless flow, now called the “Bernoulli equation”. The Bernoulli equation is very famous and very widely used, but one should be wary of its restrictions - all fluids are viscous and thus all flows have friction to some extent. to use the Bernoulli equation correctly, one must confine it to regions of the flow which are nearly frictionless. For an incompressible fluid, the Bernoulli equation is ( p2 – p1 ) 1 2 2 ---------------------- + --- ( V 2 – V 1 ) + g ( z 2 – z 1 ) = 0 [44] 2 ρ 2 2 V p V p -----1 + -----1- + gz 1 = -----2 + -----2- + gz 2 = const [45] ρ 22 ρ 22 V p V p -----1 + -----1- + z 1 = -----2 + -----2- + z 2 = const [46] γ 2g ρ 2g 2 p V where --- is the static pressure head; ------ is the velocity pressure head; and z is the potential energy head. γ pressure head is equal to the2gsum of the static and velocity pressure heads. This is the Bernoulli The total equation for steady frictionless incompressible flow along a streamline. A venturi tube can be used to demonstrate the Bernoulli equation as shown in Figure 3. Figure 3: Venturi AIR FLOW DIRECTION to It is readily apparent that the potential energy head is zero ( z 1 2 = z 2 , the Bernoulli equation reduces 2 p V p V -----1 + -----1- = -----2 + -----2- = const γ 2g ρ 2g [47] Using the conservation of mass, the mass flow rate at points 1 and 2 must be the same, or ρV 1 A 1 = ρV 2 A 2 [48] 16 MEEM 3220 ENERGY LABORATORY EXPERIMENT IV (HAMPDEN WINDTUNNEL) Objective To investigate the Bernoulli equation as it relates to pressure and velocity of a fluid along a streamline. Experimental Setups 3. Attached the venturi section with convergent and divergent sections oriented as shown in Figure 4. Make sure that the fastening screws are tightened to provide a tight seal. Figure 7 Schematic Diagram 4. Install a pitot-static probe into the probe positioner and one access hole in the duct. Align the probe head with the center line of the convergent-divergent section. 5. Connect the total and static pressure taps of the pitot-static tube to the appropriate manometers as shown in Figure 4. please note that the choice of which inclined manometer is used depends on the magnitude of the static pressure; and this changes along the length of the venturi tube. Two universal tee connectors are required. 17 Experimental Procedure 6. Turn ON the fan and use the variable frequency drive control to adjust fan speed. Always run the fan in forward for proper air flow direction. STEP 1 Press “JOG” button. STEP 2 Press “LOCAL”. STEP 3 Press “FWD”. STEP 4 Press “ARROW BUTTON UP” to increase the speed or Press “ARROW BUTTON DOWN” to decrease the speed. STEP 5 Press “STOP” to turn OFF the fan STEP 6 Directly Press “FWD” to choose the same speed as chosen before. 7. Measure and record the total, static, and velocity pressures (inches of H2O) at various points along the cross section of the venturi tube at each location. Equations: P total = P static + P dynamic [49] ∆P = P total – P static = P dynamic = P velocity ; P dynamic is also known as P velocity [50] P = ρgh static = γ h static [51] ( P static ) abs ρ = -------------------------RT [52] 2 where P static in absolute pressure (Pa or N ⁄ m ) ( P static ) abs 2 2 constant (287 m ⁄ ( s • K ) T is the absolute temperature (K) 2 2∆P ----------- in m/s; where ∆P in Pascal or N ⁄ m ρ V = = P atm + ( P static ) gauge R is the gas [53] Conversions: 2 –4 1cm = 1 × 10 m 1Pa = 1N ⁄ m 2 [54] 2 [55] 1inH 2 O = 249.1Pa [56] 1atm = 101325Pa [57] 1inHg = 3372.2Pa [58] 1mmHg = 133.32Pa [59] Assignments Plot ρAV and Bernoulli Constant along the venturi. (Refer to Eq (3) for Bernoulli Constant) 18 DATA SHEET IV Fan = _____rpm Patm = ___ inH2O = ____N/m2 T = ________ K (Pressure)gauge Test # Types inH2O N/m2 A V ρAV P/γ V2/2g Bernoulli Constant m2 m/s kg/s meter meter meter Pstatic 1 Ptotal ∆P Pstatic 2 Ptotal ∆P Pstatic 3 Ptotal ∆P Pstatic 4 Ptotal ∆P Pstatic 5 Ptotal ∆P Pstatic 6 Ptotal ∆P Pstatic 7 Ptotal ∆P Pstatic 8 Ptotal ∆P Pstatic 9 Ptotal ∆P Pstatic 10 ρ = _______ kg/m3 Ptotal ∆P 19